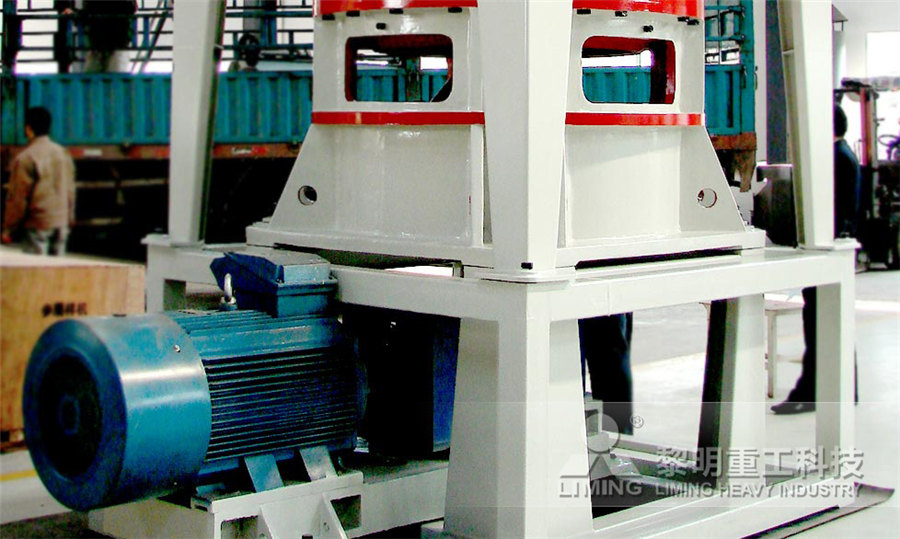

Gypsum ore powder processing test

Purity Determination in Gypsum Application Note Gypsum

In this process, sulfur dioxide (SO 2) reacts with lime (CaCO 3) to produce high purity gyp sum The correct functioning of the desulfurization process can therefore be monitored by testing the purity of the obtained gypsum Quality criteria published by Euro gypsum, the association of 11 These test methods cover the chemical analysis of gypsum and gypsum products, including gypsum readymixed plaster, gypsum woodfibered plaster and gypsum concrete NOTE Standard Test Methods for Chemical Analysis of Gypsum and 11 These test methods cover the chemical analysis of gypsum and gypsum panel products, including gypsum readymixed plaster, gypsum woodfibered plaster, and gypsum concrete Standard Test Methods for Chemical Analysis of Gypsum and 2016年4月1日 In this study, batch grinding tests of gypsum ore were performed using a ball mill to investigate the effects of grinding parameters such as mill speed, ball filling ratio, ball size An experimental study on the ultrafine grinding of gypsum ore in

C472 Standard Test Methods for Physical Testing of Gypsum,

2020年4月29日 Test methods are detailed for the following: precautions for physical tests, reagents and materials, free water, fineness, normal consistency of gypsum plaster and 2015年12月1日 In response, in this study, we have systematically investigated how certain grinding parameters (ie, mill speed, ball filling ratio, ball size distribution, powder filling ratio, An experimental study on the ultrafine grinding of gypsum ore in In this study, the relationship between four expansion indices and the expansion potential of gypsum rock was studied; on this basis, a criterion for judging expansion potential is establishedTest of physical and mechanical properties of the high 2019年4月1日 To investigate this phenomenon, and how much it affects the saturation, all the three methods were tested using freshwater and water fully saturated using a gypsum powder Analysis of drying and saturating natural gypsum samples for

Purity Determination in Gypsum Moisture Analysis METTLER

Learn how to analyze the purity of gypsum by determining the free moisture content and crystal water content in natural and synthetic gypsum produced by FGD2018年10月27日 To investigate the temperature at which gypsum transforms to hemihydrate, we used a helium pycnometer to measure the particle densities of gypsum, hemihydrate and anhydrite In this research,(PDF) Analysis of drying and saturating natural gypsum 2024年11月25日 Vinayak Gypsum and Interiors Pvt Ltd is committed to Manufacturing and Marketing only the best quality of Gypsum Plaster from sophisticated technology for higher purity of Gypsum Powder Only the Top Plaster of paris Gypsum Powder Gypsum plaster2023年9月9日 Gypsum is a naturally occurring mineral that has been used by humans for various purposes for thousands of years It is a versatile mineral with a wide range of applications in construction, agriculture, industry, and even Gypsum Properties, Formation, Uses and Deposits

Plaster of paris Gypsum Powder Gypsum plaster

Vinayak Gypsum and Interiors Pvt Ltd is committed to Manufacturing and Marketing only the best quality of Gypsum Plaster from sophisticated technology for higher purity of Gypsum Powder Only the Top grade Gypsum Powder is Even wellknown minerals such as gypsum require testing on a case by case basis to ensure quality results The following list outlines key material characteristics that affect gypsum processing 1 Abrasive Mined gypsum is a somewhat abrasive material As a result, robust equipment must be used when processing gypsum oreMaterial Characteristics to Consider in Gypsum Processing42 Gypsum (Specification C22/C22M)—Gypsum samples will be received in the form of rocks or powder, or both If necessary crush and reduce the entire dried sample in accordance with 413 and 415 43 Gypsum Plaster (Specification C28/C28M): 431 Gypsum Readymixed Plaster or Gypsum Woodfibered Plaster—Screen the dried sample Standard Test Methods for Chemical Analysis of Gypsum and Gypsum 2024年1月23日 Step 3: Stone Powder Grading The gypsum powder enters the powder screen machine for classification The unqualified gypsum powder goes back to the Raymond mill for secondary grinding Step 4: Calcination of stone powder Gypsum powder meets the fineness requirement and enters a fluidized bed furnace for calcination treatmentGypsum Powder Grinding And Processing Plant Equipment

.jpg)

Powder Characterization and Testing Elsevier

single property or for preparing test pieces It should normally be taken by splitting the composite sample test portion – a defi ned quantity of powder drawn from the test sample, on which the test is performed or from which test pieces are produced Figure 11 Sampling scheme 06V422Ch01dd 7 11/13/2008 10:29:23 AM2015年12月1日 Öksüzoglu and Uçurum [27] studied the ultrafine grinding of gypsum ore in a dry ball mill In their grinding tests, the mill speed was varied from 50 to 90% of the critical speed for gypsum oreAn experimental study on the ultrafine grinding of gypsum ore Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery2023年11月13日 1 Crusher: Gypsum ore is initially crushed into smaller pieces in a crusher to reduce its size for further processing 2 Grinding Mill: After crushing, the gypsum ore is often ground into a fine powder using a grinding mill The grinding process further reduces the size of the gypsum particles 3 Rotary Kiln or Fluidized Bed Calciner: The calcination process, where Gypsum Manufacturing Process Gypsum Processing Equipment

Background Report, AP42, Vol I, SECTION 1116 Gypsum

1970年8月25日 The purpose of this report is to provide background information from test reports and other information to support preparation of AP42 Section 814, for gypsum processing is 3275 The first six digits of the Source Classification Codes Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant AsGypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeFactsheet on: What is Gypsum?In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle Gypsum Powder Ultrafine Grinding MillC 471M Test Methods for Chemical Analysis of Gypsum and Gypsum Products [Metric] C 472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete 3 Terminology 31 Definitions—Definitions shall be in accordance with Terminology C11 4 Chemical Composition 41 Gypsum shall contain not less than 700 weight percent Standard Specification for Gypsum1

Manual of Procedure for Chemical and Instrumental Analysis of

arsenic ores 28 barium ores 28 bismuth ores 34 chrome ores 36 cobalt ores 39 fluorspar ores 41 gypsum 44 iron ores 46 limestone, dolomite, magnesite and allied materials 47 manganese ores 48 molybdenum ores 51 nickel ores 55 copper, lead, zinc (polymetallic ores) 58 pyrites 59 rock phosphate and apatite 60Gypsum ore is dug out from quarries and mines It is crushed and stored close to the plant As per the requirement, the stored ore is further ground and screened to approximately a size of 2 inches or 50 mm diameter In case the mined ore has a high moisture content (more than 05% of weight), it is sent to a rotary dryer for further dryingFive Stages of Gypsum Production Process PermuTrade11 These test methods cover the chemical analysis of gypsum and gypsum products, including gypsum readymixed plaster, gypsum woodfibered plaster and gypsum concrete 12 The test methods appear in the following order: Sections Alternative Procedure for Analysis for Calcium Sulfate by Ammonium Acetate Method 1722Standard Test Methods for Chemical Analysis of Gypsum and Gypsum 3 天之前 Vinayak Gypsum and Interiors Pvt Ltd is committed to Manufacturing and Marketing only the best quality of Gypsum Plaster from sophisticated technology for higher purity of Gypsum Powder Only the Top grade Gypsum Powder is used to produce at 'Bikaner' in Rajasthan state and at 'Bharuch' Dist in Gujarat statePlaster of paris Gypsum Powder Gypsum plaster Perlite ore

Plaster of paris Gypsum Powder Gypsum plaster Perlite ore

3 天之前 Vinayak Gypsum and Interiors Pvt Ltd is committed to Manufacturing and Marketing only the best quality of Gypsum Plaster from sophisticated technology for higher purity of Gypsum Powder Only the Top grade Gypsum Powder is used to produce at 'Bikaner' in Rajasthan state and at 'Bharuch' Dist in Gujarat statePROCESSING GYPSUM WASTE Closedloop gypsum board recycling begins when construction site waste is brought to a recycling center for processing The recycling center separates the paper from the gypsum and breaks down the gypsum into a ine powder The gypsum powder is then ready to be used in recycled gypsum products Additionally,The FEECO Gypsum Processing Handbook FEECO International 2016年4月1日 When gypsum is heated, it loses approximately threequarters of its water and becomes hemihydrate gypsum (CaSO 4 ½H 2 O), which is soft and can easily be ground to a powder called hemihydrate gypsum plaster or plaster of Paris If the powder is mixed with water to form a slurry or paste, it will dry and set rock hardAn experimental study on the ultrafine grinding of gypsum ore 1982年5月21日 used as building stones In pottery, gypsum is used for moulding purposes Besides, gypsum rock is used as flux in the smelting of nickel ores and in tin plate industry for polishing plates 05 Alabaster, a massive and granular variety of gypsum is employed forIS 1288 (1982): Methods of test for mineral gypsum

500 Tons Per Day Gypsum Powder Production Machine

Raw Material Gypsum Type Natural gypsum ore Gypsum powder Mesh Within 220 meshes Heating method Calcination system is the key link in the production and processing of gypsum powder, and the main engineer went to test and debug the machine in December 2018 It has only taken 5 days to run the machine and put it into productionGypsum ore samples were obtained from a mine at Ibese in Ogun State, Nigeria and processed in a multistage degritting operation to obtain a gritfree powder which was converted to gypsum plaster (Plaster of Paris, POP) at about 220oCProcessing a Locally Sourced Gypsum Material for Medical and 2013年3月19日 College Cement Plant Gypsum Processing In copper ore processing plant, of equipment that can be drawn from to set up a customized pilot plant test set up, debugging, gypsum powder processing plant compare the cost and price between Gypsum processing plant setup cost Mining Quarry Plantbut the gypsum powder used for these products are usually well processed Gypsum ore samples were obtained from a mine at Ibese in Ogun State, Nigeria and processed in a multistage degritting operation to obtain a gritfree powder which was converted to gypsum plaster (Plaster of Paris, POP) at about 220oCProcessing a Locally Sourced Gypsum Material for Medical and

Table of Bond Abrasion Index for Varied MineralsMaterials

2015年10月8日 The Bond Abrasion Test determines the Abrasion Index, which is used to determine steel media and liner wear in crushers, rod mills, and ball mills Bond 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Table of Bond Abrasion Index types and grades of gypsum plaster or plaster boards There are five basic stages in gypsum processing: Excavation is sometimes carried out by digging out an area of ground where the gypsum is located using opencast techniques To reach deeper deposits drift or shaft mines may be needed Crushing the gypsum rock is advisable before processingGypsum processing and use Humanitarian LibraryWhen gypsum (CaSO42H2O) is ground to a powder and heated at 150° to 165°C, threequarters of its combined water is removed producing hemihydrate plaster (CaSO41/2 H2O), commonly know as Plaster of Paris When this powder is mixed with water the resulting paste sets hard as the water recomMineral Planning Factsheet Gypsum Mining Association of the 2016年4月1日 Gypsum has been known for centuries as a building material The earliest known use of gypsum as a building material was in Anatolia, approximately 6000 BC Gypsum has been found on the interiors of the great pyramids in Egypt, which were erected in approximately 3700 BC Gypsum is found on every continent in the world and is among the most widely used An experimental study on the ultrafine grinding of gypsum ore

Plaster of paris Gypsum Powder Gypsum plaster

2024年11月25日 Vinayak Gypsum and Interiors Pvt Ltd is committed to Manufacturing and Marketing only the best quality of Gypsum Plaster from sophisticated technology for higher purity of Gypsum Powder Only the Top 2023年9月9日 Gypsum is a naturally occurring mineral that has been used by humans for various purposes for thousands of years It is a versatile mineral with a wide range of applications in construction, agriculture, industry, and even Gypsum Properties, Formation, Uses and DepositsVinayak Gypsum and Interiors Pvt Ltd is committed to Manufacturing and Marketing only the best quality of Gypsum Plaster from sophisticated technology for higher purity of Gypsum Powder Only the Top grade Gypsum Powder is Plaster of paris Gypsum Powder Gypsum plasterEven wellknown minerals such as gypsum require testing on a case by case basis to ensure quality results The following list outlines key material characteristics that affect gypsum processing 1 Abrasive Mined gypsum is a somewhat abrasive material As a result, robust equipment must be used when processing gypsum oreMaterial Characteristics to Consider in Gypsum Processing

.jpg)

Standard Test Methods for Chemical Analysis of Gypsum and Gypsum

42 Gypsum (Specification C22/C22M)—Gypsum samples will be received in the form of rocks or powder, or both If necessary crush and reduce the entire dried sample in accordance with 413 and 415 43 Gypsum Plaster (Specification C28/C28M): 431 Gypsum Readymixed Plaster or Gypsum Woodfibered Plaster—Screen the dried sample 2024年1月23日 Step 3: Stone Powder Grading The gypsum powder enters the powder screen machine for classification The unqualified gypsum powder goes back to the Raymond mill for secondary grinding Step 4: Calcination of stone powder Gypsum powder meets the fineness requirement and enters a fluidized bed furnace for calcination treatmentGypsum Powder Grinding And Processing Plant Equipmentsingle property or for preparing test pieces It should normally be taken by splitting the composite sample test portion – a defi ned quantity of powder drawn from the test sample, on which the test is performed or from which test pieces are produced Figure 11 Sampling scheme 06V422Ch01dd 7 11/13/2008 10:29:23 AMPowder Characterization and Testing Elsevier2015年12月1日 Öksüzoglu and Uçurum [27] studied the ultrafine grinding of gypsum ore in a dry ball mill In their grinding tests, the mill speed was varied from 50 to 90% of the critical speed for gypsum oreAn experimental study on the ultrafine grinding of gypsum ore

Gypsum Powder Production Line Hongji Mining Machinery

Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the 2023年11月13日 1 Crusher: Gypsum ore is initially crushed into smaller pieces in a crusher to reduce its size for further processing 2 Grinding Mill: After crushing, the gypsum ore is often ground into a fine powder using a grinding mill The grinding process further reduces the size of the gypsum particles 3 Rotary Kiln or Fluidized Bed Calciner: The calcination process, where Gypsum Manufacturing Process Gypsum Processing Equipment