Knowledge related to the production line of calcium carbonate powder making equipment

.jpg)

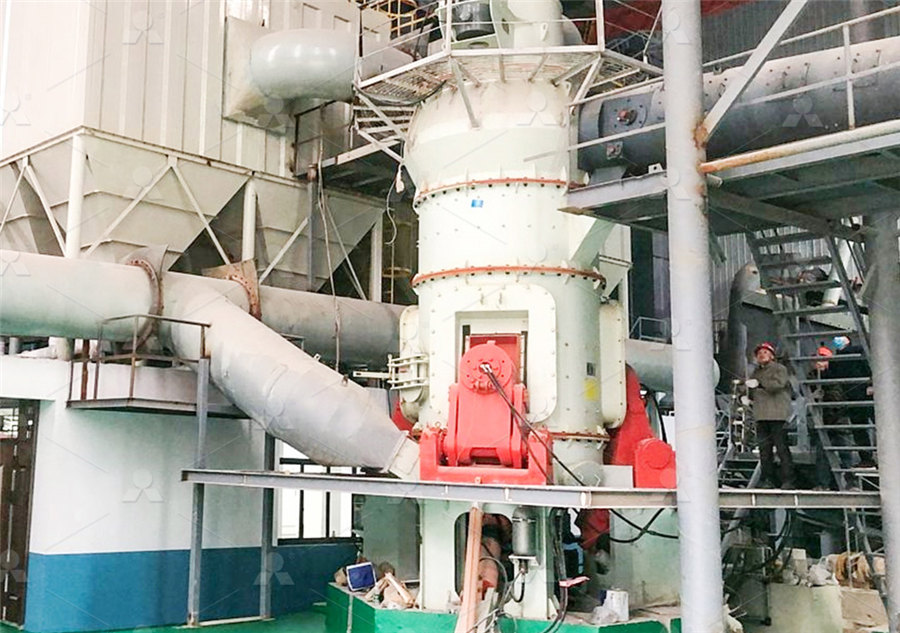

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production Calcium carbonate powder production line includes several machines such as crushers, dryers, grinding mills, classifiers, coating machines, and packing machines Each stage of the Calcium Carbonate Powder Production Line – Powder Equipment2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonate 300,000 tons of calcium carbonate powder production line GRINDING CL ASSIF YING PROCESSING OF BALL MILL AND AIR CLASSIFIER THIS PROCESS IS MATURE AND RELIABLE, WIDELY USED IN THE PRODUCTION OF ALPA Calcium Carbonate powder Processing Technology

Customize Suitable Calcium Carbonate Plant DASWELL

A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are 2022年5月5日 Calcium carbonate grinding mill is an efficient industrial ultrafine powder mill It can grind calcium carbonate into fine and superfine powder (1503000mesh) SBM is China’s famous calcium carbonate grinding mill Calcium Carbonate Grinding Mill Powder ModifyCalcium carbonate is divided into two industrial categories: Ground Calcium Carbonate (GCC) and precipitated calcium carbonate (PCC) The two categories use different manufacturing methods GCC is manufactured by physically How Calcium Carbonate is 2024年10月1日 There are several methods for producing calcium carbonate, including: This is the most straightforward method of obtaining calcium carbonate Natural deposits of limestone or chalk are mined, crushed, and ground into a how to make calcium carbonate Sudarshan Group

.jpg)

CALCIUM CARBONATE (GCC) Hosokawa Alpine

The production of calcium carbonate fillers (GCC) from chalk, limestone or marble is challenging today GCC stands for dry powder or a suspension and is indispensable inA calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are available Grinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end productCustomize Suitable Calcium Carbonate Plant DASWELL2024年2月5日 In the construction industry, the use of Calcium Carbonate Powder is involved in the production of concrete as well as other buildingrelated products The Calcium Carbonate Powder produced by Sudarshan Group Applications of Calcium Carbonate Powder: A In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding Mill

.jpg)

Production Process for Calcium Carbonate Tablet Supplement

2024年6月25日 The raw material for calcium carbonate is abundant and inexpensive, making the production of calcium carbonate tablets costeffective This allows manufacturers to offer these supplements at a competitive price, increasing their accessibility to consumers 3 Ease of Formulation Calcium carbonate is relatively easy to formulate into tablets2022年9月29日 Method 2 Mass of the reaction vessel Measure 040 g of calcium carbonate into a weighing boat; Add 50 cm 3 of dilute hydrochloric acid to a conical flask; Place the conical flask of hydrochloric acid AND the weighing boat of calcium carbonate onto the balance; Measure the combined mass and record this as the t = 0 result Add the 040 g of calcium carbonate into Rate of Reaction Calcium Carbonate Hydrochloric Acid2019年5月9日 Carbonation is one of the methods for the production of precipitated calcium carbonate (PCC) on the industrial scale A gaseous CO2 is used as a reagent in this processThe overview of reactors used for the production of precipitated 2023年11月14日 Calcium carbonate supplements are an effective way to increase your calcium intake if your diet isn’t sufficient, or you have a condition that leads to lower calcium levels Learn about Calcium Carbonate: Uses, Dosage, and Potential Side Effects

.jpg)

PROFILE ON THE PRODUCTION OF CALCIUM CARBONATE AND

Minerva Alganza Roldán Álvaro Ibáñez Chacón (ed) Mythographica Graeca Transmisión, textos y contextos Madrid, Dykinson, 2024 The purpose of this study is to examine the text of the two socalled epitomes of the Library in order to critically reconsider some of the assumptions based on Wagner’s presentation at the time of their discoveryAnd with unique characteristics, coated calcium carbonate powder can be applied in wide range areas Usually the machine is added to existing carbonate plant to produce both coated and normal types of calcium carbonate powder Of course, you can build a new ground calcium carbonate production line with calcium carbonate coating machineCalcium Carbonate Powder Coating Machine DASWELL2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonatecontaining minerals such as limestone, marble, chalk, icelandite, stalactite, aragonite, vaterite, and semihydrated calcium carbonate A summary of the production line equipment for a 300,000 tons of calcium carbonate powder production line equipment2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a review

(PDF) Calcium Carbonate Synthesis, Optimization

2020年7月30日 In this study, to determine the calcium carbonate availability in eggshells waste and factors those affect its extraction The parameters like temperature, the size of the eggshell powder and the 2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more Calcium Carbonate Grinding Mill Powder Modify2024年3月26日 Calcium carbonate is an important industrial raw material with a wide range of applications With the development of economy, the demand for calcium carbonate will continue to grow Therefore, the establishment of a calcium carbonate ultrafine grinding production line has broad market prospectsHow to set up a calcium carbonate ultrafine grinding production line?Relying on our sales managers′ professional knowledge and our services throughout the life cycle of products, we help our customers out of their difficulties in equipment procurement, operation cost accounting, operation management, and aftersales service obtainment, thus improving their profitmaking capability and realizing sustainable development of our businessCalcium Carbonate Powder Coated Production Line

PERFORMANCE EVALUATION OF CONCRETE USING ULTRA FINE CALCIUM CARBONATE

2018年5月22日 Investigations report that the effect of limestone powder addition in concrete is more beneficial in concretes containing fly ashIn the present study, a commercially available ultrafine calcium Calcium carbonate, quartz, zircon, paillite, barite, kaoline etc Technical parameters of ball mill grinding and classifying production line (taking calcium carbonate as an Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials The above Ball Mill and Air Classifier Production Line ALPA PowderKeywords: Calcium carbonate, Stearic acid, Treatment method, Void content Abstract Calcium carbonate (CaCO 3) is often treated with stearic acid (SA) to decrease its polarity However, the method of application of the SA treatments has a strong influence on Characteristics of the treated calcium carbonate particles with Ground calcium carbonate’s production line takes 95% of calcium carbonate powder production line Ground calcium carbonate is mainly made of calcite,China has a lot of calcite mine, at first, caclite get from mine, then washing and selecting, the most important process is grinding: factories used different kind of grinding mills,such as Calcium Carbonate – What Is It And How To Make It

How to make the calcium carbonate powder?

2019年7月22日 YGM high pressure Raymond grinding mill: 20325 mesh(06130033 mm) calcium carbonate powder making,with capacity 125 t/h CLUM ultrafine powder vertical grinding mill: 4003000 mesh (D97 less than 3000 mesh, D50 less than 2 micron) calcium carbonate powder making, with capacity 318 t/h The chemical method for calcium carbonate powder 2017年11月1日 Tests were also performed at calcium chloride (CaCl2) concentrations of 01 and 03 M, resulting in specimens with average calcium carbonate (CaCO3) content ranging from 15 to 25% for the 50/70 (PDF) Methods for Calcium Carbonate Content 2015年6月4日 A calcium carbonate powder production line uses equipment like jaw crushers, hammer crushers, Raymond mills, and other grinding mills to crush and grind calcium carbonate rock into a fine powder Shanghai Clirik Machinery Co, Ltd is an experienced manufacturer of calcium carbonate powder production lines and offers services from equipment selection to Calcium Carbonate Powder Production Line PDF SlideShareCalcium carbonate Calcium Carbonate (CaCO3) is a naturally found material in chalk, Personal Protective Equipment dust mask type N95 (US), Eyeshields, Gloves Documentation Research Development Production We are a leading supplier to the global Life Science industry with solutions and services for research, Calcium carbonate powder, particle size = 50um, 98 471341

.jpg)

Calcium carbonate in the paper industry Blessing for coated

2014年11月1日 Calcium carbonate provides good optical properties to graphic paper and is relatively inexpensive Therefore, the use of calcium carbonate for the production of paper has steadily increased2022年1月1日 The crab shell (Portunus Pelagicus) wastes are constituted of major calcium carbonate (account for 70 wt %) and have the potential to reuse as a starting biomaterial for precipitated calcium REUSE OF WASTE CRAB SHELLS FOR SYNTHESIS OF CALCIUM CARBONATE 2019年6月26日 The Elongation of Bioplastic Samples with Variations in Calcium Carbonate According to Figure 4, the amount of lengthening in bioplastic with 04%, 05%, and 06% added calcium carbonate is lower The Effect of Calcium Carbonate Addition to Mechanical Properties 2023年11月21日 A ground calcium carbonate production line typically involves several stages, including mining, crushing, grinding, and classification What Is Ground Calcium Carbonate? Ground calcium carbonate (GCC) is a type of calcium carbonate that is obtained by mechanically grinding and crushing natural calcite, limestone, chalk, marble, or other sourcesGround Calcium Carbonate Production Line

.jpg)

325 mesh calcium carbonate powder production line

325 mesh calcium carbonate powder production line Kefid MTW110 series trapezium mill has a processing capacity of 35~25t/h, a feed particle size of 30~40 mm, a finished product size of 160045 mm, a fineness of 0038 mm, and a fineness of about 0425 mesh/ 20033 microns, mainly used for processing limestone, calcite, dolomite, barite, talc, calcium carbonate, gypsum, 2024年3月21日 Calcium carbonate is classified from the perspective of production methods, ball mill and other equipment to obtain 1003000 mesh powder, and the sedimentation volume is smaller than that of light calcium carbonate Application Calcium carbonate powder is an important inorganic chemical product, widely used in rubber, plastic General Introduction of Calcium Carbonate Powder2021年9月14日 Laser diffraction technology is one of several methods currently employed to determine particle size distributions But laser diffraction is the only technology applicable for powders, suspensions (PDF) Measuring the Particle Size Distribution of Calcium Carbonate A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are available Grinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end productCustomize Suitable Calcium Carbonate Plant DASWELL

Applications of Calcium Carbonate Powder: A

2024年2月5日 In the construction industry, the use of Calcium Carbonate Powder is involved in the production of concrete as well as other buildingrelated products The Calcium Carbonate Powder produced by Sudarshan Group In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding Mill2024年6月25日 The raw material for calcium carbonate is abundant and inexpensive, making the production of calcium carbonate tablets costeffective This allows manufacturers to offer these supplements at a competitive price, increasing their accessibility to consumers 3 Ease of Formulation Calcium carbonate is relatively easy to formulate into tabletsProduction Process for Calcium Carbonate Tablet Supplement 2022年9月29日 Method 2 Mass of the reaction vessel Measure 040 g of calcium carbonate into a weighing boat; Add 50 cm 3 of dilute hydrochloric acid to a conical flask; Place the conical flask of hydrochloric acid AND the weighing boat of calcium carbonate onto the balance; Measure the combined mass and record this as the t = 0 result Add the 040 g of calcium carbonate into Rate of Reaction Calcium Carbonate Hydrochloric Acid

.jpg)

The overview of reactors used for the production of precipitated

2019年5月9日 Carbonation is one of the methods for the production of precipitated calcium carbonate (PCC) on the industrial scale A gaseous CO2 is used as a reagent in this process2023年11月14日 Calcium carbonate supplements are an effective way to increase your calcium intake if your diet isn’t sufficient, or you have a condition that leads to lower calcium levels Learn about Calcium Carbonate: Uses, Dosage, and Potential Side EffectsMinerva Alganza Roldán Álvaro Ibáñez Chacón (ed) Mythographica Graeca Transmisión, textos y contextos Madrid, Dykinson, 2024 The purpose of this study is to examine the text of the two socalled epitomes of the Library in order to critically reconsider some of the assumptions based on Wagner’s presentation at the time of their discoveryPROFILE ON THE PRODUCTION OF CALCIUM CARBONATE AND And with unique characteristics, coated calcium carbonate powder can be applied in wide range areas Usually the machine is added to existing carbonate plant to produce both coated and normal types of calcium carbonate powder Of course, you can build a new ground calcium carbonate production line with calcium carbonate coating machineCalcium Carbonate Powder Coating Machine DASWELL

300,000 tons of calcium carbonate powder production line equipment

2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonatecontaining minerals such as limestone, marble, chalk, icelandite, stalactite, aragonite, vaterite, and semihydrated calcium carbonate A summary of the production line equipment for a