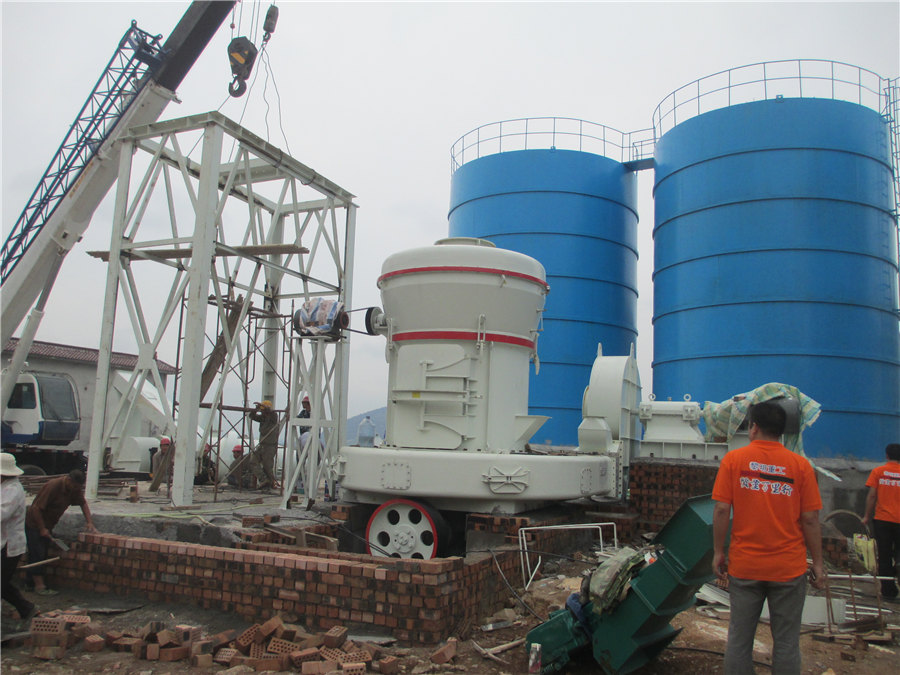

Ceramic heavy calcium powder grinder 2

.jpg)

CaseIndustrial Grinding Mill, Ultrafine Grinding Mill, Vertical Roller

From the coal powder preparation, heavy calcium and slag powder processing, to largescale nonmetallic mineral powder, power plant environmental desulfurization, limestone powder, As a highquality inorganic chemical substance, heavy calcium carbonate China Hubei heavy calciuProduction capacity: 213t/h Heavy calcium carbonate is abbreviated as heavy calcium It uses highquality limestone as raw material and is processed into white powder by a lime mill Its HEAVY CALCIUM CARBONATE POWDER GRINDING PLANT HEAVY CALCIUM CARBONATE POWDER QUALITY ULTRAFINE GRINDING MILL EQUIPMENT is a new type of highfine grinding equipment newly developed by Guilin LXJM HEAVY CALCIUM CARBONATE POWDER QUALITY ULTRAFINE GRINDING

.jpg)

Heavy calcium carbonate grinding, surface modification

2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has 2021年8月27日 Heavy calcium ultrafine processing equipment is divided into grinding equipment and grading equipment The grinding equipment includes Raymond mill, vibration Heavy calcium + superfine processing equipment ALPA Powder This product is mainly suitable for ultrafine grinding of nonmetallic mineral powders such as heavy calcium carbonate, kaolin and talc The company selects high whiteness and highfineness raw materials to ensure noncontaminated Zhejiang Humo Polishing Grinder Manufacture 2023年12月22日 High Safety and Reliability Ceramic Powder Grinding Mill Machine for Calcium Carbonate Limestone Gypsum Kaolin Powder Plant, Find Details and Price about Mining High Safety and Reliability Ceramic Powder Grinding Mill

重质碳酸钙喷射结合剂真空浸渍法制备低成本高强度可溶陶瓷

2023年8月13日 以CaMg(CO 3 ) 2组成的白云石加工的重质碳酸钙(HCC)为原料,采用粘合剂喷射法印刷陶瓷坯体,并采用纳米ZrO 2分散液对陶瓷坯体进行真空浸渍。 烧结后得到低成本高强 2024年10月13日 Ball mill grinding is one of the most traditional and widely used methods for ultrafine grinding of heavy calcium powder The working principle is to rotate the cylinder with UltraFine grinding processing method and flow of heavy calcium powder 2024年8月23日 The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies It can be Heavy calcium carbonate dry production process 2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium

.jpg)

Calcium Carbonate Grinding Mill Powder

2022年5月5日 Stage 2: grinding The crushed small pieces of calcium carbonate are sent to the silo by elevator, and the vibrating feeder sends them to the grinding chamber of the mill evenly and quantitatively for grinding For fine 2020年11月13日 Such quality problems may cause abnormal operation of the wet end system of the paper machine Normally, calcium carbonate with a content of 2 μm and 65% (solid content: 17%) 18%) 15min settling velocity is ≤ 1mm 2 Heavy calcium carbonate grinding process and process parameter controlQuality requirements and grinding process control of heavy calcium 2023年10月16日 The settling volume of light calcium is 2428mL/g, and the settling volume of nanolight calcium is 3040mL/g 10 Specific surface area The specific surface area of ordinary heavy calcium is generally about 1m2/g, and the specific surface area of heavy fine calcium carbonate is 145~21m2/g;Learn the 17 differences between light calcium and heavy calcium 2024年10月13日 2 Grinding Methods of Heavy Calcium Powder Ball Mill Grinding Ball mill grinding is one of the most traditional and widely used methods for ultrafine grinding of heavy calcium powder The working principle is to rotate the cylinder with the grinding body (steel ball) to generate collision, friction, and compression forces on the material UltraFine grinding processing method and flow of heavy calcium powder

Quality requirements and grinding process control of heavy calcium

Taking into account the quality of the medium itself and the control of the particle size of the calcium carbonate after grinding and the current of the grinding machine, the amount of the medium is 1/2~3/5 of the grinding volume of the grinding machine, and the types of media used by different grinding units are different, according to For the 2018年11月10日 Powder mixtures prepared by mechanical activation from synthetic hydrated acidic calcium phosphates Ca(H2PO4)2 H2O and CaHPO4 2H2O were used to obtain resorbable ceramic in the system Ca (PO3)2–Ca2P2O7 The phase composition of the ceramic after firing in the interval 700 – 1000°C was represented by biocompatible and bioresorbable Calcium Phosphate Ceramic in the System Ca(PO3)22021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the (PDF) Effects of Grinding Aids Used in Grinding Calcium It is heavy calcium carbonate and can be used for grinding powder The ground calcite powder can be used in the cement manufacturing industry and is the main raw material for making cement Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in ultramillindustrial grinding mill, ultrafine grinding mill,

.jpg)

High Pressure Grinder Mill325 SHANGHAI LATITUDE

2023年10月1日 Widely used in mineral processing, heavy calcium powder, boiler coal powder, metallurgical charge, power plant desulfurization, refractory materials and other fields Mainly used for power plant desulfurization limestone powder, lime, dolomite, gypsum, coal, barite, calcite, and other materials for grinding processing2021年7月20日 Application of ground calcium carbonate 372% of the ground calcium carbonate is used in the paper industry, 253% of the heavy calcium is used in the plastic industry, 111% of the heavy calcium is used in the filler and coating industry, 66% of the heavy calcium is used as an adhesive and sealant, and 198% of the ground calcium carbonate is Calcium carbonate grinding millCLIRIK Machinery2021年8月24日 The wet method is used to process refined and functional heavy calcium powder, the mesh number is above 3000, and the equipment mostly uses stirring mills Adding pulverizing aids in the fine media mill can prepare submicron or even nano ultrafine powder Wet grinding mainly produces products above 3000 mesh, Production and modification process of heavy calcium 2024年9月13日 Methods Equipment Finished product(D97/ μ m) Features Dry grinding process Raymond roller mill 25150 1Applicable materials: medium and low hardness; 2Product features: medium and lowend products, suitable for the production of coarse powder;How to Choose a Calcium Carbonate Grinding Mill DASWELL

.jpg)

Calcium Hydroxyapatite, Ca10(PO4)6(OH)2 Ceramics

2006年9月1日 Request PDF Calcium Hydroxyapatite, Ca10(PO4)6(OH)2 Ceramics Prepared by Aqueous Sol–Gel Processing Aqueous sol–gel chemistry routes based on ammonium–hydrogen phosphate as the Ultrafine powder grinding Menu Toggle Ball Mill; Raymond Mill; Roller Mill; Table Roller Mill; Ultrafine Air Classifier Menu Toggle Horizontal Air Classifier; Heavy calcium powder is not equal to talc powder Both Read More » Comparison of powder preparation by ring roller mill and table roller mill April 3, 2024Machines EPIC Calcium carbonate powder production "Focusing on the RD and manufacturing of nonmetallic mineral grinding equipment, industrial powder making equipment and green building materials equipment, and providing professional solutions and mature supporting products to create value for our customers" How a Ceramic Mill Machine Revolutionizes Grinding Processes Double Toothed Roll GrinderTalc Mill MachineGuilin Advantages and features: high grinding and powder selection efficiency, energy saving, high efficiency, convenient maintenance, low comprehensive operation cost, reliable performance, high degree of automation, stable product quality and excellent quality 2Hongcheng's heavy calcium superfine mill is a powerful equipment in terms of Calcium Carbonate Powder Processing hcmill

.jpg)

Preparation of lowcost high strength soluble ceramic cores using heavy

Request PDF On Aug 1, 2023, Yanqing Niu and others published Preparation of lowcost high strength soluble ceramic cores using heavy calcium carbonate by binder jetting and vacuum impregnation 2023年12月1日 Binder jetting method was used for printing ceramic green body using heavy calcium carbonate (HCC) processed from dolomite consisting of CaMg(CO 3) 2 as raw material, and the nanoZrO 2 dispersion was used to vacuum impregnate the ceramic green body After sintering, the lowcost high strength soluble ceramic core was obtained The CaO generated Preparation of lowcost high strength soluble ceramic cores using heavy Project Introduction CustomisableJiangsu Rugao Calcium Powder Factory purchased two sets of Jianye 4121 highpressure mills for the production of heavy calcium powder, which is mainly used in the filler industry and coating industry, and now it also maintains a Rugao calcium powder production line建冶重工机械官网2023年12月1日 In the production of the castings with complex cavity structures, the selection of ceramic core materials is a crucial consideration due to the high chemical reactivity of the titanium alloys [1]At present, the most widely used ceramic cores are mainly SiO 2 ceramic cores [16], [17], [18] and Al 2 O 3 ceramic cores [19], [20], [21]However, the SiO 2 and Al 2 O 3 are Preparation of lowcost high strength soluble ceramic cores using heavy

Calcium Carbonate Powder Production Line

Providing with green, highvalue calcium carbonate ultrafine grinding, classifying and powder coating processes Get Started Our Services Quality is fundamental Creating trustworthy products EPIC Powder Machinery is a 2024年9月13日 Application: Chemical, mineral, metallurgy, paint, ceramics and other industries Online Inquiry Content Directory Calcium carbonate plant is also known as calcium carbonate processing or grinding plant Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or Customize Suitable Calcium Carbonate Plant DASWELL2024年11月12日 From largecapacity grinders to multipurpose, we've tested the best spice grinders to help give your cooking a flavor boost Electric spice grinders typically work by using a spinning blade to pulverize whole spices and herbs into powder Manual grinders use a ceramic or metal (usually carbon or stainless steel) mechanism to crush spices The 7 Best Spice Grinders of 2024 The Spruce Eats2024年6月4日 Calcium hydroxide production line (Quick Lime Plant Hydrated Lime Automated Production Line ) Hydrated lime, chemical formula Ca(OH)2 As powder, it loses water and becomes quicklime at 580℃, and its clarified aqueous solution is called lime water; The Calcium hydroxide production line SHANGHAI LATITUDE

.jpg)

Ball Mill Calcium carbonate dry grinding high quality

2024年6月7日 The ratio of length to diameter of ball mill is optimized to provide more ideal output and fine powder rate, avoid excessive grinding and improve grinding efficiency; Heavy calcium powder is not equal to talc powder Both Read More » Comparison of powder preparation by ring roller mill and table roller mill April 3, 20242 In 1 Combined Powder Grinder And Grass Cutter Chaff Cutter And Pulverizer Capacity: 1000 Kg/hr Calcium Carbonate Super Fine Powder Mill Get Best Deal Coal Ore Pulverizer Application: Wall and mining industry It can be used for grinding barite, calcite, potash feldspar, talc, marble, ceramic, glass and some other material that Moh's Powder Grinder Manufacturers, Suppliers, Dealers Prices2023年8月13日 Binder jetting method was used for printing ceramic green body using heavy calcium carbonate (HCC) processed from dolomite consisting of CaMg(CO 3) 2 as raw material, and the nanoZrO 2 dispersion was used to vacuum impregnate the ceramic green body dispersion was used to vacuum impregnate the ceramic green bodyPreparation of lowcost high strength soluble ceramic cores Xuzhou Churun Heavy Machinery Manufacturing Co, Ltd Mineral Powder Grinding Equipment Large Capacity Ball Grinder Machine Limestone Small Ball Mill for Gold Manganese Iron Chromite Kaolin Bentonite Quartz Limestone Zircon Coal Ceramic Cement Powder Ultrafine Calcium Carbonate Powder Gold Ore Copper Pyrite Diesel Grinding Ball Mill US Limestone Grinding Mill MadeinChina

.jpg)

Heavy calcium carbonate dry production process

2024年8月23日 The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies It can be 2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium 2022年5月5日 Stage 2: grinding The crushed small pieces of calcium carbonate are sent to the silo by elevator, and the vibrating feeder sends them to the grinding chamber of the mill evenly and quantitatively for grinding For fine Calcium Carbonate Grinding Mill Powder 2020年11月13日 Such quality problems may cause abnormal operation of the wet end system of the paper machine Normally, calcium carbonate with a content of 2 μm and 65% (solid content: 17%) 18%) 15min settling velocity is ≤ 1mm 2 Heavy calcium carbonate grinding process and process parameter controlQuality requirements and grinding process control of heavy calcium

.jpg)

Learn the 17 differences between light calcium and heavy calcium

2023年10月16日 The settling volume of light calcium is 2428mL/g, and the settling volume of nanolight calcium is 3040mL/g 10 Specific surface area The specific surface area of ordinary heavy calcium is generally about 1m2/g, and the specific surface area of heavy fine calcium carbonate is 145~21m2/g;2024年10月13日 2 Grinding Methods of Heavy Calcium Powder Ball Mill Grinding Ball mill grinding is one of the most traditional and widely used methods for ultrafine grinding of heavy calcium powder The working principle is to rotate the cylinder with the grinding body (steel ball) to generate collision, friction, and compression forces on the material UltraFine grinding processing method and flow of heavy calcium powder Taking into account the quality of the medium itself and the control of the particle size of the calcium carbonate after grinding and the current of the grinding machine, the amount of the medium is 1/2~3/5 of the grinding volume of the grinding machine, and the types of media used by different grinding units are different, according to For the Quality requirements and grinding process control of heavy calcium 2018年11月10日 Powder mixtures prepared by mechanical activation from synthetic hydrated acidic calcium phosphates Ca(H2PO4)2 H2O and CaHPO4 2H2O were used to obtain resorbable ceramic in the system Ca (PO3)2–Ca2P2O7 The phase composition of the ceramic after firing in the interval 700 – 1000°C was represented by biocompatible and bioresorbable Calcium Phosphate Ceramic in the System Ca(PO3)2

.jpg)

(PDF) Effects of Grinding Aids Used in Grinding Calcium

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the It is heavy calcium carbonate and can be used for grinding powder The ground calcite powder can be used in the cement manufacturing industry and is the main raw material for making cement Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in ultramillindustrial grinding mill, ultrafine grinding mill,