Limestone XK3125.0035 ore grinding mill

Limestone Grinding Mill MadeinChina

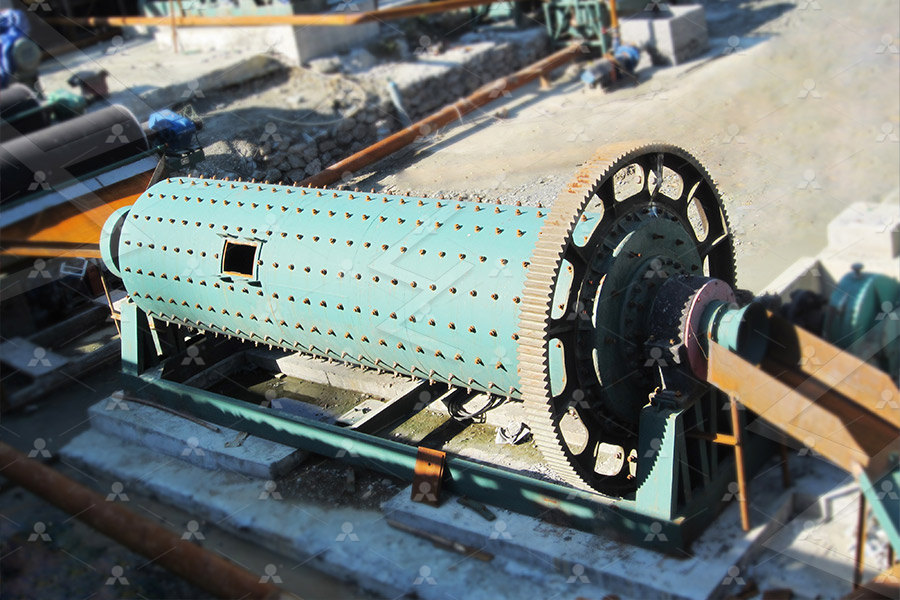

China Limestone Grinding Mill wholesale Select 2024 high quality Limestone Grinding Mill products in best price from certified Chinese Mill manufacturers, Milling Machine suppliers, Limestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, chalk, limestone, calcite, carbon black, Limestone grinding mill Hengtu Machinery5 天之前 The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of Limestone Grinding Mill Plant TAYMACHINERY2023年12月20日 1 2 5 10 Ton Per Hour Limestone Grinding 1200X2400 1200X3000 Ball Mill for Chrome Ore Mineral, Find Details and Price about Ball Grinder Small Ball Mill with Diesel Engine from 1 2 5 10 Ton Per Hour 1 2 5 10 Ton Per Hour Limestone Grinding

.jpg)

High Efficiency Limestone/Copper Ore Grinding Mill Mineral Grinding

2024年10月6日 Type: Calcite Grinding Mill Motor Type: AC Motor Motor Power: 185160kw Rotationl Speed: 1719r/min Application: Mine Materials: Stone, Ore, Sand2024年10月19日 Large Capacity Iron Ore Ball Mill Limestone Grinding Machine, Find Details and Price about Ball Mill Grinding Mill from Large Capacity Iron Ore Ball Mill Limestone Large Capacity Iron Ore Ball Mill Limestone Grinding Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, it has two ore grinding ways: dry way Limestone mill, Limestone grinding mill AllChina Grinding Machine For Limestone wholesale Select 2024 high quality Grinding Machine For Limestone products in best price from certified Chinese Machinery For Plastic Grinding Machine For Limestone MadeinChina

.jpg)

Limestone Ores Cement Clinker Fine Powder Grinding Ball Mill

2024年7月23日 Limestone Ores Cement Clinker Fine Powder Grinding Ball Mill, Find Details and Price about Ball Mill Mineral Ore Ball Mill from Limestone Ores Cement Clinker Fine 4 天之前 A wet grinding 4 x 10 center peripheral discharge rod mill used for producing fine aggregates Twelve 7 x 24 Compeb mills grinding cement clinker to a product of 1750 surface area, 90% passing a 200 mesh screen An 8 x 7 Grinding Mills 911Metallurgist2024年4月26日 b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semiautogenous (SAG) mills are used for grinding These mills utilize the ore itself as the grinding media, reducing the need for Iron Ore Processing: From Extraction to 2024年10月16日 Limestone After grinding Limestone is an important nonmetallic mineral resource that can provide raw materials for construction, metallurgy and other industries through grinding The limestone grinding mill uses the principle of mechanical crushing to grind large pieces of limestone into fine particlesLimestone Grinding Mill

.jpg)

EnergyModel and Life CycleModel for Grinding Processes of Limestone

2022年5月22日 Dry and wet grinding experiments have been carried out with a Bond mill and a laboratory stirred ball mill During the grinding processes, the grinding time and the filling ratio have been adjusted2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of different balls (127–375 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%) The net power consumption in a ball mill is Optimization of Ball Mill Grinding of a LimestoneType Final grain size: 250 µm 800 µm Rotational speed: 1,500 rpm 6,000 rpm Output: 650 kg/h 13,000 kg/h any type of dry of soft products with average hardness THEORY OF OPERATION: The product is loaded in the center of the mill by a feeding chute The product is so moved by centrifugation and milled by impacts Limestone mill, Limestone grinding mill All DirectIndustryThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill Clirik Grinding Mill

How to choose limestone grinding mill? SANDMINE

2024年1月29日 Limestone is a common mineral, typically composed mainly of calcium carbonate (CaCO3) After grinding limestone into powder, it has various uses depending on the fineness of the powder and its chemical properties Here are some common uses: Manufacture of Building Materials: Limestone powder is often used in the production of cement The 5 Our Limestone powder grinding mill is made of more wearresistant materials, which can effectively reduce the cost of maintenance and replacement parts Saving costs means increasing customer benefits 6 Our Limestone powder grinding mill adopts intelligent control, easy to operate, and can effectively save labor costs for investorsLimestone Powder Grinding Mill In India Clirik Grinding MillWilliams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus Limestone Mills Limestone Crushers Pulverizers2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness6 Types Of Limestone Dry Powder Grinder Machines

The Role of Grinding Mills in Limestone Powder Production

The Role of Grinding Mills in Limestone Powder Production Grinding mills are indispensable in the process of creating limestone powder, serving as a key component in various industries Application of ball mill in gold ore beneficiation process 1000 tons per day cement crushing production equipment 2021年5月7日 Dolomite grinding mill: five models: HGM80, HGM90, HGM100,HGM125,and HGM168 finished production fineness: 200meshes~2500meshes, 574 micron the capacity (ton/hour) ranges from 04T/H to 30T/H Application of dolomite grinding mill : HGM Series dolomite Grinding Mill is the equipment specializing in producing fine and superfine powder of Dolomite grinding mill Stone Grinding MillGypsum Grinding Mill 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder 2024年11月11日 The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from Limestone Grinding Mill Plant TAYMACHINERY

Optimization of Ball Mill Grinding of a LimestoneType

2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with Description I Application Limestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, chalk, limestone, calcite, carbon black, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomaceous Limestone grinding mill Hengtu Machinery2023年5月15日 A limestone grinding mill is a machine that grinds and powderizes limestone It is very useful in the manufacture of cement, glass, steel and other industrial products that require finely ground limestone Limestone enters the mill where it is processed and crushed by grinding media (balls or rollers) Separators collect the resulting powders What is Limestone Grinding Mill SBM Mill Crusher2023年7月13日 the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of dierent balls (127–375 mm) and interstitial lling of 50% (20% ball lling ratio at xed material lling ratio= 4%) The net power consumption in a ball mill is proportional to the Optimization of Ball Mill Grinding of a Limestone‐Type

.jpg)

Closed and Open Circuits Ball Mill for Cement, Limestone, Iron ore

We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirementsProduct Application Of Limestone Ultrafine Vertical Mill Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as Limestone Ultrafine Vertical Mill2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material When choosing primary autogenous grinding, run of mine ore up to 200300 mm in size is fed to the mill When using a crushing step before the grinding, the crusher setting should be 150200 mm Grinding Mill Design Ball Mill Manufacturer2023年7月20日 According to the ore discharging method, the grinding mill is divided into overflow type, grating type, and peripheral discharging type According to the different grinding medium, the grinding mill is divided into three types: (1) ball mill – it is used widely, and almost all materials can be triturated by ball mill; (2) rod mill – its Ore Grinding SpringerLink

Powder Grinding Mills Engineered by FTM Fote Machinery

2024年11月23日 ②Ultrafine Grinding Mill: $14,600/set (the lowest price) It is an upgraded Raymond mill for making micro powder and fine powder Widely applied in metallurgy, mining, chemical, cement, construction, refractory materials, ceramics, and other industries2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2022年4月20日 Before the limestone is pulverized, it needs to be crushed by a crusher to the particles that match the feed size of the mill Then it is sent to the limestone grinding mill at a constant speed through a vibrating screen for grinding The ground limestone is sorted by the separator at the upper end of the millLimestone crushing and grinding production line SBM 2024年11月13日 Limestone powder grinding mill is a kind of new hightech milling machine This mill is mainly used for grinding coarse limestone, the finished product size can be adjusted discretionarily from 80325 meshes and finished product size of some materials can reach up to 600 meshes Raw Materials Processing NonMetalic ore, like limestone Limestone Powder Grinding MillFote Machinery

.jpg)

Limestone mills price, 2024 limestone mills price

limestone mills price Select 2024 high quality limestone mills price products in best price from certified Chinese Limestone Grinding Mill manufacturers, Cement Mill suppliers, wholesalers and factory on MadeinChina EnergySaving Gold Copper Ore Wet Ball Mill /Dry or Wet Grinding US$ 200050000 / Piece 1 Piece (MOQ) Shandong Huate 2019年4月16日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM The limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder Fineness4 天之前 A wet grinding 4 x 10 center peripheral discharge rod mill used for producing fine aggregates Twelve 7 x 24 Compeb mills grinding cement clinker to a product of 1750 surface area, 90% passing a 200 mesh screen An 8 x 7 Grinding Mills 911Metallurgist

Iron Ore Processing: From Extraction to

2024年4月26日 b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semiautogenous (SAG) mills are used for grinding These mills utilize the ore itself as the grinding media, reducing the need for 2024年10月16日 Limestone After grinding Limestone is an important nonmetallic mineral resource that can provide raw materials for construction, metallurgy and other industries through grinding The limestone grinding mill uses the principle of mechanical crushing to grind large pieces of limestone into fine particlesLimestone Grinding Mill2022年5月22日 Dry and wet grinding experiments have been carried out with a Bond mill and a laboratory stirred ball mill During the grinding processes, the grinding time and the filling ratio have been adjustedEnergyModel and Life CycleModel for Grinding Processes of Limestone 2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of different balls (127–375 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%) The net power consumption in a ball mill is Optimization of Ball Mill Grinding of a LimestoneType

Limestone mill, Limestone grinding mill All DirectIndustry

Final grain size: 250 µm 800 µm Rotational speed: 1,500 rpm 6,000 rpm Output: 650 kg/h 13,000 kg/h any type of dry of soft products with average hardness THEORY OF OPERATION: The product is loaded in the center of the mill by a feeding chute The product is so moved by centrifugation and milled by impacts The Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill Clirik Grinding Mill2024年1月29日 Limestone is a common mineral, typically composed mainly of calcium carbonate (CaCO3) After grinding limestone into powder, it has various uses depending on the fineness of the powder and its chemical properties Here are some common uses: Manufacture of Building Materials: Limestone powder is often used in the production of cement The How to choose limestone grinding mill? SANDMINE5 Our Limestone powder grinding mill is made of more wearresistant materials, which can effectively reduce the cost of maintenance and replacement parts Saving costs means increasing customer benefits 6 Our Limestone powder grinding mill adopts intelligent control, easy to operate, and can effectively save labor costs for investorsLimestone Powder Grinding Mill In India Clirik Grinding Mill

Limestone Mills Limestone Crushers Pulverizers

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus