FP63AM ore mill drawing

.jpg)

sbm/sbm fp63am crusher drawingsmd at main sbm2023/sbm

Contribute to sbm2023/sbm development by creating an account on GitHubThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 Metallurgistcrushed ore is fed into a SAG/Ball mill circuit with a median size of approximately 12,000 microns Most SAG Mills are operated in closed circuit with a screen The screen fi lters undersized Mill Circuit Pump Manual 911 MetallurgistThis paper presents the structure of the latest version of the JKTech autogenous and semiautogenous (AG/SAG) mill specific energy model, which is an adaptation of that previously SAG Mill Design and Benchmarking Using Trends in the JKTech

Mill power draw models

The mill power draw models are used to predict how much power will be consumed by a particular type of mill, mill geometry and set of mill operating conditions This power is transferred to the Explain the role of critical speed and power draw in design and process control Recognize important considerations in ball mill selection Reading Lecture In ball mills, steel balls or hard pebbles to break particle based on impact and AMIT 135: Lesson 7 Ball Mills CircuitsIn this module, you will learn how to characterize the performance of ball mill circuits Specifically, after completing this module, you will be able to: List and describe the four elements of the MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLINGThe scope of this thesis is to examine the dynamic relations between the SAG mill and the pebble crusher in a closed circuit and thus to optimize the circuit efficiency by controlling the pebble Dynamic Modeling and Simulation of SAG Mill Circuits with

.jpg)

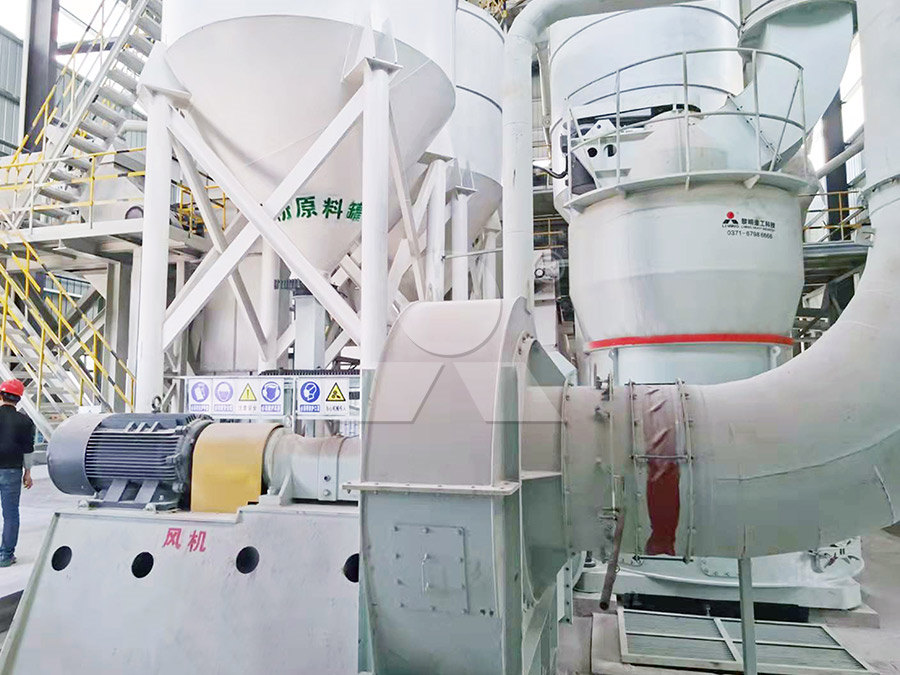

BALL MILL FOR ALL YOUR NEEDS FTM Machinery

Ball mill is the key equipment for grinding materials after crushing and screening It is also commonly used in grinding equipment I It is mainly used in refractory, fertilizer, cement and 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia2016年2月16日 When stamp mills are used for dry crushing, double discharge mortars are provided (see Fig 50), and the screens are put low down, giving a small depth of discharge These arrangements are necessitated by the Stamp Mill Animation 911Metallurgist2018年4月17日 Therefore select a mill to draw at least 5440 Hp at the pinionshaft Based upon the pilot plant test results, the volumetric loading for the mill can be determined Normally, autogenous and semiautogenous mills are selected for a 30% volumetric loading; however, with soft ore, and conglomerates it is not always possible to build up a 30% loadingAutogenous and SAG SemiAutogenous Mill Design Calculations

.jpg)

Colorado Gold Rush Gallery The Argo Mill and Tunnel

Name: Abandoned and vandalized Argo Mill Date: 1960 – 1976 Phase: Prior to Jim Maxwell’s purchase Notes: Leanto shed on left housed bags of high value ore concentrates bound for Denver smelters or the US Mint via the Colorado Southern Railroad The leanto shed on the right is the coal bunker for the mill boilerThis is a game built with machine learning You draw, and a neural network tries to guess what you’re drawing Of course, it doesn’t always work But the more you play with it, the more it will learn So far we have trained it on a few hundred concepts, and we hope to add more over timeQuick, Draw!ϕC, mill speed, the rotational speed of the mill as a fraction of the critical speed of the mill based on the effective diameter, D ρore, ore density, (kg/L) the density of the ore solids in the mill charge XXVIII International Mineral Process Congress September 2016, Quebec City, Canada 2AN UPDATED DATA SET FOR SAG MILL POWER MODEL SMALL MULEBACK BALL MILL Small (Muleback Type) Ball Mill is built for “muleback” transportation in 30″ and 3′ diameters (inside liners) A 4′ (Muleback Type) Ball Mill is of special design and will be carefully considered upon request Mankind’s search for valuable minerals often leads him far away from modern transportation 05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

Grinding Mill Power 911Metallurgist

2017年5月8日 The power required to drive a tumbling mill is of interest both to the designer and to the mill operator: to the former as a basis of design for the determination of the necessary size of the elements of the machine; and to the latter because all other factors being equal, the most economical machine is that which demands a minimum power for driving2016年10月31日 homemade ball mill plans By this drawing, it is suggested that a typical homemade laboratory rod mill or ball mill might be fabricated from 20 cm (8 inches) diameter schedule40 type 316 stainless steel pipe and would be about 38 cm (15 inches) long The plans show stainless steel grinding rods for this size of mill may be a graduated charge from 25 to 10 DIY Ball Mill Plans – Homemade Rod Mill Drawing911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Processing

Mill Circuit Pump Manual 911 Metallurgist

crushed ore is fed into a SAG/Ball mill circuit with a median size of approximately 12,000 microns Most SAG Mills are operated in closed circuit with a screen The screen fi lters undersized ore, normally minus ½ inch, to a ball mill discharge sump The combined mill discharg2015年4月15日 Discharge from each mill Feed to each classification stage Oversize from each classification stage Fines from each classification stage, k Power drawn by each mill (motor input) Motor and drive efficiency of each What Ore Testing is Required For Mill SelectionSAG Mill power draw models are used in mill design and grinding circuit modelling to predict how much power will be consumed by a particular mill geometry and operating configuration This paper will compare SAG mill models by Morrell, Loveday (using "Power Numbers" published by Barratt) and Austin against several published mill surveysA comparison of SAG mill power modelsHGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding Mill

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

Figure 2 illustrates that the total mill power draw multiplied by the classification system efficiency is the effective mill power draw * The effective mill power draw is the power draw that is applied to the grinding of coarse particles Figure 2 The "effective mill power draw" Now let's see how the remaining two terms, ore grindability and 2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Mineral Processing and Ore Mineral Processing and Ore Dressing 911MetallurgistLearn how to using a drawing mill, to pull wire through a draw plate to reduce its crosssection while increasing the wire length Learn how to using a drawing mill, How to use the Drawing Mill YouTube2019年12月23日 A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need The power required to deliver the through put efficiency of the machine was DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

.jpg)

(PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing

2013年7月15日 PDF The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and Find, read and cite all the research 2016年2月2日 The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentGrinding Circuit Startup and Shutdown ProcedureFind Water Mill Drawing stock images in HD and millions of royaltyfree photos, illustrations, and vectors on Shutterstock 1,720 Water Mill Drawing photos for downloadWater Mill Drawing royaltyfree images Shutterstock2018年1月18日 Atlas Mill Drawings Factory Drawings Categories Categories CLICK HERE 1st For List of Alpha Sorted File Categories 2K CLICK HERE 2nd For List of Machine Manuals, Parts Lists, Catalogs Drawings AlphaSorted By Brand 2K Manuals For Unknown Brand Machiness if you can ID, notify WA5CAB 1Atlas Mill Drawings The HobbyMachinist

The Stamp Mill in Mexico’s Antique Mines SpringerLink

2022年4月7日 The stamp mill was used for breaking ore stones before extracting the silver with mercury (quicksilver) The kinematic and dynamic model were determined using the kinematic chain concept, the operation and dimensions were estimated from original drawings and technical data written in Europe and in Mexico Nevertheless, This includes the primary crusher, coarse ore stockpile, conveyors, The SAG mill cost $122 million, whilst the SAG mill motor PHYSICAL PROPERTIES OF CADIA ORES Laboratory test work data, shown in Table 1, indicated hard and competent ores (monzonite, monzodiorites and volcanics), although not necessarily of such competency as to create concernDesign of the 40 foot SAG Mill Installed at the Cadia Gold Copper 2017年6月9日 Circulating load, feed rate, pulp density of feed, and the quantity of grinding medium in the mill were also studied Results indicated that the overall capacity and effectiveness of the attrition mill were influenced by the limited capability of the bowl classifier to make a good separation of the clay particles in the 2micrometer rangeAttrition Grinding Mill Design 911MetallurgistChoose your favorite old mill drawings from 314 available designs All old mill drawings ship within 48 hours and include a 30day moneyback guaranteeOld Mill Drawings for Sale Fine Art America

Drawings from the Society’s archives and publications

Open top cars include drop bottom gondolas, air dump cars, solid bottom gondolas, ballast cars, hopper cars, and ore cars Folio drawing of Ga83 class 40 ft ballast hopper car dated September 4, 1953 Folio drawing of Ga95 class 34 ft highside gondola dated July 2, 1956 Folio drawing of Ga55 class 66 ft mill gondola dated July 27 1949Browse 600+ steel mill drawings stock illustrations and vector graphics available royaltyfree, or start a new search to explore more great stock images and vector art Steelworks at Chorzów (Königshütte) is a city in Silesia in southern Poland, near 600+ Steel Mill Drawings Stock Illustrations, RoyaltyFree 2020年10月9日 In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the particles by controlling three Operation Analysis of a SAG Mill under Different Conditions Based on 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia

.jpg)

Stamp Mill Animation 911Metallurgist

2016年2月16日 When stamp mills are used for dry crushing, double discharge mortars are provided (see Fig 50), and the screens are put low down, giving a small depth of discharge These arrangements are necessitated by the 2018年4月17日 Therefore select a mill to draw at least 5440 Hp at the pinionshaft Based upon the pilot plant test results, the volumetric loading for the mill can be determined Normally, autogenous and semiautogenous mills are selected for a 30% volumetric loading; however, with soft ore, and conglomerates it is not always possible to build up a 30% loadingAutogenous and SAG SemiAutogenous Mill Design CalculationsName: Abandoned and vandalized Argo Mill Date: 1960 – 1976 Phase: Prior to Jim Maxwell’s purchase Notes: Leanto shed on left housed bags of high value ore concentrates bound for Denver smelters or the US Mint via the Colorado Southern Railroad The leanto shed on the right is the coal bunker for the mill boilerColorado Gold Rush Gallery The Argo Mill and TunnelThis is a game built with machine learning You draw, and a neural network tries to guess what you’re drawing Of course, it doesn’t always work But the more you play with it, the more it will learn So far we have trained it on a few hundred concepts, and we hope to add more over timeQuick, Draw!

.jpg)

AN UPDATED DATA SET FOR SAG MILL POWER MODEL

ϕC, mill speed, the rotational speed of the mill as a fraction of the critical speed of the mill based on the effective diameter, D ρore, ore density, (kg/L) the density of the ore solids in the mill charge XXVIII International Mineral Process Congress September 2016, Quebec City, Canada 2SMALL MULEBACK BALL MILL Small (Muleback Type) Ball Mill is built for “muleback” transportation in 30″ and 3′ diameters (inside liners) A 4′ (Muleback Type) Ball Mill is of special design and will be carefully considered upon request Mankind’s search for valuable minerals often leads him far away from modern transportation 05 TO 15 TPH SMALL SCALE MINER’S BALL MILL2017年5月8日 The power required to drive a tumbling mill is of interest both to the designer and to the mill operator: to the former as a basis of design for the determination of the necessary size of the elements of the machine; and to the latter because all other factors being equal, the most economical machine is that which demands a minimum power for drivingGrinding Mill Power 911Metallurgist2016年10月31日 homemade ball mill plans By this drawing, it is suggested that a typical homemade laboratory rod mill or ball mill might be fabricated from 20 cm (8 inches) diameter schedule40 type 316 stainless steel pipe and would be about 38 cm (15 inches) long The plans show stainless steel grinding rods for this size of mill may be a graduated charge from 25 to 10 DIY Ball Mill Plans – Homemade Rod Mill Drawing

Metallurgists Mineral Processing Engineers 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables