Calcite mill fthp60*100

.jpg)

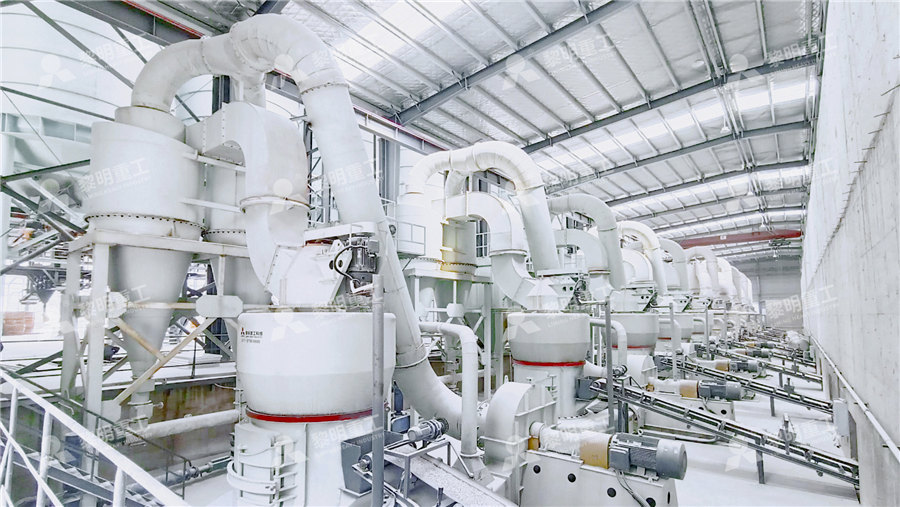

MTW Trapezium Grinding Mill Zenith Crusher

It can grind limestone, calcite, marble, talcum, dolomite, bauxite, barite, petroleum coke, quartz, iron ore, phosphate rock, gypsum, graphite and other noninflammable and nonexplosive 2022年3月1日 Influences of different grinding aids on dry fine grinding of calcite using a laboratorytype ball mill were investigated Tested grinding aids had affected the flowability Analysis of grinding aid performance effects on dry fine milling of The ultrafine grinding mill for calcite is designed to achieve high efficiency and throughput It utilizes advanced classifier technology to ensure that the powder produced meets the exact The specialist ultrafine grinding mill for calcite processingThe Influence of Stirred Mill Orientation on Calcite Grinding Serkan Cayirli1 Hasan Serkan Gokcen2 Received: 28 September 2020/Accepted: 7 April 2021 % 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 1552 Mining, Metallurgy The Influence of Stirred Mill Orientation on Calcite Grinding

.jpg)

Calcite powder mill 100200 mesh 5TPH, HCQ1290 Raymond mill

This calcite powder mill plant using our HCQ1290 grinding mill, which has the output of 5t/h, and 100200 mesh fineness Calcite is a calcium carbonate mineral that main component is CaCO3 It is generally transparent, colorless or white, some may contain mottled colors with vitreous lusterPDF On Jan 1, 2017, Serkan Cayirli and others published The Effect of Stirred Mill Orientation on Calcite Grinding Find, read and cite all the research you need on ResearchGateThe Effect of Stirred Mill Orientation on Calcite 2023年4月21日 Calcite crusher plays a very important role in mining, metallurgy, chemical industry, construction, cement, sand and gravel and other industries They also have double insurance and control over the hydraulic and lubricating systems Calcite Mill The calcite ball mill is the primary grinding instrument in the manufacturing plantCalcite Processing SBM Mill CrusherÇukurova Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 33(3), ss 225236, Eylül 2018 Çukurova University Journal of the Faculty of Engineering and Architecture, 33(3), pp 225236, September 2018 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 225 Optimization of Wet Grinding Parameters of Calcite Ore in StirredOptimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill

.jpg)

XRD line profile analysis of calcite powders produced by high

100 Phase content (wt %) Milling time (h) Figure 1 XRD patterns of calcite ground in the P4 mill for increasing time with indication of main peaks of aragonite (*), quartz (#) and ferrite ( ) (airon) contaminant) (a); corresponding phase percentages for calcite (circle) and aragonite (square) are shown in (b) 20 30 40 50 60 70 0 2000 4000 A ball mill is to grind 100 MT/day of calcite (sphericity = 075 and SG = 2711) with a specific surface area of 3250 cm2/g No recrushing of the material was done The overall effectiveness of the ball mill is 5% Using a Rittinger’s No of 00825 m2/J, Solved A ball mill is to grind 100 MT/day of calcite Chegg2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with The Influence of Stirred Mill Orientation on Calcite Grinding2021年4月1日 Ultrafine grinding of calcite powder was studied under batch wet conditions in a laboratory stirred mill After grinding, the suspension was allowed to age at 30°C for 12 and 24 hThe Influence of Stirred Mill Orientation on Calcite Grinding

World’s Largest Limestone Quarry The Historical

2023年9月23日 with 115 employees It has been described as a “man made Grand Canyon,” as it is more than 150 feet (46 m) deep This open pit mine, operating for 111 years since 1912, was at times called “the Calcite Quarry” 2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle Effect of Operating Parameters on the Breakage Process of Calcite listello mosaic ukuran 100 x 100 ukuran 120 x 240 ukuran 15 x 60 ukuran 15 x 90 ukuran 20 x 120 ukuran 20 x 40 ukuran 20 x 80 ukuran 20 x 20 ukuran 25 x 25 ukuran 25 x 40 ukuran 25 x 50 ukuran 30 x 30 ukuran 30 x 60 ukuran 30 x 90 NIRO NIKTO GNT01 CALCITE 60X60 UKURAN 60 X 60 of calcite in a laboratory scale conventional ball mill Within the context, the influence of operating parameters such as mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid dosage and grinding time were studied The results of grinding tests were evaluated based on the product particle size (d 50, d 80Influences of operating parameters on dry ball mill performance

.jpg)

Calcite Ultrafine Grinding Mill

Calcite is a calcium carbonate mineral, widely distributed, usually white or colorless Common shapes are granular, massive, fibrous, earthy, and so on The calcite mill can grind calcite into a fine powder of 1503000 mesh, which is widely used Generally, calcite is used as industrial raw material such as chemical industry and cementType of Grinding Mill for Calcite 1 CLRM Enhanced Roller Mill CLRM Enhanced Roller Mill is suitable for crushing 80425 mesh calcite fine powder, the machine output can be increased by more than 15%, the triple shock absorption technology ensures stable Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine MillName: Calcite RRUFF ID: R Ideal Chemistry: Ca(CO 3) Locality: Tie Siding, Albany County, Wyoming, USA Source: Dave Bunk Minerals Owner: RRUFF Description: Pseudomorph after aragonite, not single crystal Trace of aragonite still present Status: The identification of this mineral has been confirmed by Xray diffraction and chemical analysis Mineral Group: [ Calcite Calcite R RRUFF Database: Raman, Xray, Infrared, and 2022年3月1日 Toraman et al [38] investigated the influence of grinding additives on calcite grinding using a stirred mill They observed that more product fineness regarding d 97 was obtained by using TEA Regarding its grinding performance, GE had the highest development among the grinding aids that were testedAnalysis of grinding aid performance effects on dry fine milling of calcite

Michigan Limestone and Chemical Company WikiMili

The Michigan Limestone and Chemical Company operated the world's largest limestone quarry (Michigan Limestone; a/k/a the "Calcite Quarry"; "Calcite Plant and Mill"; and "Carmeuse Lime and Stone"), which is located near Rogers City in Presque Isle County, MichiganIt was formed and organized in 1910; however, production did not begin until 1912 Ownership of the quarry In addition, the capacity of the conventional ball mill for the fabrication of nanosized products should be significantly reduced When the mill capacity is reduced by 75% (5 tph) and grinded with Cylpebs, the fineness (d 90) of the product reaches 1300 nanometers Key words: Ball Mill, Ball, Calcite, Cylpebs, Nano Grinding 1 IntroductionGrinding of Calcite to NanoSize: Effect of Mill Capacity and Grinding There are five models of calcite grinding mill: HGM80, HGM90, HGM100, HGM125 and HGM1680L, both ultra fine grinding mill Finished production fineness: 250meshes2500meshes, 574 micronCalcite Grinding MillThe proportion of aragonite can be calculated by difference from 100% For a binary mixture of calcite and dolomite, the heights of the calcite d104 and dolomite Between 10 to 20 g of each crushed material was pulverized in a steel ringandpuck mill for 05 min (Spex Shatterbox) Mixtures of carbonate powders were prepared by weight (to Recommended Method for Semiquantitative Measurement of

(PDF) Comparison of Particle Shape, Surface Area, and

2023年1月8日 Particle size distributions of feed for calcite grinding by the stirred mill and ball mill (modified from [39,40] Mills used in this study (a) stirred mill [39], (b) ball mill [40] Figure 4100 mesh calcined powder is used as the raw material for hightemperature calcined alpha alumina powder, which is produced using a 1450 oC hightemperature tunnel kiln calcining process, special additives to reduce impurity content, improve alpha conversion rate, control crystal shape, and particle calcination under enough heat preservation time The micro calcite 100 Mesh Calcined Powder Price Calcite Powder Manufacturers 2023年8月1日 Effect of grinding aids on the kinetics of fine grinding energy consumed of calcite powders by a stirred ball mill Adv Powder Technol, 20 (4) (2009), pp 350354 View PDF View article View in Scopus Google Scholar [39] M Hasegawa, M Kimata, M Shimane, T Effective role of grinding aids in the dry grinding performance of calcite2009年7月1日 Request PDF Effect of grinding aids on the kinetics of fine grinding energy consumed of calcite powders by a stirred ball mill a b s t r a c t An experimental investigation was carried out on Effect of grinding aids on the kinetics of fine grinding energy

.jpg)

Limestone grinding mill Hengtu Machinery

Limestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, chalk, limestone, calcite, carbon black, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomaceous earth, calcite, gypsum, alum Type: Roller Mill Motor Type: AC Motor Motor Power: 132kw Rotationl Speed: 15003000 Rpm Application: Mine Materials: NonMetallic Minerals StonesCalcium Carbonate Powder Mill for Limestone, Calcite, Dolomite, Calcite Azul slabs are cut from blocks extracted from quarries Each block will varyPictures shown are representations only Approx Size: 701/2x114x3/4"Calcite Azul Natural Stone Rock Mill Tile StoneFive calcite, CaCO3 (MM 100085 g/mol), samples of equal mass have a total mass of 116± 01g What is the average mass and absolute uncertainty of calcium in each sample? Assume that the relative uncertainties in atomic mass are small compared the uncertainty of the total mass Asked in United StatesFive calcite, CaCO3 (MM 100085 g/mol), samples of equal mass

.jpg)

The Influence of Stirred Mill Orientation on Calcite Grinding

The Influence of Stirred Mill Orientation on Calcite Grinding Serkan Cayirli1 Hasan Serkan Gokcen2 Received: 28 September 2020/Accepted: 7 April 2021 % 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 1552 Mining, Metallurgy This calcite powder mill plant using our HCQ1290 grinding mill, which has the output of 5t/h, and 100200 mesh fineness Calcite is a calcium carbonate mineral that main component is CaCO3 It is generally transparent, colorless or white, some may contain mottled colors with vitreous lusterCalcite powder mill 100200 mesh 5TPH, HCQ1290 Raymond millPDF On Jan 1, 2017, Serkan Cayirli and others published The Effect of Stirred Mill Orientation on Calcite Grinding Find, read and cite all the research you need on ResearchGateThe Effect of Stirred Mill Orientation on Calcite 2023年4月21日 Calcite crusher plays a very important role in mining, metallurgy, chemical industry, construction, cement, sand and gravel and other industries They also have double insurance and control over the hydraulic and lubricating systems Calcite Mill The calcite ball mill is the primary grinding instrument in the manufacturing plantCalcite Processing SBM Mill Crusher

.jpg)

Optimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball Mill

Çukurova Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi, 33(3), ss 225236, Eylül 2018 Çukurova University Journal of the Faculty of Engineering and Architecture, 33(3), pp 225236, September 2018 ÇÜ Müh Mim Fak Dergisi, 33(3), Eylül 2018 225 Optimization of Wet Grinding Parameters of Calcite Ore in Stirred100 Phase content (wt %) Milling time (h) Figure 1 XRD patterns of calcite ground in the P4 mill for increasing time with indication of main peaks of aragonite (*), quartz (#) and ferrite ( ) (airon) contaminant) (a); corresponding phase percentages for calcite (circle) and aragonite (square) are shown in (b) 20 30 40 50 60 70 0 2000 4000 XRD line profile analysis of calcite powders produced by high A ball mill is to grind 100 MT/day of calcite (sphericity = 075 and SG = 2711) with a specific surface area of 3250 cm2/g No recrushing of the material was done The overall effectiveness of the ball mill is 5% Using a Rittinger’s No of 00825 m2/J, Solved A ball mill is to grind 100 MT/day of calcite Chegg2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill The experimental results were evaluated using stress intensity analysis The performance was also compared in terms of mill orientation The results showed that the d50 values decreased with The Influence of Stirred Mill Orientation on Calcite Grinding

The Influence of Stirred Mill Orientation on Calcite Grinding

2021年4月1日 Ultrafine grinding of calcite powder was studied under batch wet conditions in a laboratory stirred mill After grinding, the suspension was allowed to age at 30°C for 12 and 24 h