Longitudinal swing grinding mill

Review on vertical roller mill in cement industry its

2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system 2022年12月31日 In the experiment, the swing grinding CNC machine tool was used to grind the camshaft and the physical drawing of the equipment is shown in Fig 3 The longitudinal micro Experimental study of the influence of swing grinding Technical advantages of longitudinal swing mill (1) Brand new grinding system: 1 The new technology adopts a new longitudinal pendulum grinding roller device The grinding roller and Longitudinal Pendulum Type Millluqi2023年5月23日 Ultrasonic vibration–assisted grinding is an effective method for improving the surface quality of brittle and hard materials The grinding force is one of the key factors Modeling of grinding force in longitudinal ultrasonic

Extremum seeking control for optimization of an openloop grinding mill

2022年6月1日 In this study, a classical perturbationbased method, a timevarying parameter estimationbased method and the Nelder–Mead simplex method are employed as extremum 2023年9月27日 The longitudinaltorsional coupled rotary ultrasonic machining (LTCRUM) is regarded as an effective processing for the material; however, the SiC f /SiC composite’s Longitudinaltorsional coupled rotary ultrasonic machining 2019年6月1日 The method of calculating the kinematics of motion of grinding media in a mill with longitudinal and transverse motion of the grinding media is described and formulae for determining theMechanics of the grinding media in ball mills 2023年8月10日 The longitudinal twist compound ultrasonic vibration grinding test was mainly set up with different grinding parameters (spindle speed, feed rate and depth of cut) to compare ultrasonic grinding of SiC and ordinary grinding Precision Grinding Technology of Silicon Carbide

.jpg)

(PDF) The latest innovative technology for vertical roller mills

2014年4月1日 The newly developed MVR roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12 000 kW was specifically designed to 2021年2月15日 Cylindrical Grinding is a process where you use a grinding wheel rotating in a horizontal axis to cut or grind a cylindrical workpiece mounted on a chuck or between centers rotating in an axis parallel to the grinding Cylindrical Grinding Fine MetalWorking2003年9月22日 Swing hammer mills have been used for a long time in the Australian coal industry to prepare coke oven feed Coke quality is controlled by coal properties, bulk material properties and coke oven parameters It is also controlled by feed preparation, in particular the best grinding process to achieve an optimum size distribution for coking An energybased model for swing hammer mills2023年11月4日 Figure 1 shows the diagram of UASG and UAEG; where the workpiece coordinate system OXYZ is taken as the global coordinate system, a p is the grinding depth (μm), b is the grinding width (mm), and A is the ultrasonic amplitude (μm) As shown in Fig 1(a) and (b), the longitudinal ultrasonic vibrations are parallel and perpendicular to the machined surface Longitudinal ultrasonic vibration effects on grinding

Review on vertical roller mill in cement industry its

2021年1月1日 Swing type stacker Reclaimer: Limestone other raw material are stored in open area into a longitudinal storage unit called stockpile through Stacker These are then extracted transversely from the stockpile through reclaimer The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from 3 天之前 RGrind Cylindrical Grinding Machine Series Our highperformance manual cylindrical grinding machines are built with highquality Meehanite cast iron with heavy ribbing to ensure high overall stiffness, even with heavy workpieces These cylindrical grinders for sale feature a precision grinding spindle for high accuracy and repeatabilityCylindrical Grinders Industrial Grinders KAAST Machine Tools2024年10月26日 Swing Type Grain Mill: Versatile Grinding for Various Ingredients Its swing type design allows for versatile grinding You can use it for various ingredients, including spices, coffee, and dry grains Any kitchen can use it due to its versatility The design ensures that the grinder can handle different textures and consistenciesVEVOR 1000g Electric Grain Mill Grinder, 3750W HighSpeed 2023年5月2日 Artudatech Stainless Steel Electric Grain Mill, available on Wayfair The hopper/crush cabin holds up to 105 ounces of food The lid is securely fastened in place with two large clamps When finished, the swing design makes it easy to tip the crush cabin contents into a bowl or canisterThe Best Countertop Grain Mills and Flour Grinders in 2023 Foodal

.jpg)

Modeling of grinding force in longitudinal ultrasonic

2024年3月21日 usually used instead of the end grinding force Therefore, in this paper, the grinding force of LUVAG is divided into three parts: side grinding chip formation force Fig 1 The diagram of ultrasonic vibration–assisted grinding Fig 2022年10月6日 Effect of crack propagation on surface formation mechanism and surface morphology evaluation of longitudinal–torsional composite ultrasonic millgrinding of Si3N4 October 2022 DOI: 1021203/rs3 Effect of crack propagation on surface formation mechanism Technical advantages of longitudinal swing mill (1) Brand new grinding system: 1 The new technology adopts a new longitudinal pendulum grinding roller device The grinding roller and the grinding ring are always in a balanced state during the grinding process Longitudinal Pendulum Type MillluqiCheap grinder, Buy Quality grinding machine directly from China swing grinder Suppliers:1000g Swing Full Stainless Herb Grinder/ stone Grinding Machine/Coffe grinder Jones Lamson 8 x 48 (19 Swing) Thread Grinding Machine Swing Grinding Machine Crusher Mills, Cone Crusher, Jaw

Grinding Media in Ball Mills for Mineral Processing

2023年11月24日 Autogenous and semiautogenous mills are used in primary grinding whilst rod and ball mills are used in secondary grinding, with the ball mills being the most commonly used The ball mills are either used in a drymilling or wetmilling setup depending on the needs of the industry in which they are utilised2022年10月11日 trajectory, (c) circumferential trajectory, and (d) combined longitudinal–torsional trajectory By coupling the longitudinal and torsional ultrasonicassisted millgrinding motions, the trajectory of the grinding grain in the longitudinal–torsional composite ultrasonicassisted millgrinding process can be obtained, as shown in Fig 1(d)Effect of crack propagation on surface formation 2024年9月30日 LowStress Grinding and Polishing: Our longitudinal polisher system TensilePolish GR04 minimizes surface stress by making use of controlled and precise polishing methods This is critical for maintaining material integrity, especially in specimens intended for highstress testing environments like fatigue or tensile testingAutomatic Longitudinal Polisher System: A Review by 2024年11月24日 These mills use balls or beads to crush, grind, or impact materials with high kinetic energy, resulting in rapid and efficient size reduction Highenergy ball mills are commonly used for grinding hard and brittle materials, such as metals, alloys, ceramics, and mineralsLab Milling and Grinding from ColeParmer India

.jpg)

SWING MILL GRINDER SP2000 SCP SCIENCE

2013年2月7日 SWING MILL GRINDER SP2000 SP2000 SWING MILL GRINDER Catalog Number Catalog Number Capacity (in / cm) Power Size (in / cm) Weight (lbs / kgs) 010010200 (208 V, 60 cycle) 010010250 (230V, 50 cycle) 5 x 7 / 13 x 18 3 phase, 1HP 25 W x 25 D x 41 H* / 64 W x 64 D x 104 H* 480 / 1056 SCP SCIENCE Providing Innovative Solutions to Analytical 2024年7月8日 milling和grinding的区别: 一、明确答案 Milling和grinding都是材料加工中常用的工艺方法,但二者之间存在明显的区别。Milling主要是指通过切削的方式去除材料,而grinding则是通过研磨来平滑表面或减小尺寸。二、详细解释 1 定义与原理milling和grinding的区别 百度知道2019年11月13日 mill 、 grit 、grind的磨,有什么区别?你好。希望以下的解答能为你解惑。三个词你查字典都有磨的意思,但有区别。【mill】:碾磨。特别是磨成粉状都用这个词。【grit】: 这个词做 磨 讲,一般只用在 咬牙切齿 上,mill 、 grit 、grind的磨,有什么区别? 百度知道Longitudinal segregation effects also occur This paper presents and discusses these results and illustrates how the new acoustic knowledge can be used to manage and improve mill operation and stabilityx000D Citation: Pax, R and Cornish, B, 2016 Understanding Size Effects of Semiautogenous Grinding (SAG) Mill Operation as a Pathway to Understanding Size Effects of Semiautogenous Grinding (SAG) Mill

.jpg)

Automatic Longitudinal Polisher System TensileMill CNC

The Longitudinal Polisher ver GR 04 offers many main advantages, including longitudinal polishing and lowstress grinding, the ability to polish specimens of assorted geometries, automatic polishing with four different grades of sandpaper, and automatic change of sandpaper and cleaning during the polishing process2022年3月30日 Various components and machines are used for grinding applications and that’s where highenergy ball mill comes into play Overview of Ball Mill Ball mill, also known as tumbling or pebble mill is milling equipment Introduction to HighEnergy Ball Mill: Working 2023年12月4日 Electric Grain Mill Grinder, 247 oz Blade 3750W Commercial Coffee Grinder, Stainless Steel Pulverizer Powder Machine (2) Questions Answers (6) Hover Image to Zoom Share Print $ 145 51 Swing Grinder: The swing type is more convenient than the upright type You could swing the commercial spice grinder body 270° to help pour instead of VEVOR Electric Grain Mill Grinder, 247 oz Blade 3750W 2021年4月27日 Condition in one of the grinding chambers of the mill Results of Optimization The graphical analysis presented in Figure 2 represents progress of grinding along the length of the mill after optimizing the grinding process rogress of grinding is clearly visible in Desired p the graphs Figure 2: Analysis of longitudinal samplesOPTIMIZATION OF CEMENT GRINDING OPERATION IN

.jpg)

Precision Grinding Technology of Silicon Carbide (SiC)

2023年8月10日 This is due to the fact that the bottom of the mill head first touches the workpiece at the beginning of stage 1, when the material removal mainly relies on the bottom edge of the mill head the maximum crushing depth of subsurface wear of SiC ceramics processed by ordinary grinding and longitudinal twist compound ultrasonic vibration 2019年11月1日 The rotary vibration mill with inclined mill shell creates grinding conditions for almost all grinding bodies, which increases the efficiency of grinding in general(PDF) Optimization of material grinding in vibration mills2022年12月31日 The swing grinding method is an excellent choice for the manufacturing of the largewidth cam to avoid the grinding defects and form splendid surface quality Since the influence of swing grinding parameters on machining surface quality has not been clearly clarified, experimental study was conducted in the paper The orthogonal experiment was designed, Experimental study of the influence of swing grinding Hammer mills Hammer mills such as the Pulverizer MP swing hammer mill are suitable for shredding soft to mediumhard products Here, crushing is achieved using rotating hammers that strike the material to be ground The hammers also fling the ground material against the mill wall, where it is further broken up due to the impactGrinding Hosokawa Alpine

.jpg)

DYNO®MILL KD WAB

By consistently expanding the variety of materials, the material quality and, if necessary, by adapting the DYNOMILL KD models to highly specialized customer requirements, this type of agitator bead mill has been used in many applications for decades since todayThe DYNOMILL KD disc mills are available with grinding chamber volumes from 015 to 600 liters and are 2021年1月16日 Surface Grinder 101: What is a surface grinder and how do grinding machines work? See different types of surface grinders and their uses to pick the best one and the table with Tslots is mounted on the saddle and has longitudinal movements You can mount magnetic chuck, vice and fixture on the table for clamping the workpieces or Surface Grinder Types of Grinders How They Work Fine The mill consists of the lower casing, uppercasing, table mounted on the vertical planetary gear reducer, and the grinding roller supported by the swing levers The separator is installed at the upper parts of the millVRM – AMCL Machinery Limited2021年2月15日 Cylindrical Grinding is a process where you use a grinding wheel rotating in a horizontal axis to cut or grind a cylindrical workpiece mounted on a chuck or between centers rotating in an axis parallel to the grinding Cylindrical Grinding Fine MetalWorking

An energybased model for swing hammer mills

2003年9月22日 Swing hammer mills have been used for a long time in the Australian coal industry to prepare coke oven feed Coke quality is controlled by coal properties, bulk material properties and coke oven parameters It is also controlled by feed preparation, in particular the best grinding process to achieve an optimum size distribution for coking 2023年11月4日 Figure 1 shows the diagram of UASG and UAEG; where the workpiece coordinate system OXYZ is taken as the global coordinate system, a p is the grinding depth (μm), b is the grinding width (mm), and A is the ultrasonic amplitude (μm) As shown in Fig 1(a) and (b), the longitudinal ultrasonic vibrations are parallel and perpendicular to the machined surface Longitudinal ultrasonic vibration effects on grinding 2021年1月1日 Swing type stacker Reclaimer: Limestone other raw material are stored in open area into a longitudinal storage unit called stockpile through Stacker These are then extracted transversely from the stockpile through reclaimer The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from Review on vertical roller mill in cement industry its 3 天之前 RGrind Cylindrical Grinding Machine Series Our highperformance manual cylindrical grinding machines are built with highquality Meehanite cast iron with heavy ribbing to ensure high overall stiffness, even with heavy workpieces These cylindrical grinders for sale feature a precision grinding spindle for high accuracy and repeatabilityCylindrical Grinders Industrial Grinders KAAST Machine Tools

.jpg)

VEVOR 1000g Electric Grain Mill Grinder, 3750W HighSpeed

2024年10月26日 Swing Type Grain Mill: Versatile Grinding for Various Ingredients Its swing type design allows for versatile grinding You can use it for various ingredients, including spices, coffee, and dry grains Any kitchen can use it due to its versatility The design ensures that the grinder can handle different textures and consistencies2023年5月2日 Artudatech Stainless Steel Electric Grain Mill, available on Wayfair The hopper/crush cabin holds up to 105 ounces of food The lid is securely fastened in place with two large clamps When finished, the swing design makes it easy to tip the crush cabin contents into a bowl or canisterThe Best Countertop Grain Mills and Flour Grinders in 2023 Foodal2024年3月21日 usually used instead of the end grinding force Therefore, in this paper, the grinding force of LUVAG is divided into three parts: side grinding chip formation force Fig 1 The diagram of ultrasonic vibration–assisted grinding Fig Modeling of grinding force in longitudinal ultrasonic 2022年10月6日 Effect of crack propagation on surface formation mechanism and surface morphology evaluation of longitudinal–torsional composite ultrasonic millgrinding of Si3N4 October 2022 DOI: 1021203/rs3 Effect of crack propagation on surface formation mechanism

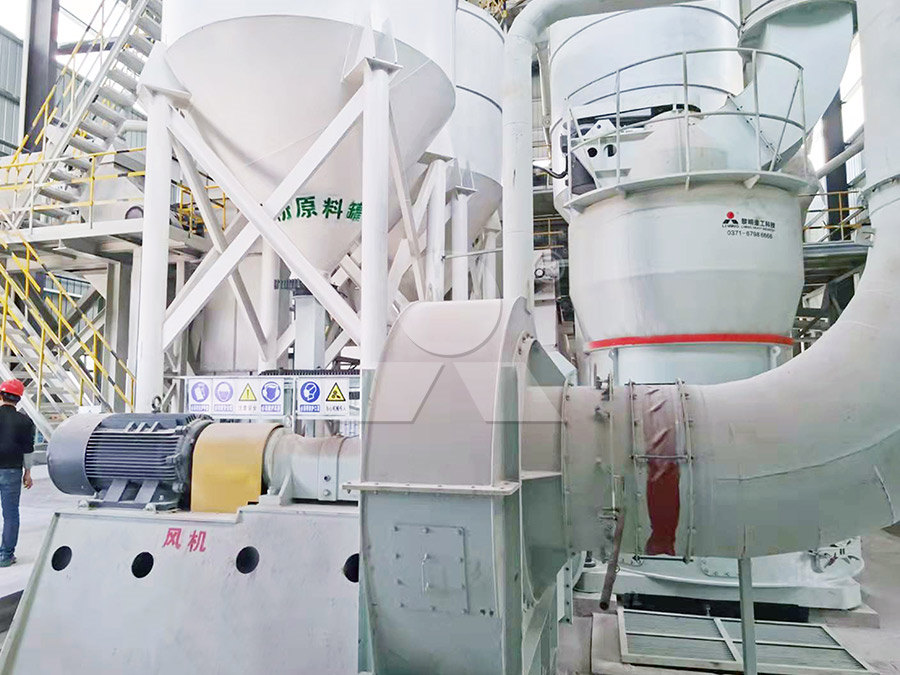

Longitudinal Pendulum Type Millluqi

Technical advantages of longitudinal swing mill (1) Brand new grinding system: 1 The new technology adopts a new longitudinal pendulum grinding roller device The grinding roller and the grinding ring are always in a balanced state during the grinding process