Lepidolite ore mill accessories manufacturer

China Lepidolite, Lepidolite Wholesale, Manufacturers, Price

China Lepidolite wholesale Select 2024 high quality Lepidolite products in best price from certified Chinese Mica manufacturers, China Dolomite suppliers, wholesalers and factory on Our patented L‑Max ® and LOH‑Max ® technologies extract lithium from lepidolite, other lithium mica minerals and the highgrade lithium phosphate mineral, amblygonite They open up a Technologies LepidicoThe lepidolite ore mobile jaw crusher is a critical component in the journey from raw ore to the production of lithium for batteries Its mobility, adaptability, and efficiency contribute to the Lepidolite ore mobile jaw crusher – Mining Equipment Manufacturer2023年5月16日 This lepidolite ore flotation processing plant is highly effective in recovering Lithium(Li2O) The plant design can be customized per rock minerals conditions and customer 10TPH Lepidolite Processing Plant JXSC Machine

.jpg)

Equipment Machines For Lithium Extraction From

2024年1月20日 Lepidolite is a lithiumcontaining mineral that can be a potential source for lithium carbonate production The process of extracting lithium carbonate from lepidolite ore Lepidolite Ore We are able to supply ore; Zinc (Zn) unrefined Ore Copper Cathodes Sisal Fibre Donkey Hides Cobalt hydroxide (Co) Enquir Send Us Your Inquiry for the Product You Want to Lepidolite Ore – OTD GroupsWe supply Lithium Ore to Lithium buyers We work with trusted Lithium Ore miners to export and sell Lepidolite, Amblygonite, Spodumene, Petalite to buyersLithium Ore Suppliers In Nigeria: Lepidolite, Spodumene Exporters, Strategic Metallurgy Pty Ltd, in collaboration with Lepidico, has developed a hydrometallurgical process that produces high purity LiOH from a lithium sulphate intermediate without the Developing High Purity Lithium Chemicals from Lepidolite

Analysis of Advantages And Disadvantages of Different Lepidolite

2024年1月30日 Currently, a variety of beneficiation technologies are available for the extraction of lepidolite, each with its unique advantages and disadvantages This article will introduce in 2022年2月10日 Residual Analysis XRD analysis was performed to evaluate the components of the roasted samples Figure 5 shows the XRD patterns of the ore and Na 2 CO 3 after roasting with a molar ratio of Li: Na 2 CO 3 of 1:3 at different roasting conditions At a roasting temperature of 500 °C, the main components of the unleached sample + Na 2 CO 3 (Fig 5A) were Treatment of an Indigenous Lepidolite Ore for Sustainable Energy There are several ways to extract spodumene lepidolite ore from the ground One way is to use a crusher machine to break down the rock into smaller pieces This allows for easier extraction of the minerals inside How is spodumene lepidolite ore used? Spodumene lepidolite ore is a type of ore that is found in South America The ore is crushed Limestone lithium mica ore crusher NEWS SMMVIK Machinery2015年11月16日 Of all these pegmatitic lithium minerals, lepidolite ores are of importance because of their widespread distribution, the characteristic of being poor in iron and the additional content of rare (PDF) Extraction of Lithium from Lepidolite Using

Lithium Ore Lepidolite Suppliers and Manufacturers

Our resource is in nigeria, DRC and Tanzania We have grade ranging from 3% to 6% spodumene ore Mostly demands in market is of spodumene ore We have huge stock of spodumene ore and can supply you you up to 15,000MT of Spodumene ore per month Lithium is used in battery manufacturing and is very useful ore Connect with us to get the product asap2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, lepidolite The spodumene lepidolite ore moving crusher manufacturer addresses the crushing of the spodumene lepidolite ore with Raymond Mill, Jaw Crusher, Cone Crusher, and Impact Crusher The primary application areas for this equipment are mineral ore processing, building materials, and engineering materials What is spodumene lepidolite ore?Manufacturer of spodumene lepidolite ore mobile crushing 2023年6月8日 Lepidolite is the most common lithium mineral and an important mineral for extracting lithium Due to the low grade of lepidolite ore, the content of lithium oxide is usually 123% to 590% It is a basic aluminosilicate of potassium and lithium, which is Three Common Beneficiation Process For Lithium Ore

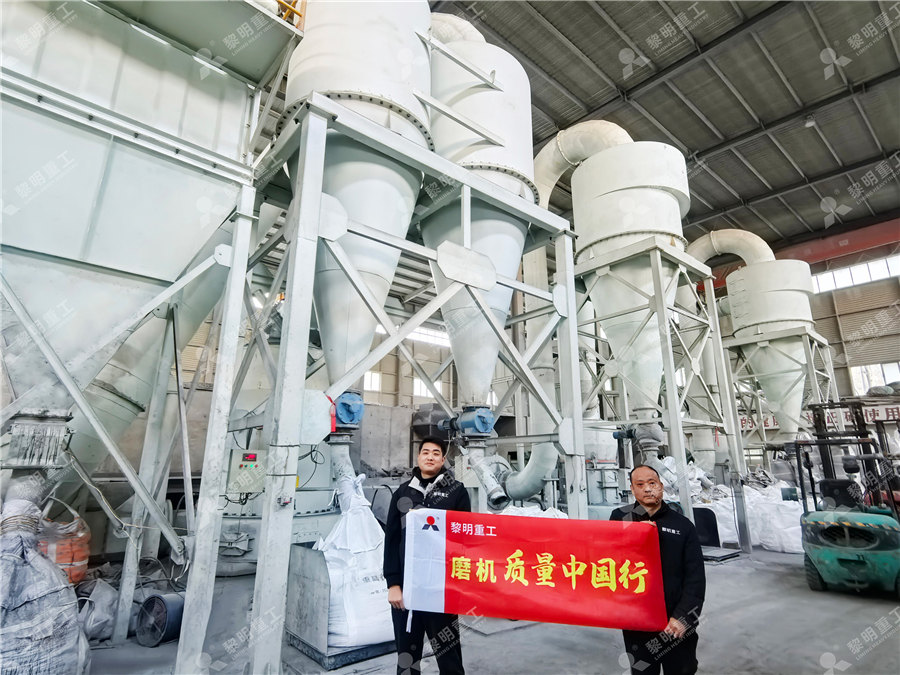

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

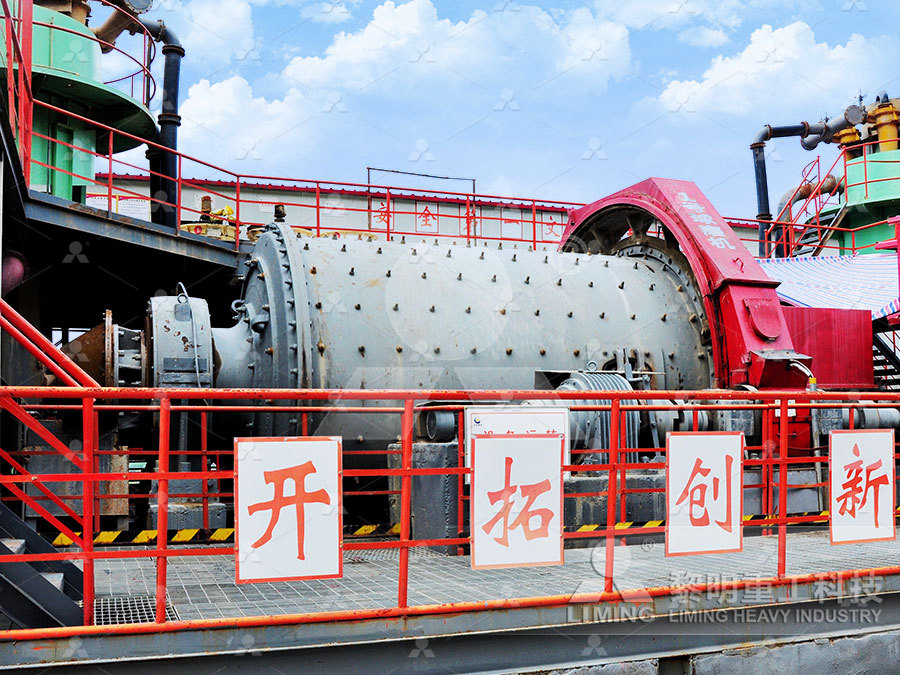

ball mill for grinding spodumene lepidolite production proces

The production process of ball mill for grinding spodumene lepidolite The first stage of the ball mill for grinding spodumene lepidolite production process is to gather the necessary ingredients This includes the lepidolite, which is the main mineral ore, water, and any other desired additives The lepidolite ore is then crushed using a ball 2016年12月5日 Mixtures of lepidolite ore and sodium sulfate (Na2SO4) at mass ratios of 1:05 and 1:1 were prepared and milled using zirconia media in a planetary ball mill for 5 hOptimization of Lithium Extraction from Lepidolite by Roasting With the optimization of the lithium extraction process from lepidolite, lepidolite has achieved largescale production, and its advantages of abundant reserves and low cost of raw ore have gradually emerged Therefore, the development of lepidolite to extract lithium will become a strategic need in China A key step in the lithium extraction technology from lepidolite is the News What Is The Grindability Of Clinker Lepidolite?Ore Lepidolite Spodumene Lithium Feldspar Porcelain Stone Chemical Agitation Micro Powder Grinding Mill Motor Type: AC Motor Motor Power: 30KW Rotationl If you are about to import Lepidolite, you can compare the Lepidolite and manufacturers with reasonable price listed above More related options such as lithium process plant China Lepidolite, Lepidolite Wholesale, Manufacturers, Price

Analysis of Advantages And Disadvantages of Different

2024年1月30日 1 Flotation method Flotation is one of the most commonly used methods in lepidolite beneficiation The basic principle is to use the difference in surface physical and chemical properties of 2023年5月22日 Lepidolite (lithium mica) is a mineral in the mica group and has a layered structure Lepidolite is the most common lithium mineral, usually containing 123%590% Li₂O The ironrich ore is called iron lepidolite, which How to Process Lepidolite in 4 Steps (With Machines)2019年1月15日 There are two economic sources of lithium; brines and hard rock ores The majority of the global lithium production, greater than 60%, is produced from brines while lithium ores accounted for the remaining production (Ebensperger et al, 2005)Table 1 summarises the world’s major lithium producers from ores and brines, and the total reservesThe beneficiation of lithium minerals from hard rock ores: A What is the Best Type of Crusher for Lepidolite Ore Processing Plant? Lepidolite ore is a type of lithiumrich mica that is used in the manufacture of batteries and electronic equipment The most common type of crusher for lepidolite ore processing plants is the short head cone crusherDifference between short and standard head cone crushers in

Application of Isa mill to lepidolite flotation separation

The Isa mill has simple process, covering a small area, with less capital investment, convenient operation and easy to maintenance The raw material for a lepidolite beneficiation in Yichun, Jiangxi Province, is tantalum niobium tailings Most of the lepidolite ores belongs to finegrained embedded type, which is usually associated or coexisted with gangue minerals such as quartz Working principle of lepidolite stone powder grinding machine After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipeWhen the grinding mill is at work, the main bearing and each dial are driven by Lepidolite Stone Powder Grinding Machine Micro Powder Grinding Mill 2023年5月27日 Ball milling is one such technique that has proven to be highly effective in lithium ore processing +86 ; xlyin@xinhaimining; Follow us; In this article, we will mainly introduce the lithium ore ball mill Let’s start! 01 Ball They are used in the mining and manufacturing industries to grind materials into Ball Milling in Lithium Ore Processing: A Comprehensive GuideHe, XM Tan, and WZ Liu, Simultaneous extraction of lithium, rubidium, cesium and potassium from lepidolite via roasting with iron(II) sulfate followed by water leaching, Hydrometallurgy, 208(2022), art No [69] Yan QX, Li XH, Wang ZX, et al Extraction of lithium from lepidolite using chlorination roastingwater leaching process A review of lithium extraction from natural resources PMC

Spodumene lepidolite high performance mine impact crusher

How is spodumene lepidolite mined? The lepidolite ore is mined by underground methods and the crushed rock is then loaded into trucks for transport to the mine The lepidolite ore is dug out of the ground using a dump truck, a frontend loader, and a backhoe The lepidolite ore is then loaded onto crushers and sent down the mine shaft2019年10月9日 Mixtures of lepidolite ore and sodium sulfate (Na2SO4) at mass ratios of 1:05 and 1:1 were prepared and milled using zirconia media in a planetary ball mill for 5 hLithium recovery from mechanically activated mixtures of lepidolite A spodumene lepidolite crusher is used for the production of lithium battery because it has excellent properties that make it a good choice for this kind of manufacturing process These properties include its ability to reduce large rocks into small pieces, which makes it ideal for extracting minerals like lithium from the rocksType of spodumene lepidolite crusher used for production of Ball mill for spodumene lepidolite processing: Process The ball mill is a key equipment for the spodumene lepidolite processing It is mainly used to grind the ore into small pieces and to remove the impurities The ball mill can also be used to preparing other minerals for market Ball mill for spodumene lepidolite processing: FeaturesWhat is the function of ball mill for spodumene lepidolite

.jpg)

200 tons/hour spodumene and lepidolite crushing plant for rent

Equipment Required for Operating a Spodumene Lepidolite Crushing Plant To operate a spodumene lepidolite crushing plant, you will need the following equipment: Crushers: To crush the spodumene lepidolite ore into small pieces, you will need crushers The most common type of crusher is a hammer millShop MilliporeSigma Lithium ore Lepidolite NIST(R) SRM(R) 183 at Thomas Scientific, your trusted partner in Science Skip To Main Content Skip To Main NavigationLithium ore Lepidolite NIST(R) SRM(R) 183 Thomas Scientificcrusher and then continuously ground in a quartzitelined mill Sixinch lumps of ore served as the principal grinding agent After screening and passage through a magnetic separator, the product was sacked for direct shipment to glass manufacturers There was considerable demand for the ground lepidolite,New Mexico Geological Society2022年9月1日 A pegmatite ore from the Gonçalo (Portugal) lepidolite deposit was studied The samples were collected at the mine site within the framework of the FAME project The ore was crushed in a jaw crusher (single toggle 5′’ × 6″, 4 kW, 325–375 rpm, Denver) to produce particles between 20 and 6 mmSeparation of lepidolite from hardrock pegmatite ore via dry

.jpg)

Lithium ore is how to process crushing, grinding equipment?

26 Dec 2022; Typical lithium ore is divided into spodumene, diathene, lepidolite and so on With the development of science and technology, the progress of The Times, the rise of new energy industry, which makes some rare resources are reused, including lithium ore, then, how is lithium ore processed?Lepidolite ores were obtained from Boam mine (Uljin, South Korea) Tyler Standard) The crushed samples were then ground in a single runner mill, and ¹65 meshsize fractions (¹212µm), ¹100 meshsize fractions (¹150µm), ¹150 meshsize fractions (¹106µm) and ¹200 meshsize fractions (¹75µm) were collected andElectrostatically Controlled Enrichment of Lepidolite via FlotationNew and Used Grinding Mill Parts and Accessories for Sale Savona Equipment is your source for Mill Components and Accessories for large primary ore process concentrating through secondary and tertiary fine material as well as complete ore processing facilities We buy, sell and consign Grinding Mill Parts Accessories of various manufacturersGrinding Mill Parts for Sale Ball Mill Parts SAG Mill Parts2022年2月10日 Residual Analysis XRD analysis was performed to evaluate the components of the roasted samples Figure 5 shows the XRD patterns of the ore and Na 2 CO 3 after roasting with a molar ratio of Li: Na 2 CO 3 of 1:3 at different roasting conditions At a roasting temperature of 500 °C, the main components of the unleached sample + Na 2 CO 3 (Fig 5A) were Treatment of an Indigenous Lepidolite Ore for Sustainable Energy

Limestone lithium mica ore crusher NEWS SMMVIK Machinery

There are several ways to extract spodumene lepidolite ore from the ground One way is to use a crusher machine to break down the rock into smaller pieces This allows for easier extraction of the minerals inside How is spodumene lepidolite ore used? Spodumene lepidolite ore is a type of ore that is found in South America The ore is crushed 2015年11月16日 Of all these pegmatitic lithium minerals, lepidolite ores are of importance because of their widespread distribution, the characteristic of being poor in iron and the additional content of rare (PDF) Extraction of Lithium from Lepidolite Using Our resource is in nigeria, DRC and Tanzania We have grade ranging from 3% to 6% spodumene ore Mostly demands in market is of spodumene ore We have huge stock of spodumene ore and can supply you you up to 15,000MT of Spodumene ore per month Lithium is used in battery manufacturing and is very useful ore Connect with us to get the product asapLithium Ore Lepidolite Suppliers and Manufacturers2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, lepidolite

Manufacturer of spodumene lepidolite ore mobile crushing

The spodumene lepidolite ore moving crusher manufacturer addresses the crushing of the spodumene lepidolite ore with Raymond Mill, Jaw Crusher, Cone Crusher, and Impact Crusher The primary application areas for this equipment are mineral ore processing, building materials, and engineering materials What is spodumene lepidolite ore?2023年6月8日 Lepidolite is the most common lithium mineral and an important mineral for extracting lithium Due to the low grade of lepidolite ore, the content of lithium oxide is usually 123% to 590% It is a basic aluminosilicate of potassium and lithium, which is Three Common Beneficiation Process For Lithium OreThe production process of ball mill for grinding spodumene lepidolite The first stage of the ball mill for grinding spodumene lepidolite production process is to gather the necessary ingredients This includes the lepidolite, which is the main mineral ore, water, and any other desired additives The lepidolite ore is then crushed using a ball ball mill for grinding spodumene lepidolite production proces2016年12月5日 Mixtures of lepidolite ore and sodium sulfate (Na2SO4) at mass ratios of 1:05 and 1:1 were prepared and milled using zirconia media in a planetary ball mill for 5 hOptimization of Lithium Extraction from Lepidolite by Roasting

.jpg)

News What Is The Grindability Of Clinker Lepidolite?

With the optimization of the lithium extraction process from lepidolite, lepidolite has achieved largescale production, and its advantages of abundant reserves and low cost of raw ore have gradually emerged Therefore, the development of lepidolite to extract lithium will become a strategic need in China A key step in the lithium extraction technology from lepidolite is the