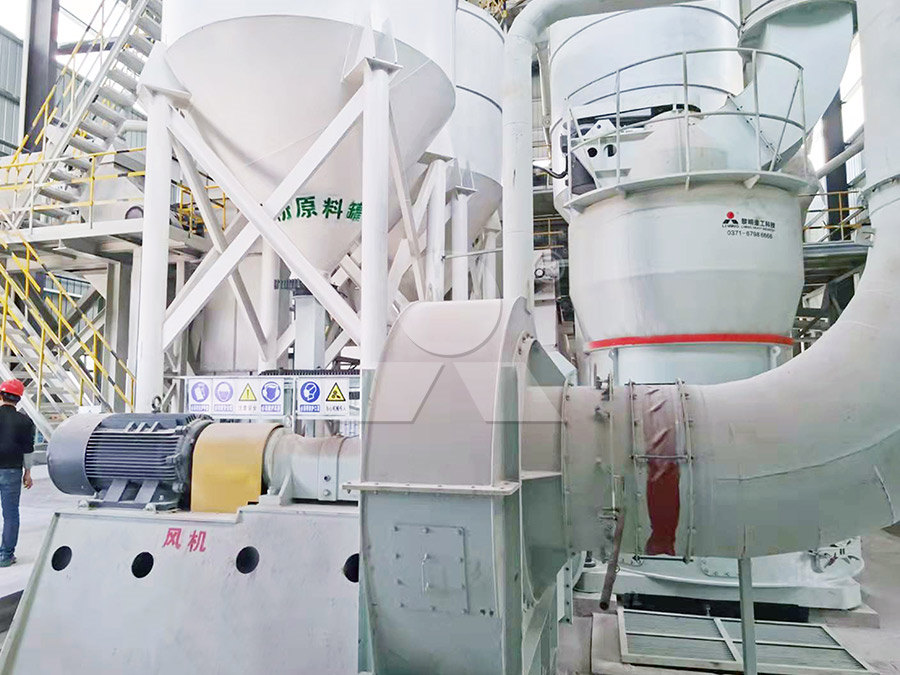

RK slide Q50×70 type dry grinding strong 200 mesh mill operation method

.jpg)

Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and

The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls, cylpeb, and pebbles) put in the shell, and has a simple structure and ease of 展开Conventional Milling machines Turret Mills and Bedmills with manual or CNC control options Ideal for every toolroom, workshop and education facilityMilling Machines RK InternationalThis paper will try to answer the WHY, WHAT, and HOW of attrition fine dry milling using Attritors in continuous or batch type modes The principle of Attritor dry grind processing is achieved by Attrition Dry Milling In Continuous And Batch Modes Union Retsch provides a comprehensive range of grinding mills, each designed to meet specific needs for particle size reduction Below is an overview of the grinding mill types offered by Retsch, Grinding Mills for reliable size reduction tasks RETSCH

.jpg)

Dry milling mill, Dry milling grinding mill All DirectIndustry

Find your dry milling mill easily amongst the 105 products from the leading brands (Fritsch GmbH, Retsch, Brabender, ) on DirectIndustry, the industry specialist for your professional ZSCH Dry Fine Grinding: From A (activated carbon) to Z (zinc) we offer the right mill for your productDry Grinding NETZSCH Grinding Dispersing2018年8月17日 Grinding can be either Dry or Wet Dry processing (Marty says that you would have guessed!) either does not require water for processing or no water is permitted in the Grinding Mills — Types, Working Principle ApplicationsCustomized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Grinding mills for mining and minerals processing Metso

Hammer Milling and Jet Milling Fundamentals AIChE

This article gives a detailed description of hammer mill and jet mill operation, and describes how to characterize the feed material and control product particle size Before designing a milling 2013年12月8日 2 INTRODUCTION TO GRINDING PROCESS • • • It is the only economical method of cutting hard material like hardened steel It produces very smooth surface , suitable for bearing surface Surface pressure is minimum in Grinding operation PPT SlideShareJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

(PDF) Analysis of ball mill grinding operation using mill power

2014年3月1日 Analysis of ball mill grinding operation using mill power specific kinetic parameters 200 mesh 2132 %) has presented data on dry grinding of 8/10 mesh limestone in 127, 2016年6月6日 In fully autogenous or semiautogenous grinding the design of the discharge arrangement is allimportant to successful mill operation This applies to either diaphragm or peripheral discharge If the discharge diaphragm does not have a large enough capacity the mill will display all the outward appearances of being too small (or a given capacitySAG Mill Liner Design 911Metallurgist2020年9月20日 The inconsistencies of these studies may be explained by a study of Prziwara et al [54] on the impacts of grinding aids on the dry stirred milling of limestone: The authors found that the strategy of adding the grinding aid only influences the grinding result, if an early (or delayed) addition of chemicals influences the flow behavior of the product in such a way, that Grinding aids for dry fine grinding processes ScienceDirect2017年2月13日 Center peripheral discharge Rod Mill for minimal slimes in final product CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′Ball Mills 911Metallurgist

Dry Grinding VS Wet Grinding 911Metallurgist

2017年5月25日 Consideration can now well be given to some of the factors upon which the choice of the type of mill, or the method of operation of a given mill, for the grinding of a specified material will depend In the first place it is perhaps of interest to note that the problems encountered in the preparation of powdered materials are not necessarily reduced when the 2020年6月29日 Belt grinding has become an important production process, in some cases replacing conventional grinding operations such as the grinding of camshafts Belt speeds are usually in the range of 2,500 to 6,000 ft/min Machines for abrasivebelt operations require proper belt support and rigid construction to minimize vibrationChapter 17: Grinding Methods and Machines American Machinist2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the Grinding SpringerLinkNote) Capacities listed in the above table are based on tests with ores of Wi13KWH/MT with wet processing in closed circuit A : Capacities are based on tests with grinding material of 80% and 10 mm in pass particle size to produce Horizontal Grinding Mill Overflow Type, Grate

Ball Mill Grinding Machines: Working Principle, Types,

Advantages of Ball Mill Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or continuous grinding, and fine or Batch mill suitable for dry grinding of hard and brittle substances up to 250 ml with a fixed speed of 20000 rpm The slabtype grinding tail discharges, the discharging is smooth, and the cylinder does not need to be cooled; 200 kg/h 4,000 kg/h The Dry milling mill, Dry milling grinding mill All DirectIndustryCapacities up to 250 t/h, at 80% − 200 mesh, • Higher wear rates: 05–15 kg steel/t of product, • • Energy consumption 20–30 kWh/t Szego Mill™ (dry and wet) • Highspeed ringroller mill with long, helically grooved rollers, • Roller assembly rotates Grinding Mill an overview ScienceDirect Topics2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, Rajamani RK (1992) The discrete element method for the simulation of Ball Mills Appl Math Model 16:598–604 Numerical Investigation of Vertical Roller Mill Operation Using Discrete Element MethodNumerical Investigation of Vertical Roller Mill Operation Using

.jpg)

GRINDING PPT SlideShare

2017年4月27日 It can achieve very high accuracies and fine surface finishes There are two main types precision grinding for accurate dimensions and surface grinding, and nonprecision grinding for roughing operations The grinding wheel consists of abrasive grains bonded together using a bonding material and is precisely balanced for highspeed rotationXinhai dry ball mill is a grinding equipment used to deal with dry materials Production capacity 025100t/h Product Improvement Xinhai dry ball mill is horizontal type and tubular running device, which has two warehouses then the grinding operation is completed Product ApplicationDry Ball Mill, Dry Grinding, Dry Grinder, Dry Grinding MachineWastewater Treatment Technologies Iyyanki V Muralikrishna, Valli Manickam, in Environmental Management, 2017 12612 Comminuting Devices Grinders, cutters, and shredders are devices to break or cut up solids to such size that they can be returned to the wastewater without danger of clogging pumps or piping or affecting subsequent treatment devices They may be separate Grinding Mill an overview ScienceDirect TopicsOur ball mills are suitable for all different type of ores They can be used for softer ore like limestone to hard rock like copper and gold ore Ball mills can be utilized as a primary grinding stage (after precrushing) or as a secondary grinding operation following a SAG mill Additionally ball mills are also implemented for regrind Ball Mills – efficient grinding FLS

What is Grinding: Definition, Process, Types Specifications

2024年1月23日 Dry Grinding Dry grinding is a technique where the grinding process is carried out without any coolant or lubricant This method is often used when heat generation during the process is not a significant concern or when dealing with 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 Grinding Mills Common Types 911Metallurgist2016年6月6日 SAG Mill Operation In order to initiate the design of any mill, including autogenous and semiautogenous types, the operating conditions must be defined This includes the basic parameters of: A Mill Charge Charge SAG Mill Grinding Circuit Design 911Metallurgist2012年10月10日 A B S T R A C T: The effects of dry grinding on the structure of sepiolite were studied by XRD, surface area measurement, TGDTA and IR spectroscopy techniquesThe Effect of Grinding Media Type in Vibrating Mill Dry Grinding

JAINNHER JHP Plunge Type Grinding Machine RK International

JAINNHER JHP Plunge Type Grinding Machine Since 1982 , JAINNHER has been a leading force in precision grinding machines Their expertise spans various types of grinding machines, including Plunge type grinding machines, with swing over bed options of 200mm, 350mm and 400mm, grinding lengths from 300mm, 600mm and 1000mm2016年7月8日 The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill 75 feet in diameter in open circuit; and to a wet grinding overflow type ball mill 75 feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 meshEquipment Sizing: Crusher or Grinding Mill 911MetallurgistMorse 5×6” 95 mm: 1 mm: Jaw crusher: 200 kg/h: User selectable: Fritsch P1, II: 75 mm: 65 mm: 70 x 70 mm: 025 mm: Cutting Mill: 50 L/h: User selectable: Fritsch P15: 25 mm: 025 mm: The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast, wet or dry, grinding of larger sample Crushers, Pulverizers, Grinders Lavallab2021年11月23日 This is a sort of plain cylindrical grinder Its worktable, headstock, and grinding head are of swivel type That is why all types of grinding can be done easily with this type of grinders 8 Tool and Cutter Grinder This is a small grinding machine Drill, reamer, tap, and the particularly milling cutter are grinded with this grinding machine14 Types of Grinding Machines [Working, Diagram PDF] The

Wet vs Dry Milling: Key Differences Hockmeyer

2021年6月17日 Now that we have a basic understanding of the industrial milling process, let’s examine the difference between wet milling and dry milling Dry milling typically uses particleonparticle contact to reduce materials’ size, while wet milling involves dispersing the material in a liquid and using solid, grinding elements to reduce size2022年1月23日 In this work, the discrete element method (DEM) was used to examine the effects of stirrer helix angle (α), stirrer diameter (d), and rotating speed (n) on the grinding performance in an Analysis and Optimization of Grinding Performance of Vertical 2023年2月15日 Dry grinding Dry grinding is suitable for materials that can react with water, which may not be used for wet grinding such as cement, marble and other building materials Some products that require storage and sale in powder form are suitable for dry grinding And in some arid areas, dry grinding can be used to save water Wet grindingWhat Are the Differences between Dry and Wet Type Ball Mill?2013年12月8日 2 INTRODUCTION TO GRINDING PROCESS • • • It is the only economical method of cutting hard material like hardened steel It produces very smooth surface , suitable for bearing surface Surface pressure is minimum in Grinding operation PPT SlideShare

.jpg)

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2014年3月1日 Analysis of ball mill grinding operation using mill power specific kinetic parameters 200 mesh 2132 %) has presented data on dry grinding of 8/10 mesh limestone in 127, (PDF) Analysis of ball mill grinding operation using mill power 2016年6月6日 In fully autogenous or semiautogenous grinding the design of the discharge arrangement is allimportant to successful mill operation This applies to either diaphragm or peripheral discharge If the discharge diaphragm does not have a large enough capacity the mill will display all the outward appearances of being too small (or a given capacitySAG Mill Liner Design 911Metallurgist

.jpg)

Grinding aids for dry fine grinding processes ScienceDirect

2020年9月20日 The inconsistencies of these studies may be explained by a study of Prziwara et al [54] on the impacts of grinding aids on the dry stirred milling of limestone: The authors found that the strategy of adding the grinding aid only influences the grinding result, if an early (or delayed) addition of chemicals influences the flow behavior of the product in such a way, that 2017年2月13日 Center peripheral discharge Rod Mill for minimal slimes in final product CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′Ball Mills 911Metallurgist2017年5月25日 Consideration can now well be given to some of the factors upon which the choice of the type of mill, or the method of operation of a given mill, for the grinding of a specified material will depend In the first place it is perhaps of interest to note that the problems encountered in the preparation of powdered materials are not necessarily reduced when the Dry Grinding VS Wet Grinding 911Metallurgist2020年6月29日 Belt grinding has become an important production process, in some cases replacing conventional grinding operations such as the grinding of camshafts Belt speeds are usually in the range of 2,500 to 6,000 ft/min Machines for abrasivebelt operations require proper belt support and rigid construction to minimize vibrationChapter 17: Grinding Methods and Machines American Machinist

Grinding SpringerLink

2022年2月28日 Comparing dry and wet grinding curves in a ball mill in the same condition (an equal amount of materials and grinding media has been used on each pair of wetdry experiments) (Fig 17) indicated two significant differences at higher power values of wet grinding, specifically when speed exceeded 06 critical speed and for higher ω Pmax in the