Heavy calcium powder processing machine

Heavy calcium + superfine processing equipment ALPA Powder

2021年8月27日 Heavy calcium ultrafine processing equipment is divided into grinding equipment and grading equipment The grinding equipment includes Raymond mill, vibration Ada banyak jenis peralatan penggilingan dan pemrosesan kalsium berat Mereka digabungkIndonesia1 What equipment is required for heavy calcium powder processing? 01 Raymond Mill Raymond mill is a machine suitable for grinding ores with Mohs hardness no more than 93 Which equipment is needed for heavy calcium powder Detailed explanation of calcium powder processing machinery and equipment: Ordinary heavy calcium carbonate with d97≥5μm is mainly produced by dry method The equipment includes improved Raymond mill (hanging roller mill News Calcium powder processing machinery and

Global Case SBM Ultrafine Powder Technology

From the coal powder preparation, heavy calcium and slag powder processing, to largescale nonmetallic mineral powder, power plant environmental desulfurization, limestone powder, A heavy calcium carbonate ball milling and grading + modification production line in a mineral factory in SerbiaTurbo Mill ALPA Powder EquipmentThe ultrafine grinding of heavy calcium powder plays a crucial role in improving its application performance Choosing an appropriate grinding method and optimizing the grinding process UltraFine grinding processing method and flow of heavy calcium 2024年8月23日 The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies It can be Heavy calcium carbonate dry production process and

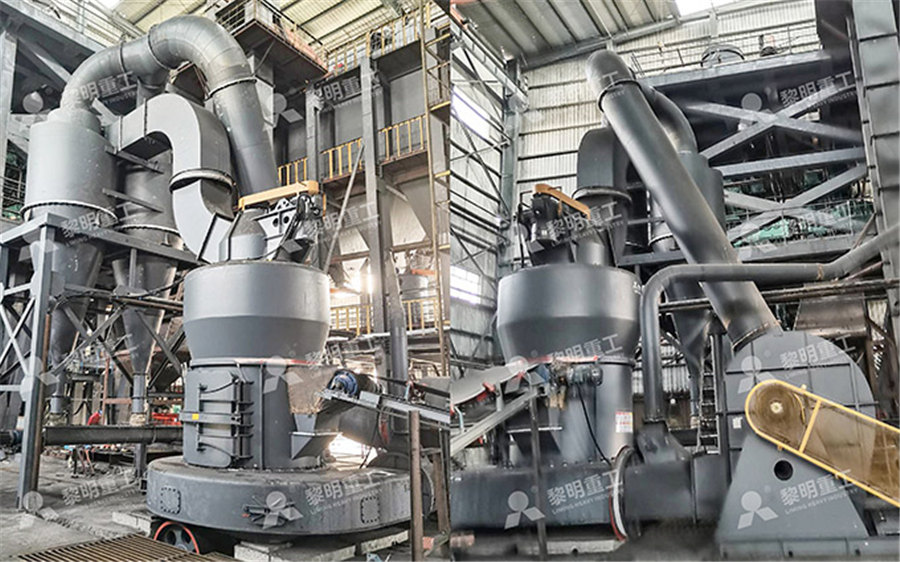

China Hubei heavy calcium carbonate HGM100P ultrafine

2023年11月13日 Highlights of the ultrafine grinding mill production line process 1 The customer purchases two HGM100P series ultrafine powder production linesHosokawa Alpine provides the perfect process technology for every demand and covers all areas of (fineness) ranges, capacity and logistical aspects in a customerspecific and costeffective CALCIUM CARBONATE (GCC) Hosokawa AlpineNote: This specification is just referencing, any changes are subject to the products Shanghai clirik machinery co, LTD Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machineease do not hesitate to contact us Phone: ;86Heavy calcium carbonate micro powder grinderProcessing Technology Calcium Carbonate powder can be generally divided into coarse powder processing (03MM), fine powder processing (20 mesh400 mesh), and ultrafine powder deep processing (400 mesh1250 mesh) and micro powder processing (1250 mesh3250)Calcium carbonate millGrinding mill machine, mineral mill,

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Focus on powder processing equipment and systems, Thailand a mineral factory, heavy calcium carbonate coating, output 1T/H, particle size D97:10μm, 2 The customer is a worldrenowned nonmetallic mineral processing enterprise in Powder Equipment – Powder MachineryAs a result, your calcium carbonate grinding plant can both produce natural calcium carbonate powder as well as coated calcium carbonate powder, which make more economic value for you Powder packing machine Daswell offers mainly two kind of calcium carbonate powder packing machine according to automatic styleCustomize Suitable Calcium Carbonate Plant DASWELLAt present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of News Apply The Heavy Calcium Grinding Mill Machine To The

.jpg)

Processing of 1500 mesh heavy calcium carbonate powder with

1 Importance of 1500 Mesh Heavy Calcium Carbonate Powder The 1500 mesh heavy calcium carbonate powder refers to a powder with a particle size of approximately 10 microns This ultrafine powder offers several advantages: Enhanced Whiteness and Purity The ultrafine powder has a higher degree of whiteness and purity, making it suitable for Powder Particle Processing Process Solutions Dry Grinding; Classifying Separating; It slings the powder into the ring between the stator and the machine body, 815micron heavy calcium carbonate ring roller mill ultrafine grinding production line 30,000t/h A mineral factory in Guangdong produces 20,000 tons, Ring Roller Mill ALPA Powder Equipment2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97% 7 Specific surface area The specific surface area of Heavy calcium and light calcium, 10 essential differences80425mesh heavy calcium powder grinding mill For processing heavy calcium powder in the range of 80425 mesh fineness, European mills and vertical roller mills can be selected 1 European version grinding mill The European 4 Steps to Build a Calcium Carbonate Processing Plant

Guide to Calcium Carbonate Grinding: Mills, Tips, and

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Pin Mill Coating Machine: Equipment used for highend calcium carbonate coating and modification The coating is effective Skip to content This speed is ideal for processing brittle materials Differences in uses and properties between heavy calcium powder and talc powder May 11, 2024 Heavy calcium powder is not equal to talc powderPin Mill Coating Machine Calcium Carbonate Production Line2021年8月5日 Heavy calcium powder for paper industry – heavy calcium carbonate (heavy calcium powder) for papermaking: 325 mesh, whiteness requirement: 95%, calcium carbonate content: 98% Calcium carbonate plays an important role in the paper industry It can ensure the strength and strength of paper Whiteness, and low costCalcite Industrial Ultrafine Powder GrinderAt present, the market demand for nonmineral powder is increasingly strong, and the annual average growth rate of consumption of heavy calcium is nearly 95% It is predicted that the annual demand for nonmetallic mineral powder will still maintain a high growth rate in the next 10 years In the pursuit of stable product quality and uniform particle size distribution, the market News Application of HLMX Ultrafine Vertical Roller Mill for Non

Calcium carbonate manufacturing process

2020年1月7日 Heavy calcium / heavy calcium powder is widely used in many fields because of its many advantages The true value of heavy calcium carbonate/ ground calcium carbonate powder is its deepprocessed products, that is, ultrafine, Calcium Carbonate Processing Machine; Calcium Carbonate Vertical Roller Grinding Mill;Calcium Carbonate Modified Line Highspeed rotor pulverizer is used as the modified main machine to heat the air intake to keep the modified main machine at a suitable modification temperature, and the superfine heavy calcium (D97 10um) is coated with stearic acid, and the processing capacity is from 500 to 6000Kg /h, the coverage rate is above 98%Industrial Powder Grinding Machine Manufacturers, FactoryHeavy calcium powder processing production process is generally divided into dry and wet production TSP dry production of calcium carbonate can produce 5μm, 10μm and 18μm of GCC products, currently used in the superior performance of the European version of the mill technology professionals to build, can produce more than 80% less than 2μm products, mainly Where to sale Heavy calcium carbonate powder grinder mill processing What equipment is required for heavy calcium powder processing? 01 Raymond Mill Raymond mill is a machine suitable for grinding ores with Mohs hardness no more than 93 and humidity below 6% The grinding fineness is 80325 meshes, the hourly output is 122t/h, and there are 3R, 4R and 5R typesWhich equipment is needed for heavy calcium powder processing

4 Steps To Build A Calcium Carbonate Processing Plant Zenith

2022年9月29日 Heavy calcium carbonate (commonly known as heavy calcium) is the first filler in the world coating industry, it is not only cheap, can greatly reduce the production cost of coating, as one of the functional fillers, it can affect many properties of the coating, such as changing the mechanical strength of the coating, improve the water resistance, resistance to powder and so The heavy duty efficient vibrating sieve machine is widely applied in the production of calcium carbonate powder processing lines for sizes grading and classiflying greatly increase the Calcium Carbonate Powder Sieving efficiency Efficient Calcium Carbonate Powder Sieving Vibrating The mills is integrant machines in the processing of calcium carbonate and their properties directly deside the production costs Well, one good mill usually has advantages as follows: stable performance, convenient operation, low energy calcium carbonate powder machine,calcium 2023年9月19日 Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, HGM ultrafine powder grinding mill is mainly suitable for ultrafine powder processing of nonflammable and brittle Calcium carbonate milling process SBM Ultrafine

.jpg)

Sand and Powder Grinding Machine Guilin Mining Machinery

It is suitable for grinding nonflammable and explosive materials with hardness below Mohs level 7 and humidity below 6% in chemical industries such as glass, rubber, pesticides, enamel, paint, phosphate fertilizer, papermaking, etc, such as limestone, quartz stone, heavy Processing of heavy calcium powder such as spar and marbleAt present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of News Apply The Heavy Calcium Grinding Mill Machine To The 2020年2月10日 In this work, The modification of heavy calcium carbonate powder was studied by dry surface modification with stearic acid and anhydrous citric acid we have developed a facile and inexpensive dry Dry surface modification of heavy calcium carbonate powder calcium carbonate shandong alpa powder technology co, ltd ©2022 calcium carbonate powder 02 grinding classifying 10 surface modification 17 project sites 19 application 22 alpa profile dry grinding / classifying / surface modificationCALCIUM CARBONATE POWDER

PPDS HeavyDuty Classifier Mill (HDCM)

Address: Powder Process Design Services Brooklands Church Lane Tel: +44 (0)845 094 1248 Bramshall Staffordshire : ST14 5BQ England Web: powderprocessingcouk About Powder Process Design Services Ltd Milling and drying system to produce Limestone powders and grits supplied with stateoftheart control system2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium Looking for a highquality machine to improve your Calcium carbonate powder production machinery business? EPIC is here to support you Skip to content Home; Heavy calcium powder is not equal to talc powder Both Read More » Comparison of powder preparation by ring roller mill and table roller mill April 3, 2024Machines EPIC Calcium carbonate powder production machineryNote: This specification is just referencing, any changes are subject to the products Shanghai clirik machinery co, LTD Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machineease do not hesitate to contact us Phone: ;86Heavy calcium carbonate micro powder grinder

Calcium carbonate millGrinding mill machine, mineral mill,

Processing Technology Calcium Carbonate powder can be generally divided into coarse powder processing (03MM), fine powder processing (20 mesh400 mesh), and ultrafine powder deep processing (400 mesh1250 mesh) and micro powder processing (1250 mesh3250)The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYFocus on powder processing equipment and systems, Thailand a mineral factory, heavy calcium carbonate coating, output 1T/H, particle size D97:10μm, 2 The customer is a worldrenowned nonmetallic mineral processing enterprise in Powder Equipment – Powder MachineryAs a result, your calcium carbonate grinding plant can both produce natural calcium carbonate powder as well as coated calcium carbonate powder, which make more economic value for you Powder packing machine Daswell offers mainly two kind of calcium carbonate powder packing machine according to automatic styleCustomize Suitable Calcium Carbonate Plant DASWELL

.jpg)

News Apply The Heavy Calcium Grinding Mill Machine To The

At present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of 1 Importance of 1500 Mesh Heavy Calcium Carbonate Powder The 1500 mesh heavy calcium carbonate powder refers to a powder with a particle size of approximately 10 microns This ultrafine powder offers several advantages: Enhanced Whiteness and Purity The ultrafine powder has a higher degree of whiteness and purity, making it suitable for Processing of 1500 mesh heavy calcium carbonate powder with Powder Particle Processing Process Solutions Dry Grinding; Classifying Separating; It slings the powder into the ring between the stator and the machine body, 815micron heavy calcium carbonate ring roller mill ultrafine grinding production line 30,000t/h A mineral factory in Guangdong produces 20,000 tons, Ring Roller Mill ALPA Powder Equipment2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97% 7 Specific surface area The specific surface area of Heavy calcium and light calcium, 10 essential differences