Screening powder processing stone mill pictures

Screening Machines Comparison JXSC Machinery

5 天之前 In this article, we’ll detail the advantages and disadvantages of 8 kinds of screening machines, and tell you how to choose the right screening machine for your processing operation2024年10月13日 Screening is an essential step in the kaolin production process, as it separates particles based on size The following equipment is commonly used for screening kaolin: Kaolin production equipment: Screening and stone grinding process Choosing the right sizing screen is critical for optimal mill performance Bulk solids processing often includes one or more size reduction steps to improve a material’s value or functionalityScreen selection criteria for milling machines2024年10月13日 Stone particle size and shape: Identify the particle size and shape of the stones you will be processing This information will help you choose screens with the How to choose the screening equipment for the stone

Contained Milling and Particle Size Reduction

2024年11月26日 Find out how you can achieve unparalleled milling flexibility and improved powder processing efficiency in a labscale environment Easily interchange between Fitzpatrick’s FitzMill™, Quadro’s Comil ® conical mills In this article, we’ll take a closer look at some of the best screening machines and screening equipment available in 2023, what they do, and the benefits they provide to any manufacturing process Screening machines and screening What are The Different Types of Industrial 2024年7月26日 Review external factors (type of material, amount of near size in the material, shape of material) Review the screen sizing formula and the effects that each of the above Principles of Screening and Sizing 911 MetallurgistThe ability to screen coarse and fine powders allows companies to enter into new markets or create entirely new products that were once unachievable when screening with standard screeners or ultrasonics As the world continues to Fine Powder Screening Screening Fine Metal

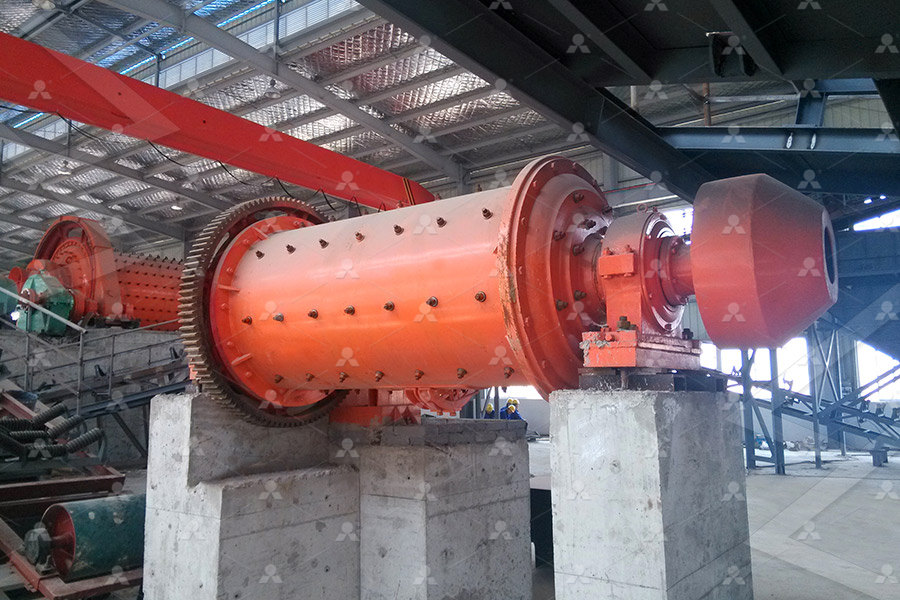

Crushing, screening, grinding plant for Aggregate, Ore Processing

The crushing, screening, grinding, washing plant from SBM Machinery play a great role in aggregate production, ore processing, industrial powder production industry in the world2021年5月10日 To meet the needs of the powder processing industry, Kemutec offers a wide range of milling technologies including standard particle size reduction machines and Powder Processing Equipment Systems Qlar2022年7月4日 Before the hammer mill (prescreening) After the hammer mill (postscreening) Tietjen configures the screening process for its customers in accordance to the application and the whole grinding system Leading Why an Optimized Screening and Sieving 2024年9月13日 Find Flour Mill stock images in HD and millions of other royaltyfree stock photos, illustrations and vectors in the Shutterstock collection Thousands of new, highquality pictures added every dayFlour Mill Photos, Images Pictures Shutterstock

What Is Chinese Stone Mill? (4 Types) Son

2023年6月19日 The mill base serves as the foundation of the stone mill and is typically constructed using three stable stones, with the size and height determined by the dimensions of the stone mill The grinding disc is a large 2021年5月10日 The Kek Cone Mill is recognized as an intermediate energy mill and one of the most versatile size reduction machines in the powder processing industry Its ability to process a wide range of feed material and produce an equally wide range of product make it ideal for sizing in both wet and dry granulation processesPowder Processing Equipment Systems Qlar2016年6月10日 Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of sizeScreening 101 911Metallurgist2023年7月20日 The process of powder coating involves several distinct steps, ensuring a consistent and highquality finish The process of silk screening as a metal finishing technique involves the following steps: Design Preparation: The first step in silk screening is preparing the design to be printed onto the metal surface The design is typically Metal Finishing Guide: Painting, Powder Coating, Silk Screening

Quartz Stone Manufacturing Process: Everything You Need

2019年9月26日 Once thoroughly cleaned, a particular team will be responsible for screening quartz Then, it will be crushed into different sizes which will depend on its future use Using a crusher, quartz will undergo the crushing process, while a vibrating screen will be used to separate it Next is to utilize a ball mill to ground the quartz2024年11月19日 Screening in mineral processing is a very important process that sort particles based on size and shape inclined and horizontal types and they can process materials ranging from fine powder to coarse aggregate Vibrating screens are most useful in the separation of materials such as iron ores, copper, and gold, and hence are a vital tool Optimizing Screening in Mineral Processing for Success JXSC2024年7月26日 U: Required screening area (Sqft) • A: Nominal capacity for separation • B: % Oversize (33 – 121) • C: % Halfsize (40 – 240) • D: Deck location (80 – 10) Screening Area = U / (A x B x C x D x E x F x G x H x J) • E: Wet screening (10 – 125) • F: Material weight (30 – 150) lbs/cuft • G: Open area of media •Principles of Screening and Sizing 911 Metallurgist2024年11月23日 Capacity: 301000TPH / Customizable Feed size: various sizes Application material: Stone crushing production line for crushing and screening limestone, marble, granite, basalt, cobble, andesite, river stone, Stone Crushing Production Line JXSC Machinery

.jpg)

Screenings: What are they? Gravelshop

Screenings are a pulverized byproduct of the stonecrushing process at quarries and rock yards Once considered a waste product, screenings are the smaller crushed stone pieces and fines that pass through the screens meant to catch 2024年10月8日 Benefits of Powder Grinding Mills: 1 Fine Grinding Capabilities: Powder grinding mills excel in achieving fine particle sizes, making them ideal for applications that require highquality powders with precise particle distribution 2 Consistent and Controlled Grinding: These mills offer precise control over the grinding process, ensuring Powder grinding mills: Revolutionizing the manufacturing 23 小时之前 force is largely utilized in hammer ball mills 3 Attrition, rubbing action or frictional forces may be utilized for size reduction Such action is largely responsible for crushing in attrition mill, tube and pebble mills 4 Cutting force is utilized in knife edge mills to reduce the size of fibrous materials like mica, asbestosLECTURE NOTES ON Mineral Processing (3rd Semester Portable Track Screening Plants : EarthWORKS Machinery Company 10’ wide x 6½’ long Read Model RD90B Portable Screening Plant (1) – one – Read Sand Screening Plants Crusher Mills, Cone Crusher, Jaw

What are The Different Types of Industrial Screening

What are the benefits of screening machines and screening equipment? Increased Efficiency: Screening machines and equipment allow for a more efficient production process by separating materials into different sizes, grades, and specifications This reduces the amount of material that needs to be processed, saving time and resourcesOur highperformance powder processing equipment ensures the highquality and reliable processing of all kinds of powders For over 50 years, Kason Corporation has provided powder processing solutions for food, chemical, and pharmaceutical businesses worldwide Kason’s powder processing equipment is available in a host of standard and customengineered Powder Processing Equipment Kason Corporation① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costsStone Powder Making Machine2021年7月5日 1TPD Chili Powder Production Line; This is a onestop chili powder assembly line, and the daily capacity is 1TPD per day The total investment is small, which is an ideal machinery for grinding powder pigment factory The whole unit can save labor electricity, high output; 1TPD Chili Powder Processing Flowchart for Edible UseChili Powder Processing and Chili Powder Machine

Eggshell Powder Making Machine

① Fine powder processing: Raymond mill or highpressure suspension roller mill can be used ② Ultrafine powder processing: HGM ultrafine grinding mill or CLUM vertical roller mill can be used ③ Coarse powder processing: European version of coarse powder mill can be usedStone powder making machines have emerged as a pivotal technological advancement in the field of mineral processing Their benefits extend far beyond increased efficiency and productivity, with substantial cost reduction, improved Stone Powder Making Machines: Approach To 2024年11月26日 Discover the Scalable Lab System™ (SLS), the world's most advanced benchtop, multipurpose powder milling and screening platform Download Find out how you can achieve unparalleled milling flexibility and Contained Milling and Particle Size Reduction2024年11月18日 SDx™ Series Production / MidSize Milling Screening Platforms Multiple size reduction options in one easytouse platform A collaboration between the Fitzpatrick Company and Quadro Engineering Corp, the SDx™ Series, is our nextgeneration production, midsize / pilotscale powder processing platform with conical milling, security screening, and hammer Milling and Screening Platform for Production and Pilot Scale

Understanding the SAG Mill in Copper Ore Mining Process

2023年10月10日 The Vertical Shaft Impactor Mill, also known as the VSI Mill, is a unique type of grinding mill that operates on a completely different principle compared to other types of mills This type of mill uses highspeed rotors with wearresistant tips to crush and grind materials into smaller particles6 天之前 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;Ball Mill Mining Grinding Mill JXSC MachineryScreening machines for fine and ultrafine screening Tumbler screening machines from Allgaier are convincing in the processing of ultrafine powder up to a particle size of 002 mm This means that the screening machine meets the highest quality requirements even in fine and ultrafine screening of dry and wet bulk materialsScreening Allgaier Process TechnologyStone Mill has been growing and processing whole ingredients since 1987 We were pioneers in specialty grain cleaning, driven by the motto, “If they say it can’t be cleaned, check with us” With our history we bring a wealth of knowledge, expertise, and innovative techniques to support our growers and deliver the best product to our About Stone Mill

Stone milling versus roller milling: A systematic review of the

2020年3月1日 During the stone milling (one singlepass process milling for processing WWF), most of the intracellular lipids and lipases will be released by the compression, shear, and abrasion forces Screening Room: Emma Stone Attached to New Cameron Crowe Love From left: Matt Damon, Emma Stone, Josh Duhamel, Julianne Hough (Photos by: Pacific Coast News Getty Images)Trailer of the WeekLife of PiOne of the most popular Screening Stone Crusher Mills, Cone Crusher, Jaw Crushers2022年7月4日 Before the hammer mill (prescreening) After the hammer mill (postscreening) Tietjen configures the screening process for its customers in accordance to the application and the whole grinding system Leading Why an Optimized Screening and Sieving 2024年9月13日 Find Flour Mill stock images in HD and millions of other royaltyfree stock photos, illustrations and vectors in the Shutterstock collection Thousands of new, highquality pictures added every dayFlour Mill Photos, Images Pictures Shutterstock

What Is Chinese Stone Mill? (4 Types) Son

2023年6月19日 The mill base serves as the foundation of the stone mill and is typically constructed using three stable stones, with the size and height determined by the dimensions of the stone mill The grinding disc is a large 2021年5月10日 The Kek Cone Mill is recognized as an intermediate energy mill and one of the most versatile size reduction machines in the powder processing industry Its ability to process a wide range of feed material and produce an equally wide range of product make it ideal for sizing in both wet and dry granulation processesPowder Processing Equipment Systems Qlar2016年6月10日 Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of sizeScreening 101 911Metallurgist2023年7月20日 The process of powder coating involves several distinct steps, ensuring a consistent and highquality finish The process of silk screening as a metal finishing technique involves the following steps: Design Preparation: The first step in silk screening is preparing the design to be printed onto the metal surface The design is typically Metal Finishing Guide: Painting, Powder Coating, Silk Screening

.jpg)

Quartz Stone Manufacturing Process: Everything You Need

2019年9月26日 Once thoroughly cleaned, a particular team will be responsible for screening quartz Then, it will be crushed into different sizes which will depend on its future use Using a crusher, quartz will undergo the crushing process, while a vibrating screen will be used to separate it Next is to utilize a ball mill to ground the quartz2024年11月19日 Screening in mineral processing is a very important process that sort particles based on size and shape inclined and horizontal types and they can process materials ranging from fine powder to coarse aggregate Vibrating screens are most useful in the separation of materials such as iron ores, copper, and gold, and hence are a vital tool Optimizing Screening in Mineral Processing for Success JXSC