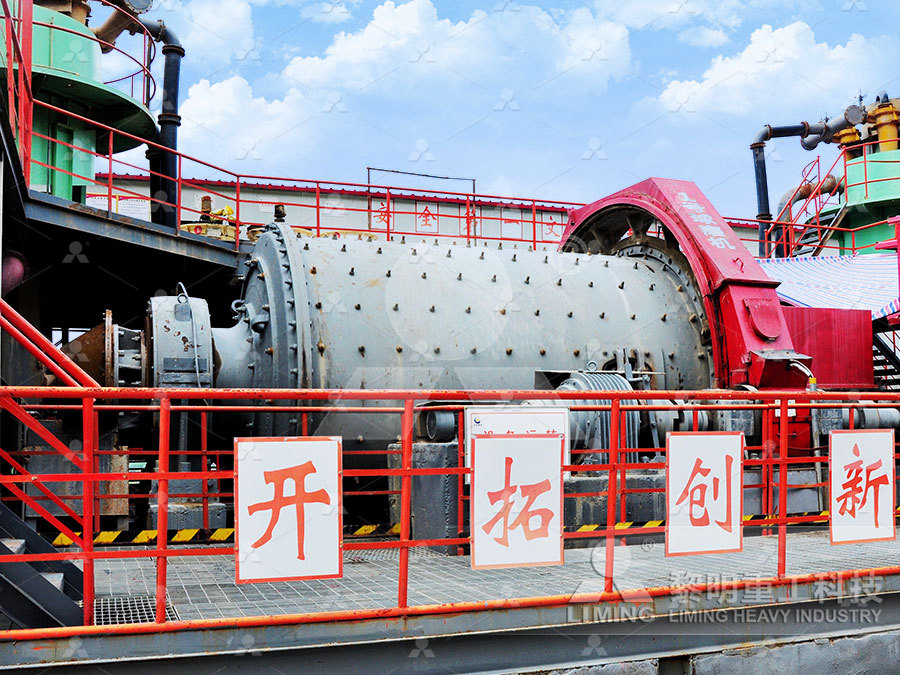

Spodumene grinding equipment processing equipment working principle

Aspects of Spodumene Lithium Extraction Techniques

2024年9月30日 In the last several decades, many techniques have been demonstrated and patented to process hardrock mineral spodumene The objective of this review is to present a thorough analysis of significant findings SGS supports the minerals and chemical industries in the design and operation of efficient crushing and grinding circuits using both power and modelbased methods We can design Hard Rock Lithium Processing SGS2023年12月27日 Two process pathways to achieve batterygrade chemical production from spodumene are summarized herein, with a focus on improving process yields and costs in the saline water circuitHard Rock Spodumene Lithium Processing Saltworks In this article, we will discuss the properties of three common types of grinding mills: spodumene lepidolite mills, sandpaper grit mills, and ball milling Spodumene lepidolite mills are used to Grinding equipment for spodumene and spodumene

.jpg)

Lithium processing technology Complete solutions that FLSmidth

Spodumene concentration Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate of about 6–65% Li20 To achieve this, the ore passes through a 2016年5月9日 Lithium Ore (Spodumene) Flotation The conditioned pulp is diluted to approximately 20% solids for flotation in “SubA” Flotation Machines of standard steel construction The cell to cell type machine with spitzkasten and Processing Spodumene by Froth Flotation for Lithium 2018年8月19日 Spodumene processing can be conducted using Dense Media Separation (DMS ), flotation or combination of both If spodumene liberation is sufficient at coarse particle sizes, Flowsheet Development for Benefication of Lithium Minerals from The extraction process of lithium from spodumene (LiAlSi 2 O 6) begins with comminution such as crushing and grinding to liberate the lithium minerals from the ore matrix followed by METS Engineering Group Pty Ltd Level 3, 44 Parliament Place,

.jpg)

Lithium Shakeup: An alternative crushing and grinding circuit for

with mining concentrator plants, particularly the equipment that FLS supplies to these facilities This investigation presents the results of a conceptual study into a hard rock Lithium 2022年10月31日 This work investigates the energy efficiency of different grinding circuits used for upgrading the lithium content in the finer fraction of the calcined spodumene oreLithium deportment by size of a calcined spodumene ore2024年7月9日 Lithium ore is mainly used to extract lithium, which is widely used in batteries, ceramics, glass, lubricants, aerospace, medicine and other fields In recent years, due to the increasing demand for lithium batteries in electric Lithium Ore Grinding Mills SBM Ultrafine Powder 2021年1月25日 Working Principle of Comminuting Mill Comminuting Mill is the equipment used for the downsizing, milling, pulverization, and dispersion of wet and dry products in pharmaceuticals, chemicals, food, cosmetics, fertilizers, etc How this equipment works are that the product is poured from the top through in feed hopper and the material falls on a rotating Working Principle of Different Pharmaceutical Equipment

The Working Principle and Structure of Rod Mill

2019年10月17日 Rod mill is a common equipment for grinding mineral Let's see its working principle and structure in details! : hm@gmail Toggle navigation Home 7 Tips for Energy Saving and Consumption According to the processing principle of "more crushing and less grinding", rod mills, etc When secondary grinding is required, a wet overflow ball mill can be selected as the grinding equipment for this stage Classification equipment can adopt graded Oretype lithium ores generally include spodumene, lepidolite, lithium A Comprehensive Guide to Lithium Processing Equipment2016年3月26日 Humphreys Spiral Concentrator The Humphreys Spiral Concentrator, which was invented by I B Humphreys and first used in 1943 for concentrating chromite in Oregon beach sands, consists of five or six spiral turns of a modified semicircular launder which is about the size of a conventional automobile tireGravity Spiral Concentrator Working Principle 911MetallurgistFood Processing Unit Operations Questions and Answers – Size Reduction – Grinding Equipments This set of Food Processing Unit Operations Multiple Choice Questions Answers Explanation: The working principle of the jaw crushers is motorized by a diesel or gas motor, Grinding Equipments Size Reduction Questions and Answers

Grinding Mill Types, Working Principle Applications Savona Equipment

2017年10月3日 Share with Facebook; Share with Twitter; Share with Google+; Share with LinkedIn; Posted: October 3, 2017 Grinding Mills Types, Working Principle Applications The purpose of this article is to explain the usage of grinding mills in a mineral processing operation and to enable buyers to understand the best suitable grinding mill as per their specific needs2022年11月8日 The principle of millet processing equipment, after the material enters the whitening room from the feeding hopper through the flow regulating mechanism, it is sent to the grinding roller by the screw head and spirally advances along the surface of the grinding roller, and the sharp sand edge on the surface of the emery grinding roller rotates at a specific line What is the working principle of millet processing equipment?2018年3月1日 Grinding Mills — Types, Working Principle Applications As is quite evident (Marty knows that you know!), the ultimate objective of processing a mineral is to extract the maximum value from a Screening Plants — Types, Working Principle Applications2021年5月5日 Grinding Machine Working Principle: In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel The action of rubbing or friction generates between wok price and tool therefore the material removes Lets see step by step, First, clean the machine with a clean brushGrinding Machine: Definition, Parts, Working Principle, Operation

.jpg)

Guide to Centerless Grinding Machine: Advantages,

2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other The working principle of the highpressure homogenizer (HPH) is based on the use of a highpressure pump and a valve (nozzle, orifice), which makes the equipment large, heavy, and expensive The processed slurry is forced with Homogenizers Working Principle, Use and ScaleUp2024年8月17日 Our guide provides an overview of the process flow, equipment involved, as well as the principles and characteristics of the casting method Close; Articles Protective eyewear Ensure the working area is free from Casting Production: Process Flow, Equipment, Pineer offers a multidisciplinary team that is involved from the initial stages of the characterization of the lithium deposit to the production of highgrade spodumene concentrate (460%) We Pineer provides the comprehensive range of equipment required to extract lithium These processing equipment include:Lithium Ore Flotation Plant Pineer Mining Machinery

What Is Grinding and Its Working Principle and Type?

2021年9月28日 What Is the Working Principle of Grinding Machines? During the grinding process, the grinding surface of the grinder tool is evenly coated with abrasive If the material hardness of the grinding tool is lower than that of the workpiece, when the grinding tool and the workpiece move relative to each other under pressure, the abrasive has sharp edges and 2020年9月22日 Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod mills This article will introduce the characteristics and selection principles of grinding equipment Let's get started! 1 Types of Grinding Machine 1) Ball millGrinding Machines: Types and Selection Principles MiningpediaBall Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts 2016年5月9日 Removal of undersize reduces the amount of resulting fines and increases the capacity of the equipment Grinding and The spodumene concentrate is discharged at the tailing discharge of the flotation machine and is ready for final processing The spodumene pulp contains approximately 20% solids and must be dewatered before Processing Spodumene by Froth Flotation for Lithium Extraction

.jpg)

Jaw Crusher Working Principle 911Metallurgist

2021年5月6日 A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point The motion is, however, a more complex one than the Dodge motion, being 2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?2021年8月27日 Before understanding the working we must go through the principle of working of electrochemical grinding The working principle of electrochemical grinding is When a metal surface is acted upon with an Electrochemical Grinding: Definition, Parts or Grinding equipment and machinery is essential in all mining operations When you are looking for a rock grinder for sale, it is vital to ensure that you get the best and most durable machine This way, you are guaranteed of the longer useful life of the machine and, therefore, more returns on your investmentGrinding Equipment for Sale OEM CamaMach Grinding Equipment

METS Engineering Group Pty Ltd Level 3, 44 Parliament Place,

processing plant and has installed several ancillary equipment in order to produce 204 kTPA of >55% of lithium oxide concentrate Production capacity of 200,000 TPA of lithium oxide at 6% chemical grade spodumene concentrate, 60,000 TPA of mica and 30 TPA of tantalite concentrate is anticipated from this newly upgraded mining facilityIntroduction – Process Equipment is indispensable and its usage in the modern era has become very important They are classified based on their features, application, and working principles A diverse number of industries use them and they are designed for the utmost efficacy and smooth functioning An overview is provided belowWorking Principle of Different Process EquipmentThe Nile Machinery Co, Ltd: Welcome to buy discount crushing equipment, grinding equipment, screening machine, mobile crushing plant, mineral processing equipment in stock here from professional manufacturers in China Our factory is mainly engaged in providing high quality products for sale For price consultation, contact us nowcrushing equipment, grinding equipment, screening machine, Sweet Potato Starch Processing EquipmentThe Working Principle of Pulsed Air Drier How much is a set of Working principle of Cassava Grinding Machine The grinding effect is achieved by horizontal extrusion of the surface of the roller and friction at different speedsWorking Principle and Testing of Cassava Grinding Machine

Size Reduction1: Grinding – Unit Operations in Food Processing

FIGURE 307 Principle of MikroAtomizer (Courtesy: McGrawHill publ) 30433 Agitated mills: In such mills, the grinding medium consists of hard solid elements such as balls, pellets, or sand grains The grinding medium is suspended in a vertical vessel of 4 to 1200 L in capacity which is filled with liquidElectrochemical machining (ECM) is a machining process in which electrochemical process is used to remove materials from the workpiece In the process, workpiece is taken as anode and tool is taken as cathode The two electrodes workpiece and tool is immersed in an electrolyte (such as NaCl)Electrochemical Machining (ECM) Working Principle, Equipment 2023年4月25日 Under the opportunity of 'Made in China 2025', in the field of ultraprecision, China has broken through many key bottleneck technologies, achieved many remarkable scientific research results, built a number of highlevel ultraprecision processing technology innovation platforms, talent growth platforms and application demonstration bases, and Ultraprecision grinding and polishing processing technology The comminution section of the processing plant will comprise: feed bunker loading followed by the crushing carried out with a vibrating grizzly and a jaw crusher, clay removal via washing trommel, secondary crushing via cone crusher, rod milling with Processing Technology Cornish Lithium Plc

.jpg)

Lithium Ore Grinding Mills SBM Ultrafine Powder

2024年7月9日 Lithium ore is mainly used to extract lithium, which is widely used in batteries, ceramics, glass, lubricants, aerospace, medicine and other fields In recent years, due to the increasing demand for lithium batteries in electric 2021年1月25日 Working Principle of Comminuting Mill Comminuting Mill is the equipment used for the downsizing, milling, pulverization, and dispersion of wet and dry products in pharmaceuticals, chemicals, food, cosmetics, fertilizers, etc How this equipment works are that the product is poured from the top through in feed hopper and the material falls on a rotating Working Principle of Different Pharmaceutical Equipment2019年10月17日 Rod mill is a common equipment for grinding mineral Let's see its working principle and structure in details! : hm@gmail Toggle navigation Home 7 Tips for Energy Saving and Consumption The Working Principle and Structure of Rod MillAccording to the processing principle of "more crushing and less grinding", rod mills, etc When secondary grinding is required, a wet overflow ball mill can be selected as the grinding equipment for this stage Classification equipment can adopt graded Oretype lithium ores generally include spodumene, lepidolite, lithium A Comprehensive Guide to Lithium Processing Equipment

.jpg)

Gravity Spiral Concentrator Working Principle 911Metallurgist

2016年3月26日 Humphreys Spiral Concentrator The Humphreys Spiral Concentrator, which was invented by I B Humphreys and first used in 1943 for concentrating chromite in Oregon beach sands, consists of five or six spiral turns of a modified semicircular launder which is about the size of a conventional automobile tireFood Processing Unit Operations Questions and Answers – Size Reduction – Grinding Equipments This set of Food Processing Unit Operations Multiple Choice Questions Answers Explanation: The working principle of the jaw crushers is motorized by a diesel or gas motor, Grinding Equipments Size Reduction Questions and Answers2017年10月3日 Share with Facebook; Share with Twitter; Share with Google+; Share with LinkedIn; Posted: October 3, 2017 Grinding Mills Types, Working Principle Applications The purpose of this article is to explain the usage of grinding mills in a mineral processing operation and to enable buyers to understand the best suitable grinding mill as per their specific needsGrinding Mill Types, Working Principle Applications Savona Equipment2022年11月8日 The principle of millet processing equipment, after the material enters the whitening room from the feeding hopper through the flow regulating mechanism, it is sent to the grinding roller by the screw head and spirally advances along the surface of the grinding roller, and the sharp sand edge on the surface of the emery grinding roller rotates at a specific line What is the working principle of millet processing equipment?

Screening Plants — Types, Working Principle Applications

2018年3月1日 Grinding Mills — Types, Working Principle Applications As is quite evident (Marty knows that you know!), the ultimate objective of processing a mineral is to extract the maximum value from a 2021年5月5日 Grinding Machine Working Principle: In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel The action of rubbing or friction generates between wok price and tool therefore the material removes Lets see step by step, First, clean the machine with a clean brushGrinding Machine: Definition, Parts, Working Principle, Operation