Principle of largescale aggregate grinding system

.jpg)

ReviewRobotic grinding of complex components: A step towards

2020年10月1日 Specifically, the robotic grinding system for largescale complex components mainly includes robots, guide rails, grinding tools, measurement, dust removal and total control system Its working principle is illustrated as follows: Through the local measurement and 2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent Principles of Modern Grinding Technology2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy Grinding in Ball Mills: Modeling and Process Control ResearchGate2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, (PDF) A comprehensive review on the grinding process:

Development of Single Step Grinding System for Large Scale ϕ300

2001年1月1日 Three core technologies: the hybrid process mechanics, the GMM (giant magnetostrictive material) actuated positioning/alignment device and the ecologically friendly 2023年12月21日 This research presents a multiscale model to capture the interaction state of the grainworkpiece by determining the transient stage of each individual grain based on the A multiscale model revealed in the grinding process and its 2022年2月12日 This study investigated a novel methodology called equivalentsphere swing grinding (ESSG) for the cup wheel grinding of large revolving aspheric and spherical surfaces An equivalentspherebased grinding of large aspheric and 2021年1月8日 The most important decision in the design of a grinding circuit is the definition of total installed power required It must include the allowance for treating hard and soft ores as A CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE

.jpg)

We will discuss the principle of the Attritor and its applications

In this presentation we will discuss the principle of the Attritor and its applications The Attritor is a grinding mill containing internally agitated media It has been generically referred to as a 2021年12月17日 Traditional aggregate production systems require the use of three or four grinding stages (depending on the particle size of the feed), but fine fractions contain Production Methods for Regular Aggregates and InnovativePublisher Summary Dressing is performed on a grinding wheel in preparation for grinding The aspects of dressing include truing to eliminate deviations from specified form or straightness; dressing to achieve a sharp cutting surface and a uniform random distribution of cutting edges; conditioning to remove the bonds surrounding the abrasive grains and create a more open Principles of Modern Grinding Technology ScienceDirectTypes of Grinding Machine: Parts, Working Principle Grinding Wheel :A grinding machine is an industrial power tool that is used to perform the grinding operation Grinding is the process of removing excess material from a Types of Grinding Machine: Parts, Working Principle

.jpg)

Gradation Of Aggregates Types of Aggregate

2019年10月5日 Types of Grading7•Denseor wellgraded aggregate–Has gradiationclose to the FWHA maximum density grading curve•Gapgraded aggregate–Has only a small percentage of particles in the midsize 2022年4月7日 A large component of the building material concrete consists of aggregate with varying particle sizes between 0125 and 32 mm Its actual size distribution significantly affects the quality (PDF) Learning to Sieve: Prediction of Grading Curves from Images 2002年11月1日 An aggregate model of a largescale offshore wind farm, comprising 72 wind turbines of 2 MW rating each, is set up Representation of the shaft systems of the wind turbines shall be taken into An aggregate model of a gridconnected, largescale2018年8月9日 Permeability can thus be controlled by adjusting the aggregate gradations of various fractions to ensure voids are filled and packing efficiency is achievedPermeability Potential of Asphalt Mixes via Binary Aggregate

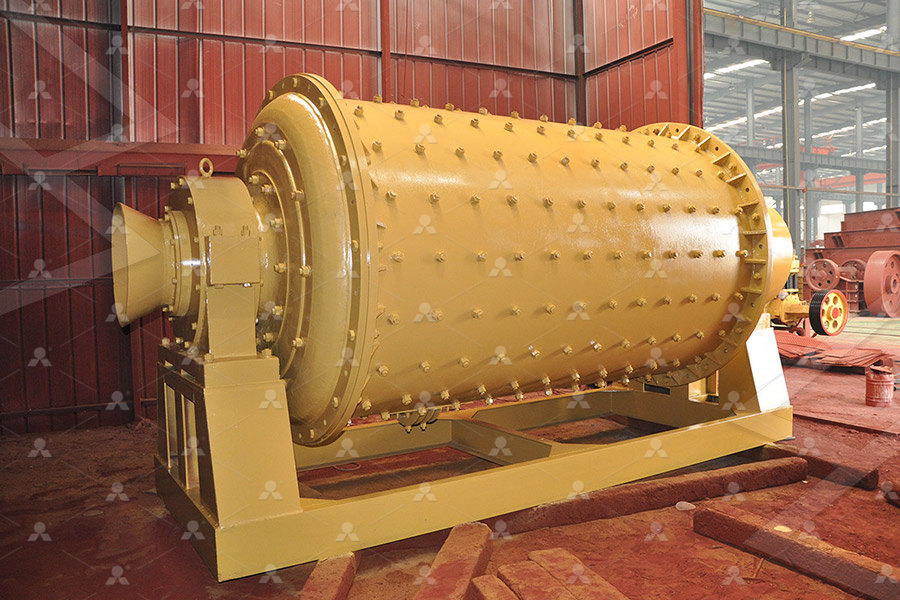

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and 2023年10月13日 Principles of particle reduction The most common method for obtaining a homogeneous sample is grinding of comminution Grinding samples has many benefits for sample preparation since it increases homogeneity, increases surface area and decreases particle size which can improve extraction efficiencyPrinciples of Sample Preparation by Grinding or ComminutionThe results demonstrate that the principle prototype has a satisfactory asphaltstripping effect and achieves fine stripping of aged asphalt on the surface of aggregate without largescale crushing This principle prototype has significant Developing and Testing of the Principle Prototype for Dry grinding is more often a continuous operation and is more advantageous for mass production However, dry grinding tends to aggregate the powder particles because of the high surface energy of the particles A major benefit of dry grinding is that higher densities can be achieved at lower temperaturesWe will discuss the principle of the Attritor and its applications

Design principles for UltraLargeScale (ULS) Systems

in the engineering of ultralarge scale information intensive systems of systems Much of the thinking presented in this paper was crystallised by the Socio Technical Systems Engineering workshop held in St Andrews in September 2009 as part of the UK EPSRC funded LSCITS (Large Scale Complex IT Systems) research programme2012年10月1日 The Bailey Method presents a model of an aggregate matrix based on particle compaction as influenced by particle size distribution Also provides a set of tools for the design and the evaluation An Application to the European Practice of the Bailey Method for 2001年12月31日 Request PDF Development of Single Step Grinding System for Large Scale ϕ300 Si Wafer: A Total Integrated FixedAbrasive Solution This research has developed an integrated manufacturing system Development of Single Step Grinding System for Large Scale 2021年3月26日 Request PDF Multimobile Robot Cluster System for Robot Machining of LargeScale Workpieces In this article, a novel work pattern for largescale workpiece machining, that is, multimobile robot Multimobile Robot Cluster System for Robot Machining of LargeScale

Industrial application of large raw material roller press finish ZKG

Industrial application shows that the optimal power consumption of the large raw material roller press final grinding system is only 91 kWh/t, and the average power consumption is 120 kWh/t Compared with the other roller press systems, it has obvious power saving advantages2021年4月2日 (1) Particle shapes and textures The TRACs appear to be very course and angular because of the grinding of the concretes and due to the presence of toughened cement mortars or pastes adhered to original coarse aggregate surfaces (Andal et al 2016)Depending on the sizes of aggregates, particles of TRACs typically have thirty to sixty percent mortars or Principles of TailorMade Recycled Aggregate ConcreteMachine 35 IMPROVED INTERCONNECTED VOID MONITORING WITH BINARY AGGREGATE PACKING (BAP) PRINCIPLES Fine aggregate Coarse aggregate 10 Diameter ratio (fine/coarse) 05 09 08 Void index (e) learning techniques have recently been used to develop permeability prediction of HMA based on the principles and approach described in this paper (Blaauw et al Monitoring permeability potential of hot mix asphalt via binary 2020年9月1日 Educators, parents, and students should know the specific purpose of their grading and reporting system: what it will communicate, what it does not communicate, and what additional information is available There is no perfect grading system All systems involve some tradeoffs involving specificity, recency, and precision of informationEight Essential Principles for Improving Grading ASCD

.jpg)

Industrial application of system integration updated

(1) After comprehensive technology modification, the mill resistance is reduced by about 2000 Pa, the whole grinding system resistance is reduced by about 4000 Pa, the system output is increased by 5~10%, the mill power consumption is 2020年10月1日 Specifically, the robotic grinding system for largescale complex components mainly includes robots, guide rails, grinding tools, measurement, dust removal and total control system Its working principle is illustrated as follows: Through the local measurement and matching analysis of the workpiece, the mapping between the workpiece and the design Robotic grinding of complex components: A step towards • Purity of required material: grinding methods often create exposure to other materials of the grinding system or other previously ground materials The most efficient grinding system is a system that applies the minimum amount of energy to Principles of Sample Preparation by Grinding or Comminution2016年4月1日 The elemental composition of an aggregate is the definition of aggregate grading or also can be called as sieve analysis Aggregate gradation consists of particles of different sizes will give the Gradation of Aggregates and its Effects on Properties of Concrete

EnergyEfficient Technologies in Cement Grinding IntechOpen

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a Semantic Scholar extracted view of "Development of Single Step Grinding System for Large Scale ϕ300 Si Wafer: A Total Integrated FixedAbrasive Solution" by H Eda et alDevelopment of Single Step Grinding System for Large Scale 2021年1月8日 As a direct result of the introduction of the SPI test, the viability of largescale 50 tonne pilot plant SAG grinding programs has been questioned Since the cost of obtaining and testing large samples can be prohibitive a choice needs to be made between extensive SPI testing and limited SPI testing followed by a 100 kg / hour pilot plantA CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE Scalability: Ball mills can be scaled up or down to accommodate production requirements, making them suitable for both smallscale and largescale operations Energy Efficiency: The design and operation of ball mills allow for energyefficient grinding, reducing energy consumption and operating costsBall Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

Electromechanical Coupling Dynamic and Vibration Control of

2023年1月10日 The robotic grinding system for a thinwalled workpiece is a multidimensional coupling system composed of a robot, a grinding spindle and the thinwalled workpiece In the grinding process, a dynamic coupling effect is generated, while the thinwalled workpiece stimulates elastic vibration; the grinding spindle, as an electromechanical coupling actuator, is 2001年1月1日 Development of Single Step Grinding System for Large Scale @300 Si Wafer: A Total Integrated FixedAbrasive Solution H Edal, L Zhoul, H Nakanol, R Kondol J Shimizu' Faculty of Engineering, lbaraki University, Hitachi, Japan Submitted by T Nagao (I), Kochi University of Technology, Kochi, Japan 1 Abstract This research has developed an integrated Development of Single Step Grinding System for Large Scale Publisher Summary Dressing is performed on a grinding wheel in preparation for grinding The aspects of dressing include truing to eliminate deviations from specified form or straightness; dressing to achieve a sharp cutting surface and a uniform random distribution of cutting edges; conditioning to remove the bonds surrounding the abrasive grains and create a more open Principles of Modern Grinding Technology ScienceDirectTypes of Grinding Machine: Parts, Working Principle Grinding Wheel :A grinding machine is an industrial power tool that is used to perform the grinding operation Grinding is the process of removing excess material from a Types of Grinding Machine: Parts, Working Principle

Gradation Of Aggregates Types of Aggregate

2019年10月5日 Types of Grading7•Denseor wellgraded aggregate–Has gradiationclose to the FWHA maximum density grading curve•Gapgraded aggregate–Has only a small percentage of particles in the midsize 2022年4月7日 A large component of the building material concrete consists of aggregate with varying particle sizes between 0125 and 32 mm Its actual size distribution significantly affects the quality (PDF) Learning to Sieve: Prediction of Grading Curves from Images 2002年11月1日 An aggregate model of a largescale offshore wind farm, comprising 72 wind turbines of 2 MW rating each, is set up Representation of the shaft systems of the wind turbines shall be taken into An aggregate model of a gridconnected, largescale2018年8月9日 Permeability can thus be controlled by adjusting the aggregate gradations of various fractions to ensure voids are filled and packing efficiency is achievedPermeability Potential of Asphalt Mixes via Binary Aggregate

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and 2023年10月13日 Principles of particle reduction The most common method for obtaining a homogeneous sample is grinding of comminution Grinding samples has many benefits for sample preparation since it increases homogeneity, increases surface area and decreases particle size which can improve extraction efficiencyPrinciples of Sample Preparation by Grinding or Comminution