Grinding production line quicklime How to fix the locking of the sleeve

Realtime monitoring of efficiency in quicklime grinding

grinding process of quicklime can be exactly monitored by evaluation of the acceleration sensor signal The method allows a definite distinction between efficient and insufficient grinding due 2021年7月6日 This study has investigated an existing production line of an angle grinder manufacturing and used an LM approach to improve the production process to ensure the Balancing of the Production Line Process in the Manufacturing of Calcium oxide within quicklime reacts readily with water, liberating 267 kcal/kg CaO, as follows: CaO + H2O –> Ca(OH) + heat The reaction takes place at an average temperature of 100 ̊C Developing a modular lime plant Cimprogetti2023年2月4日 These highquality lime briquetting machines can be used for highload production and longterm production in harsh working environments, ie afford heavy duty and Lime/quicklime for metallurgy – how producing and briquetting

.jpg)

CYCLE TIME REDUCTION OF GRINDING PROCESS USING SIX

improve cycle time of production by keeping the quality of product, reduce process costs, accelerate productivity and etc Most process improvement work so far has2016年10月19日 The grinding aids were found to influence the product size and decrease the grinding energy This is attributed to the prevention of agglomeration and coating of the Optimization of Grinding Parameters of Quicklime CaO at1998年5月14日 Summary This chapter contains sections titled: Processing Production of Ground Quicklime Storage, Handling and Transport References Skip to Article Content; Skip Processing Storage and Transport of QuicklimeControlling these factors is important to fully convert the limestone to calcium oxide while avoiding recarbonation that could reduce the quality The document discusses the limestone calcination Factors Affecting The Quality of Quicklime

.jpg)

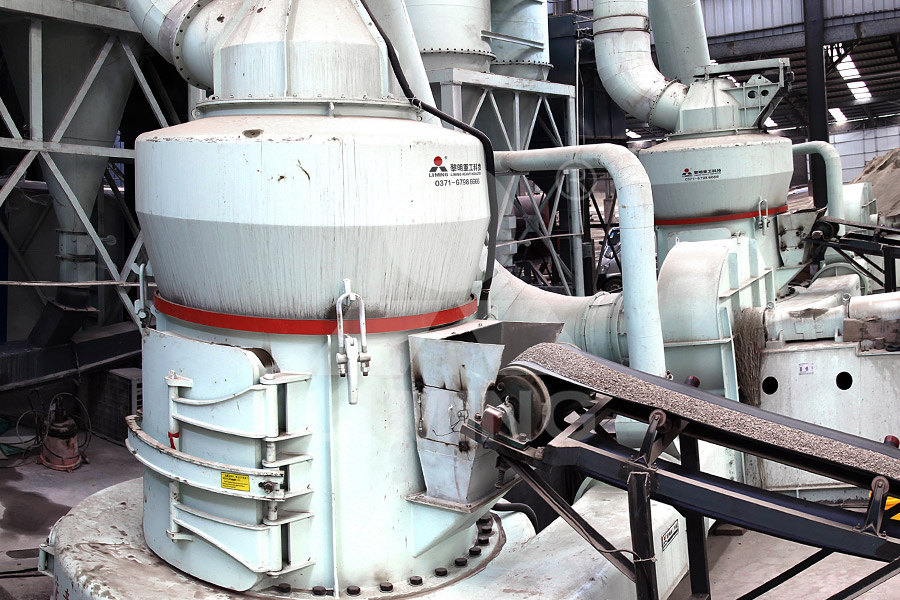

Vertical mill: The preferred equipment for quicklime production

The vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced 2020年11月17日 Still facing challenges that you and your team are struggling to overcome? Meister has the expertise required to diagnose and fix any grinding difficulty Contact Meister today to talk with an application engineer to get The Top 10 Grinding Problems (And How to Fix 2021年7月6日 So many production factories in Africa are still using manual production methods A few of them have introduced a semiautomated production process, wasting lots of time trying to balance the production line As a result, it is essential to investigate the production line balance problem and optimize the production line layoutBalancing of the Production Line Process in the Manufacturing Product: Lime Production Plant Capacity: 50 – 1200 TPD FUEL: Coal Gas, Natural Gas, and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line Main Equipment for Lime Production Line: Rotary Lime Kiln / Vertical Lime Kiln, Raymond Mill, Jaw Crusher, Bucket Elevator, Separator, Dust Collector, etcLime Production Line for HighOutput Lime Production Plant

Lime/quicklime for metallurgy – how producing and briquetting

2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is 3 Benefits of Using Vertical Mill in Quicklime Production High Efficiency The vertical mill offers a high grinding efficiency, which is essential for the production of quicklime It can handle large volumes of limestone and produce a consistent and finely ground product Energy Savings Compared to traditional grinding equipment, the Vertical mill: The preferred equipment for quicklime production2022年2月1日 Decomposing limestone (CaCO3) into quicklime (burnt limestone; CaO) releases significant CO2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of CO2 from the reaction itself (CaCO3 → CaO + CO2) Because quicklime is a key ingredient in the production of cement, as well as being Reducing the carbon footprint of quicklime production2024年9月10日 Excessive Retraction Settings: High retraction settings pull the filament back too far or too often, leading to wear and eventual grinding in the extruder 4 How to Fix Filament Grinding Once you’ve identified the cause of filament grinding, there are several steps you can take to fix the issue and prevent it from happening againHow to Identify and Resolve Filament Grinding in Your 3D Printer

8 Ways to Improve Quality on a Production Line: A

2023年12月5日 Improve production line quality with these 8 proven strategies Learn how to implement quality control measures, When you identify deviations, plan and take prompt and effective corrective actions to fix the issue The objective is to bring the process back to acceptable limits, which may involve process adjustments, The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln such as temperature, particle size of the limestone, rate of temperature rise, retention time, and CO2 concentration Controlling these Factors Affecting The Quality of Quicklime2016年5月8日 Locking coupling types Locking couplings can be categorised according to the amount of stabilization they provide Blank locking couplings Black, standard and full hole locking couplings Blank locking couplings have the same diameter (7300mm) as the standard core barrel, without additional tungsten carbide pads or hard weldingThe Locking Coupling: A key factor for hole deviation control2021年2月16日 Addi king here is how to fix needle skipping and grinding sounds‼️Easy fix for skipping needles and end all grinding, and the unsettling sounds that come witAddi king, here is how to fix needle skipping grinding

How to choose quicklime powder grinding mill?

Process flow of quicklime grinding production line First, the calcite and other materials transported from the quarry are evenly sent to the jaw crusher under the action of the vibrating feeder, and crushed to the feed fineness (15mm50mm) If you just throw a stack of peat and a stack of lime into a fire pit and walk away, you end up with like 7 or 8 quicklime in exchange for that entire stack of peat There is a method that is far more efficient, if you are okay with babysitting the fire, and you can scale it up to about 10x productionQuicklime mass production? : r/VintageStory Reddit2022年8月30日 The price positioning of the cristobalite grinding production line produced by SBM is very affordable, which reduces the user’s production investment in the operation and makes it more profitable SBM can not only provide users with more costeffective and more reliable cristobalite grinding powder production equipment, but also a complete range of How to configure the cristobalite grinding production line?2020年5月29日 Quick Fix Solution for Extruder Grinding Filament Before getting into the reasons, although there isn’t a catchall fix to this problem, a solution that has worked out for several people in the same position is upgrading to an AllMetal Extruder Kit for Creality 3D Printers with new Capricorn PTFE tubingWhy Is My Extruder Grinding The Filament? Causes Solutions

.jpg)

6 Causes of Grinding Chatter – And How to Fix Them Okuma

2016年3月23日 RELATED: How to Avoid Grinding Burn Grinding Fluid Try enriching your grinding fluid We usually run our coolant at 7% Try using a higher percentage of coolant to see if that helps Slender Work Unsupported If you’re grinding slender work make sure you’re using a steady rest that’s suitable for the workpiece you’re grinding Machine The lime cycle shows the stages from quarrying the limestone through to the production of mortars and plasters for our buildings and how it slowly, through the reabsorption which is commonly known as Quicklime or Lumplime It needs to be burnt at 900°C to ensure a good material is produced The temperature at which it is burnt will Lime and its Production2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is scarce Subsequent hydration of lime would lead to the synthesis of slaked/hydrated lime Ca(OH) 2; the production of a tonne of Ca(OH) 2 emits ∼12 tonnes of CO 2 arising mainly from the Decarbonising the lime industry: Stateoftheart ScienceDirect2024年11月8日 quicklime (CaO), compound of one atom of calcium and one atom of oxygen that is a white or grayish white solid produced in large quantities by roasting calcium carbonate so as to drive off carbon dioxideAt room temperature, CaO will spontaneously absorb carbon dioxide from the atmosphere, reversing the reactionIt will also absorb water, converting itself into Quicklime Formula, Uses, Definition Britannica

The Amazing Uses of Quicklime You Probably Didn’t Know

Quicklime was used in the infamous Holocaust The Nazis would place a thick layer of quicklime on the floor of the cattle cars before loading the Jews This would burn the skin of the victims on contact Quicklime, also known as burnt lime, is a chemical compound called 2023年3月27日 The Last Plague: Blight is an authentic survival experience rooted in realism and immersion Endure the hazards of a brutal open world and uncover the originRemoving The Blight Quicklime Productionproduction costs to a minimum In the majority of cases, a very major production cost will be the fuel used Thus, the efficiency of the burning process (as opposed to the whole process of production which will involve labour costs etc) is judged by how much fuel it takes to produce a quantity of quicklime For instance, a limeHOW TO CALCULATE EFFICIENCY OF YOUR LIME BURNING 2022年7月28日 The Chapter 2 covers the strategies for yearround production while in the Chapter 3 we discuss about technologies developed to maintain the quality and extended postharvest life of lime fruitLime: A Technical Guide for Production, Processing and Value

.jpg)

Limestone crushing and grinding production line SBM Ultrafine

2022年4月20日 Before the limestone is pulverized, it needs to be crushed by a crusher to the particles that match the feed size of the mill Then it is sent to the limestone grinding mill at a constant speed through a vibrating screen for grinding The ground limestone is sorted by the separator at the upper end of the millThe UNE 36001 norm includes the following classification of steel products: Irons, steels, foundry or pigiron, ferroalloys, ferrous aggregates and special ferric alloysEspecially worth highlighting is steel, a very versatile material that accounts for 80% of metal production and which is obtained by mixing Iron (Fe) and Carbon (C)The carbon content in steel does not exceed 15%, whilst Lime, an essential component in the steel industry2008年1月2日 This paper describes the factors influencing the reactivity of quicklime; namely the chemical composition of the raw material, the calcination and decrepitation processes to manufacture calcium Factors influencing the reactivity of quicklime ResearchGateJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

.jpg)

How to Calculate the Energy Efficiency of your Lime Burning

Thus, the efficiency of the burning process (as opposed to the whole process of production which will involve labour costs etc) is judged by how much fuel it takes to produce a quantity of quicklime For instance, a limeburner may say “I produced X tonnes of quicklime using Y tonnes of coal which cost me Z dollars†2023年9月3日 If the grinding noise when putting it into gear is due to a physical defect or a bad motor mount, you might get away with a cheap repair bill From there, the potential reasons your transmission is grinding when you put it in gear are expensive and usually require a transmission specialist to confirm and complete the repair8 Reasons For Automatic Transmission Grinding Noise: How To 2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically What is Grinding Process How It Works Different Types of Grinding2020年11月17日 Still facing challenges that you and your team are struggling to overcome? Meister has the expertise required to diagnose and fix any grinding difficulty Contact Meister today to talk with an application engineer to get The Top 10 Grinding Problems (And How to Fix

.jpg)

Balancing of the Production Line Process in the Manufacturing

2021年7月6日 So many production factories in Africa are still using manual production methods A few of them have introduced a semiautomated production process, wasting lots of time trying to balance the production line As a result, it is essential to investigate the production line balance problem and optimize the production line layoutProduct: Lime Production Plant Capacity: 50 – 1200 TPD FUEL: Coal Gas, Natural Gas, and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line Main Equipment for Lime Production Line: Rotary Lime Kiln / Vertical Lime Kiln, Raymond Mill, Jaw Crusher, Bucket Elevator, Separator, Dust Collector, etcLime Production Line for HighOutput Lime Production Plant2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is Lime/quicklime for metallurgy – how producing and briquetting3 Benefits of Using Vertical Mill in Quicklime Production High Efficiency The vertical mill offers a high grinding efficiency, which is essential for the production of quicklime It can handle large volumes of limestone and produce a consistent and finely ground product Energy Savings Compared to traditional grinding equipment, the Vertical mill: The preferred equipment for quicklime production

.jpg)

Reducing the carbon footprint of quicklime production

2022年2月1日 Decomposing limestone (CaCO3) into quicklime (burnt limestone; CaO) releases significant CO2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of CO2 from the reaction itself (CaCO3 → CaO + CO2) Because quicklime is a key ingredient in the production of cement, as well as being 2024年9月10日 Excessive Retraction Settings: High retraction settings pull the filament back too far or too often, leading to wear and eventual grinding in the extruder 4 How to Fix Filament Grinding Once you’ve identified the cause of filament grinding, there are several steps you can take to fix the issue and prevent it from happening againHow to Identify and Resolve Filament Grinding in Your 3D Printer 2023年12月5日 Improve production line quality with these 8 proven strategies Learn how to implement quality control measures, When you identify deviations, plan and take prompt and effective corrective actions to fix the issue The objective is to bring the process back to acceptable limits, which may involve process adjustments, 8 Ways to Improve Quality on a Production Line: A The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln such as temperature, particle size of the limestone, rate of temperature rise, retention time, and CO2 concentration Controlling these Factors Affecting The Quality of Quicklime

.jpg)

The Locking Coupling: A key factor for hole deviation control

2016年5月8日 Locking coupling types Locking couplings can be categorised according to the amount of stabilization they provide Blank locking couplings Black, standard and full hole locking couplings Blank locking couplings have the same diameter (7300mm) as the standard core barrel, without additional tungsten carbide pads or hard welding