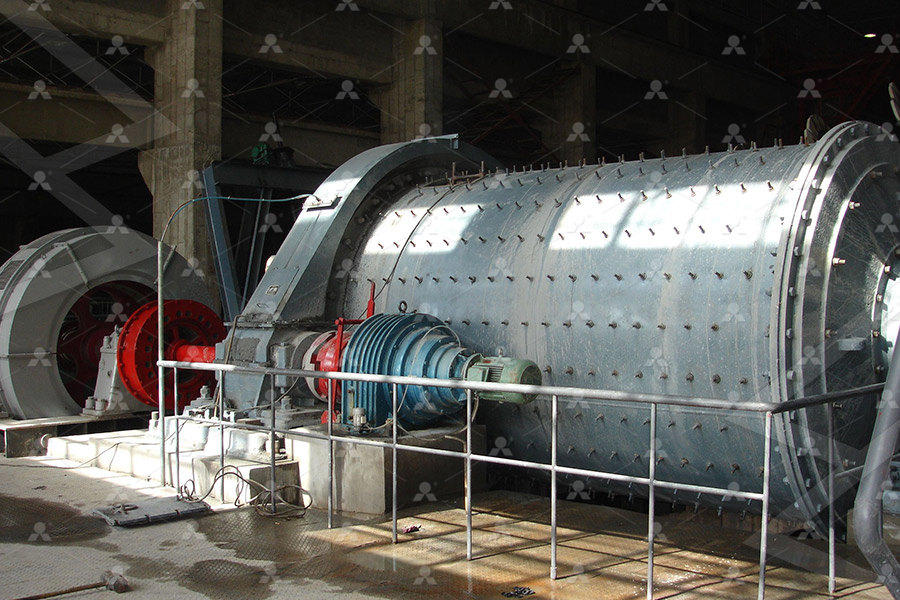

Grinding machine for desulfurization in Baiyun Power Plant

.jpg)

Summary of research progress on industrial flue gas

2022年1月15日 Through the purification technology of flue gas desulfurization, ultralow emissions of SO 2 flue gas in industrial flue gas can be achieved This article involves dry With the professional technology and a full range of services, SBM can provide integrated solutions and professional products for desulfurization agent of thermal power enterprises At Power plant desulfurization2019年3月1日 This work summarizes the desulfurization and denitration technology of coalfired power plants in China Firstly, it summarizes the existing desulfurization and denitration Progress of Desulfurization and Denitration Technology of Flue Limestone desulfurization vertical grinding machine, also known as desulfurization grinding machine, is a kind of equipment used in the desulfurization system of thermal power plants It Limestone desulfurization vertical grinding machine

The limestone powder vertical grinding production line for

This advanced grinding technology allows for the efficient production of fine limestone powder, which is essential for effective desulfurization Key Components of the Production Line: 2020年8月15日 Since the “Eleventh FiveYear Plan” period, the construction of flue gas desulfurization and denitrification facilities for coalfired power plants have been accelerated to Comprehensive evaluation of flue gas desulfurization and environmentally friendly solutions from individual machines to complete turnkey installations for the mining, cement, chemical and fertilizer industries as well as for coalfired power plants,Industrial Solutions Mining ThyssenKruppEach type of grinding mill equipment brings unique features and benefits to power plant desulfurization processes, catering to specific requirements and operational goals It’s crucial Types of Grinding Mill Equipment Used in Power Plant

Recent advances in process and materials for dry desulfurization of

Microwave desulfurization achieves selective heating by using different responses of different components in coal to microwave irradiation, achieving efficient desulfurization with no catalyst Overview Column mill limestone powdering system is currently the five major domestic power groups and foreign power groups of CFB boiler power plant desulfurizer preparation system Limestone Grinding System For Infurnace Desulfurization For CFB MTW series European version grinding machine: All are very suitable and can meet the application requirements of power plant desulfurization pulverizers In addition to highperformance equipment, SMMVIK has also launched an overall solution for the desulfurization and pulverizing system of thermal power plantsWhich mill is the best for desulfurization in power plants?2019年3月1日 This work summarizes the desulfurization and denitration technology of coalfired power plants Machine Science Technology Information 138138 Google Scholar [11] Zhong Y, Gao X, Huo W, Luo Z Y, Ni M J and Cen K F 2008 A model for performance optimization of wet flue gas desulfurization systems of power plants Progress of Desulfurization and Denitration Technology of Flue

14 Types of Grinding Machines [Working, Diagram

2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel Integrated Limestone Grinding System for Infurnace and Outoffurnace Desulfurization in CFB Power Plant Contact Us Join us and be the first to know about our latest products andpromotionsPower IndustryChangsha Shenxiang General Machinery Co, LTD2024年3月20日 Desulfurization wastewater is industrial wastewater with a high salt content, high metal ions, and high hardness produced by flue gas desulfurization of the limestonegypsum method in coalfired power plants This paper summarizes the source of desulfurization wastewater, water quality characteristics, water quality impacts, and other factors, combined Current Status of Zero Liquid Discharge Technology for Desulfurization 2022年1月19日 The desulfurization wastewater in coalfired power plants is difficult to treat due to its high salt concentration and complex composition In this study, a pilotscale evaporation tower system Experimental study on the treatment of desulfurization

Sustainable Operation Strategy for Wet Flue Gas Desulfurization

2024年9月30日 Coalfired power plants account for a large share of the power generation market in China The mainstream method of desulfurization employed in the coalfired power generation sector now is wet flue gas desulfurization This process is known to have a high cost and be energy/materially intensive Due to the complicated desulfurization mechanism, it is 2022年3月1日 Among all existing flue gas desulfurization systems, the wet limestone FGD accounts for about 90% because of its high desulfurization performance and low operation costs (Córdoba, 2015, Srivastava and Jozewicz, 2001)Computational fluid dynamic (CFD) simulation for the wet limestone FGD system has been widely studied (Özdemir and Serincan, 2018, Online application oriented dynamic modeling for the flue gas Here's how the MTW grinding machine is applied in the wet desulfurization process: 1 Efficient Grinding: The MTW grinding machine is designed to achieve high grinding efficiency, resulting in lower energy consumption compared to ball mills This is particularly beneficial for power plants looking to reduce operational costs 2Application of mtw grinding machine in wet desulfurization Fluegas desulfurization – Wikipedia, the free encyclopedia For a typical coalfired power station, fluegas desulfurization Lime is typically used on large coal or oilfired boilers as found in power plants, » More detailed Flue Gas Desulfurization Technologies for CoalFired Power Plants Babcock Wilcox 1 Abstract The control of sulfur dioxide emissions from thermal desulfurization in coal fired power plants – Grinding Mill China

Flue Gas Desulfurization Technologies for CoalFired Power Plants

The control of sulfur dioxide emissions from thermal power plants is examined in light of the recent advances made in developing commercial processes for this appli cation Beginning with a discussion of some of the more recent developments in the conventional wet and dry scrubbing technologies, the paper provides a description of the results of the recent fullscale The milling process of lime stone powder for desulfurization in power plants requires the selection of an appropriate Raymond mill that meets the specific requirements of the application The choice of Raymond mill should be based on factors such as material properties, production capacity, energy efficiency, and maintenance needsLime stone powder for desulfurization: Which raymond mill is 2020年8月15日 Since the “Eleventh FiveYear Plan” period, the construction of flue gas desulfurization and denitrification facilities for coalfired power plants have been accelerated to control the emissions of sulfur dioxide (SO 2) and nitrogen oxides (NO X) and thus to address the issue of acid rain in ChinaAccording to the goal of the “Thirteenth FiveYear Plan for Energy Comprehensive evaluation of flue gas desulfurization and VSI Sand Making Machine is known as vertical shaft impact crusher, which is commonly used as sand maker and shaper in the final stage of crushing and grinding circuit Applications Quarry, sand concrete, dry mortar, manufactured sand, power VSI Sand Making Machine Eastman Rock Crusher

Novel Regenerative Desulfurization of power plant flue gas

2020年11月16日 of power plant flue gas streams Habiba Nouali 1 , Sophie Dorge 2 , JeanFrancois Brilhac 2 , David Habermacher 2 , Benedicte Lebeau 1 , M atthieu Vierling 3 , Frederic Geiger 3 , Joel Patarin 4 PDF On Jan 1, 2019, 薇 王 published Research Progress of Desulfurization Wastewater Treatment Technology in Thermal Power Plant Find, read and cite all the research you need on ResearchGate(PDF) Research Progress of Desulfurization Wastewater is the most widely used desulfurization technology in coalfired power plants [1] In order to ensure the normal operation of the desulfurization system, the chlorine ion concentration in the circulating slurry should be controlled within 20,000 mg/L, so the desulfurization system can discharge a certain amount of desulfurization wastewater [2]Experimental study on solidification of high concentration Sample preparation consists of grinding the powder to achieve a particle size of ~325 mesh followed by pressing the sample into a pellet with a diameter of 40 mm using a Analysis of limestone for flue gas desulfurization in a power plant with ARL QUANT’X EDXRF Spectrometer Author: Thermo Fisher ScientificAnalysis of limestone for flue gas desulfurization in a power plant

.jpg)

Quantifying the “Water–Carbon–Sulfur” Nexus for Coal Power

2022年3月21日 China has implemented strict policies for the installation of desulfurization facilities in coal power plants in order to mitigate their negative environmental and human health impacts However, it is rarely acknowledged that desulfurization processes lead to increased water consumption and carbon emissions from the coal power sector By using a bottomup 2015年10月30日 A Review of Desulfurization Technology using Limestone in Circulating Fluidized Bed Boiler Type Power Plant October 2015 Journal of the Korean Institute of Resources Recycling 24(5):314(PDF) A Review of Desulfurization Technology using Limestone in Flue gas desulfurization is the most effective and leading method to control acid rain and SO2 pollution and limestonegypsum FGD method is most matured until now The simplified wet limestonegypsum FGD system applied in Taiyuan No1 Cogeneration Power Plant is introduced in detail in this article Through the analysis of operation data during trial operation, The application of flue gas desulfurization Semantic Scholar2022年1月6日 This study aims to perform energy, exergy, economic and emissionremoval performance analysis of wet flue gas desulphurisation (FGD) systems in a coalfired power plant with 660MW capacityA wet type flue gas desulphurization system used in a

The 20TH limestone desulfurization grinding production line in a

The 20TH limestone desulfurization grinding production line in a coalfired power plant Coalfired power plants are a significant source of electricity worldwide, but they also contribute to environmental pollution through the emission of sulfur dioxide (SO2) To combat this issue, limestone desulfurization is a widely adopted methodThe desulfurization of coalfired power plants mainly uses limestone wet desulfurization In actual operation, desulfurization wastewater has become the most complex and difficult category of wastewater treatment Desulfurization wastewater from coalfired power plants is generally acidic, high in suspended solids, and high in CODCoalfired power plant desulfurization wastewater treatment processUnder the background of zero liquid discharge of flue gas desulfurization ( FGD) wastewater,the conventional evaporation and crystallization process can’t effectively avoid the secondary pollution of FGD wastewater Thus, a technical route of concentrating FGD wastewater using flue gas wasteheat and solidification with cement is proposed In the concentration tower,the FGD Basic experimental on solidification for high salt desulfurization ARL OPTIM’X, lime/limestone, power plant, WDXRF, XRay fluorescence Water Vapor Gypsum out +95% SO2 captured Limestone and SO2 mix to form gypsum, CaSO4 Flue Gas Booster Fans Limestone in LIMESTONE PREPARATION Lime / Limestone ARL OPTIM’X XRF Spray Tower Flue Gas Desulfurization Unit in a Coal Fired Power Plant Element/ Oxide Concentration Analysis of limestone for flue gas desulfurization in a power plant

.jpg)

Cost and Benefit Analysis of Desulfurization System in Power Plant

The economy of desulfurization system is of great significance for operation of desulfurization system and improving the environment quality in power plant Based on the desulfurization power price policy, this paper analyzes the cost and benefit structure of the wet flue gas desulfurization system in Chinese power plant; that puts forward the calculation methods of total cost present 2017年6月20日 The commissioning and operation of desulfurization system is one of most important measures of sulfur dioxide emission reduction for thermal power plantsStudy on Operation Optimization and Control Model for Desulfurization The power plant flue gas desulfurization environmental protection project is a very important task It is directly related to people’s health and life safety, and is closely related to the environment we live in Doing a good job in the power plant flue gas desulfurization environmental protection project will be an important stepPower plant desulfurization, denitrification and oxidation, Raymond mill is developed by ZENITH's experts based on 10 years' RD on grinding machines, which can perfectly satisfy the production demands of the customers on 20033μm (80425Mesh) fine powder Output Size: 80400mesh Capacity: 350TPH Application: Used for power plant desulfurization Equipment: Raymond Mill

.jpg)

Which mill is the best for desulfurization in power plants?

MTW series European version grinding machine: All are very suitable and can meet the application requirements of power plant desulfurization pulverizers In addition to highperformance equipment, SMMVIK has also launched an overall solution for the desulfurization and pulverizing system of thermal power plants2019年3月1日 This work summarizes the desulfurization and denitration technology of coalfired power plants Machine Science Technology Information 138138 Google Scholar [11] Zhong Y, Gao X, Huo W, Luo Z Y, Ni M J and Cen K F 2008 A model for performance optimization of wet flue gas desulfurization systems of power plants Progress of Desulfurization and Denitration Technology of Flue 2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel 14 Types of Grinding Machines [Working, DiagramIntegrated Limestone Grinding System for Infurnace and Outoffurnace Desulfurization in CFB Power Plant Contact Us Join us and be the first to know about our latest products andpromotionsPower IndustryChangsha Shenxiang General Machinery Co, LTD

]@S0{UDKK%G24F3JGHC.jpg)

Current Status of Zero Liquid Discharge Technology for Desulfurization

2024年3月20日 Desulfurization wastewater is industrial wastewater with a high salt content, high metal ions, and high hardness produced by flue gas desulfurization of the limestonegypsum method in coalfired power plants This paper summarizes the source of desulfurization wastewater, water quality characteristics, water quality impacts, and other factors, combined 2022年1月19日 The desulfurization wastewater in coalfired power plants is difficult to treat due to its high salt concentration and complex composition In this study, a pilotscale evaporation tower system Experimental study on the treatment of desulfurization 2024年9月30日 Coalfired power plants account for a large share of the power generation market in China The mainstream method of desulfurization employed in the coalfired power generation sector now is wet flue gas desulfurization This process is known to have a high cost and be energy/materially intensive Due to the complicated desulfurization mechanism, it is Sustainable Operation Strategy for Wet Flue Gas Desulfurization 2022年3月1日 Among all existing flue gas desulfurization systems, the wet limestone FGD accounts for about 90% because of its high desulfurization performance and low operation costs (Córdoba, 2015, Srivastava and Jozewicz, 2001)Computational fluid dynamic (CFD) simulation for the wet limestone FGD system has been widely studied (Özdemir and Serincan, 2018, Online application oriented dynamic modeling for the flue gas

.jpg)

Application of mtw grinding machine in wet desulfurization

Here's how the MTW grinding machine is applied in the wet desulfurization process: 1 Efficient Grinding: The MTW grinding machine is designed to achieve high grinding efficiency, resulting in lower energy consumption compared to ball mills This is particularly beneficial for power plants looking to reduce operational costs 2Fluegas desulfurization – Wikipedia, the free encyclopedia For a typical coalfired power station, fluegas desulfurization Lime is typically used on large coal or oilfired boilers as found in power plants, » More detailed Flue Gas Desulfurization Technologies for CoalFired Power Plants Babcock Wilcox 1 Abstract The control of sulfur dioxide emissions from thermal desulfurization in coal fired power plants – Grinding Mill China