HOME→Calcium carbide mud mill powder making process Calcium carbide mud mill powder making process Calcium carbide mud mill powder making process

Calcium carbide mud mill powder making process Calcium carbide mud mill powder making process Calcium carbide mud mill powder making process

.jpg)

Comparison of new twostep calcium carbide production process

2022年11月1日 The new twostep CaC 2 production process (NTCCPP) uses hot pellets of calcium oxide powder and pulverized coal after pelletizing and pyrolysis as raw materials in The present invention provides a method for the production of calcium carbide comprising introducing powdered lime/limestone and carbon powder, optionally together with a reducing USA Method of manufacturing calcium carbide from 2022年2月1日 In this paper, a new calcium carbide production process of coalcokeelectricity grading substitution method (GSM) is proposed and evaluated by inter grating the first and Energy and exergy analysis of a new calcium carbide production This article provides an overview of the new process and equipment, highlighting the advancements relative to the current stateofthe art in the industry The first application of the A STEP CHANGE IN CALCIUM CARBIDE PRODUCTION TECHNOLOGY

A rotary kiln process for making calcium carbide

Two new models for predicting the reaction kinetics for the formation of calcium carbide (CaC2) from coalderived coke and calcium oxide (CaO), or lime, are proposed and compared to four 2020年9月21日 The calcium coke can increase the contact area of calcium and carbon in the calcium carbide production process Furthermore, the pore structure of the calcium coke can Development of calcium coke for CaC2 production using calcium 2013年3月25日 To replace the hightemperature and energy extensive traditional calcium carbide (CaC 2) production technique, characterized by electric arc heating and large granular Kinetic Behaviors of CaC2 Production from Coke and CaO2018年7月11日 Calcium carbide (CaC 2) is widely used for the production of various acetylene derivatives, accompanying with a huge amount of carbide slag waste To develop a clean Greener Production Process of Acetylene and Calcium

2FD{P}PC]854]XQ.jpg)

Calcium Carbide an overview ScienceDirect Topics

The modern technology used for the production of calcium carbide is based on the reduction of calcium oxide (lime) to CaC 2 by carbon for the overall reaction CaO + 3C = CaC 2 + CO Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2 Its main use industrially is in the production of acetylene and calcium Calcium carbide Wikipedia2022年12月12日 Calcium carbide slag is a waste slag produced after the hydrolysis of calcium carbide to obtain acetylene gas, with very fine particles, offwhite color due to the presence of trace carbon and sulfur impurities, slightly odorous, with Ca(OH) 2 as the main component, and a slag liquid pH value of 12 or more, thus often causing serious pollution to the environment [18]Comprehensive performance study of aluminum ash and calcium carbide 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US Environmental

Synthesis of nano and ultrafine refractory carbide powders by

2024年6月15日 The use of fine carbide particles as a dispersed phase leads to sufficient strengthening due to the Orowan mechanism through dislocations bowing the particles and can be considered a way to elevate the properties of refractory alloys [3, 4]Moreover, ultrafine carbides might be used as additives in the 3Dprinting of MMCs [5], resulting in the refined At Carbide Industries, calcium carbide production in different sizes (grades) is all we do Generally speaking, the different grades of carbide that we make correspond to different reactivities of the carbide For example, we produce fastacting carbide powder that is injected into molten iron to combine with and remove sulfurCalcium Carbide Applications Carbide Industries LLC2022年1月10日 The CCR has been proved to have high potential as an activator for preparing some solid wastebased AAMs For instance, Phetchuay et al used CCR as an activator to improve the properties of fly ashclay based AAMs, adding 12% CCR can increase the strength of AAMs by 15 times and has a 22–43% lower carbon footprint than cement stabilized soil Mechanical, microstructure and reaction process of calcium carbide Calcium carbide and carbon monoxide are produced in this step Preparation of acetylene from calcium carbide Calcium carbide and water reaction CaC 2 + H 2 O = HCCH + Ca(OH) 2 Add calcium carbide into water You can see a smoke is coming out of water This smoke is the acetylene gas which is highly flammable Acetylene's IUPAC name is ethyneCalcium carbide and acetylene manufacturing process

.jpg)

Calcium Carbide Applications Carbide Industries LLC

At Carbide Industries, calcium carbide production in different sizes (grades) is all we do Generally speaking, the different grades of carbide that we make correspond to different reactivities of the carbide For example, we produce fastacting carbide powder that is injected into molten iron to combine with and remove sulfurCalcium Carbide (CaC2) Calcium Carbide is a colorless and odorless solid Calcium Carbide is the chemical name of CaC2 For an indepth knowledge on the uses, physical and The entire process is carried out in an electric arc furnace; This compound is widely used in the manufacture of calcium cyanamide and acetylene Properties of Calcium Carbide Structure, Properties, and Uses of CaC2try’s technology for producing calcium carbide A process has been developed incorporating a 90 MW rectangular 6electrode furnace, dry gas cleaning system for fuel gas recovery, and fully automated calcium carbide cooling and handling system Underpinning these advances are Carbide Industries’ proven and robust calcium carbide production proA STEP CHANGE IN CALCIUM CARBIDE PRODUCTION Tungsten carbides are made by blending micronsized tungsten carbide particles with Cobalt (or Nickel) powders Get started by sending Yillik an ! info@yillik 8008549847Precision Tungsten Carbide Manufacturing Process Yillik PSM

.jpg)

Preparation and Performance Assessment of Calcium Carbide

2024年10月29日 Preparation and Performance Assessment of Calcium Carbide Slag Alkali activated Red Mudbased Cementitious Red mud pretreatment process the fragments were dried at 60°C A portion of the fragments was then ground into powder form using a ball mill and screened through a 200 mesh squareholed sieve for subsequent XRD 2021年11月1日 Pei et al [17] explored a low calcium sintering process of red mud, The Na2O residue and bulk density of the calcium silicate powder are 042% and 030 Red mud (RM) and calcium carbide A novel process to fully utilize red mud based on lowcalcium 2018年7月11日 Calcium carbide (CaC2) is widely used for the production of various acetylene derivatives, accompanying with a huge amount of carbide slag waste To develop a clean production process, we explored the reaction of CaC2 and glycerol at varying conditions for the first time The products were characterized by various techniques It is observed that CaC2 Greener Production Process of Acetylene and Calcium Calcium carbide is efficiently and safely employed to provide heat to a steel melt during subsurface refining by providing the steel melt with acidic component(s) and/or oxidizable component(s), which when oxidized will yield acidic components, in a amount sufficient to flux the products of calcium carbide oxidation, while insuring that the calcium carbide does not reside Steelmaking process using calcium carbide as fuel

News Calcium Silicate Production Raw Materials And Technology

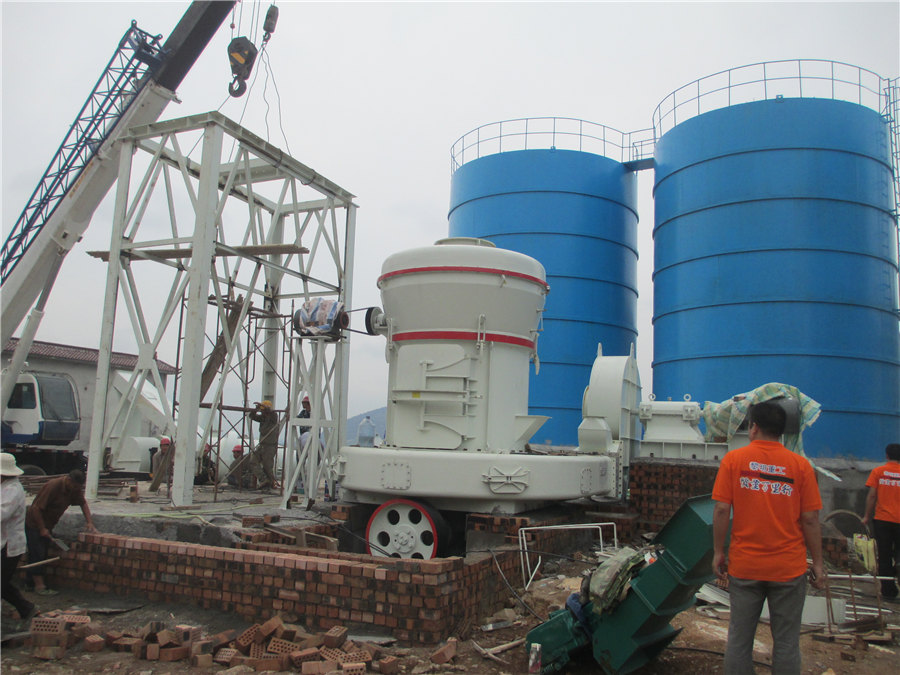

2 Calcareous materials: slaked lime powder, cement, calcium carbide mud, etc 3 Reinforcing fiber: wood paper fiber, wollastonite, cotton fiber, etc 4Main ingredients and formula: silicon powder + calcium powder + natural log pulp fiber Quartz powder silica powder calcium powder diatomite wollastonite grinding mill114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA2024年8月9日 Currently, the current focus of mud treatment research primarily centers on addressing issues such as oil drilling waste fluid, road and bridge waste mud, and the utilization of activated sludge resources [3], [4], [5]Treatment methodologies encompass a range of approaches including land tillage, chemical flocculation for solidliquid separation [6], [7], [8], Study on mechanical properties and microstructure of metakaolin 2021年8月1日 As calcium carbide (CaC 2) production is an energyintensive industry, a novel low rank coal to CaC 2 (LRCtCC) process has been developed This study is aimed to evaluate the technoeconomic performance of the LRCtCC process A model integrating particle swarm optimization and nonlinear programming (PSONLP) is developed to predict the behavior of Case study of a novel low rank coal to calcium carbide process based

Calcium carbide Wikipedia

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P 2022年5月1日 Dryprocess calcium carbide slag is a large amount of calciumbased solid waste produced in the process of making acetylene by the calcium carbide process, in which residual calcium carbide and Recycling and utilization of calcium carbide slag ResearchGate2024年8月9日 Utilizing MSC composite materials (MMetakaolin(MK)), SSlag, CCalcium carbide residue (CCR)), the waste engineering mud produced through the drilling and grouting pile construction method was solidifiedThrough the analysis of unconfined compressive strength (UCS), Xray diffraction (XRD), and scanning electron microscope (SEM) on solidified Study on mechanical properties and microstructure of metakaolin Calcium carbide is a chemical compound salt Also, we can refer it to as calcium acetylide Besides, it is a compound that we use in industries for production The calcium is harmful for human consumption The other name of Calcium Calcium Carbide – Definition and How to Make it?

Life cycle assessment of acetylene production from calcium carbide

2021年11月1日 Acetylene production processes include the calcium carbide, hydrocarbon cracking, and methane partial oxidation methods, etc (Kang et al, 2016)The calcium carbide method is a traditional and universally used acetylene production process; it is relatively simple, but is a large energy consumer and results in CO 2 emissions, which have a negative 2023年2月1日 To track this problem with a costeffective approach, the incorporation of other solid wastes has been attracting increasing attention, such as calcium carbide residue and Glauber's salt [12 Performances and microstructure of onepart fly ash geopolymer 2022年5月5日 Recommended calcium carbonate grinding mill Most of the production process of calcium carbonate is inseparable from the milling process Common calcium carbonate powders include 300 mesh, 400 mesh, 600 mesh, 800 mesh, 1200 mesh, 1500 mesh, and 2000 mesh Their uses are more extensiveCalcium Carbonate Grinding Mill Powder Modify SBM Ultrafine Powder Grind the above silicon carbide dry particles into d50=95115 with silicon carbide Raymond mill machine μ M of silicon carbide powder During crushing, the main flow of the mill is set at 6575a, and the fan flow is set at 4050 m3/min Analyzer speed 400600 rpmNews How Is Silicon Carbide Powder Produced? Production Process

Recycling and utilization of calcium carbide slag ScienceDirect

2022年5月1日 CarbonCaO composites have the following advantages: 1) Making full use of calciumbased solid waste (CCS powder, limestone powder), blue carbon powder and coking coal, etc The use of CCS realizes the circulation of CaO, reducing the exploitation of highquality limestone resources, CO 2 emission, as well as the environmental pollution and waste of 2012年12月31日 Calcium carbonate superfine powder with high purity was prepared from calcium carbide residue by a liquid phase process using ammonium chloride as extraction agent and ammonium carbonate agentPreparation of Calcium Carbonate Superfine Powder by Calcium Carbide In this article, we’ll explore the silicon carbide powdermaking process flow, Impurities such as iron, aluminum, and calcium are removed from the silicon carbide powder through chemical or physical methods Purification Methods: 1 Chemical Etching: The powder is treated with chemical agents to dissolve and remove impurities 2What is the Silicon Carbide PowderMaking Process Flow?This video shows calcium carbonate powder manufacturing process of Praveen Mineral Chemical (PMC) The process describes how PMC offers calcium powder thatCalcium Carbonate Powder Manufacturing Process YouTube

.jpg)

Comprehensive performance study of aluminum ash and calcium carbide

2022年12月12日 Calcium carbide slag is a waste slag produced after the hydrolysis of calcium carbide to obtain acetylene gas, with very fine particles, offwhite color due to the presence of trace carbon and sulfur impurities, slightly odorous, with Ca(OH) 2 as the main component, and a slag liquid pH value of 12 or more, thus often causing serious pollution to the environment [18]114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US Environmental 2024年6月15日 The use of fine carbide particles as a dispersed phase leads to sufficient strengthening due to the Orowan mechanism through dislocations bowing the particles and can be considered a way to elevate the properties of refractory alloys [3, 4]Moreover, ultrafine carbides might be used as additives in the 3Dprinting of MMCs [5], resulting in the refined Synthesis of nano and ultrafine refractory carbide powders by At Carbide Industries, calcium carbide production in different sizes (grades) is all we do Generally speaking, the different grades of carbide that we make correspond to different reactivities of the carbide For example, we produce fastacting carbide powder that is injected into molten iron to combine with and remove sulfurCalcium Carbide Applications Carbide Industries LLC

Mechanical, microstructure and reaction process of calcium carbide

2022年1月10日 The CCR has been proved to have high potential as an activator for preparing some solid wastebased AAMs For instance, Phetchuay et al used CCR as an activator to improve the properties of fly ashclay based AAMs, adding 12% CCR can increase the strength of AAMs by 15 times and has a 22–43% lower carbon footprint than cement stabilized soil Calcium carbide and carbon monoxide are produced in this step Preparation of acetylene from calcium carbide Calcium carbide and water reaction CaC 2 + H 2 O = HCCH + Ca(OH) 2 Add calcium carbide into water You can see a smoke is coming out of water This smoke is the acetylene gas which is highly flammable Acetylene's IUPAC name is ethyneCalcium carbide and acetylene manufacturing processAt Carbide Industries, calcium carbide production in different sizes (grades) is all we do Generally speaking, the different grades of carbide that we make correspond to different reactivities of the carbide For example, we produce fastacting carbide powder that is injected into molten iron to combine with and remove sulfurCalcium Carbide Applications Carbide Industries LLCCalcium Carbide (CaC2) Calcium Carbide is a colorless and odorless solid Calcium Carbide is the chemical name of CaC2 For an indepth knowledge on the uses, physical and The entire process is carried out in an electric arc furnace; This compound is widely used in the manufacture of calcium cyanamide and acetylene Properties of Calcium Carbide Structure, Properties, and Uses of CaC2

.jpg)

A STEP CHANGE IN CALCIUM CARBIDE PRODUCTION

try’s technology for producing calcium carbide A process has been developed incorporating a 90 MW rectangular 6electrode furnace, dry gas cleaning system for fuel gas recovery, and fully automated calcium carbide cooling and handling system Underpinning these advances are Carbide Industries’ proven and robust calcium carbide production proTungsten carbides are made by blending micronsized tungsten carbide particles with Cobalt (or Nickel) powders Get started by sending Yillik an ! info@yillik 8008549847Precision Tungsten Carbide Manufacturing Process Yillik PSM