Micro powder mill mechanical movement diagram

.jpg)

General geometry of micro milling cutters: (a)

Micro milling cutters or micro mills are unique and important micro tools for fabricating miniaturised devices with sufficient geometrical and dimensional accuracy and machined surfaceMicro milling is one of the most frequently used micromechanical machining method with high potential for the precise manufacturing of complex parts The aim of this work is to present the principal aspects related to micro milling Micro milling process modeling: a review2020年10月27日 In particular, the micromilling process is highly suitable for very precise and accurate machining of mold prototypes with high aspect ratios in the microdomain, as well as for rapid microtexturing and micropatterning, Precision micromilling process: state of the art2021年9月24日 Powder metallurgy (P/M) is a manufacturing process used for the production of costeffective tools and efficient components made from metallic, ceramic, or composite powdersMechanical Milling: A Superior

.jpg)

The Mechanism and Grinding Limit of Planetary Ball

In this paper, the grinding of dry silica sand in a batch type planetary ball mill is reported The effects of various technical parameters, such as ball size and density of ball material, 2013年10月19日 Mechanical Alloying describes the process where mixtures of powders, usually of different metals or alloys/compounds, are milled together Milling of uniform composition HighEnergy Milling SpringerLinkIn this paper, micromilling related recent results and developments are reviewed and discussed including microchip removal and microburr formation mechanisms, cutting forces, cutting A review on micromilling: recent advances and future trendsTh e gasdynamic grinding method realized in jet mills is one of the most promising for production of highly dispersed (micronized) powders with particle sizes (fractions) of units and tens of μm4 Schematic representation of the grinding

Schematic diagram of ball milling process for

To address this issue, the review article proposes three different strategies: (i) adding alloying elements, (ii) coating powder particles, and (iii) using lowwavelength lasers (green or blue)2016年8月1日 A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, Modeling of the planetary ballmilling process: The case This paper is a study of mechanical properties and microstructure of rotary friction welded tungsten heavy alloy with aluminum alloy (AA) A plastic deformation is visible on AA sideSchematic of ball movement in typical ball mills used for MA 2023年7月4日 The fine powder becomes the finished product, and the coarse powder returns to the column mill for regrinding Because the roller only makes regular revolution and rotation, and the force on the material layer mainly comes from the elastic pressurization mechanism, the energy consumption, wear, and damage of parts caused by the impact between Roller Mill SpringerLink

(a) Fritsch Pulverisette P5 four station ball mill

The planetary ball mill owes its name to the planetlike movement of its vials ball mill at ®xed rotation speed A diagram featuring the phase constitution in the Pd±Si system is shown in 2021年9月24日 Figure 2 depicts a freeenergy (DG) diagram of two phases engaged in the MA and MD processes In these two opposite Suzuki, K Preparation of AlxTa1x amorphous alloy powder by mechanical alloying J NonCryst Solids 1990, 118, 729–732 [Google sketches illustrate (b) ball movement inside attritor ball mill, (c) impact Mechanical Milling: A Superior Nanotechnological Tool for2022年11月30日 2 WORKING PRINCIPLE OF VIBRATION MILL Superfine powder preparation device is a type of highly efficient pulverizing equipment Its working theory is utilizing collision and smashing between the medium in the cylinder and diamond powder to refines the diamond powder into smaller particles [2]Vibration Mill Bentham OpenMechanical alloying uses ball mills to fuse powder particles an alternative to hightemperature alloy production methods small quantities Learn more This ratio is standard for most planetary ball mills For mechanical alloying applications, planetary ball mills with a higher energy input and a speed ratio of 1:25 or even 1:3 are Mechanical Alloying with Ball Mills Retsch

.jpg)

The Art of Precision: An InDepth Look at Mechanical Watch Movements

2024年4月20日 Achieving Precision in Mechanical Movements One of the key features of the Caliber 240 is its use of a microrotor, which is a small rotor that is integrated into the movement itself This allows for a thinner and more streamlined design, while still providing the benefits of automatic winding The movement also incorporates a Gyromax 2020年10月27日 Micromilling is a precision manufacturing process with broad applications across the biomedical, electronics, aerospace, and aeronautical industries owing to its versatility, capability, economy, and efficiency in a wide range of materials In particular, the micromilling process is highly suitable for very precise and accurate machining of mold prototypes with high Precision micromilling process: state of the art Advances in Micro Powder Grinding Mill is a device that breaks solid materials into powder by grinding, such comminution is an important unit operation in many processes The finished powder can be used as highperformance auxiliary materials for aerospace hightech materials and can be used to make cosmetics It can be widely used in hightech materials Micro Powder Grinding MillThe ball mill diagram is essential for understanding the operation of the ball mill It shows the movement of the material inside the mill and the grinding process The material to be ground is introduced into the hollow cylinder through the feeding device and is impacted and ground by the grinding media as the cylinder rotatesThe Ultimate Guide to Understanding Ball Mill Diagrams

Powder preparation during ball milling and laser additive

2022年8月1日 Laser powder bed fusion (LPBF) also called selective laser melting, as one of the additive manufacturing technologies which uses a highenergy laser beam to melt metal powder layer by layer to form a dense entity according to computer aided design (CAD) data, provides the possibility of forming complex metal parts [1], [2]Moreover, high cooling rates (10 310 6 K/s) The history and necessity of mechanical alloying M Sherif ElEskandarany, in Mechanical Alloying (Second Edition), 2015 2515 Planetary ball mills The Planetary ball mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Figure 11 In this type of mill, the milling media have considerably high Ball Mill an overview ScienceDirect Topics2024年10月18日 The escapement consists of several parts working together, including the escape wheel, pallet fork, and balance wheelThe escape wheel is a toothed wheel connected to the gear train, and the pallet fork engages with Parts of a Watch Movement: A Detailed Guide2023年7月4日 integration with the dry micro classifier, etc It is widely applied in chemical raw materials, non and the coarse powder returns to the column mill Because the roller only makes Roller Mill, Fig 4 Structure diagram of Raymond mill Roller Mill 5 regular revolution and rotation, and the force on the material layer mainly comes from Roller Mill Springer

The Basic Principles of Sieve Analysis RETSCH

dimensional movement 11 Throwaction sieving Throwaction sieve shakers are also known as vibratory sieve shakers An electromagnetic drive sets a springmass system in motion and transfers the oscillations to the sieve stack The sample is subjected to a 3dimensional movement and is distributed uniformly across the whole area of the sieve TheDownload scientific diagram (a) Schematic diagram for the planetary ballmill showing movement of a milling vessel and planetary disks in a clockwise and counter clockwise direction (b) A (a) Schematic diagram for the planetary ballmill showing movement 2020年6月3日 Since cemented carbide has been used as a microlens array mold, its processing method and microtool is one of the research priorities In order to achieve highquality milling of cemented carbide microlens array, the design and fabrication of the 05mm diameter polycrystalline diamond (PCD) micro ballend mill were studied Based on the space vector, Structural design and fabrication of polycrystalline diamond micro 2021年9月30日 Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 meshes It is a highly efficient industrial micro powder grinding mill +17 The contact point between the roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the Chalk Micro Powder Mill SBM Ultrafine Powder Technology

(a) Schematic diagram for the planetary ballmill showing movement

Download scientific diagram (a) Schematic diagram for the planetary ballmill showing movement of a milling vessel and planetary disks in a clockwise and counter clockwise direction (b) A Micro milling is one of the most frequently used micromechanical machining method with high potential for the precise manufacturing of complex parts The aim of this work is to present the principal aspects related to micro milling technology, with emphasis on process modeling and quality of the finished product developed a model for Micro milling process modeling: a review Manufacturing The OTMT 0T2213 mini mill is a small, compact benchtop milling machine with 1/2 HP and a 35” x 15” work table This benchtop milling machine has some great features that make it a useful addition to your workspace For example, 10 Best Benchtop Milling Machines 2024 (All (The \(V\) and \(M\) diagrams should always close, and this provides a check on the work) 4 The moment diagram starts from zero as shown in Figure 10(e), since there is no discontinuously applied moment at the left end It moves 41: Shear and Bending Moment Diagrams

Mechanical Milling: a Top Down Approach for the Synthesis

2012年2月3日 Synthesis of nanomaterials by a simple, low cost and in high yield has been a great challenge since the very early development of nanoscience Various bottom and top down approaches have been developed so far, for the commercial production of nanomaterials Among all top down approaches, high energy ball milling, has been widely exploited for the synthesis Download scientific diagram Types of mills for highenergy milling: Aball mill, Bplanetary mill, Cvibration mill, Dattritor (stirring ball mill), Epin mill, Frolling mill 4k Modified from Types of mills for highenergy milling: Aball mill, Bplanetary mill 2002年7月1日 The rotational direction of a pot in a planetary ball mill and its speed ratio against revolution of a disk were studied in terms of their effects on the specific impact energy of balls calculated Effects of rotational direction and rotationtorevolution 2024年9月27日 Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the chemical, mineral, pharmaceutical, cosmetic, food and plastic industries Hosokawa Micron Powder Systems specializes in coarse to ultrafine grinding, classification, mixing, drying, containment, compaction and analytical Home Hosokawa Micron Powder Systems

.jpg)

A review on mechanical activation and mechanical alloying

2019年8月1日 Mechanical activation (MA) is a wellknown technique since prehistoric times, when reactions could be initiated during grinding accidentally The first records about systematic investigation of mechanochemistry were registered by Spring and Lea at the end of the 19th century (Takacs, 2013)Nevertheless, Ostwald introduced the terminology of Coating has been formed for 672 hours by mixing of serpentine powder with steel balls in a ball mill The coating has an adhesive bond to the substrate The phase composition of the coating is difPlanetary ball mill and ball motion (a) Planetary ball mill; (b The mechanical methods are simple and costeffective but they affect the powder morphology, whereas nonmechanical methods allow one to obtain uniform coatings with methods that are more costly Schematic diagram of ball milling process for coating 2014年6月13日 I have a ST 96 movement and trying to verify if its an vintage oris movment or a china segull stricklandivan@stricklandivan Brad Howard November 29, 2022 at 11:56 pm ReplyVisual Diagram of a Mechanical Watch Movement

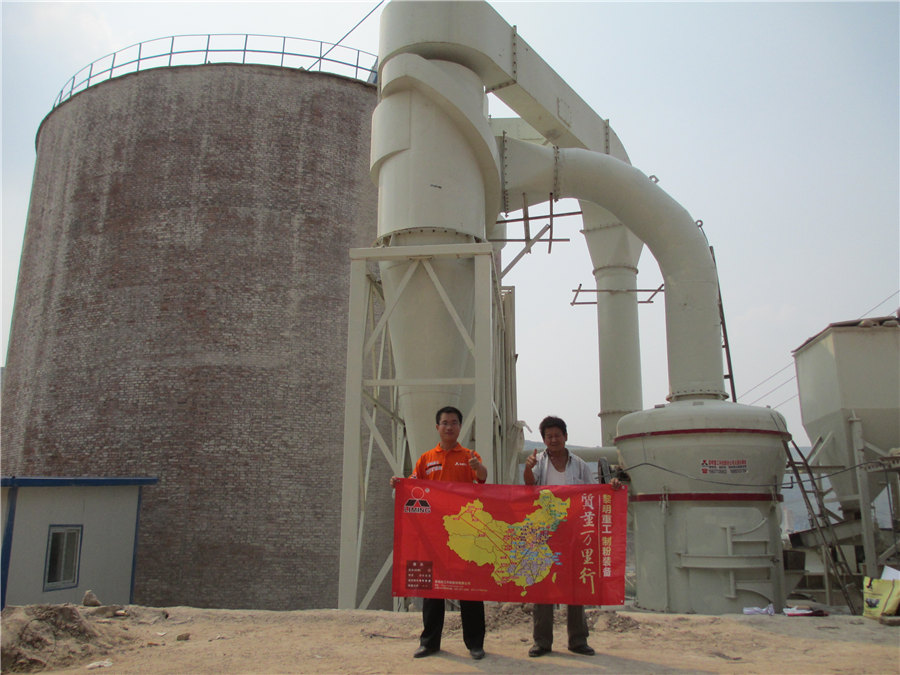

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Schematic of ball movement in typical ball mills used for MA

This paper is a study of mechanical properties and microstructure of rotary friction welded tungsten heavy alloy with aluminum alloy (AA) A plastic deformation is visible on AA side2023年7月4日 The fine powder becomes the finished product, and the coarse powder returns to the column mill for regrinding Because the roller only makes regular revolution and rotation, and the force on the material layer mainly comes from the elastic pressurization mechanism, the energy consumption, wear, and damage of parts caused by the impact between Roller Mill SpringerLinkThe planetary ball mill owes its name to the planetlike movement of its vials ball mill at ®xed rotation speed A diagram featuring the phase constitution in the Pd±Si system is shown in (a) Fritsch Pulverisette P5 four station ball mill2021年9月24日 Figure 2 depicts a freeenergy (DG) diagram of two phases engaged in the MA and MD processes In these two opposite Suzuki, K Preparation of AlxTa1x amorphous alloy powder by mechanical alloying J NonCryst Solids 1990, 118, 729–732 [Google sketches illustrate (b) ball movement inside attritor ball mill, (c) impact Mechanical Milling: A Superior Nanotechnological Tool for

Vibration Mill Bentham Open

2022年11月30日 2 WORKING PRINCIPLE OF VIBRATION MILL Superfine powder preparation device is a type of highly efficient pulverizing equipment Its working theory is utilizing collision and smashing between the medium in the cylinder and diamond powder to refines the diamond powder into smaller particles [2]Mechanical alloying uses ball mills to fuse powder particles an alternative to hightemperature alloy production methods small quantities Learn more This ratio is standard for most planetary ball mills For mechanical alloying applications, planetary ball mills with a higher energy input and a speed ratio of 1:25 or even 1:3 are Mechanical Alloying with Ball Mills Retsch2024年4月20日 Achieving Precision in Mechanical Movements One of the key features of the Caliber 240 is its use of a microrotor, which is a small rotor that is integrated into the movement itself This allows for a thinner and more streamlined design, while still providing the benefits of automatic winding The movement also incorporates a Gyromax The Art of Precision: An InDepth Look at Mechanical Watch Movements2020年10月27日 Micromilling is a precision manufacturing process with broad applications across the biomedical, electronics, aerospace, and aeronautical industries owing to its versatility, capability, economy, and efficiency in a wide range of materials In particular, the micromilling process is highly suitable for very precise and accurate machining of mold prototypes with high Precision micromilling process: state of the art Advances in

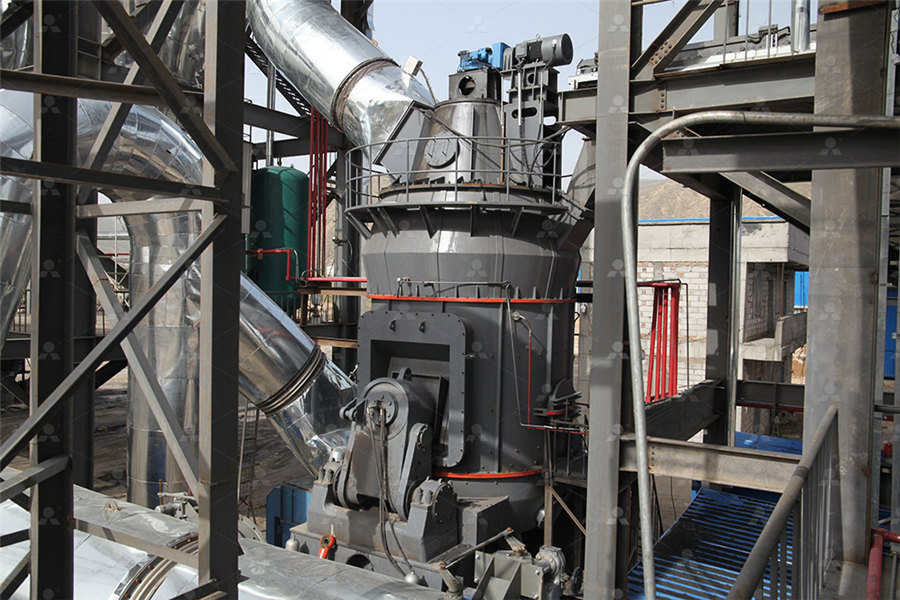

Micro Powder Grinding Mill

Micro Powder Grinding Mill is a device that breaks solid materials into powder by grinding, such comminution is an important unit operation in many processes The finished powder can be used as highperformance auxiliary materials for aerospace hightech materials and can be used to make cosmetics It can be widely used in hightech materials The ball mill diagram is essential for understanding the operation of the ball mill It shows the movement of the material inside the mill and the grinding process The material to be ground is introduced into the hollow cylinder through the feeding device and is impacted and ground by the grinding media as the cylinder rotatesThe Ultimate Guide to Understanding Ball Mill Diagrams