Zinc ore grinding mill

Ball Mill Ball Grinding Mill SKE

You can apply our ball mill in ore beneficiation plant to grind iron ore, copper ore, gold ore, lead ore, zinc ore, kaolin, bentonite, feldspar, silica, etc The Grid Type Ball Mill has high discharge speed and high productivity (2030% higher than Stirred milling was developed for fine grained ores that required an economic grind to sub 10 micron sizes The first examples were lead zinc deposits – McArthur River, George Fisher and Fine Grinding as Enabling Technology – The IsaMill2019年8月23日 Zinc processing description from gold geology mineral property to how to extract Zinc from rock and placer deposit, related Zinc processing plant flow chart and layout designZinc Processing Equipment, Process Flow, CasesFine grinding, in particular in the zinc retreatment circuit requiring a milled product P80 of 7 micron, is essential to treat the ores from the Mount Isa Mines depositsISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

Evaluating the performance of an industrialscale high pressure

2023年1月1日 This paper presents the commercial implementation of a novel comminution circuit with high pressure grinding rolls (HPGR) followed by tower mill in a copper–lead–zinc ore dressing plant With a throughput of 650 t/d, the comminution circuit comprises three stages of crushing by a jaw crusher, cone crusher, and HPGR as primary, secondary, and tertiary 2023年5月17日 Stage 2: Leadzinc ore grinding 1 Grinding: The leadzinc ores of 015mm are evenly sent to the ball mill for grinding 2 Classification: After grinding ores, the spiral classifier controls the classification, which can also How to Process LeadZinc Ore by Gravity and Froth 2024年4月26日 The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) Iron Ore Processing: From Extraction to Manufacturing1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;Ball Mill Mining Grinding Mill JXSC Machinery

.jpg)

Ball Mill Is The Key To Grinding Lithium Ore JXSC Machinery

6 天之前 Lithium ore ball mill In the grinding and grading stage of lithium ore, Tin Ore Processing Plant; Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86 [ protected] Factory Address: No16, Gongye Avenue, Guzhang Industrial Park, Ganzhou, Jiangxi, China;2016年4月27日 Lead Ore Grinding Circuit The dewatered minus ½’ ore from the classifier feeds to a 6’x4′ Peripheral Discharge Ball Mill This type of mill was selected to produce a minus 10 mesh product for jigging with a minimum of overgrindingHow to Process LowGrade Lead Zinc Ore by FlotationWet pan mill is mainly used for grinding gold, and it is the grinding equipment favored by the majority of gold mineral processing plants Skip to content JXSC Machinery Us Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86 [ protected]Wet Pan Mill JXSC MachineryWet Grinding Mills is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and other minerals selected With less investment, fast results, small footprint saving power, sturdiness and durability, ease of maintenance and high return on investment It is the preferred production for alternative ball mill, is ideal for small and medium Wet Grinding Mill ore processing

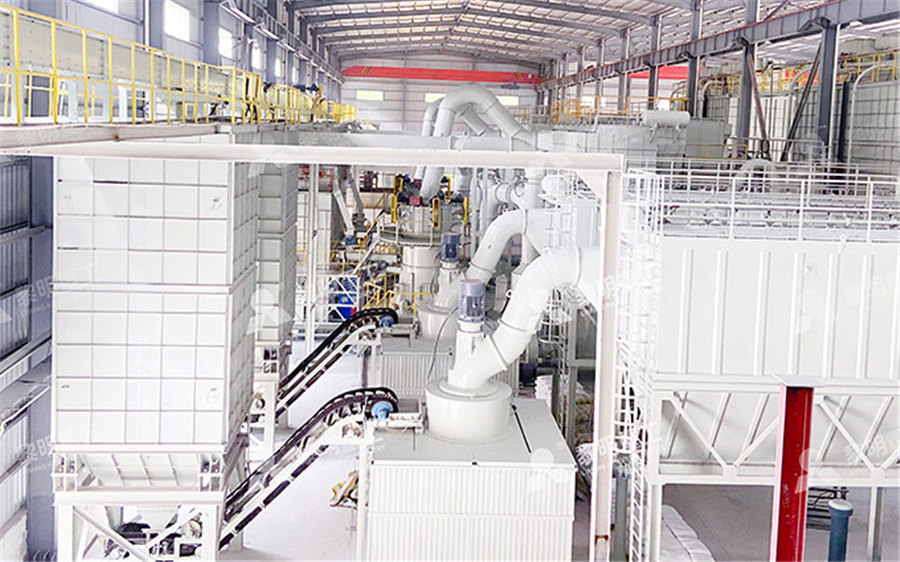

CFB石灰石脱硫剂制备96.jpg)

Fine Grinding as Enabling Technology – The IsaMill

The first examples were lead zinc ore) as grinding media These features distinguish stirred mills as fundamentally different from both ball mills and Tower Mills, as demonstrated by Tables 1 and 2 Table 1 : Typical Power Intensities of different Grinding Devices Table 1: Power Intensity of Different Grinding Devices Ball Mill is a 5 Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreThe core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials, and to separate the tailings, which is Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball MillThe current lead/zinc deposits at Mount Isa Mines (George Fisher, Hilton and Isa) have an average grade of 105% of zinc, 72% of lead and 165g/t of silver Fine grinding, in particular in the zinc retreatment circuit requiring a milled product P 80 of 7 micron, is essential to treat the ores from the Mount Isa Mines depositsISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL 2024年11月21日 Leadzinc sulfide ore flotation is the key to extracting lead and zinc metals from ores, But there still has some +25mm particles , so better send to vibration screen to sieving out 025mm go to ball mill grinding Analysis of LeadZinc Sulfide Ore Flotation JXSC

IMPROVING ZINC RECOVERY AT PERILYA BROKEN HILL

eters line up when grinding the bulk sample collected during the metallurgical survey This task is not trivial Once the Magotteaux Mill® is calibrated, oxygen demand and flotation tests are completed on the ground ore Phase 3 – Media testing: With the Magotteaux Mill® calibrated, alternative grinding me2022年6月17日 Semiautogenous (SAG) mills are widely used grinding equipment, but some ore with critical particle sizes cannot be effectively processed by SAG mills and turned into pebbles This research aims to analyze and compare the properties of raw ore and pebbles from a zinc and tinbearing ore The results show that the contents of sphalerite, cassiterite, biotite, Differences in Properties between Pebbles and Raw Ore from a SAG Mill 2024年8月22日 ball mill 2 Slurry Concentration The adjustment of slurry before flotation is an important part of the flotation process Before the slurry enters the flotation machine, it must be reasonably adjusted (ie “slurry adjustment”) so that the flotation machine can fully play its roleIn most cases, the concentration of slurry adjustment and roughing operation is almost the same Six Factors Affecting The Flotation of Leadzinc OrePb/Zn ores Using synthetic lead–zinc ores (mixing of galena, sphalerite, cerussite and anglesite) they found that sphalerite showed natural floatability, as well as some extent of activation by lead ions, which reduced its separation from galena when ground in a porcelain mill Grinding this ore in an iron mill reduced the natural Effects of grinding environment on the flotation of Rosh

2200 TPD Copper Lead Zinc Ore Processing and Recovery Plant

Savona Equipment Ltd is offering a complete 2200 TPD Copper Lead Zinc Ore Processing and Recovery plant for sale SAG Mill Liner Handler Mclellan 3000; Grinding Area Sump Pump Toyo DEC51805E60HCV; SAG Mill Lubrication System Zinc Regrind: Zn Regrind Mill Cyclone Feed Pump Box; Zn Regrind Ball Mill (600 HP) Allis Chalmers 9' X Zinc ore is an important industrial mineral and it is widely used in the production of various products such as brass, zinc oxide, MTWZ European Trapezium Mill is new product researched and developed by LIMING based on ordinary European type grinding mill Because of more advanced idea Zinc Ore Crusher612 Lead and Zinc Ore beneficiation Due to low zinc content, runofmine zincbearing ores must be concentrated before smelting and refining Beneficiation, which usually occurs at the mine, consists of crushing, grinding, and flotation to produce concentrates of 50 to 60 percent zinc Lead ore also requires processing toLead and Zinc Department of EnergyFigure 3 : Grinding Energy versus Product Size for a Gold Ore IsaMill 2 mm media Ball Mill 80 60 40 20 0 140 120 100 Net E KWh/t 0 10 20 30 40 50 60 70 80 90 100 110 Product P80 microns • Power efficiency is demonstrated by Figure 3, comparing the power required to grind a gold ore in a ball mill with 9 mm balls with an IsaMill with 2 mm mediaIMPROVING FINES RECOVERY BY GRINDING FINER Glencore

Ball Mill Grinding Machines: Working Principle, Types,

They are widely employed in both wet and dry grinding processes for the comminution of materials such as gold, copper, iron, and leadzinc ores Pharmaceutical Industry: Ball mills are utilized in the pharmaceutical industry 2023年8月1日 Some processors use pregrinding with a ball mill or vibratory mill to shorten the grinding time of the stir mill and improve production efficiency and yield How to choose lead zinc ore grinding process and grinding equipment? July 30, 2023 2034 1Zircon Ball Mill, Zircon Grinding Process Zoneding Machinebution after grinding, it could be seen that the ore treated by 7kW microwave power was more conducive to grinding 15 30 45 60 75 0 400 800 1200 1600 Intensity (counts) Twotheta (deg) SiO2 ZnS PbS Figure 1: Xray diffraction pattern of leadzinc ore for grinding test Table 1: Main chemical composition of leadzinc ore Component Pb Zn S Fe Effect of Microwave Pretreatment on Grindability of Lead Zinc Ore2023年9月2日 of a LowGrade Oxidized Lead and Zinc Ore from Lanping Mine Anmei Yu 1,2, Zhan Ding 1,2, of the crushed product was ground by a rod mill China) The grinding time was set to 40 s, 60 s, 80 s, 100 s, and 120 s, and the Minerals 2023, 13, 1167 3 of 16 products were wet sieved by a 74 µm sieve, and the grinding fineness was Process Mineralogy Characteristics and Flotation Optimization of a

.jpg)

Process Mineralogy Characteristics and Flotation Optimization of a

2023年9月2日 The beneficiation of lowgrade oxidized lead and zinc ore from the Lanping mine has attracted extensive interest in the mineral processing field due to the extremely rich resource reserves and the challenge in lead and zinc recovery This study’s objective is to analyze the process mineralogy characteristics and to conduct the flotation optimization of this ore 2023年7月3日 (1) Crushing and Grinding of the Ore The ores occur in nature as huge lumps They are broken to small pieces with the help of crushers or grinders These pieces are then reduced to fine powder with the help of a ball mill or stamp mill This process is called pulverisation (2) Concentration of Ore or Ore BenefactionCrushing, Grinding and Concentration of the Ore2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Wet Pan Mill also known as amalgamation grinding mill, gold grinder mill, which is a versatile ore grinding pan mill for wet materials It’s the best replacement for a mediumsmall capacity ball mill, owing to the excellent performance for wet crushing, small investment, and high output, widely used for separating gold, iron, molybdenum, lead, zinc, antimony, and so onWet Pan Mill JXSC Mineral

Effect of Microwave Pretreatment on Grindability of LeadZinc Ore

2021年7月16日 The influence of microwave pretreatment on grindability of leadzinc ore was studied through comparison analysis on the changes of particle size distribution, percentage of below 0074 mm, energy HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding Mill2023年1月1日 This paper presents the commercial implementation of a novel comminution circuit with high pressure grinding rolls (HPGR) followed by tower mill in a copper–lead–zinc ore dressing plant With a throughput of 650 t/d, the comminution circuit comprises three stages of crushing by a jaw crusher, cone crusher, and HPGR as primary, secondary, and tertiary Evaluating the performance of an industrialscale high pressure 2023年5月17日 Stage 2: Leadzinc ore grinding 1 Grinding: The leadzinc ores of 015mm are evenly sent to the ball mill for grinding 2 Classification: After grinding ores, the spiral classifier controls the classification, which can also How to Process LeadZinc Ore by Gravity and Froth

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;Ball Mill Mining Grinding Mill JXSC Machinery6 天之前 Lithium ore ball mill In the grinding and grading stage of lithium ore, Tin Ore Processing Plant; Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86 [ protected] Factory Address: No16, Gongye Avenue, Guzhang Industrial Park, Ganzhou, Jiangxi, China;Ball Mill Is The Key To Grinding Lithium Ore JXSC Machinery2016年4月27日 Lead Ore Grinding Circuit The dewatered minus ½’ ore from the classifier feeds to a 6’x4′ Peripheral Discharge Ball Mill This type of mill was selected to produce a minus 10 mesh product for jigging with a minimum of overgrindingHow to Process LowGrade Lead Zinc Ore by Flotation

Wet Pan Mill JXSC Machinery

Wet pan mill is mainly used for grinding gold, and it is the grinding equipment favored by the majority of gold mineral processing plants Skip to content JXSC Machinery Us Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86 [ protected]Wet Grinding Mills is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and other minerals selected With less investment, fast results, small footprint saving power, sturdiness and durability, ease of maintenance and high return on investment It is the preferred production for alternative ball mill, is ideal for small and medium Wet Grinding Mill ore processingThe first examples were lead zinc ore) as grinding media These features distinguish stirred mills as fundamentally different from both ball mills and Tower Mills, as demonstrated by Tables 1 and 2 Table 1 : Typical Power Intensities of different Grinding Devices Table 1: Power Intensity of Different Grinding Devices Ball Mill is a 5 Fine Grinding as Enabling Technology – The IsaMillOre ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreThe core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials, and to separate the tailings, which is Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill