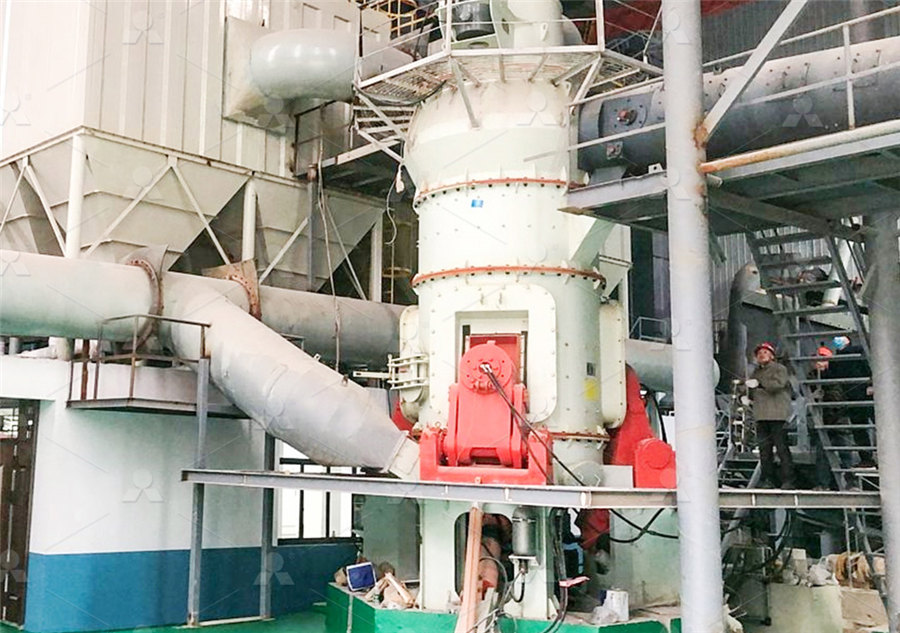

HOME→Calcium carbide mud, Qinhuangdao City, Funing County, Chang'an Raymond Mill Equipment Manufacturing Plant, vertical shaft crusher

Calcium carbide mud, Qinhuangdao City, Funing County, Chang'an Raymond Mill Equipment Manufacturing Plant, vertical shaft crusher

Preparation and curing method of red mudcalcium carbide slag

2023年5月1日 A low carbon geopolymer (RCFG) was developed from the 100% solid wastes including red mud (RM), calcium carbide slag (CS), GGBS and FA in this study The effect of A low carbon geopolymer (RCFG) was developed from the 100% solid wastes including red View Abstract2022年5月1日 For the chloralkali industry, CCS can regenerate massive CaO through purification, molding, calcination Thus, CCS can be used as raw material for CaC2 Recycling and utilization of calcium carbide slag ScienceDirect2022年11月21日 Red mud (RM) and calcium carbide residue (CCR) are waste generated from alumina refining and acetylene gas producing, respectively This study utilized alkaliactivated Strength development and microstructure of sustainable

Strength Development and Microstructure of Sustainable SSRN

2022年8月18日 Red mud (RM) and calcium carbide residue (CCR) are waste generated from alumina refining and acetylene gas producing, respectively This study utilized alkaliactivated Using the solid waste carbide slag produced by the calcium carbide industry to absorb CO 2 and convert it into useful products not only improves the utilization value of carbide slag but also Resource utilization of solid waste carbide slag: a brief review of 2023年5月2日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The Effects of Various Curing Methods on the Properties of Red Mud 2023年8月14日 Carbide slag (CS), soda residue (SR), and red mud (RM) are the main waste residues from the hydrolysis of calcium carbide to produce acetylene gas, production of soda Production of a new type of cemented paste backfill with

.jpg)

Evaluation of calcium carbide residue and fly ash as sustainable

2024年1月5日 This study presents an indepth evaluation of calcium carbide residue and coal fly ash as alternative binders The assessment of raw materials emphasized their chemical 2022年1月27日 Calcium carbide residue (CCR) is a solid waste resulting from acetylene gas production In this study, CCR was used as an alkali activator to prepare fly ash (FA)based Utilization of Calcium Carbide Residue as Solid Alkali for MDPI2019年5月23日 In 2015, the domestic overall production of calcium carbide was 265 million tons/a Carbide slag is the waste generated during industrial production, which is hard to be Comprehensive Utilization of Carbide Slag SpringerLinkNew calcium carbide production facilities must be colocated with other industry in order to enable the full reuse of calcium carbide coproducts such as furnace offgas and recovered dusts, and the lime hydrate (Ca(OH) 2) coproduct from associated acetylene generation operations Emissions controls must meet releA STEP CHANGE IN CALCIUM CARBIDE PRODUCTION

Inner Mongolia Sanwei's BDO project to have trial production

2023年7月25日 At present, the calcium carbide plant will immediately enter the commissioning stage and can be put into production after smooth operation The main BDO equipment has been installed, and preparations are under way before commissioning, and then can have trial production Source: InternetArticle "Strength development and microstructure of sustainable geopolymers made from alkaliactivated ground granulated blastfurnace slag, calcium carbide residue, and red mud" Detailed information of the JGLOBAL is an information service managed by the Japan Science and Technology Agency (hereinafter referred to as "JST") It provides free access to secondary Strength development and microstructure of sustainable Change Currency Back USD EUR GBP View Categories Back Healthcare sustainable practices in carbide manufacturing and waste management, 72 Global Calcium Carbide Market, Split By Country, Historic and Forecast, 20182023, 20232028F, 2033F, $ Billion 8Calcium Carbide Global Market Report 2024 Research and 2018年1月1日 Persistent use of calcium carbide as artificial ripening agent despite various criticisms informed the need to investigate its effect on some important nutritional components of the plantains and Calcium Carbide in Ripening of Plantains and Bananas: Effects on

.jpg)

National carbon emissions from the industry process: Production

2015年12月11日 Combined with emissions derived from raw materials production (coke and lime) and furnace gas combustion, the CO 2 emissions of calcium carbide production range from 16 to 62 kg CO 2 eq/kg CaC 2 Report Overview: IMARC Group’s report, titled “Calcium Carbide Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a calcium carbide manufacturing plantIt covers a comprehensive market overview to microlevel information such as unit Calcium Carbide Manufacturing Plant Project Report 4 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA2022年11月1日 The purpose of the paper was to analyze trends in the formation of alkaliactivated materials (AAMs) produced from alternative starting materials to blast furnace slags and fly ashStrength development and microstructure of sustainable

.jpg)

Performances enhancing of supersulfated cement (SSC) using

2024年10月25日 Kühl firstly present that the hydration and hardening of slag could be accelerated by adding nonhygroscopic alkali metal salts, such as sulfates, and patented it in 1908 [3]However, the relatively slow strength development of sulfateactivated slag cement during the early stages still limited its practical applications2022年6月1日 As foundry sand, SBS has the advantages of high strength, good thermal stability, and lack of any harmful gas emissions in casting [5], [6]The SBS mainly includes silica sand, limestone sand and other highquality sands, which are considered excellent materials and valuable resources [7]In China, about 50 million tons of casting waste sand is discharged Carbon dioxidehardened sodium silicatebonded sand 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPAWe are one of the main manufactories of calcium carbide in China, from size from 410, 715, 1525, 2550, 5080mm, 70100mm, etc, gas yield upto 295l/kg, packing has 50kg drum and 100kg drum, welcome your inquiryCalcium Carbide Manufacturer, Calcium Carbide Supplier

The use of calcium carbide in food and fruit ripening: Potential

2022年1月29日 The global increase in the demand for ripe fruits has induced unhealthy use of toxic chemicals in fruit ripening One of such chemicals in common use is calcium carbide (CaC2)2022年11月21日 The increased production of industrial waste accompanies global industrialization The discharge and storage of industrial wastes seriously pollute the natural environment and limit the development of related industries [1]Red mud (RM), also known as bauxite residue, is a category of industrial waste produced from alumina plantsStrength development and microstructure of sustainable 2022年2月28日 The global increase in the demand for ripe fruits has induced unhealthy use of toxic chemicals in fruit ripening One of such chemicals in common use is calcium carbide (CaC 2)Due to its nature, commercial CaC 2 is consistently found to contain impurities such as Arsenic and other toxic and carcinogenic chemicals Few studies have only reported acute associative The use of calcium carbide in food and fruit ripening: Potential 2013年3月29日 The aim of this study was to evaluate the relative performance of three nitrification inhibitors (NIs) viz calcium carbide (CaC2), and plant derivatives of Pongamia glabra Vent (karanj) and Melia azedarach (dharek) in regulating N transformations, inhibiting nitrification and improving N recovery in soil–plant systems In the first experiment under laboratory Effect of soilapplied calcium carbide and plant derivatives on

.jpg)

Strength development and microstructure of sustainable

Red mud (RM) and calcium carbide residue (CCR) are waste generated from alumina refining and acetylene gas producing, respectively This study utilized alkaliactivated ground granulated blastfurnace slag (GGBS) and wetbasis CCR stabilized RM to prepare geopolymers material The alkali activator solution was composed of CCR supernatant, sodium hydroxide (NaOH) and up Calcium Carbide (CaC2) Manufacturing plant ? 14 What will be the income and expenditures for Calcium Carbide (CaC2) Manufacturing Business? 15 What are the Projected Balance Sheets of Calcium Carbide (CaC2) Manufacturing plant ? 16 What are the requirement of utilities and overheads for setting up Calcium Carbide (CaC2) Manufacturing Manufacturing Business of Calcium Carbide (Calcium Acetylide 2020年11月5日 In the mix design of geopolymer samples, the sandbinder ratio was 3:1, the liquid solid ratio (L/S) was fixed at 07 and the different percentages of the geopolymer materials were shown in Table 4Solid particles (fly ash, red mud) and wetbased carbide slag were firstly mixed for 3 min, then the upper clear solution of carbide slag was poured into the mixture and Frontiers Microstructure and Composition of Red MudFly Ash 2011年10月7日 SACC operations manager JuanManual Sabio said that the additional 8 MW capacity would enable the company to operate at full production, or produce about 100 000 t/y of calcium carbide He noted that the company had been operating at about 70% capacity because of electricity constraints SACC sourced its funding for the cogen project from the Industrial Calcium carbide firm builds 8 MW cogen plant in Newcastle

Life cycle assessment and sustainable production evaluation of calcium

2022年5月1日 With the rapid development of the calcium carbide (CaC2) industry in China, the growth in CaC2 demand is confronting an increasing pressure to reduce environmental emissions2024年3月5日 Anchiy/E+ via Getty Images Calcium carbide (CaC 2) is a chemical that’s used to ripen fruit Ripening chemicals are used to keep fresh fruit available, even when it’s not in seasonBut calcium carbide is risky to use Calcium Carbide for Fruit Ripening: Is It Something to 2019年11月27日 Aiming to make full use of three kinds of solid wastes from calcium carbide industry, this paper first investigated elements and mineral compounds of them through inductively coupled plasma and Xray diffraction (XRD) The three solid waste samples, removed dust (RD), coke dust (CD) and purified dust (PD), have higher Ca/S molar ratios than Fundamental characteristics of solid wastes from calcium carbide 2022年11月21日 An important aspect in the case of AAM binders containing red mud is the leaching experiment An et al [169], in their work on RM and calcium carbide residue, performed this test after 28 days of curing The results presented by them showed that toxic heavy metal levels are below the acceptable limit, which proves their safety for the environmentStrength development and microstructure of sustainable

Recycling sediment, calcium carbide slag and ground granulated

2021年10月25日 Request PDF Recycling sediment, calcium carbide slag and ground granulated blastfurnace slag into novel and sustainable cementitious binder for production of ecofriendly mortar The 2021年11月1日 In China, the calcium carbide and methane partial oxidation methods are used to produce acetylene, with the former being predominantly used China is the largest producer and consumer of calcium carbide worldwide, with 2018 output reaching 2608 million tons, 90% of which was used to produce polyvinyl chloride, 1,4butanediol, and vinyl acetate through Life cycle assessment of acetylene production from calcium carbide 2021年9月27日 The use of cement is gradually limited due to its enormous thermal energy consumption and carbon dioxide emissions The plant ash and calcium carbide residue, as waste byproducts, are adopted in this research for clayplant ash geopolymer The primary purpose of this research is to evaluate the feasibility of calcium carbide residue as an alkaline activator to Experimental study of the feasibility of using calcium carbide IMARC’s newly published report, titled “Calcium Carbide Prices, Trend, Chart, Demand, Market Analysis, News, Historical and Forecast Data Report 2024 Edition,” offers an indepth analysis of calcium carbide pricing, covering an analysis of global and regional market trends and the critical factors driving these price movementsCalcium Carbide Prices, News, Chart, Demand and Forecast

.jpg)

Calcium Carbide Imports in World Volza

2024年7月17日 According to Volza's Global Import data, World imported 2,403 shipments of Calcium Carbide during Mar 2023 to Feb 2024 (TTM) These imports were supplied by 487 exporters to 614 Global buyers, marking a growth rate of 22% compared to the preceding twelve months Within this period, in Feb 2024 alone, World imported 142 Calcium Carbide New calcium carbide production facilities must be colocated with other industry in order to enable the full reuse of calcium carbide coproducts such as furnace offgas and recovered dusts, and the lime hydrate (Ca(OH) 2) coproduct from associated acetylene generation operations Emissions controls must meet releA STEP CHANGE IN CALCIUM CARBIDE PRODUCTION 2023年7月25日 At present, the calcium carbide plant will immediately enter the commissioning stage and can be put into production after smooth operation The main BDO equipment has been installed, and preparations are under way before commissioning, and then can have trial production Source: InternetInner Mongolia Sanwei's BDO project to have trial productionArticle "Strength development and microstructure of sustainable geopolymers made from alkaliactivated ground granulated blastfurnace slag, calcium carbide residue, and red mud" Detailed information of the JGLOBAL is an information service managed by the Japan Science and Technology Agency (hereinafter referred to as "JST") It provides free access to secondary Strength development and microstructure of sustainable

.jpg)

Calcium Carbide Global Market Report 2024 Research and

Change Currency Back USD EUR GBP View Categories Back Healthcare sustainable practices in carbide manufacturing and waste management, 72 Global Calcium Carbide Market, Split By Country, Historic and Forecast, 20182023, 20232028F, 2033F, $ Billion 82018年1月1日 Persistent use of calcium carbide as artificial ripening agent despite various criticisms informed the need to investigate its effect on some important nutritional components of the plantains and Calcium Carbide in Ripening of Plantains and Bananas: Effects on 2015年12月11日 Combined with emissions derived from raw materials production (coke and lime) and furnace gas combustion, the CO 2 emissions of calcium carbide production range from 16 to 62 kg CO 2 eq/kg CaC 2 National carbon emissions from the industry process: Production Report Overview: IMARC Group’s report, titled “Calcium Carbide Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a calcium carbide manufacturing plantIt covers a comprehensive market overview to microlevel information such as unit Calcium Carbide Manufacturing Plant Project Report 2024

114 Calcium Carbide Manufacturing US EPA

114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO2022年11月1日 The purpose of the paper was to analyze trends in the formation of alkaliactivated materials (AAMs) produced from alternative starting materials to blast furnace slags and fly ashStrength development and microstructure of sustainable 2024年10月25日 Kühl firstly present that the hydration and hardening of slag could be accelerated by adding nonhygroscopic alkali metal salts, such as sulfates, and patented it in 1908 [3]However, the relatively slow strength development of sulfateactivated slag cement during the early stages still limited its practical applicationsPerformances enhancing of supersulfated cement (SSC) using