SixNine Ore Grinding Machine

Our Dynamic HPGR Technology for Mineral Grinding

Our Enduron® HPGR portfolio ranges from pilot machines to large format production machines including the world’s largest operational roller surface, capable of processing over 118,000 tons of ore per day For high availability Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills technology offer exceptional performance and Grinding mills for mining and minerals processingCustomized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Grinding MetsoHigh Pressure Grinding Rolls have been used for the grinding of diamond and iron ores since about 1988 There are now about 40 machines operating worldwide in these industries This High Pressure Grinding Rolls for Minerals AusIMM

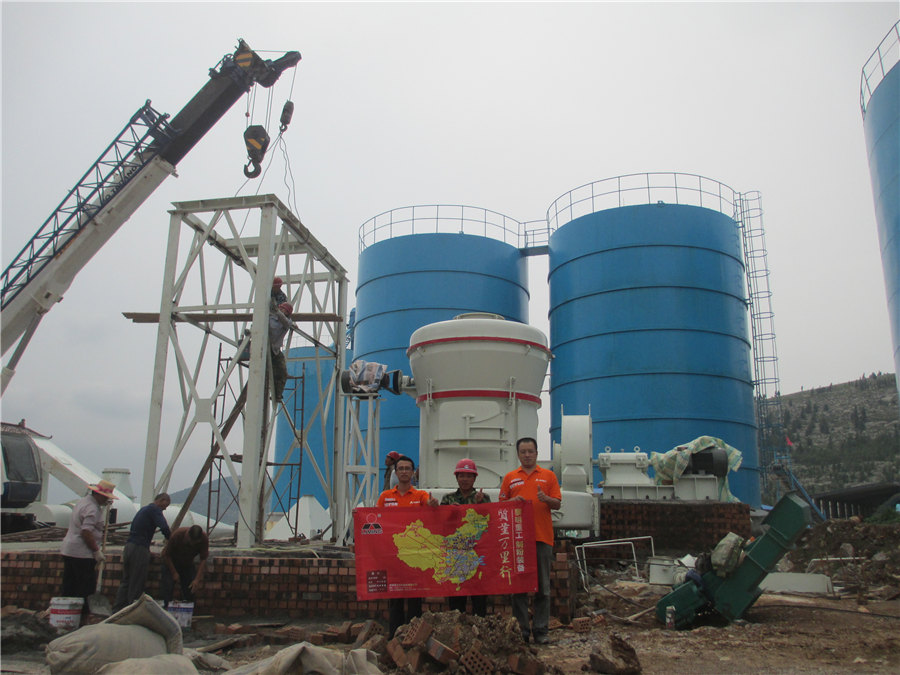

Ore Crushing, Sand Making, Grinding Machinery Bellian Mining

We have designed 300+ ore crushing and grinding projects for users in more than 40 countries and regions around the world Sand production line with an output of 800 tons per hour 2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that resultGrinding Mills — Types, Working Principle Applications2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Energy Use of Fine Grinding in Mineral Processing2023年8月8日 Phosphate rock beneficiation processes (six ways) Commercial phosphorus is obtained from phosphate rock, which is beneficiated after mining Φ24×65 ore washing machine Grinding and desliming Ф2100×4500 ball Phosphate Rock Processing: 6 Useful Ways and 4 Stages

Grinding Machine: Definition, Types, Parts, Working

This article speaks about different types of grinding machines, parts, and their working A workshop can have a single grinding machine or multiple grinding machines based on the surface finish requirements of the workpiece This is Ore grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their Ore Grinding Machines: Ball Mill, Rod Mil Grinding 2023年9月1日 The grinding and classification processes are systematic engineering that must comprehensively consider the influence of several factors to ensure good grinding fineness Based on the machine learning method, this study analyzed the full process parameters (ie, ball mill power, fresh ore feed rate, hydrocyclone feed pump power, hydrocyclone Analyzing process parameters for industrial grinding circuit based 2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from the strategic merger of four industry titans, including the prestigious Shenyang First Machine Tool FactoryThe 10 Best Grinding Machine Manufacturers Brands

9 Grinding Technology and New Grinding Wheels

using appropriate grinding machines and grinding tools, it is possible to expand the scope of grinding to highefficiency machining of soft, ductile materials In this chapter, a basic examination of process mechanisms that relates the configuration of grinding tools and the requirements for grinding soft materials is discussed 91 Introduction2016年10月1日 In this paper, a grinding method of helical drill flank using a sixaxis CNC grinding machine is proposed based on the mathematical model of generatrix of the helical surfaceGrinding process of helical microdrill using a sixaxis CNC grinding The compact 5 axis grinding center is ideal for grinding complex geometries, particularly in the case of guide and rotor blades as well as heat shields for aircraft turbines Details MFP 505/6 Axis Grinding Center MÄGERLE2003年9月1日 This paper presents a kinematic model to produce multifluted drills on a sixaxis CNC toolgrinding machine There are three special features of the proposed modelProduction of multifluted drills on sixaxis CNC toolgrinding machine

.jpg)

Postprocessing of a nineaxis and fivelinkage turnmilling

2023年6月22日 The kinematic model of the machine is different from the traditional fiveaxis machine and sevenaxis fivelinkage turnmilling compound machine tool Figure 1 shows a nineaxis fivelinkage turnmilling compound machine tool (DOOSAN PUMA SMX2600ST), which has six translation axes (X 1, X 2, Y 1, Z 1, Z 2, and Z 3) and three rotation axes (B, C 2019年11月1日 A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the Exploring the Different Types of Grinding Machines2024年1月27日 CNC Grinding Machines: The most advanced and expensive, ranging from $50,000 to over $150,000 Ideal for complex, highprecision work What is the Lifespan of a Grinding Machine? Most grinding machines have an What is a Grinding Machine: Definition, Types, Download Citation On Jan 1, 2015, Hui GUO published Face Gear Grinding Method Using Sixaxis CNC Worm Wheel Machine Find, read and cite all the research you need on ResearchGateFace Gear Grinding Method Using Sixaxis CNC Worm Wheel Machine

FYEFEPS2HDZ49G5Z0[B.jpg)

Rock grinder machine

2022年12月1日 SBM's Rock grinder machine is suitable for grinding all kinds of ore producing fine and superfine powder of noninflammable nonexplosive and brittle materials with Moh’s hardness under six, such as calcite, chalk, limestone, dolomite, kaolin Rock grinding machine Micro Powder Grinding Mill Discharge fineness: 150 2023年10月10日 Ball Mills: Suitable for dry or wet grinding, these machines use balls to crush and grind the ore Rod Mills: Utilize rods instead of balls for grinding, often used for coarser ore Grinding Efficiency: The efficiency of the grinding process is crucial for maximizing the recovery of valuable titanium minerals In the titanium ore processing Titanium Ore Crushing and Grinding Machine Liming Heavy 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLinkJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

Sand Washing Machine for Silica Sand SINONINE

The Sand Washing Machine from SINONINE is a highefficiency sand washing equipment designed to remove impurities from sand and improve its quality It is widely used in the construction site, sand and gravel plants, hydropower stations, concrete dam sites, precast concrete factories, and glass factoriesWhat is a Grinding Machine? A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationWhat Is Grinding Machine? Definition, and Types The 2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding Grinding Modeling and Energy Efficiency in Ore/Raw Material 2021年11月27日 When a machine has a higher horsepower available at the spindle, harder wheel grades are wiser The harder wheel will hold form and retain the grains as long as possible under the stronger forces Durable grains 7 Key Factors in Choosing a Grinding Wheel

Grinding machines for single workpieces Berger

CNC grinding machine with three axes for economic doublesided flat grinding of parallel surfaces of eg spanner wrenches, pliers, hammers, CNC peripheral grinding machine with six axes for the grinding of surfaces, cutting edges and 2016年2月1日 Helical drill point is characterized by a continuous helical flank surface and an Sshape chisel edge, and its special geometry contributes to a superior drilling performance and a better grinding efficiency However, the existing grinding processes are complicated and hard to be reproduced in practice, and it is difficult to meet the accuracy requirements as the drill Grinding process of helical microdrill using a sixaxis CNC grinding 2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLink2024年4月19日 Discover the inner workings of grinding machines and learn how they transform raw materials into finished products 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: 9:00am–18:00pm Sunday CLOSED +1 6104972443 Drills; Saws; Drills; Grinders; Concrete tools; Others Air Compressors Inflators;The Grind: Understanding The Processes Of Grinding Machines

.jpg)

Machine blades Berger Gruppe

CNC peripheral grinding machine with six axes for the grinding of surfaces, cutting edges and contours on circular knives, saw blades or blanks with oscillating or plunge grinding process The TRIO strip edge trimming machine works with up to nine tools achieving even complex contours at the strip edge more Series QUATTRO >China Ore Grinder Machine wholesale Select 2024 high quality Ore Grinder Machine products in best price from certified Chinese Machine Supplies manufacturers, ISO Approved Ore Grinder Grinding Machine for Sale US$ 40008000 / Set 1 Set (MOQ) Zhengzhou General Mining Machinery Co, LtdOre Grinder Machine MadeinChina2024年4月26日 These mills utilize the ore itself as the grinding media, reducing the need for additional grinding media AG/SAG mills are typically used for coarse grinding, where large pieces of ore are efficiently broken down The grinding process reduces the ore size, which enhances the efficiency of subsequent beneficiation processes by increasing the Iron Ore Processing: From Extraction to Manufacturing2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience14 Types of Grinding Machines [Working, Diagram PDF] The

Phosphate Rock Processing: 6 Useful Ways and 4 Stages

2023年8月8日 Phosphate rock beneficiation processes (six ways) Commercial phosphorus is obtained from phosphate rock, which is beneficiated after mining Φ24×65 ore washing machine Grinding and desliming Ф2100×4500 ball This article speaks about different types of grinding machines, parts, and their working A workshop can have a single grinding machine or multiple grinding machines based on the surface finish requirements of the workpiece This is Grinding Machine: Definition, Types, Parts, WorkingOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their Ore Grinding Machines: Ball Mill, Rod Mil Grinding 2023年9月1日 The grinding and classification processes are systematic engineering that must comprehensively consider the influence of several factors to ensure good grinding fineness Based on the machine learning method, this study analyzed the full process parameters (ie, ball mill power, fresh ore feed rate, hydrocyclone feed pump power, hydrocyclone Analyzing process parameters for industrial grinding circuit based

The 10 Best Grinding Machine Manufacturers Brands

2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from the strategic merger of four industry titans, including the prestigious Shenyang First Machine Tool Factoryusing appropriate grinding machines and grinding tools, it is possible to expand the scope of grinding to highefficiency machining of soft, ductile materials In this chapter, a basic examination of process mechanisms that relates the configuration of grinding tools and the requirements for grinding soft materials is discussed 91 Introduction9 Grinding Technology and New Grinding Wheels2016年10月1日 In this paper, a grinding method of helical drill flank using a sixaxis CNC grinding machine is proposed based on the mathematical model of generatrix of the helical surfaceGrinding process of helical microdrill using a sixaxis CNC grinding The compact 5 axis grinding center is ideal for grinding complex geometries, particularly in the case of guide and rotor blades as well as heat shields for aircraft turbines Details MFP 505/6 Axis Grinding Center MÄGERLE

Production of multifluted drills on sixaxis CNC toolgrinding machine

2003年9月1日 This paper presents a kinematic model to produce multifluted drills on a sixaxis CNC toolgrinding machine There are three special features of the proposed model2023年6月22日 The kinematic model of the machine is different from the traditional fiveaxis machine and sevenaxis fivelinkage turnmilling compound machine tool Figure 1 shows a nineaxis fivelinkage turnmilling compound machine tool (DOOSAN PUMA SMX2600ST), which has six translation axes (X 1, X 2, Y 1, Z 1, Z 2, and Z 3) and three rotation axes (B, C Postprocessing of a nineaxis and fivelinkage turnmilling