Weathered coal anthracite lignite grinding mill

COAL GRINDING IMPS: more than meets the eye Gebr

2016年12月19日 grinding and drying coal for use in cement plants, power stations and in the steel industry In these plants very different coal types like anthracite, bituminous coal or lignite 2021年7月14日 Types of coal, lignite, subbituminous coal, anthracite, bituminous Stove Help Advice Home The rank of coal is based on the degree to which the orginal plant material lignite, bituminous coal, and anthracite coal – Grinding Mill 2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90%(PDF) MPS mills for coal grinding ResearchGate2017年8月12日 Individual grinding mill design with a proven track record, encompassing 2, 3 and 4 rollers for fuel throughput rates up to and in excess of 200 t/h Pressure shock LOESCHEMILLS

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials2022年9月30日 Aiming to explore the limitation of Hardgrove Grindability Index (HGI) and broken behavior of lignite, coal samples were ground for different minutes in the Hardgrove Research on the grinding characteristics of lignite based on grinding 2017年8月12日 Loesche produces grinding mills and classifiers for all solid fuels, with throughputs ranging from 8 to 240 t/h (16,000 to 640,000 lb/h) With a long wear life and easy Loesche Grinding Technology for the Power Industry2023年1月1日 To successfully utilize anthracite in rotary kilns it is necessary to take special precautions such as grinding the pulverized coal (fuel) to high coal fineness, and special Coal utilization in the cement and concrete industries

Numerical Investigation of the Grinding Process in a Beater Wheel Mill

1997年7月1日 A numerical investigation is presented for a twodimensional simulation of the gas flow field and of the dynamic behavior of lignite particles inside Beater Wheel mills with 2016年12月19日 So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a throughput rate of minimum 100 t/h at a residue of 15% R009 mm The installed power for the mill main drive is 1300 kWReprint from ZKG 3 Gebr Pfeiffer2023年10月7日 Coal mills are used to pulverize the raw coal and conveyor the fine coal particles to primary zone of boiler for an efficient combustion Performance of the pulverizing systemAn investigation of performance characteristics and 2023年10月6日 The document discusses coal mill equipment, including the names, functions, and working principles of different types of equipment It focuses on vertical roller mills (VRM), describing the three main sections of Coal Mill PDF Coal Lignite

Beater Wheel Mill PDF Lignite Mill (Grinding)

2023年11月5日 This document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within the mill 2 Diagrams of beater wheel mills with different configurations, such as with or without a separating classifier or with a precrusher 3 2015年2月20日 The principal types of coal, in order of metamorphic development, are lignite, subbituminous, bituminous, and anthracite While not generally considered a coal, peat is the first development stage in the “coalification” process, in which there is a gradual increase in the carbon content of the fossil organic material and concomitant reduction in oxygenCoals, Lignite, and Peat Keppeler Wiley Online Library2013年5月15日 The objective of this study was to analyze dry grinding kinetics of three different solid fuels in terms of selection and breakage distribution functions values using a batch laboratory ball parisons of Dry Grinding Kinetics of Lignite, Bituminous Coal2024年7月11日 2 After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment; 3 Coal particles in the ground in a mill, grading, Eligible grader after the powder was collected by unqualified, Powder will be coal grinding mill, coal pulverizer machine, coal powder

distinction between peat, lignite, bituminous and anthracite coal

Dec 06, 2008 Similarities and differences among peat, lignite, bituminous coal, and anthracite coal? 4 years ago; Report Abuse » Free Online Chat Differences Between Anthracite and Bituminous Coal – Scribd Differences between Anthracite and Bituminous Coal Anthracite Coal Bituminous Coal better quality than and burns with a short The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsMill Feeders: Feeders for coal mill are generally installed directly under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to conveyor or feeding chute to mill For coal mill feeding, table feeders, belt feeders, Coal Grinding Cement Plant Optimization17 Lignite Combustion – US Environmental Protection Agency In a pulverized lignitefired boiler, SCCs = pulverized coalfired boilers, 10100301, Boiler Design And Operating Variables Affecting Uncontrolled » More detailed! Coal Firing Systems – Hitachi w Polsce Designed as coal bunker dischargers, the mill feeders supply the pulverizers with In hard coal boiler units layout of coal mill /bunker for lignite fired boilers

Types of Coal Anthracite, Bituminous, Sub

2023年11月1日 Anthracite Coal – High Carbon Content and Heating Value Anthracite coal is a type of coal that stands out for its high carbon content and impressive heating value With carbon content ranging from 86% to 97%, it 6 天之前 To meet the needs of customers, we have equipped them with 3 vertical coal mills, each with a capacity of 30 t/h Material: Anthracite, lignite Capacity: 300,000 tons per year Feed particle size: ≤25 mm Output particle Energysaving and Efficient Vertical Roller Mill2023年10月31日 Batch experiments were conducted using lignite, coking coal, and anthracite as adsorbents Both coking coal and anthracite showed favorable adsorption properties for the chosen contaminants These coal samples underwent initial crushing, grinding, and sieving through a 74 μm sieve Subsequently, they were ovendried at 120 °C for 2 h Removal of Pyridine from Aqueous Solutions Using Lignite, Coking Coal 2011年2月1日 Download Citation A comparison of the results obtained from grinding in a stirred media mill lignite coal samples treated with microwave and untreated samples Various studies have been carried A comparison of the results obtained from grinding in a

.jpg)

VRM In Cement Plant Maximize Energy Saving CNBM

Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy 2018年2月28日 Coal – Formation of Coal – Types of Coal – Peat, Lignite, Bituminous Coal Anthracite Coal Carbon content in different types of coal Importance of each type Coal Also called black gold Found in sedimentary strata [layers of soil] Contains carbon, volatile matter, moisture and ash [in some cases Sulphur and phosphorous]Coal Types of Coal: Peat, Lignite, Bituminous Coal Anthracite Coal 2021年8月19日 Three comminution devices – Raymond Mill (RM), Rolls Crusher (RC) and Ball Mill (BM) were used to grind a UK high volatile bituminous coal (UK1) A representative sample was split from the bulk 2 tonne sample of 50 mm material This subsample was staged crushed in a jaw crusher set at 20 mm and then to 6 mm This material was thenEffect of the grinding behaviour of coal blends on coal 2016年9月23日 Lignite is a lowquality energy source which accounts for 13 % of China’s coal reserves It is imperative to improve the quality of lignite for largescale utilization To further explore and analyze the influence of various key processes on the environment and economic costs, a lignite drying and compression technology is evaluated using an integrated approach Future of lignite resources: a life cycle analysis

Anthracite Rice Coal – The Mill

Anthracite Rice Coal is The Mill's smallsized coal that is good for automatic stokers that are mechanically fed Rice Coal 3/16" 5/16" similar to a pencil eraser Nut (Chestnut) Coal 13/16" 1 5/8" similar to a golf ball+ Stove Coal 1 5/8" 2 7/16" Close to a baseball size Anthracite Coal Fact Sheet2024年5月22日 As a fossil fuel, coal was formed when ancient plants were buried underground before being decomposed and decomposed, converted into peat, then converted into lignite, then subbituminous, then bituminous, and finally anthracite The hydrocarbons produced by coal act under the pressure and temperature conditions of crustal moving air, and the Coal Making Process, Coal Grinding Mill mzenithmills2021年8月5日 The slow speed and medium speed mills are selected for coals ranging from subbituminous to anthracite The highspeed mills are used mainly for lignite Operation Of Bowl Mill Pulveriser In bowl mill pulveriser raw coal Pulveriser in Thermal Power Plant Bowl Mill2021年6月25日 17 Lignite Combustion 171 General15 Coal is a complex combination of organic matter and inorganic ash formed over eons from successive layers of fallen vegetation Coals are classified by rank according to their progressive alteration in the natural metamorphosis from lignite to anthracite Coal rank depends on the volatile17 Lignite Combustion US Environmental Protection

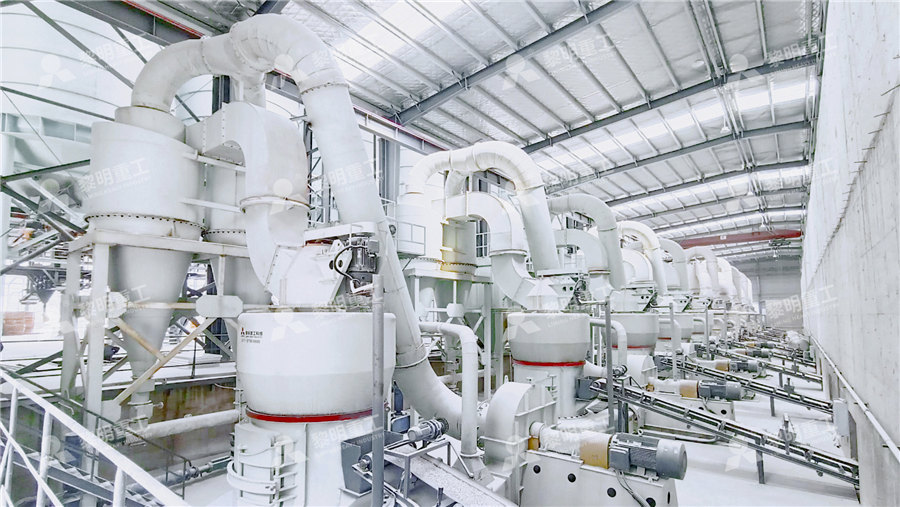

Vertical Coal Mill for Coal Grinding in Cement Plant Power

Vertical coal grinding mill is a professional coal grinding equipment for all kinds of coal It can grind peat, lignite, bituminous coal, anthracite and other single raw coal, and can also grind a variety of mixed raw coal Since the vertical coal mill is a combination of drying and milling functions, it can grind raw coal with different 2024年9月28日 In coal combustion, the efficiency and safety of the process are paramount Indirect firing coal grinding systems play a critical role in optimizing these aspects, especially in industrial applications such as power plants and cement manufacturing This article explores the components, advantages, and operational considerations of indirect firing cIndirect Firing Coal Grinding Systems: Enhancing Efficiency 2018年12月17日 An open air stockpile of conical shape was formed with 35 m base diameter and 5 m height using 500 tons of − 200 mm size ROM thermal coal on a concrete floor Coal sample from the stockpile were collected at 30 days interval for analysis of various chemical properties like; proximate analysis, ultimate analysis, gross calorific value (GCV) and various Effect of weathering on physicochemical properties and 2020年3月1日 Understanding the energysize reduction relationship is vital to grinding process; therefore, this paper aims to show the energysize reduction of magnetitecalcite binary mixture in a laboratory Energysize reduction of mixtures of anthracite and coking coal

An assessment of grindability index of coal ResearchGate

2002年4月1日 Grindability of coal is a central characteristic of coal which is closely related to pulverizer performance and mill capacity (ACARP, 1998) and is defined as ease of grinding of coal which is, in 2020年6月1日 The energy consumption of grinding is the subject of many studies, especially in the case of ball mills for grinding clinkers [8,9], fuels [10], iron ore [11], hematite ore [12], sulfide ore [13 Effect of moisture on energysize reduction of lignite coal in 2021年7月14日 Coal – Wikipedia, the free encyclopedia The harder forms, such as anthracite coal, Subbituminous coal, whose properties range from those of lignite to those of bituminous coal, » More detailed Anthracite – Wikipedia, the free encyclopedia which also include bituminous coal and ligniteAnthracite is the most metamorphosed type of coal (but still lignite, bituminous coal, and anthracite coal – Grinding Mill 2016年12月19日 So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a throughput rate of minimum 100 t/h at a residue of 15% R009 mm The installed power for the mill main drive is 1300 kWReprint from ZKG 3 Gebr Pfeiffer

.jpg)

An investigation of performance characteristics and

2023年10月7日 Coal mills are used to pulverize the raw coal and conveyor the fine coal particles to primary zone of boiler for an efficient combustion Performance of the pulverizing system2023年10月6日 The document discusses coal mill equipment, including the names, functions, and working principles of different types of equipment It focuses on vertical roller mills (VRM), describing the three main sections of Coal Mill PDF Coal Lignite2023年11月5日 This document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within the mill 2 Diagrams of beater wheel mills with different configurations, such as with or without a separating classifier or with a precrusher 3 Beater Wheel Mill PDF Lignite Mill (Grinding)2015年2月20日 The principal types of coal, in order of metamorphic development, are lignite, subbituminous, bituminous, and anthracite While not generally considered a coal, peat is the first development stage in the “coalification” process, in which there is a gradual increase in the carbon content of the fossil organic material and concomitant reduction in oxygenCoals, Lignite, and Peat Keppeler Wiley Online Library

Comparisons of Dry Grinding Kinetics of Lignite, Bituminous Coal

2013年5月15日 The objective of this study was to analyze dry grinding kinetics of three different solid fuels in terms of selection and breakage distribution functions values using a batch laboratory ball mill2024年7月11日 2 After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment; 3 Coal particles in the ground in a mill, grading, Eligible grader after the powder was collected by unqualified, Powder will be coal grinding mill, coal pulverizer machine, coal powder Dec 06, 2008 Similarities and differences among peat, lignite, bituminous coal, and anthracite coal? 4 years ago; Report Abuse » Free Online Chat Differences Between Anthracite and Bituminous Coal – Scribd Differences between Anthracite and Bituminous Coal Anthracite Coal Bituminous Coal better quality than and burns with a short distinction between peat, lignite, bituminous and anthracite coal The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Coal Grinding Cement Plant Optimization

Mill Feeders: Feeders for coal mill are generally installed directly under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to conveyor or feeding chute to mill For coal mill feeding, table feeders, belt feeders,