ore mill set of equipment mining volume handling related mining equipment

Mining and Mineral Processing Equipment FEECO International Inc

We’ve got you covered whether you need material handling, processing equipment, or transformation of a process byproduct or waste Our equipment and solutions are used Clay Mining and Mineral Processing Equipment FEECO International IncClayBrowse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills technology offer exceptional performance and Grinding mills for mining and minerals processing2024年8月7日 Key types include Ball Mills, which grind ore using steel balls in a rotating cylinder; Rod Mills, which use long rods for a coarser grind; and SAG Mills, which combine crushing and grinding for efficient processing of large Mineral Processing Equipment for Mining Industry

.jpg)

Reliable equipment for iron ore mines FLSmidth

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, Mining companies need specific material handling systems to efficiently move ore materials, minerals or metal products from one location to another Choosing appropriate materials Mining Materials Handling Equipment and Storage SolutionsWith more mines and processing plants running around the clock, mining operators require material handling equipment that is reliable and needs less maintenance Metso's vast assortment of material handling solutions are Material handling MetsoEfficient bulk handling solutions for the minerals mining industry Mined raw materials travel along extensive transport routes Our systems ensure smooth, economical and environmentally friendly processing at each stage of materials Minerals Mining Industry: Bulk Handling and

Mining Equipment Mining Technology

Self Driven Conveyors: the Flexihaul Haulage System and Heavy Equipment for the Mining Industry2022年7月14日 From service trucks to excavation equipment, the typical Australian mining operation requires all types of mining machines This isn’t just because the scale of mining operations has grown, but because mining 10 Types of Heavy Equipment Used in MiningThe Gould Curry mill was sold and by 1873 completely disassembled and removed The Omega Mill was built in its place Related: Arrastras Illustrated in These Historical Photos Epilogue It is almost impossible to describe, let Winning the Metal: Ore Mills of the West Western 2024年7月25日 Highlights 1 Introduction In surface mining, one of the most critical decisions involves the selection of the appropriate equipment This choice, encompassing the handling of materials through excavation and haulage, Equipment Selection and Sizing for Optimum Planning

.jpg)

(PDF) Mining MethodsPart II: Surface MiningPlanning and Design

2010年3月1日 Figures shows: In order to keep the pit dry, There are 40 dewatering pumps around the Cortez pit pumping water out of the ground at a total rate of 30,000 gallons per minuteMining PPE—equipment that miners use to stay safe while working Surface mining equipment—all the tools and mining machines used for surface mining Underground mining equipment—all the tools and mining machines used for underground mining Now that we've covered things at a high level, let's dive into each specific category Mining PPEUltimate Guide to Mining Tools Equipment FlyabilityHard Rock Gold Mining Equipment Definition and Significance of Hard Rock Gold Mining Hard rock gold mining is a method that involves extracting gold from underground deposits of solid rock, rather than from alluvial deposits (sediments in rivers, streams, or other water bodies) This type of mining requires specialized hard rock gold mining equipment and techniques to access Hard Rock Gold Mining Equipment: Essential Gear GuideCONVENTIONAL MINING AND MILLING OF URANIUM ORE Introduction Production of uranium concentrates, in the form of U3O8, or “Yellowcake” as it is commonly referred to in the industry, from ore which is mined by open pit or underground methods and processed to recover uranium, employs technology and methods common to the mining industryConventional Mining Uranium Producers of America

.jpg)

(PDF) Mining Methods: Part ISurface mining ResearchGate

2010年3月1日 PDF Surface mining; to metal mining, because this equipment is best adapted to softer bedded, large volumes of ore are broken in a single blast2015年7月30日 Keywords: Availability, Dragline, Maintainability, Mining Equipment, Overall Equipment Effectiveness (OEE), Performance Measurement, Production Index, Reliability, Shovel, Utilization Breakup of Performance Measurement of Mining Equipment ResearchGate2024年4月26日 Specialized mining equipment, such as drills, loaders, and haulage vehicles, is used to extract the ore from underground The extracted ore is transported to the surface for further processing It's important to note that the choice between openpit and underground mining depends on various factors, including the depth of the deposit, the ore quality, Iron Ore Processing: From Extraction to Manufacturing Mining 2014年4月1日 In conventional mining the selection of the mining equipment (ie main function carriers) which comply with the system requirements, the mining engineer can rely on existing equipment selection Equipment Selection for Surface Mining: A Review

Productivity in mining operations: Reversing the downward trend

volumes became the industry’s top priority Mining companies worldwide largely lost sight of productivity goals that had underpinned operating discipline in the lean years of the 1980s and 1990s, when parts of the industry had set a healthy record in productivity improvement (Exhibit 1) As the demand boom gathered pace, cost increases related toDiscover toptier mining equipment, machinery, and expert services at FLS As a premier provider in the mineral processing industry, we offer innovative solutions and unmatched expertise to enhance productivity From inpit crushing to Mining equipment and services FLS2018年5月1日 The process is usually carried out in compliance with applicable standards eg EN 1 [14] and ISO 20332 [20] for cranes or several standards devoted to the surface mining machinery: AS Material Handling and Mining EquipmentInternational Related Buyer’s Guides which cover an extensive range of mining equipment manufacturers, solutions and suppliers, can also be found here Mining screens, separation and vibration solutions The runofmine (ROM) ore undergoes a series of separation, screening and classification to become suitable for further processingMining Screens Mining Screening Equipment Separation Tools

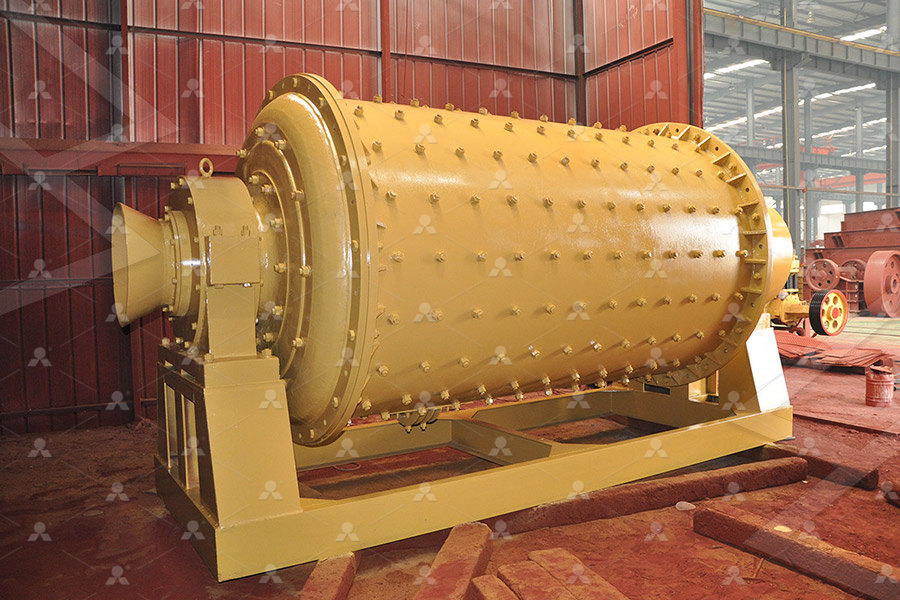

Mining Equipment Iron Ore Rod Mill of Mineral Processing Plant

Mining Equipment Iron Ore Rod Mill of Mineral Processing Plant Working Principle The transmission device drives the cylinder to rotate Materials and water are fed from the feeding end of the cylinder Ores are ground into fine particles by the grinding of steel rods, as well as the impact grinding of ores themselves2020年11月6日 There are two main categories of mining, which are underground mining and openpit mining, also known as opencast mining or surface mining Openpit mining is where the extraction of ore from rock bodies takes place on the surface of the Earth using heavy equipment like drills, shovels, and trucks for efficient and economical operations (Hartman Mutmansky, Introduction: Managing LargeScale Mining OperationsPDF On May 22, 2019, A Chowdu and others published Mine schedule optimization and mine operational realities: Bridging the gap Find, read and cite all the research you need on ResearchGate(PDF) Mine schedule optimization and mine operational realities 2024年3月15日 Mining belt conveyors are versatile and essential components in both surface and underground mining operations Their applications include: Surface Mining: Overburden Removal: Transporting soil and rock away from mining sites Ore Transport: Moving raw ore from the mining site to processing plants or stockpilesTypes of Mining Conveyor Belt: Selection and Implementation Guide

Mining and Ore Handling Mining, Minerals Metals Emerson

2021年5月3日 Mines and ore handling plants that avoid failure by using proven automation and edge technology Better data connectivity and analysis lead immediately to improved operational uptime and asset utilization Like many large processing industries, mining operations use many instruments, valves, pumps, and motor controls2019年5月31日 Working in the mining industry requires the use of different types of machinery These machines help achieve different mining tasks with precision and efficiency If you’re new to mining, it’s A Guide on Mining Equipment Used in the Mining 2020年7月23日 Innovation plays a critical role in the mining industry as a tool to improve the efficiency of its processes, to reduce costs, but also to meet the increasing social and environmental concerns among communities and Innovation in the Mining Industry: Technological In many applications, the task is to move a volume of material from a set of while the stockpiles store supplementary material for ensuring that the mill receives the correct mixing of ore mines International Journal of Surface Equipment Selection for Surface Mining: A Review

.jpg)

Mining Materials Handling Equipment and Storage Solutions

Related Buyer’s Guides which cover an extensive range of mining equipment manufacturers, service providers and technology, can also be found here Bulk mining materials handling and storage solutions Mining companies need specific material handling systems to efficiently move ore materials, minerals or metal products from one location to DOVE is the leader and powerhouse in the mining equipment manufacturing industry and over the last 50 years has produced the largest range of Semistationary Hard Rock Plants (GOLDROCKMINER ® Hard Rock Processing Plants) for small, medium and largescale hard rock mining operations, with the capacity to handle material ranging from 22,000 TPH solidsHard Rock Mining Equipment Crushing Plants DOVEOne of the challenging problems for surface mining operation optimization is choosing the optimal truck and loader fleet This problem is the Equipment Selection Problem (ESP) In this paper, we describe the ESP in the context of surface mining We discuss related problems and applications23 Equipment Selection for Mining: with Case Studies2019年8月29日 Sensor‐Based Ore Sorting Technology in Mining—Past, Present and Future The first is related to dewatering and tailings handling Mill tailings stream s with a particle size of the (PDF) Sensor‐Based Ore Sorting Technology in Mining—Past,

.jpg)

Management of mining, quarrying and oreprocessing waste

• a questionnaire related to the quantities of existing waste, associated with the typology of the mined substance(s), waste deposit(s) and mining systems and oreprocessing method(s), • an estimation, on the basis of the different processes employed throughout the production chain in mining operations and their management at each level, of the2013年12月21日 Dilution is a critical issue that affects many aspects in mining It is generally due to the geometric characteristics of the ore body, the mining operation, the characteristics of geologic contacts, and the limitations of the mining equipment to recover material to the desired boundaries or contactsMining Dilution SpringerLink2017年4月27日 In terms of mining, the geotechnical tests were related to the draw rate and the saturation conditions: a high rate of draw could cause unconsolidated conditions as the strength of the mud (PDF) Geotechnical characterization of ore related to 2022年7月14日 From service trucks to excavation equipment, the typical Australian mining operation requires all types of mining machines This isn’t just because the scale of mining operations has grown, but because mining 10 Types of Heavy Equipment Used in Mining

Winning the Metal: Ore Mills of the West Western

The Gould Curry mill was sold and by 1873 completely disassembled and removed The Omega Mill was built in its place Related: Arrastras Illustrated in These Historical Photos Epilogue It is almost impossible to describe, let 2024年7月25日 Highlights 1 Introduction In surface mining, one of the most critical decisions involves the selection of the appropriate equipment This choice, encompassing the handling of materials through excavation and haulage, Equipment Selection and Sizing for Optimum Planning 2010年3月1日 Figures shows: In order to keep the pit dry, There are 40 dewatering pumps around the Cortez pit pumping water out of the ground at a total rate of 30,000 gallons per minute(PDF) Mining MethodsPart II: Surface MiningPlanning and Design Mining PPE—equipment that miners use to stay safe while working Surface mining equipment—all the tools and mining machines used for surface mining Underground mining equipment—all the tools and mining machines used for underground mining Now that we've covered things at a high level, let's dive into each specific category Mining PPEUltimate Guide to Mining Tools Equipment Flyability

Hard Rock Gold Mining Equipment: Essential Gear Guide

Hard Rock Gold Mining Equipment Definition and Significance of Hard Rock Gold Mining Hard rock gold mining is a method that involves extracting gold from underground deposits of solid rock, rather than from alluvial deposits (sediments in rivers, streams, or other water bodies) This type of mining requires specialized hard rock gold mining equipment and techniques to access CONVENTIONAL MINING AND MILLING OF URANIUM ORE Introduction Production of uranium concentrates, in the form of U3O8, or “Yellowcake” as it is commonly referred to in the industry, from ore which is mined by open pit or underground methods and processed to recover uranium, employs technology and methods common to the mining industryConventional Mining Uranium Producers of America2010年3月1日 PDF Surface mining; to metal mining, because this equipment is best adapted to softer bedded, large volumes of ore are broken in a single blast(PDF) Mining Methods: Part ISurface mining ResearchGate2015年7月30日 Keywords: Availability, Dragline, Maintainability, Mining Equipment, Overall Equipment Effectiveness (OEE), Performance Measurement, Production Index, Reliability, Shovel, Utilization Breakup of Performance Measurement of Mining Equipment ResearchGate

.jpg)

Iron Ore Processing: From Extraction to Manufacturing Mining

2024年4月26日 Specialized mining equipment, such as drills, loaders, and haulage vehicles, is used to extract the ore from underground The extracted ore is transported to the surface for further processing It's important to note that the choice between openpit and underground mining depends on various factors, including the depth of the deposit, the ore quality,