Vertical mill output 17T H

.jpg)

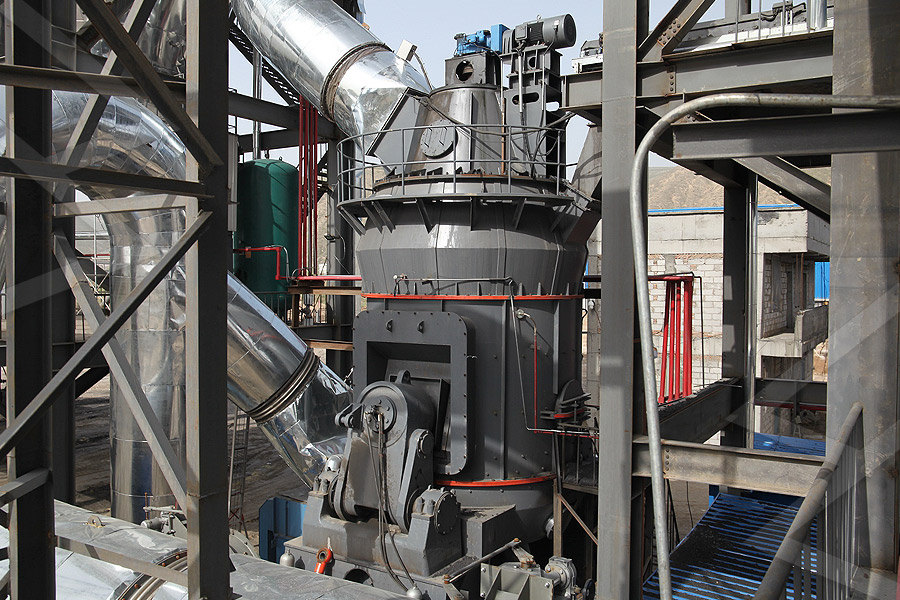

MVR vertical roller mill with planetary gearbox Gebr Pfeiffer

MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput ratesLM series vertical mill is mainly composed of classifier, roller device, grinding disk device, pressure device, speed reducer, electric motor and housing Classifier is a kind of efficient and LM series vertical millThe vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely adopted The rollers are Vertical roller mill for raw Application p rocess materialsThe rugged Summit VSeries vertical mills have been engineered and manufactured from the finest components with the operator in mind All the controls are centralized for ease of Summit Vertical Mills Summit Machine Tool

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg it can not only reduce energy consumption but also increase output(PDF) Performance Evaluation of Vertical Roller Mill 2023年3月15日 Comprehensive Optimization, Lower Operating Costs From aspects of grinding efficiency, powder drying, abrasion of vulnerable parts and maintenance replacement of spare parts, SBM’s LM Vertical Grinding Mill LM Vertical Grinding Mill SBM Mill Crusher2016年9月1日 Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilityOperational parameters affecting the vertical roller mill

Vertical Roller Mill SBM Ultrafine Powder Technology

Vertical roller mill is an efficient industrial milling equipment, suitable for mass production, can grind stones with a Mohs hardness below 7 Output: 120 T/H Product features: High grinding efficiency; Strong drying capacity; Low noises and little dust; 862021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC toolsJet mill: 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best Highend food grade finished powder Mechanically crushed, the powder has the highest fineness It is only suitable for highend or high valueadded powders High energy consumption and low output Ultrafine vertical grinding millCLUM Ultrafine Vertical Grinding MillLimestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] language Output: 120 T/H Product features: High output, low energy consumption, high intelligent control system, wide adjustable range of fineness, Limestone Ultrafine Vertical Mill

Vertical Roller Mills Cement Processing Equipment CITIC HIC

At our powerful national key laboratory, CITIC HIC has established a vertical roller mill testing platform to conduct trials and tests of different materials, Matching clinker line output: Grinding table diameter: Main reducer: Main motor power: t/h: t/d: mm: kW: LGM7027 820880: 10000: 7000: MZL710: 72007600: LGM6027 600650: 7000: 6000 Input dan Output Vertical Raw Mill; Data Temperatur dan Tekanan Input serta Output 1 1) Jurnal terapan internship multidisiplin EICN: ANALISA KINERJA ALAT VERTICAL RAW MILL PABRIK II PT7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRY2020年5月25日 Introduction The vertical monolithic olive mill of the type of mola olearia which, like the Roman trapetum, first appeared during the Hellenistic era and spread all over the GraecoRoman Mediterranean, surviving until the 20th The Vertical Olive Crushing Mill as a Machine and its

The Ultimate Guide To Vertical Axis Wind Turbines

2023年9月9日 Discover the future of renewable energy with vertical axis wind turbines! Harness the power of the wind and revolutionize your energy use Skip to content AQUAPONICS; DIY ENERGY; ECOFRIENDLY; here is a table 2024年9月5日 Vertical milling involves using a vertically oriented rotating spindle that holds the cutting tools The vertical head, oriented perpendicular to the worktable’s surface, allows for versatile machining operations As the cutters interact with the stationary workpiece, they remove excess material creating the desired geometriesVertical vs Horizontal Milling: Key Difference2017年1月1日 output of the mill is 370 t/h of cement with 47 00 Blaine Further orders include a mill LM 725 CS Schmitz, T: Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers(PDF) Drives for large vertical roller mills ResearchGatePRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in construction,coal,power plant,steel plant,construction,cement,ceramic and easy maintenance, power saving, fast investment LM series vertical mill

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit1999年4月18日 EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill) PT SEMEN BATURAJA (Persero) Tbk April 1999; Pada data perhitungan diatas nil ai massa input dan nilai massa output didapatkan (PDF) EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill) vertical roller mill, widely used in minerals grinding process of metallurgy, building materials, chemicals, mining and other fields Home Product Case About Liming Output size: LM353N: Water slag, gypsum: 5560T/H: 400 SSa: 25TPH LM1700 Vertical Coal Mill Equipment: Material: Capacity: Output size: LM1700: Coal: 2025T/H:vertical roller mill, vertical slag mill, vertical coal mill, Superfine 2017年1月1日 The MVR vertical roller mill with an installed power of up to 18000 kW offered by the Gebr an output of 410 t/h at a fineness, according to an R90 figure, of (PDF) Case studies and operational results of modern MVR vertical

Improvement of cement performances through the use of

Mill output 57 t/h Compressive strengths 2days 11 MPa 7days 30 MPa 28 days 43 MPa After introducing MAGA/VM 10 at a dosage of 400 g/t (0,04%) directly sprayed on the grinding bed, the following positive effect have been observed: Mill output increase by 12%: from 57 to 64 t/h Energy saving by 9%: from 30 to 27,6 kWh/tKURIMOTO, LTD Indonesia Informasi Produk, Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill Manufacturing the future Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill Motor output(kW) (t/h): Vertical Super Fine Grinding Mill (Vertical Roller Mill) MVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choiceMVR vertical roller mill with planetary gearbox Gebr PfeifferBrief description of vertical roller mill operation: The most basic reason why vertical roller mill is widely used is that it has low power consumption, and several units are operated in one machine, and it exhibits excellent operational flexibility and can produce various kinds of The different highquality products are now briefly described as follows:Vertical roller mill Hengtu Machinery

.jpg)

Design of a verticalaxis wind turbine: how the aspect ratio

2014年8月2日 Figure 5 shows two verticalaxis turbines with identical design power, blade number and aerodynamic profile (NACA 0018) but with two different aspect ratios (AR 1 = 2; AR 2 = 04) As stated above, the turbine with the lowest AR will have the highest power coefficient and the lowest rotational velocity This turbine will display two further advantages: firstly, a Vertical stirred mill is a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle Since it is operated with wet grinding method, the mill requires no cooling system due to the low speed operationVertical Stirred Mill Mineral Processing Equipment CITIC HICVertical Cement Mill (VCM) memiliki fungsi sebagai alat pencampur dan penghalus klinker dengan bahan – bahan korektif untuk menjadi semen, selain itu juga VCM berfungsi sebagai pengering bahan bakuANALISA KINERJA ALAT VERTICAL CEMENT MILL DI PABRIK II PTConventional Vertical Milling Machines The most popular style of milling machine in the world, the vertical mill, or knee mill, is a versatile machine for industrial applications Featuring a vertical spindle with a quill, these machines are ideal for single sided milling and drillingConventional Vertical Milling Machines KNUTH Machine Tools

Modeling and simulation of vertical roller mill using population

of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerThere is no other mill drive concept ensuring such minimum downtimes and hence minimum production loss Even if unplanned shutdowns occur, the Pfeiffer onemill solution with the MVR mill, where production can be continued, is always better on the long run in terms of ROI as compared to a twomill solution Your advantages at a glance:PFEIFFER VERTICAL MILL WITH MULTIDRIVE MORE POWERVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball mills2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg it can not only reduce energy consumption but also increase output(PDF) Performance Evaluation of Vertical Roller Mill

.jpg)

LM Vertical Grinding Mill SBM Mill Crusher

2023年3月15日 Comprehensive Optimization, Lower Operating Costs From aspects of grinding efficiency, powder drying, abrasion of vulnerable parts and maintenance replacement of spare parts, SBM’s LM Vertical Grinding Mill 2016年9月1日 Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilityOperational parameters affecting the vertical roller mill Vertical roller mill is an efficient industrial milling equipment, suitable for mass production, can grind stones with a Mohs hardness below 7 Output: 120 T/H Product features: High grinding efficiency; Strong drying capacity; Low noises and little dust; 86Vertical Roller Mill SBM Ultrafine Powder Technology2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC tools

CLUM Ultrafine Vertical Grinding Mill

Jet mill: 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best Highend food grade finished powder Mechanically crushed, the powder has the highest fineness It is only suitable for highend or high valueadded powders High energy consumption and low output Ultrafine vertical grinding millLimestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] language Output: 120 T/H Product features: High output, low energy consumption, high intelligent control system, wide adjustable range of fineness, Limestone Ultrafine Vertical MillAt our powerful national key laboratory, CITIC HIC has established a vertical roller mill testing platform to conduct trials and tests of different materials, Matching clinker line output: Grinding table diameter: Main reducer: Main motor power: t/h: t/d: mm: kW: LGM7027 820880: 10000: 7000: MZL710: 72007600: LGM6027 600650: 7000: 6000 Vertical Roller Mills Cement Processing Equipment CITIC HICInput dan Output Vertical Raw Mill; Data Temperatur dan Tekanan Input serta Output 1 1) Jurnal terapan internship multidisiplin EICN: ANALISA KINERJA ALAT VERTICAL RAW MILL PABRIK II PT