HOME→Brick factory construction process Brick factory construction process Brick factory construction process

Brick factory construction process Brick factory construction process Brick factory construction process

Structual Guide Brickwork and Modern Methods of Construction

manufacturing, site based materials and process innovation Modern Methods of Construction, definition framework produced by MHCLG Joint Industry Working Group Category 1 pre This research aims to discover the process of making concrete brick using husk rice ash as additives and the difference in quality between ordinary brick and brick made from added rice huskBrick Production Process (The Brick Industry The process of manufacturing of bricks from clay involves preparation of clay, molding and then drying and burning of bricks The bricks are building materials which are generally available as rectangular blocks The bricks do not require Manufacturing of Bricks for Masonry Construction – ' Standard specification and work procedure for brickwork in masonry construction ' provides guidelines about quality of bricks, mortar, soaking of bricks, laying of bricks, curing, scaffolding etc The construction of brickwork in substructure Procedure of Brickwork in Masonry Construction

The Fundamentals of Brick Manufacturing

Brick is made of clay or shale formed, dried and fired into a durable ceramic product There are three ways to form the shape and size of a brick: extruded (stiff mud), molded (soft mud) and 2013年9月1日 Artisanal brickmaking process often employs traditional kiln to fire brick because it is an affordable, and applicable technology in the rural region(PDF) Manufacturing of Bricks in the Past, in the 2014年2月25日 Manufacturing of bricks consists of the following 4 operations or steps 1 Preparation of brick clay or brick earth In this step the soil is excavated in steps and then laid on leveled ground Then the soil is cleaned of impurities 4 PRIMARY STEPS OF BRICK MANUFACTURING PROCESSUnderstanding this process is essential for both manufacturers and consumers looking to use bricks in construction projects Step 1: Collection of Raw Materials The first step in brick manufacturing is the collection of raw materials The Complete Process of Brick Manufacturing SBCD

.jpg)

Brick and tile Manufacturing, Clay, Firing Britannica

Basically, the process of brickmaking has not changed since the first fired bricks were produced some thousands of years ago The steps used then are used today, but with refinements The various phases of manufacture are as Brick and tile Manufacturing, Clay, Firing: Basically, the process of brickmaking has not changed since the first fired bricks were produced some thousands of years ago The steps used then are used today, but with refinements The Brick and tile Manufacturing, Clay, Firing Britannica2013年9月1日 PDF The most basic building material for construction of houses is the conventional brick The rapid growth in today’s construction industry has Find, read and cite all the research you (PDF) Manufacturing of Bricks in the Past, in the 2021年10月1日 Masonry units extracted from UK brick production lines before the firing process are typically 100 mm wide, which requires good mortarbrick bond strength to meet structural robustness Advances in Bricks and Blocks for Building

.jpg)

How to Start a Brick Factory: Setup Cost, Profit Margin, Steps

2021年12月3日 This article will focus on how to open a brick factory in seven easy steps Advantages of Opening a Brick Factory It is essential to know the various benefits of opening a brick factory before focusing on the same steps The major advantages of opening a brick factory are enumerated as below: Low capital investments Escalating demand for bricksThe components undergo a chemical reaction during a highpressure steam curing process called autoclaving This process results in a brick with a smooth finish and a uniform shape, often used when a precise and aesthetic look is necessary Process of Sand Lime Brick Making: Batching and Mixing: Sand, lime, and water are accurately measured and The Brick Making Process How Bricks Are Made Block MachineBuilding industrial factories is always a complicated problem for investors From design to setting up construction methods and schedule, , each stage in the factory construction process has important notices that investors should learn before implementing their projects Factory design stage: take all aspects into considerationMain stages in the factory construction processThe mould is then lifted up and raw brick is left on the ground The mould is dipped in water and it is placed just near the previous brick to prepare another brick The process is repeated till the ground is covered with raw bricks A brick moulder can mould about 750 bricks per day with working period of 8 hoursHow to Manufacture Bricks: Brick Manufacturing Process [With

130 Years Later: 20 Factors That Made Acme Brick into a Construction

For anyone who was around 130 years ago, 1891 was rough and rowdyThe “Gilded Age” was coming to an end Railroads were the major growth industry with the factory system, mining, and finance increasing in importance Two years later, every industry got an economic “wakeup call” in the form of the “Panic of 1893” which led to serious social and political upheaval 1891 was 2024年11月22日 The typical equipment found in a brick factory includes clay mixers, extruders, dryers, and kilns, all of which are essential for the brickmaking process The maintenance and repair of these components can account for a significant portion of the operating costs, ranging from 510% of the total expenses, depending on the age and condition of the equipmentBrick Factory Operational Expense Overview: Key Insights2024年9月9日 It is a flexible way of construction, which allows for individual element modification during the process Modular construction: Modular construction method, building frames and structures are assembled in a factory and transported to site for erection or installationWhat is Erection in Construction: Types ProcessBrick Development Association 2022 brickuk Brickwork Modern Methods of Construction General Guide General Guide Last Updated: April 2022 Brickwork andBrickwork and Modern Methods of Construction BDA

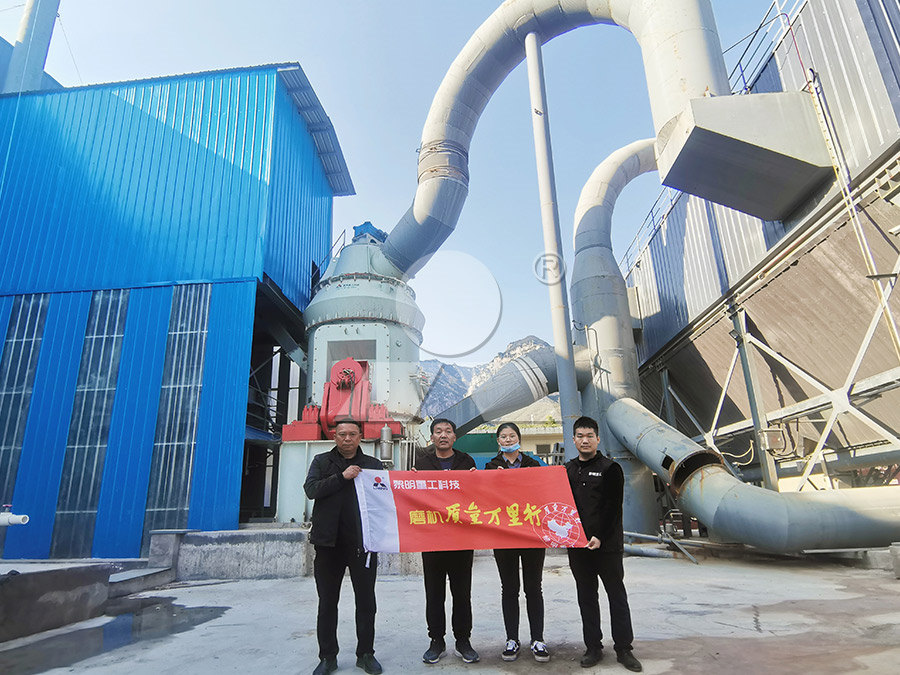

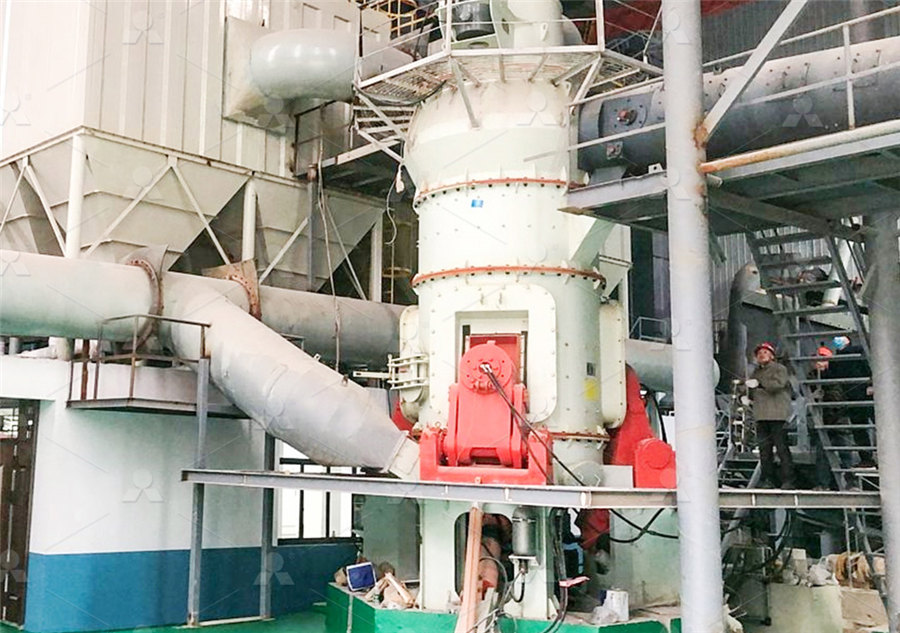

制粉项目-2023.11.17.jpg)

Brick Production Process (The Brick Industry

Download scientific diagram Brick Production Process (The Brick Industry Association, 2006) from publication: EFFECTS OF JOINT PRODUCTION ON PRODUCTION COSTS: BRICK FACTORY SAMPLE 2017年10月8日 6 FORMING OF THE BRICK • The first step in forming process is to produce a homogeneous plastic clay mass work up into proper consistency by adding water to clay in a mixing chamber with one or more revolving shafts Brick , manufacturing process types of brick PPT2020年9月30日 Find out how to develop and organize the 6 steps of the construction process and how you can use online management software like monday to simply it! Skip to main content Skip to footer Topics Project management; Brick by brick may be how a wall is built, The 6 steps of the construction process monday Blog2024年2月22日 The process of brick manufacturing, while essential for the construction industry, can have a significant environmental impact It is important to understand and address these concerns to promote sustainable practices within the brick manufacturing industryThe Brick Manufacturing Process Osum

WorkRelated Musculoskeletal Disorders Among Workers in Brick

2013年10月6日 Far from being a single activity, large scale construction involves numerous human multitasking activities Building construction, one of the types of construction, is the process of adding structure to real property However, all building construction projects include some elements in common design, financial, estimating and legal considerationsAmerican Journal of Engineering Research (AJER) 2017 American Journal of Engineering Research (AJER) eISSN: 23200847 pISSN : 23200936 Volume6, Issue10, pp1427 ajer Research Paper Open Access The Quality Of Brick Products In Brick Production Process Using SixSigma Method At A Brick Factory In Deli Serdang Regency * Risma Sinaga The Quality Of Brick Products In Brick Production Process Using 2024年5月20日 Construction Procedure for Brick Masonry First, mix the mortar with water until it’s smooth and easy to work with Then, spread the smooth mortar evenly along the baseline using a wide tool called a trowel Continue doing this Brick Masonry: Types, Importance, and Construction Basics🕑 Reading time: 1 minute Brick Masonry Definition Brick masonry is a highly durable form of construction It is built by placing bricks in mortar in a systematic manner to construct solid mass that withstand exerted loadsBrick Masonry Definition, Types, and Construction

Building Construction Process from Start to Finish (Step By Step

2020年10月7日 Building Construction Process Step by Step The PreConstruction Stage Building plan; Budget estimation; Land acquisition; Documentation The Construction Stage Site clearing; Foundation; Plinth beam or slab; Superstructure; Brick masonry work; The lintel; Roofing coating; Electrical and plumbing; Exterior and interior finishing; Flooring Clay has been used to create pottery by humans since at least 14,000 BC, with the earliest brick structures dated at 7,000 BC in Turkey The raw material is transported from the stockpile to the production factory, where it undergoes a How Are Bricks Made? wienerberger UK United Suzhou Bricmaker Automation Co, Ltd is an integrative solution provider of automatic clay brick production lines We have provided automatic brick making factories with overall layout design, raw materials analysis, production China Automatic Clay Brick Machine Factory, 8 After the brick is fired and cooled, it is unloaded from the kiln car via the dehacking process, which has been automated to the point where almost all manual brickhandling is eliminated Automated setting machines have been developed that can set brick at rates of over 18,000 per hour and can rotate the brick 180 degreesHow brick is made material, production process, manufacture,

.jpg)

DrawingtoFactory Process Using freehand drawing to drive

2021年1月1日 Meanwhile, Azambuja Varela et al (2021) experimented with an automated wallbuilding process directed by an algorithm that reads, a handdrawn curve, pushing the boundaries of brick construction 2024年7月4日 In today’s blog, BrickBolt outlines the stepbystep house construction process Here, you will find everything you need to know about the construction process, from preconstruction to postconstruction, to make your construction project smooth and efficient House Construction StepbyStep ProcessHouse Construction : Step by step Construction process29,538 concrete brick factory stock photos, Construction and Building Materials Isolated Icons Concrete Blocks, Pile of Stones and Rocks, Due to the making process concrete is an unsustainable and not ecofriendly resource Aerial view of a brick factory, Castellon de la Plana, Spain Factory isolated on white backgroundConcrete Brick Factory royaltyfree images Shutterstock2023年10月26日 The typical process of clay brick production involves clay mining, transportation to the factory, clay preparation, manufacturing, drying, firing, and packaging Construction, use, and endoflife Material Waste Management in the Construction Industry: Brick

Key Startup Costs For A Brick Manufacturing Business

2024年11月22日 Starting a brick factory business requires significant upfront investments to cover a range of essential expenses From land acquisition and construction to specialized equipment and raw material storage, the startup costs can quickly add upUnderstanding these nine key startup costs is crucial for entrepreneurs aiming to establish a successful brick 2017年9月22日 If a green brick is put to direct burning in a kiln, the rate of loss of moisture will be so fast that the brick will crack during the burning process Thirdly, to save fuel during the burning stage, a brick containing 20 percent moisture will require more fuel to burn compared to a brick containing only 24 percent moistureManufacturing of Bricks Method, Process, Types CivilSeek2014年4月21日 The document summarizes the process of brick making which includes: 1) Preparing the brick earth by removing loose soil, digging and spreading the clay, and weathering it 2) Tempering and blending the clay with other ingredients and molding bricks by hand or machine 3) Drying the wet bricks in dryer chambers for 2448 hoursManufacturing of bricks PPT Free Download SlideShareBrick and tile Manufacturing, Clay, Firing: Basically, the process of brickmaking has not changed since the first fired bricks were produced some thousands of years ago The steps used then are used today, but with refinements The Brick and tile Manufacturing, Clay, Firing Britannica

(PDF) Manufacturing of Bricks in the Past, in the

2013年9月1日 PDF The most basic building material for construction of houses is the conventional brick The rapid growth in today’s construction industry has Find, read and cite all the research you 2021年10月1日 Masonry units extracted from UK brick production lines before the firing process are typically 100 mm wide, which requires good mortarbrick bond strength to meet structural robustness Advances in Bricks and Blocks for Building 2021年12月3日 This article will focus on how to open a brick factory in seven easy steps Advantages of Opening a Brick Factory It is essential to know the various benefits of opening a brick factory before focusing on the same steps The major advantages of opening a brick factory are enumerated as below: Low capital investments Escalating demand for bricksHow to Start a Brick Factory: Setup Cost, Profit Margin, StepsThe components undergo a chemical reaction during a highpressure steam curing process called autoclaving This process results in a brick with a smooth finish and a uniform shape, often used when a precise and aesthetic look is necessary Process of Sand Lime Brick Making: Batching and Mixing: Sand, lime, and water are accurately measured and The Brick Making Process How Bricks Are Made Block Machine

Main stages in the factory construction process

Building industrial factories is always a complicated problem for investors From design to setting up construction methods and schedule, , each stage in the factory construction process has important notices that investors should learn before implementing their projects Factory design stage: take all aspects into considerationThe mould is then lifted up and raw brick is left on the ground The mould is dipped in water and it is placed just near the previous brick to prepare another brick The process is repeated till the ground is covered with raw bricks A brick moulder can mould about 750 bricks per day with working period of 8 hoursHow to Manufacture Bricks: Brick Manufacturing Process [With For anyone who was around 130 years ago, 1891 was rough and rowdyThe “Gilded Age” was coming to an end Railroads were the major growth industry with the factory system, mining, and finance increasing in importance Two years later, every industry got an economic “wakeup call” in the form of the “Panic of 1893” which led to serious social and political upheaval 1891 was 130 Years Later: 20 Factors That Made Acme Brick into a Construction 2024年11月22日 The typical equipment found in a brick factory includes clay mixers, extruders, dryers, and kilns, all of which are essential for the brickmaking process The maintenance and repair of these components can account for a significant portion of the operating costs, ranging from 510% of the total expenses, depending on the age and condition of the equipmentBrick Factory Operational Expense Overview: Key Insights

What is Erection in Construction: Types Process

2024年9月9日 It is a flexible way of construction, which allows for individual element modification during the process Modular construction: Modular construction method, building frames and structures are assembled in a factory and transported to site for erection or installation