α gypsum powder making process

CNA Technique for producing alphatype

By adopting the technique, the main points of production are put on substep crystal transformation of dihydrate gypsum ore at a low temperature and a low pressure, and washing of the ore byThe production method comprises the following steps: (1) mixing phosphogypsum with a dry basis mass content larger than or equal to 95% with water to prepare slurry; (2) adding a crystal Production method of alphagypsum powder with high strengthDomestic α gypsum high strength gypsum powder production technique has two kinds, and the one, the block pressure of steaming is steamcured, and the one, liquid phase method Process for producing highstrength alphagypsum from chemical 2024年1月17日 The synthesis of αcalcium sulfate hemihydrate (αCSH) from flue gas desulfurization (FGD) gypsum is a good way to realize the comprehensive utilization of FGD Preparation of αHigh Strength Gypsum from Flue Gas

Experimental Study and Mechanism Analysis of

2022年5月9日 In this work, the growth process and crystal structure of αHH were revealed by using test methods such as powder diffraction, scanning electron microscopy, and singlecrystal diffraction Finally, the mechanism of 2020年8月26日 The two steps included are to 1) produce CaSO4•2H2O (DH) using the discharged soda residues and H2SO4; 2) transform DH into agypsum in a mixed solution with additives at 368 K A critical stepUnraveling a Sustainable Process for the Production of 2024年10月14日 This study explored the production of a medium–low strength αhemihydrate gypsum (αHH) from phosphogypsum using an autoclaved method The influence of slurry Preparation of Medium–Low Strength Hemihydrate Gypsum from Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or 1116 Gypsum Manufacturing US EPA

Effect of Soluble Phosphorus on the Mechanical Properties of α

the ahemihydrate gypsum powder for 1 h The gypsum blocks were stored under the test conditions for 24 h and then placed in the drying oven at 40 ± 1 C to constant weight The mechanical strengths of the hardened gypsum pastes were tested by YAW300B microcomputercontrolled compressive fracture tester Characterization Methods2024年7月19日 The stockpiling of phosphogypsum (PG) poses a substantial risk of environmental pollutionTo reduce the stockpile of PG and enhance its value, this research utilized phosphogypsum to produce αhemihydrate gypsum (aHH)The study elucidates the crystallization process of αHH, which involves Ca 2+ helical growth and coordinated filling by New insights into the growth characteristics and crystal 2021年11月1日 Based on its process, HH is further divided into two kinds: αHH and βHH αHH is obtained from the calcination of gypsum in a steamsaturated under increased pressure or using autoclave system, while βHH is obtained from the calcination of gypsum under atmospheric pressure [17] βHH is usually used in the construction industry, whereas αHH, owing to better Preparation of highperformance building gypsum by calcining FGD gypsum 2023年2月22日 αHemihydrate gypsum (αHH) is known as high strength gypsum, the strength of αHHs is three times larger than that of building gypsum, in addition, αHH has good working performance, environmental performance and biological performance [7]So, αHH has been widely used in precision casting, highend building materials, arts and crafts, medical and Effect of modifiers on crystalizing habit and mechanical strength of α

Utilization of phosphogypsum to synthesize αhemihydrate gypsum

2023年3月3日 Phosphogypsum (PG) is a kind of industrial solid waste with high impurity content and low utilization rate In this study, αhemihydrate gypsum (αHH) was synthesized from PG in H 3 PO 4 –H 2 O solution (wetprocess phosphoric acid solution and phosphoric acid solution) under atmospheric pressure The crystal morphology of αHH was controlled by adding F and of different gypsums such as βgypsum, natural gypsumbased αgypsum, desulfurization gypsumbased αgypsum, and the influence of temperature, heating rate/heating mode on the thermal expansion properties of αgypsum are studied, which can provide references for the application of gypsum in the precision casting 1IntroductionSVXPLQWKH$SSOLFDWLRQRI3UHFLVLRQDVWLQJ IOPscience2017年9月1日 It consists of SiO2 (αcristobalite and αquartz) as a refractory and gypsum as a binder During burn out process, the dehydration of gypsum, the inversion of cristobalite and quartz and the III The behavior of gypsumbonded investment in the gold 2021年11月1日 α/βSiAlON composite ceramics using powders mixed through different processes were prepared via spark plasma sintering Effects of different powder mixing methods (ballmilling and ultrasonic vibration with mechanical stirring), ballmilling media (Al 2 O 3 and Si 3 N 4 balls), and mixing times (12 and 24 h) on the components and morphology of mixed Influence of powder mixing processes on phase composition

Effect of phosphate rock acid insoluble residue on hydration process

2023年3月22日 The application of αhemihydrate gypsum (αHH) is limited by several factors, such as a rapid hydration rate, short setting time, poor water resistance, and high cost Especially because of the high production cost, although αHH has excellent mechanical strength, it is rarely used in the field of building materials In this study, based on the composition characteristics of 2005年3月8日 Download Citation Autoclave‐Free Formation of α‐Hemihydrate Gypsum Flue gas gypsum may be converted to αhemihydrate by suspending the starting material in inorganic salt solutions of Autoclave‐Free Formation of α‐Hemihydrate GypsumWith a wide choice of gypsum powder making machine options and related wood machinery, look no further than Alibaba All categories Featured selections Trade Assurance Gypsum Powder Manufacturing Process Gypsum Powder Making Machine Gypsum Powder Machines $8,70000$8,88000 $14,50000$14,8000040% Min Order: 1 setPowerful Gypsum Powder Making Machine At Low Prices2023年1月31日 Preparation of αhemihydrate gypsum crystal is an approach for utilization of phosphogypsum (PG), but the soluble phosphorus impurities in PG have a crucial influence on the performance of αhemihydrate gypsum In this article, different forms of soluble phosphorus (H3PO4, H2PO4− and HPO42−) on the setting time and mechanical properties of α Effect of Soluble Phosphorus on the Mechanical Properties of α

ALPHA GYPSUM ksentials

Gypsum for the manufacture of roofing tiles In the heavy ceramics industry, as in the manufacture of highquality clay roof tiles, gypsum moulds maybe a more expensive option, but they guarantee a particularly high product quality Our 2007年10月24日 A technology of gypsum powder and liquid phase method, which is applied in the field of α gypsum powder production, which can solve problems such as unstable product performance, uneven heating, temperature adjustment, etc, and achieve stable product performance, small restrictions, and simple processProcess for producing alpha gypsum powder by liquid phase The work investigates the physical, mechanical, and technological properties of mixtures to manufacture cores in a foundry The filler is technical salt, the binder is an aqueous solution of The physical properties of different gypsum powdersDownload Citation On Nov 1, 2023, Shuangxi Zhou and others published Flowability prediction of recycled αhemihydrate gypsum for 3D powder printing under combined effects of different glidants Flowability prediction of recycled αhemihydrate gypsum for 3D powder

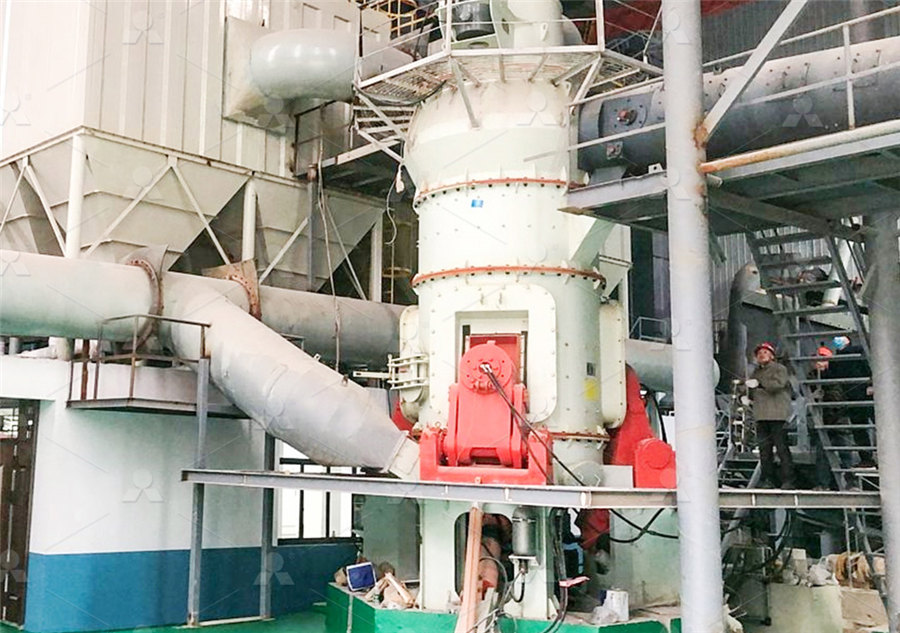

Upgrade Your Process: 3 Best Gypsum Powder Mills

2024年9月26日 2 Ultrafine mill Get the Latest Price As an advanced grinding mill combining crushing, grading, and static pressure, the ultrafine mill excels in both fineness and environmental performance It is mainly used to produce ultrafine gypsum powder or micronlevel particles, and is widely used in industries requiring highfineness powders, such as chemicals, coatings, and 2020年11月23日 DOI: 1037190/ppmp/ Corpus ID: ; Preparation of αcalcium sulfate hemihydrate from industrial byproduct gypsum: A review @article{Guan2020PreparationO, title={Preparation of $\alpha$calcium sulfate hemihydrate from industrial byproduct gypsum: A review}, author={Qingjun Guan and Ying Sui and Fangming Preparation of αcalcium sulfate hemihydrate from industrial by α formed in gypsum along caxis Figure 12 αHH The newly formed αHH α crystals can be collected by tweezers; these crystals are not firmly attached to the gypsum or the βHH β These αHHαcrystals were placed in a special measuring cell for optical microscopy, as described by Pritzel et al [18], and the rehydration process was followedFormation of αHemihydrate Inside of a Gypsum Crystal during 2014年10月1日 This paper introduced the characteristics of α highstrength gypsum preparation from FGD gypsum by autoclaved semidry process The compositions of the product in different stages of the reaction and the effects of crystal modifiers on the morphology of the αHH crystals were examined and compared The properties of αHH and the feature of hydration products Preparation of α HighStrength Gypsum from FGD Gypsum by

.jpg)

Preparation and characterization of gypsumbased materials

2018年8月17日 In this study, gypsumbased materials (GM) comprising mainly αhemihydrate gypsum, polycarboxylate, hydroxypropyl methyl cellulose and starch ether were prepared and used for 3D robocasting (3DR) The setting time and rheological properties of the GM slurry and the physical properties of the GM sample, including bulk density, porosity and mechanical 2024年10月14日 This study explored the production of a medium–low strength αhemihydrate gypsum (αHH) from phosphogypsum using an autoclaved method The influence of slurry concentration, spreading thickness, crystallizing agents, slurry pH, autoclaving temperature, and autoclaving time on the properties of αHH was investigated The energy consumption of Preparation of Medium–Low Strength Hemihydrate Gypsum from 2018年5月1日 Request PDF Synthesis of αhemihydrate gypsum from cleaner phosphogypsum Phosphogypsum (PG), as a waste byproduct with high content and complicated impurities, is difficult to be utilised Synthesis of αhemihydrate gypsum from cleaner phosphogypsum2022年1月7日 Phosphogypsum (PG) is a massive industrial solid waste In this paper, PG was purified by flotation method, and αhemihydrate gypsum (αHH) was prepared by the autoclaving method The morphology The study on the effect of flotation purification on the performance

.jpg)

Gypsum hydration: A theoretical and experimental study

PDF On Jan 1, 2009, QL Yu and others published Gypsum hydration: A theoretical and experimental study Find, read and cite all the research you need on ResearchGate2019年7月30日 To obtain αhemihydrate from gypsumbearing wastes, the salt solution method is often considered [19][20][21][22][23][24][25] In this case, dehydration is carried out in a solution of salts (Na Preparation of αhemihydrate gypsum from phosphogypsum in 2017年8月1日 A facile method to transform flue gas desulfurization gypsum (FGD gypsum) to α calcium sulfate hemihydrate (αHH) whiskers with high aspect ratios mediated by cetyltrimethylammonium bromide A facile method of transforming FGD gypsum to αCaSOThus, there is a need to provide an improved method of making a gypsum board so as to improve the control and delivery of the dry additives DETAILED DESCRIPTION [0004] Generally speaking, the present publication is directed to a method of making a gypsum slurry and a gypsum board using a particular dry additive delivery systemMETHOD OF PROVIDING DRY ADDITIVES FOR A GYPSUM BOARD MANUFACTURING PROCESS

Essential Guide to Gypsum Powder Manufacturing Process

2024年11月5日 This essential guide will delve into the gypsum powder manufacturing process, highlighting key steps, equipment used, and best practices for ensuring quality 1 Mining and Crushing The journey of gypsum powder begins with the raw material extraction Gypsum deposits are primarily found in sedimentary rock layersc( (%) (%)The study on the effect of flotation purification on the the ahemihydrate gypsum powder for 1 h The gypsum blocks were stored under the test conditions for 24 h and then placed in the drying oven at 40 ± 1 C to constant weight The mechanical strengths of the hardened gypsum pastes were tested by YAW300B microcomputercontrolled compressive fracture tester Characterization MethodsEffect of Soluble Phosphorus on the Mechanical Properties of α 2024年7月19日 The stockpiling of phosphogypsum (PG) poses a substantial risk of environmental pollutionTo reduce the stockpile of PG and enhance its value, this research utilized phosphogypsum to produce αhemihydrate gypsum (aHH)The study elucidates the crystallization process of αHH, which involves Ca 2+ helical growth and coordinated filling by New insights into the growth characteristics and crystal

Preparation of highperformance building gypsum by calcining FGD gypsum

2021年11月1日 Based on its process, HH is further divided into two kinds: αHH and βHH αHH is obtained from the calcination of gypsum in a steamsaturated under increased pressure or using autoclave system, while βHH is obtained from the calcination of gypsum under atmospheric pressure [17] βHH is usually used in the construction industry, whereas αHH, owing to better 2023年2月22日 αHemihydrate gypsum (αHH) is known as high strength gypsum, the strength of αHHs is three times larger than that of building gypsum, in addition, αHH has good working performance, environmental performance and biological performance [7]So, αHH has been widely used in precision casting, highend building materials, arts and crafts, medical and Effect of modifiers on crystalizing habit and mechanical strength of α 2023年3月3日 Phosphogypsum (PG) is a kind of industrial solid waste with high impurity content and low utilization rate In this study, αhemihydrate gypsum (αHH) was synthesized from PG in H 3 PO 4 –H 2 O solution (wetprocess phosphoric acid solution and phosphoric acid solution) under atmospheric pressure The crystal morphology of αHH was controlled by adding F and Utilization of phosphogypsum to synthesize αhemihydrate gypsum of different gypsums such as βgypsum, natural gypsumbased αgypsum, desulfurization gypsumbased αgypsum, and the influence of temperature, heating rate/heating mode on the thermal expansion properties of αgypsum are studied, which can provide references for the application of gypsum in the precision casting 1IntroductionSVXPLQWKH$SSOLFDWLRQRI3UHFLVLRQDVWLQJ IOPscience

.jpg)

The behavior of gypsumbonded investment in the gold

2017年9月1日 It consists of SiO2 (αcristobalite and αquartz) as a refractory and gypsum as a binder During burn out process, the dehydration of gypsum, the inversion of cristobalite and quartz and the III 2021年11月1日 α/βSiAlON composite ceramics using powders mixed through different processes were prepared via spark plasma sintering Effects of different powder mixing methods (ballmilling and ultrasonic vibration with mechanical stirring), ballmilling media (Al 2 O 3 and Si 3 N 4 balls), and mixing times (12 and 24 h) on the components and morphology of mixed Influence of powder mixing processes on phase composition 2023年3月22日 The application of αhemihydrate gypsum (αHH) is limited by several factors, such as a rapid hydration rate, short setting time, poor water resistance, and high cost Especially because of the high production cost, although αHH has excellent mechanical strength, it is rarely used in the field of building materials In this study, based on the composition characteristics of Effect of phosphate rock acid insoluble residue on hydration process 2005年3月8日 Download Citation Autoclave‐Free Formation of α‐Hemihydrate Gypsum Flue gas gypsum may be converted to αhemihydrate by suspending the starting material in inorganic salt solutions of Autoclave‐Free Formation of α‐Hemihydrate Gypsum