Mechanical limestone powder production line

.jpg)

Limestone Grinding Mill Plant TAYMACHINERY

5 天之前 The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of 2018年8月30日 Incorporating superfluous fine limestone powder or coarse limestone powder increases the porosity of cementbased materials due to dilution effect The chemical effect of A review on use of limestone powder in cementbased 2018年12月20日 It has been welldocumented that limestone powder in concrete mainly showed filler, nucleation, dilution and chemical effects, and they were influence by the particle size, Review A review on effects of limestone powder on the 2024年3月5日 The objective of this study is to investigate the performance of normal and highstrength concretes including limestone powder (LP) through their mechanical properties Moreover, sustainable flat plates made of these Effectiveness of Limestone Powder as a Partial

Limestone powder production lineLIMING HEAVY

Limestone powder production line Equipment: LM vertical roller mill Material: Limestone Capacity: 25TPH Output size: 200 mesh Location: Philippines Using time: 年5月25日 Compared with the control sample without limestone powder (LP), the mechanical properties of the sample with 30% LP can be significantly improved by using a Effect of High Content Limestone Powder on Microstructure 2021年3月28日 The results confirmed that 15% LSP was the optimum amount, which is responsible for the highest mechanical strength, lowest water absorption and lowest charge Effect of limestone powder on mechanical strength, 2022年6月22日 By adding 10%–40% by weight LSP, the flowability, mechanical, and microstructure properties of LSPMOC pastes (MOC pastes mixed with LSP) were Impact of Limestone Powder on the Mechanical and

.jpg)

The Effects of Fly Ash, Blast Furnace Slag, and

2023年12月7日 This study investigates the alterations in the ratios of components such as class C fly ash (FA), blast furnace slag (BFS), and waste stone powder (WSP) types of limestone powder (LP) used in the production of 2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines Lime Production Process and Required 6 天之前 Project case: 500 t/d active lime production line in Thailand In June 2019, a customer from Thailand inquired about the lime production line According to his output and final product demand, we recommended this Lime Kiln for Lime Production Fote Machinery2020年10月1日 The composited cementitious materials usually have superior performance; for example, using limestone powder (LP) and fly ash (FA) as the admixtures of cement in concrete/mortar is a popular way of improving the Investigation on Hydration and Mechanical

.jpg)

Evaluation of the Efficiency of Limestone Powder in Concrete and

2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of 2024年10月31日 Manufactured sand concrete (MSC) has increasingly applied in engineering However, how to enhance the thermal crack resistance of MSC has not clearly studied yet, which limits the wide applications of manufactured sand in engineering We have adopted the method of mixing limestone powder (LP) to make MSC with four mass fractions (wt%) of 5%, 10%, 15%, Harnessing Limestone powder to enhance the thermal crack 2023年12月2日 22 Mix proportions, specimen preparation, and test methods 221 Mixing ratio design In order to ensure that the working and mechanical properties of the mortar meet the engineering needs, the amount of cementitious material was first determined and was selected as 900 kg/m 3Based on this determined amount of cementitious materials, the content of Methods of improving the workability and mechanical 2015年2月1日 Mechanical properties, durability, and lifecycle assessment of selfconsolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder February 2015 Cement Mechanical properties, durability, and lifecycle assessment

.jpg)

Gypsum Powder Production Line Hebei Xiangyi Mechanical

Gypsum powder production line can not only process gypsum, but also process ultrafine powder of medium and low hardness, nonflammable and explosive brittle materials with Mohs hardness ≤6 Such as calcite, chalk, limestone, dolomite, carbon black,2016年6月4日 specific gravity of cement and limestone powder Type I OPC has a specific gravity of 315, while that of limestone powder is 270 Replacing the cement with limestone powder will affect the density, and since the density affects the compressive strength of concrete, it will result in lower strength (Neville, 2011) 314 Air ContentThe Effects of Limestone Powder Particle Size on the 2022年1月27日 In this work, metakaolin and red mudbased geopolymer specimens were produced with three categories of different filler materials (limestone powder, marble powder, and basalt powder), replaced with river sand of different ratios 25, 50, and 75% The mixture is activated with an activator that consists of sodium silicate (Na2SiO3) and sodium hydroxide Elevated Temperature, Freezing–Thawing and Mechanical2022年1月31日 Regarding the mechanical properties, all the ternary binders with brick powder analyzed here showed higher compressive strength that the CEM II binary mortar with limestone studied by IbáñezGosálvez et al 43 In Microstructure and mechanical properties of

.jpg)

(PDF) Mechanical properties and durability

2014年5月13日 Mechanical properties and durability characteristics of SCC incorporating crushed limestone powder May 2014 Journal of Sustainable CementBased Materials 4(3):1年1月22日 The objective of this research is to study the effect of partial substitution (0 %, 9 %, 16 %, 23 % and 30 %) of cement by limestone powder focusing on slender precast structures, natural sand Effect of limestone powder substitution on 2023年12月6日 Recently, the HGM100 ultrafine mill production line of a customer in Binzhou, Shandong, China has been installed and officially put into production The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, the grade of the finished product is quite high, and the actual Limestone ultrafine grinding production line customer site2021年2月1日 The average modulus of elasticity at 28 days with a mixture of limestone powder as fine aggregate and limestone split as coarse aggregate produced a value of Ec = 4696025 MPa (6325 √f’c) with (PDF) The mechanical properties of limestone as an

.jpg)

Evaluation of Physical and Mechanical Properties of Modified

2024年11月6日 This study aims to incorporate building and demolition waste, including lime and crushed granite, as partial alternatives for cement and fine aggregates, respectively, and to devise a plan to reduce their environmental effect resulting from their extensive prevalence in substantial amounts The use of lime in paste, mortar, and concrete has become a common practice to 2024年10月24日 In today’s era of rapid infrastructure development, ensuring the durability and environmental sustainability of soil subgrades in road construction remains a critical concern With recent advancements in nontraditional soil stabilizing binders, including environmentally friendly industrial waste materials such as fly ash and slag, there is growing recognition of the potential Evaluating the Efficacy of Limestone Powder as a Partial2017年8月1日 The inclusion of limestone powder (LSP) in cementitious systems is desirable considering its relatively low cost and reduction of CO 2 emissions from cement production while maintaining adequate Effect of limestone powder on the rheological, mechanical 5 天之前 The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material Limestone Grinding Mill Plant TAYMACHINERY

.jpg)

Limestone powder making plant Raymond MillVertical

Limestone powder making plant Hezhou City ultrafine calcium carbonate vertical roller mill production line Hangzhou CRLM2000 Learn More View More Cases Obtaining Proposals and Quotations is one of the two major manufacturers of grinding equipment designated by the former Ministry of Electrical and Mechanical Services2024年2月10日 The impact of nanolimestone (NL) on the properties of pervious concrete (PC) is the focus of this study The work explores workability, paste drain down, porosity via CT scanning, hardened density, mechanical strength, infiltration, and microstructural properties of PC Field emission scanning electron microscopy, Xray diffraction, and Fourier transform infrared Exploring the impact of nanolimestone cementitious 2022年10月20日 The limestone powder had a decisively negative effect on the tensile and flexural strength of the epoxy coating The addition of limestone powder in the amount of 7%–29% by weight in the coating caused a decrease in the tensile strength of the coating by 60–62%Recycling of waste limestone powders for the cleaner production 2021年7月19日 Limestone powder has been used as either ‘inert filler’ or supplementary cementitious materials in multiple systems for a long time [6]In cementbased materials, the LS powder mainly affect the matrix’s properties by filler, nucleation, dilution and chemical effects [6]In slagconcrete, the addition of LS can improve the earlystrength and workability of the Chemical and physical effects of highvolume limestone powder

.jpg)

Evaluation of mechanical properties and environmental

2022年4月20日 Further, higher temperature peaks and high autogenous shrinkage was observed in finer limestone mixtures due to nucleation effect and accelerating hydration reaction by finer limestone particles2020年1月1日 Partial substitution of cement by limestone powder, as studied by Nepomuceno, Oliveira and Lopes [13], presented 20 %, 40 % and 60 % substitution, showed that it can enhances rheological properties of cohesion, avoiding particles segregation [13]Varhen [15], on his study, approaches the substitutions of fines, cement and filler, for 2 %, 60 % and 80 % by Effect of limestone powder substitution on mechanical properties and 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder 2024年10月25日 Limestone powder, as particles with a particle size of less than 75 μm, is produced in the production process of manufactured sand As an important part of manufactured sand, the influence and mechanism of limestone powder content on concrete performance is one of the hot issues in research [4], [5], [6], [7]Effect of limestone powder on mechanical properties of

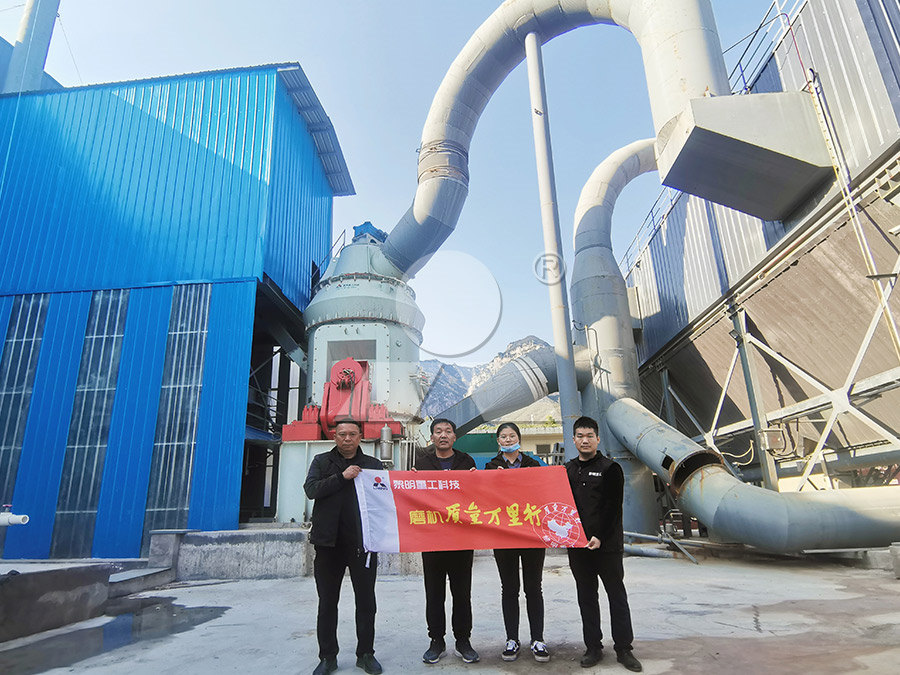

China Henan limestone ultrafine vertical mill production line

Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shapeChina Gypsum Powder Production Line wholesale Select 2024 high quality Gypsum Powder Production Line products in best price from certified Chinese Liquid Line manufacturers, Concrete Pump suppliers, wholesalers and factory on MadeinChina Shandong Tengfei Mechanical and Electrical Technology Co, Ltd 10t15t Fully Automatic Dry China Gypsum Powder Production Line, Gypsum Powder Production Line 2018年12月20日 Limestone powder is one of the alternatives recently attracted many researchers due to its wide availability and low cost K Tosun, B Felekoglu, A Altun, Determination of optimum limestone content in Portland limestone cement production from the viewpoint of mechanical performance and sulfate originated durability problems, TUBITAK Review A review on effects of limestone powder on the 2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines Lime Production Process and Required

.jpg)

Lime Kiln for Lime Production Fote Machinery

6 天之前 Project case: 500 t/d active lime production line in Thailand In June 2019, a customer from Thailand inquired about the lime production line According to his output and final product demand, we recommended this 2020年10月1日 The composited cementitious materials usually have superior performance; for example, using limestone powder (LP) and fly ash (FA) as the admixtures of cement in concrete/mortar is a popular way of improving the Investigation on Hydration and Mechanical 2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of Evaluation of the Efficiency of Limestone Powder in Concrete and 2024年10月31日 Manufactured sand concrete (MSC) has increasingly applied in engineering However, how to enhance the thermal crack resistance of MSC has not clearly studied yet, which limits the wide applications of manufactured sand in engineering We have adopted the method of mixing limestone powder (LP) to make MSC with four mass fractions (wt%) of 5%, 10%, 15%, Harnessing Limestone powder to enhance the thermal crack

Methods of improving the workability and mechanical

2023年12月2日 22 Mix proportions, specimen preparation, and test methods 221 Mixing ratio design In order to ensure that the working and mechanical properties of the mortar meet the engineering needs, the amount of cementitious material was first determined and was selected as 900 kg/m 3Based on this determined amount of cementitious materials, the content of 2015年2月1日 Mechanical properties, durability, and lifecycle assessment of selfconsolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder February 2015 Cement Mechanical properties, durability, and lifecycle assessment Gypsum powder production line can not only process gypsum, but also process ultrafine powder of medium and low hardness, nonflammable and explosive brittle materials with Mohs hardness ≤6 Such as calcite, chalk, limestone, dolomite, carbon black,Gypsum Powder Production Line Hebei Xiangyi Mechanical 2016年6月4日 specific gravity of cement and limestone powder Type I OPC has a specific gravity of 315, while that of limestone powder is 270 Replacing the cement with limestone powder will affect the density, and since the density affects the compressive strength of concrete, it will result in lower strength (Neville, 2011) 314 Air ContentThe Effects of Limestone Powder Particle Size on the

Elevated Temperature, Freezing–Thawing and Mechanical

2022年1月27日 In this work, metakaolin and red mudbased geopolymer specimens were produced with three categories of different filler materials (limestone powder, marble powder, and basalt powder), replaced with river sand of different ratios 25, 50, and 75% The mixture is activated with an activator that consists of sodium silicate (Na2SiO3) and sodium hydroxide