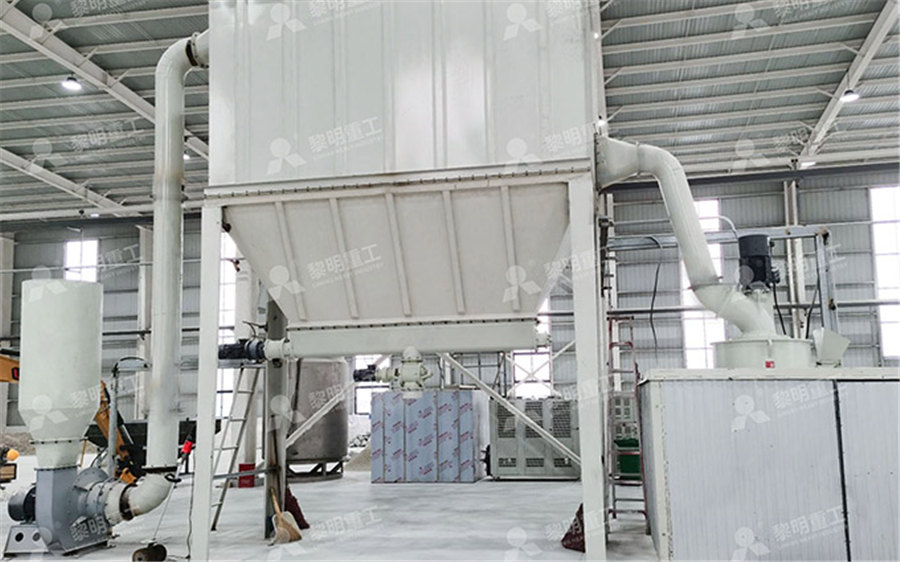

650 Ring Roller Mill Frame Production Diagram

.jpg)

Ring Frame Production Calculation Formula with

2021年4月6日 Some important calculation (Draft, Draft Twist Constant, TPI, TPM, Production Loss, Efficiency, TCP, Yarn Count etc) of Ring Frame machine are2012年2月14日 Production = 1437 lb/shift/frame By this experiment we come to know about various parts and working principle of ring doubling frame This machine is important for producing double yarn on sewing thread You may Ring Doubling Frame: Parts, Specification, Gearing Radialaxial ring rolling, the forming principle of which is shown in Fig1, is a classic form of ring rolling process and is usually adopted to manufacture various highquality large rings widely Numerical Modelling and Simulation of RadialAxial Ring Rolling 2014年12月24日 A ring spinning machine or ring frame is used to produce the required count of yarn from the supplied roving by the drafting To insert a sufficient amount of twist to the yarn Production Calculation of Ring Frame Textile Calculations

Siempelkamp RingRolling Mill

With a variety of design details, Siempelkamp achieves exceptionally high precision during ring rolling For example, the diameter of the rings during ring rolling is precisely measured via – Detailed production and quality data for every ring spinning machine – Run/stop diagram with stop reasons, chain break and extensive break alarm indications – Machine Display device The ring spinning optimization system Technical Data Uster 2019年2月6日 RadialAxial Ring Rolling (RARR) is an industrial forging process for making strong, seamless metal rings Conventionally, rings are made circular with constant cross Control of ring rolling with variable thickness and curvatureRoller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and Roller Mill Springer

.jpg)

Drawing of the basic structure of a roller mill with two

Download scientific diagram Drawing of the basic structure of a roller mill with two rotating/counterrotating rollers (crosssection) from publication: A study of operating parameters of a 2012年1月18日 Roving frame is also called simplex or speed frame The simplex process minimizes the sliver weight to a suitable size for spinning into yarn and inserting twist, which maintains the integrity of the draft strands It is Roving Frame or Simplex Machine: Description and 2024年1月10日 Experiment Name: Lab Report: Study on material passage diagram of Speed frame or fly frame or roving frame or simplex in ring spinning Introduction: A speed frame is placed after the finisher draw frame inWorking Principle of Speed Frame in Ring Spinning R Roller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, China 2Changsha Research Institute of Mining and Metallurgy, Changsha, China 3Chinese Academy of Engineering, Beijing, China Roller mill is a type of grinding equipment for crushing materials by pressure between two orRoller Mill Springer

.jpg)

The ring spinning optimization system Technical Data Uster

to show the realtime production information, such as end break, slip, idle, rogue, endbreak modification average time, and efficiency Included in the delivery – Single spindle monitoring sensor – 1 main shaft sensor for each ring spinning machine – 1 front roller sensor for each ring spinning machine – 1 doff sensor for each ring Introduction to vertical roller mill Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document provides an introduction to vertical roller mills and their production optimization It discusses key aspects of vertical roller mills including their components, operation, controls, maintenance, and Introduction To Vertical Roller Mill PDF Mill (Grinding 2023年11月19日 Passage Diagram of Draw Frame Passage Diagram of Drawing Frame Elements of Drafting Arrangement The primary elements of draw frame’s drafting arrangement are stated below1 Bottom roller 2 Top roller 3 Top roller pressure 1 Bottom Roller Bottom rollers are made of steel driven from main gear transmission The bottom rollers are Draw Frame : FunctionsDrafting ArrangementRoller TextileTutsDownload scientific diagram Schematic of raw vertical roller mill circuit in the Ilam cement plant from publication: Modeling of energy consumption factors for an industrial cement vertical Schematic of raw vertical roller mill circuit in the Ilam cement

.jpg)

Ring frame PDF SlideShare

2015年11月23日 1 RING FRAME INTRODUCTION The ring spinning will continue to be the most widely used form of spinning machine in the near future, because it exhibits significant advantages in comparison with the new spinning processes Following are the advantages of ring spinning frame It is universally applicable, ie any material can be spun to any required count analiysis of oee in spinning mill 2018 1 Professor, Dept of Electrical and Electronics Engineering, Info Institute of Engineering, Tamilnadu, India 2Info Institute of Engineering, 14/5, Janatha nagar, voc street, sivanathapuram, Coimbatore 3Info Institute of Engineering, 150 Ramasamy Nagar, narasimhanaickenpalayam, Coimbatore 4 Info Institute of Improvement of Overall Equipment Efficiency (OEE) of Ring Frame Diagram of Triple Roller Mill Diagram of triple roller mill Also Read: Double Cone Blender Principle, Construction, Diagram, Working, Applications Working of Triple Roller Mill The material after passing through the hopper comes Triple Roller Mill Principle, Construction, Diagram, (Ring Frame Introduction) Free download as PDF File (pdf), Text File (txt) or read online for free 1) The document provides an introduction to ring frames, which are important machines that produce yarn through drafting, twisting, Ring Frame Introduction PDF Spinning (Textiles)

Ring Frame PDF Spinning (Textiles) Yarn

This document provides information about ring spinning frames It discusses the advantages of ring spinning frames, including their universal applicability to materials and ability to produce yarn with optimal strength and structure characteristics It then describes the key operations of a ring frame: drafting the roving to the required fineness, imparting twist to strengthen the fibers, and 2023年7月19日 Triple Roller Mill: Principle, Construction, Diagram, Working, and Applications » Pharma Notes The Triple Roller Mill is a highly valuable Skip to content Menu Home; Production; SOPs Production SOPs QC SOPs PA SOPs EHS SOPs QA SOPs Parentral SOPs Warehouse SOPs Qualification Recent Post Medical Device Regulation EU 2017/ Triple Roller Mill: Principle, Construction, Diagram, Working, and 2021年4月2日 Introduction Roving Frame or Speed Frame or Simplex is the machine of a spinning mill, where the sliver is subjected to one or more attenuating process and the attenuated sliver receives a small amount of twist and is then wound on bobbins The output product of speed frame machine is called Roving So it is also called roving frame The main operations of Roving Frame/Simplex Machine Production Calculations with An early 20thcentury oilseed rollermill from the Olsztyn district, Poland A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022 Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York Cutaway drawing of a centrifugal roller mill for mining applications, 1913 Roller mills are mills that use cylindrical rollers, either in opposing Roller mill Wikipedia

.jpg)

14 Ring Spinning Systems Woolwise

ring frame, spindle, traveller, balloon, end break, package build, false twist device, drafting rollers, apron Figure 141 shows the essential features of a single spindle assembly, which is one production unit of a ring spinning frame Figure 141 A single spindle of a ring spinning frame Source: Wood, 2006Download scientific diagram The 3D geometry model of the vertical roller mill 1: separator outlet; 2: separator; 3: shell; 4: return hopper; 5: grinding roller; 6: wind ring; 7: air inlet; 8 The 3D geometry model of the vertical roller mill 1: separator Production introduction Our new–type ring roller mill series is a new kind of grinder depending on its technology RD capability and referring to similar products’ advantages home and abroad It has comprehensive mechanical crushing properties such as rolling,grinding and impactingRing roller mill Hengtu MachineryDownload scientific diagram Ring frame modification diagram from publication: Structure and spinning of composite yarn based on the multifilament spreading method using a modified ring frame Ring frame modification diagram Download Scientific Diagram

Ring Roller Mill Dry Grinding Solution ALPA

ALPA's Ring Roller Mill is widely renowned for its ability to process a variety of materials, The Ring Roller Mill uses a main shaft that rotates to drive a rotor frame Production capacity for D97:78μm (kg/h) 650~750: 1000~1500: 1100~1600: 2013年12月21日 Ring Frame The ring spinning machine was first invented in 1828 by the American Thorp In 1830, another American scientist, Jenk, contributed the traveler rotating on the ring There have been many Cotton Yarn Spinning Process Step by Step Textile The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies limestone, clay, costeffective production Standard size Raymond Roller Raymond Roller Mill airswept vertical ringrollRing Roller Mill Large output and high production efficiency The ultrafine roller mill drives the main shaft to rotate through the transmission device D97: 815micron heavy calcium carbonate ring roller mill ultrafine grinding production line 30,000t/h A mineral factory in Guangdong produces 20,000 tons, Ring Roller Mill ALPA Powder Equipment

Calculation of Twist, Twist Constant of Ring Frame

2012年2月14日 Front roller diameter = 1″ Tin cylinder diameter = 10″ Whrave diameter = 1125″ Twist change pinion = 48T; Gearing diagram: Fig: Gearing diagram for calculating twist and twist constant of ring frameDoubleboss roller in the roving frame and ring spinning machine About 20% of production costs in a spinning mill fall under the heading “energy”, layer must have high and even hardness in the range 800 – 850 Vickers The traveller Spinners World: Process Control in Ring Frame BloggerHRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill2024年2月18日 Keywords: highspeed wire; reducing and sizing unit; roller ring; cemented carbide; material; During the initial use, the carbide roller rings used for production and rolling suffered serious explosions, flesh loss, Frame number: Rolling mill name: Roll ring diameter/mm: Roll ring width/mm: Roll ring weight/kg:Exploration on roller ring material selection for highline sizing

Vertical Roller Mill Summary

Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementDownload scientific diagram Drawing of the basic structure of a roller mill with two rotating/counterrotating rollers (crosssection) from publication: A study of operating parameters of a Drawing of the basic structure of a roller mill with two 2012年1月18日 Roving frame is also called simplex or speed frame The simplex process minimizes the sliver weight to a suitable size for spinning into yarn and inserting twist, which maintains the integrity of the draft strands It is Roving Frame or Simplex Machine: Description and 2024年1月10日 Experiment Name: Lab Report: Study on material passage diagram of Speed frame or fly frame or roving frame or simplex in ring spinning Introduction: A speed frame is placed after the finisher draw frame inWorking Principle of Speed Frame in Ring Spinning

Roller Mill Springer

R Roller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, China 2Changsha Research Institute of Mining and Metallurgy, Changsha, China 3Chinese Academy of Engineering, Beijing, China Roller mill is a type of grinding equipment for crushing materials by pressure between two orto show the realtime production information, such as end break, slip, idle, rogue, endbreak modification average time, and efficiency Included in the delivery – Single spindle monitoring sensor – 1 main shaft sensor for each ring spinning machine – 1 front roller sensor for each ring spinning machine – 1 doff sensor for each ring The ring spinning optimization system Technical Data Uster Introduction to vertical roller mill Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document provides an introduction to vertical roller mills and their production optimization It discusses key aspects of vertical roller mills including their components, operation, controls, maintenance, and Introduction To Vertical Roller Mill PDF Mill (Grinding 2023年11月19日 Passage Diagram of Draw Frame Passage Diagram of Drawing Frame Elements of Drafting Arrangement The primary elements of draw frame’s drafting arrangement are stated below1 Bottom roller 2 Top roller 3 Top roller pressure 1 Bottom Roller Bottom rollers are made of steel driven from main gear transmission The bottom rollers are Draw Frame : FunctionsDrafting ArrangementRoller TextileTuts

.jpg)

Schematic of raw vertical roller mill circuit in the Ilam cement

Download scientific diagram Schematic of raw vertical roller mill circuit in the Ilam cement plant from publication: Modeling of energy consumption factors for an industrial cement vertical 2015年11月23日 1 RING FRAME INTRODUCTION The ring spinning will continue to be the most widely used form of spinning machine in the near future, because it exhibits significant advantages in comparison with the new spinning processes Following are the advantages of ring spinning frame It is universally applicable, ie any material can be spun to any required count Ring frame PDF SlideShareanaliysis of oee in spinning mill 2018 1 Professor, Dept of Electrical and Electronics Engineering, Info Institute of Engineering, Tamilnadu, India 2Info Institute of Engineering, 14/5, Janatha nagar, voc street, sivanathapuram, Coimbatore 3Info Institute of Engineering, 150 Ramasamy Nagar, narasimhanaickenpalayam, Coimbatore 4 Info Institute of Improvement of Overall Equipment Efficiency (OEE) of Ring Frame