Specifications of medium and fine crushing barite grinding machine

.jpg)

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the For the gravity separation of barite, the process of TAYMA is crushing, screening and jigging Then the high grade (over 80%) concentrate will be produced The jig is the main equipment Barite Mineral Production Line TAYMACHINERYThe barite sandmaking machine has the functions of medium crushing, fine crushing, ultrafine crushing, etc It has a good crushing effect on hard materials, is intelligent and environmentally Barite Aggregate Processing JXSC Machine2023年3月20日 Generally, the grinding fineness of barite200 is 85~90%, and a twostage grinding process is often used In view of the differences in the properties of barite ores, the Exceptional Barite Processing Methods and Machines

.jpg)

Quick Pick: Compare 4 Top Barite Grinding Mills for Your Needs

2024年4月17日 Barite powder grinding is generally classified into three fineness levels: coarse powder processing (≤ 100 mesh), fine powder processing (120 mesh–325 mesh), and ultra 2023年9月1日 A complete barite processing plant consists of 3 stages, which are crushing, grinding and beneficiation Barite crushing process The Mohs hardness of barite is 335, and 3 Major Stages In Barite Processing Plant Zenith CrusherManfredini Schianchi proposes solutions for the processing and milling of barytes Thanks to technology based on the combined use of leadingedge Manfredini Schianchi machines, it is Barite grinding plants Manfredini and SchianchiThe engineers at Williams Patent Crusher design and manufacture various barite grinding mills that can accomplish the appropriate size reduction needed for your application Barite, or Barite Grinding Mills Barite Crushers Williams Crusher

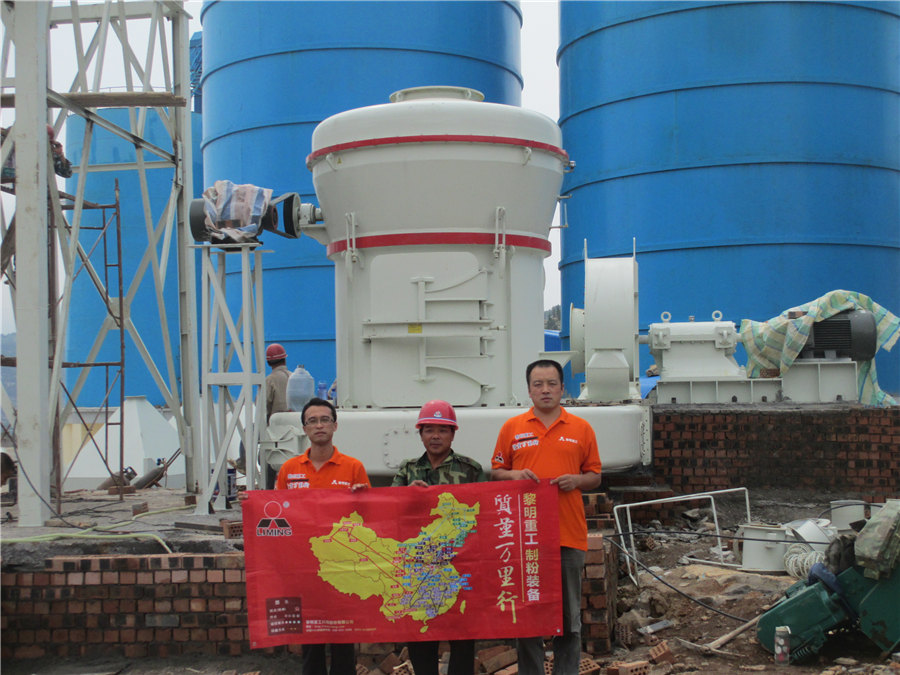

barite grinding plant Baichy Heavy Industry

Baichy produces barite grinding plant and other series of stone crusher, sand crusher, grinding mill equipment Dressing Equipment to meet the needs of different scenarios in various Angle Grinder Angle grinders are abrasive power tools consisting of a spindle at a right angle to the body of the tool Abrasive discs, grinding wheels, cutoff wheels, mounted points or wheels, cones, buffs, and nonwoven discs are mounted on the spindle Angle grinders are used in manual tasks Grinders and Grinding Machines Specifications GlobalSpecThe barite sandmaking machine has the functions of medium crushing, fine crushing, ultrafine crushing, etc It has a good crushing effect on hard materials, is intelligent and environmentally friendly, can be operated remotely, has a Barite Aggregate Processing JXSC Machine2023年3月20日 A good crushing effect will be obtained by using jaw crushers alone Sometimes, cone crushers will be added for fine crushing To fully dissociate useful barite minerals, ball mills are commonly used to grind barite Exceptional Barite Processing Methods and Machines

.jpg)

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, 2019年8月26日 Barite magnetic separation A wet magnetic separator is usually used to select some ironbearing materials such as siderite, which are used as barite feedstock for baryte based pharmaceuticals with very low iron content Barite flotation process 1 Grinding fineness: Flotation of barite generally requires grinding fineness—200 is 85 ~ 90% 2Baryte Processing Equipment, Process Flow, Cases JXSC MachineWilliams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer specifications Our expertise in rock crushing is why we’ve been an industry leader for over 150 yearsRock Crushers Pulverizers Williams CrusherHammer crusher can be used for medium and fine crushing of barite, limestone, gypsum, terrazzo, coal, slag, and other soft and hard ores The equipment can also adjust the gap between the screen strips, improve the discharge particle size to meet the need of users Hammer Crusher Features: 1 High output capacity and reduction ratio; 2Cement Crusher Crushers for Cement Plant AGICO Cement

Barite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder

2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industryCarbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine mill is also called (threering fourring) mediumspeed ring roller microgrinding machine It adopts a graded continuous grinding method to grind the material Coarse Powder Grinding Mill SBM Ultrafine Powder Technology2008年1月1日 A portable bone crushing/grinding machine for both small and medium scale industrial use was designed, constructed and tested In the designing and material selection, consideration was given to DEVELOPMENT OF A PORTABLE BONE CRUSHING AND GRINDING MACHINE FOR It can crush materials with a compressive strength of up to 320Mpa, divided into two types: coarse crushing and fine crushing Eastman has PE and PEX series jaw crushers with complete product specifications Its feed size is Copper Ore Processing Solution Eastman Rock

200250tph Complete Mining Stone Crusher Plant

Introducing the TAYMA 200250tph Complete Mining Stone Crusher Plant: Engineered for superior stone crushing efficiency This integrated system is designed to crush large stones into highquality aggregates or sand, essential The processing of limestone is mainly crushing, grading and producing quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc Limestone generally adopts dry crushing process For Limestone Crushing Solution Eastman Rock CrusherIt can crush materials with a compressive strength of up to 320Mpa, divided into two types: coarse crushing and fine crushing Eastman has PE and PEX series jaw crushers with complete product specifications Its feed size is 125mm~1020mm, and the single machine output is as high as 600TPH It is an ideal choice for primary crushing equipmentGold Ore Processing Solution Eastman Rock CrusherJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and 2024年1月27日 H3: Grinding Machine History and Developments from Ancient Times to Modern Days The evolution of grinding machines is marked by several key developments: Ancient Times: The origins of grinding can be traced back to ancient civilizations where What is a Grinding Machine: Definition, Types, Components6 天之前 In the mineral processing area, the crushing, sand making, beneficiation operations, the screening process is often used and even indispensable But there are many kinds of screen machines with their own advantages and specifications, so what’s the difference between those commonly used vibrating screens and asked how to chooseScreening Machines Comparison JXSC MachineryVI Fine Crushing Machine, Find Details and Price about Fine Grinding Machine Pulverizer from Wf130 IV VI Fine Crushing Machine Shanghai Pharmaceutical Machinery Co, Ltd Specification GMP, CE Trademark SPM Origin China HS Code Production Capacity 530kg/HWf130 IV VI Fine Crushing Machine Fine Grinding Machine

.jpg)

Dolomite Sand Making Plant And Grinding Machine

2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before discharge Step 2: Grind small stones into 2021年4月7日 To use the grinding wheel, it first clamped to the grinding machine Grinding wheel is then attached on the supporting arbors The necessary force required to transfer the rotary motion The force applies to the Guide about Grinding Wheels Types, Material2018年8月17日 Further, the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills So, which one is for you? Well, the answer essentially lies in the feed size and the Grinding Mills — Types, Working Principle ②Ultrafine Grinding Mill: $14,600/set (the lowest price) It is an upgraded Raymond mill for making micro powder and fine powder Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, Powder Grinding Mills Engineered by FTM Fote

Fine Crushing Plant With Roll Crushers Eastman Rock Crusher

2022年5月20日 Four Roll Fine Crusher Introduction The four roll crusher is suitable for ultrafine crushing of solid materials with compressive strength less than 260mpa and moisture content less than 20%, such as crushing iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, metal silicon, barite, basalt, granite, steel slag, water mud clinker, construction waste 2024年3月12日 (2) If the grinding fineness is between 400800 mesh, ultrafine vertical grinding and mediumspeed micro grinding can be selected These grinding machines have high grinding fineness, low energy consumption, and high costeffectiveness (3) If the grinding fineness exceeds 1000 mesh, use an ultrafine grinding machineDolomite Crushing Process And Grinding Equipment2020年8月31日 The machine is powered by a 3phase 10Hp medium speed electric motor The machine, being a medium sized crusher, has the capacity of crushing half a ton of plastic in a day depending on the type Design and Development of Plastic Crusher for a More Efficient Manfredini Schianchi offers solutions for the treatment and grinding of Barite Thanks to a technology based on the iteration of machines Industrial plants; Machines Mills 4,2 kg/dm3), and subject to milling in a single pendular mill: the result of milling will be material with an extremely fine particle size and with a Barite grinding plants Manfredini and Schianchi

.jpg)

HPC Hydraulic cone crusher Baichy Machinery

Hydraulic cone crusher is a medium and fine crushing machine It adopts hydraulic system to adjust the discharge opening and is used to protect the cone crusher from overload The shape design of cone crushing chamber is more scientific, and the hydraulic and lubrication systems are doublesafety controlled6 天之前 Hammer crusher is a highspeed rotary crushing machine The crusher is suitable for crushing medium hardness materials in industrial sectors such as cement, chemical, electric power, and metallurgy The medium hardness materials such as limestone, slag, coke, coal and other materials in the medium and fine crushing operationsTypes of Stone Crushers Machine Mineral ProcessingThe FTM Machinery Ultrafine Mill has a vertical structure, occupies a small area, and integrates crushing, classification, and static pressure FTM Machinery strives for perfection in every configuration The output, fineness, and environmental protection of the fine powder grinding machine far exceed any fine powder grinding machine:Ultrafine Mill or Ultrafine Grinding Mill Fote MachineryAngle Grinder Angle grinders are abrasive power tools consisting of a spindle at a right angle to the body of the tool Abrasive discs, grinding wheels, cutoff wheels, mounted points or wheels, cones, buffs, and nonwoven discs are mounted on the spindle Angle grinders are used in manual tasks Grinders and Grinding Machines Specifications GlobalSpec

Barite Aggregate Processing JXSC Machine

The barite sandmaking machine has the functions of medium crushing, fine crushing, ultrafine crushing, etc It has a good crushing effect on hard materials, is intelligent and environmentally friendly, can be operated remotely, has a 2023年3月20日 A good crushing effect will be obtained by using jaw crushers alone Sometimes, cone crushers will be added for fine crushing To fully dissociate useful barite minerals, ball mills are commonly used to grind barite Exceptional Barite Processing Methods and MachinesThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY2019年8月26日 Barite magnetic separation A wet magnetic separator is usually used to select some ironbearing materials such as siderite, which are used as barite feedstock for baryte based pharmaceuticals with very low iron content Barite flotation process 1 Grinding fineness: Flotation of barite generally requires grinding fineness—200 is 85 ~ 90% 2Baryte Processing Equipment, Process Flow, Cases JXSC Machine

Rock Crushers Pulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer specifications Our expertise in rock crushing is why we’ve been an industry leader for over 150 yearsHammer crusher can be used for medium and fine crushing of barite, limestone, gypsum, terrazzo, coal, slag, and other soft and hard ores The equipment can also adjust the gap between the screen strips, improve the discharge particle size to meet the need of users Hammer Crusher Features: 1 High output capacity and reduction ratio; 2Cement Crusher Crushers for Cement Plant AGICO Cement 2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industryBarite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder Carbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine mill is also called (threering fourring) mediumspeed ring roller microgrinding machine It adopts a graded continuous grinding method to grind the material Coarse Powder Grinding Mill SBM Ultrafine Powder Technology

.jpg)

DEVELOPMENT OF A PORTABLE BONE CRUSHING AND GRINDING MACHINE FOR

2008年1月1日 A portable bone crushing/grinding machine for both small and medium scale industrial use was designed, constructed and tested In the designing and material selection, consideration was given to