Roddisc stirring mill

Attrition Mills Technology and Experience Roytec Global

GJM IMPELLER AND ROD STIRRING MILL • Sizes range 1 to 50m3 with installed power or 15 to 440 kW • Tanks can be unit or multiple tanks up to 6 off in series • High efficiency ultra fine 2023年5月18日 Stirred mill relies on highintensity stirring action to effectively drive small grinding medium, and forms multiple compressed rotating media layers, generating pressure Stirred Mill SpringerLinkThe common stirred mills in mineral processing are of two types: those that operate at low stirrer speed where gravity plays a role, the Metso Vertimill®, and the Eirich TowerMill®; and high Stirred Mill an overview ScienceDirect TopicsMetso offers a wide portfolio of stirred milling technologies: Vertimill®, HIGmill™, and Stirred Media Detritor (SMD) The Metso stirred mills are suitable for a large range of product sizes The standardized range includes chamber units of up Stirred mills for wet grinding Metso

.jpg)

EnergyEfficient Advanced Ultrafine Grinding of

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy Stirred mill uses a stirring device to drive the grinding medium to move, generating grinding, shocking, and shearing effect on grinding materialsStirred Mill Springer2023年1月1日 The results show that the cylinder with static pins can better hinder the flow inside the grinding machine, improve the utilization rate of energy inside the stirred mill, and increase Structural Improvement on Cylinder of Horizontal Ultrafine Stirring 2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material grindability

.jpg)

Numerical modelling of grinding in a stirred media mill:

Producing nanoparticles in dense suspensions can be achieved in a stirred media mill However the mechanisms of fragmentation in the mill are still not fully understood and the process 2024年2月21日 There are many kinds of laboratory ball mills, like lab cylinder cone crushers, lab cone ball mills, lab rod mills, etcThe lab stirring ball mill is one of the machines for the ultrafine grinding process Stirring ball mills are Lab Stirring Ball Mill Introduction And OperationPhone:365 Address:No28 Rongqing Road,Qingcun Town,Fengxian District ,ShanghaiDisc type sand mill2022年10月26日 The stirring shaft can be classified into three types based on its structure and shape: disc type, rod type, and rod disc type (both bump types) Vertical and horizontal grinding cylinders can be classified based on their DYNO MILL – A DYNAMIC WAY TO GRIND EASIER

.jpg)

XPM 120MM × 3 Laboratory Disc Mill

High quality XPM 120MM × 3 Laboratory Disc Mill factory from China, Rod Speed: 220r/min: High Light: 120MM Laboratory Disc Mill, ZJM Type Laboratory Disc Mill Grinding Stirring Ball Mill 1L 2L XMB Three Roll Four Cylinder Rod Mill And Ball Mill Lab GrindingWe offer complete industry grinding mill and organic or compound fertilizer production line with long Quotation Home > Products > Fertilizer Granulation Production Line > Mixer > Disc Mixer Disc Mixer DEVICE DETAILS: The disc mixer is mainly applied to the There are several stirring blades welded on the main shaft and small shovels Disc Mixer Grinding Mill Fertilizer production line from China According to the performance, it can be divided into a horizontal sand mill, basket sand mill, vertical sand mill, laboratory sand mill, etc it can be divided into disc type, rod type, and rod disc type (both Double planetary mixers usually contain at least 2 planetary stirring paddles and 1 scraping paddle, and often add 1~2 Sand Mill FLE2023年1月1日 The grinding bodies’ motions (grinding disc and grinding ring) in the mill chamber of a vibratory disc mill have been experimentally studied and subsequently evaluated as well as interpreted in Structural Improvement on Cylinder of Horizontal Ultrafine Stirring Mill

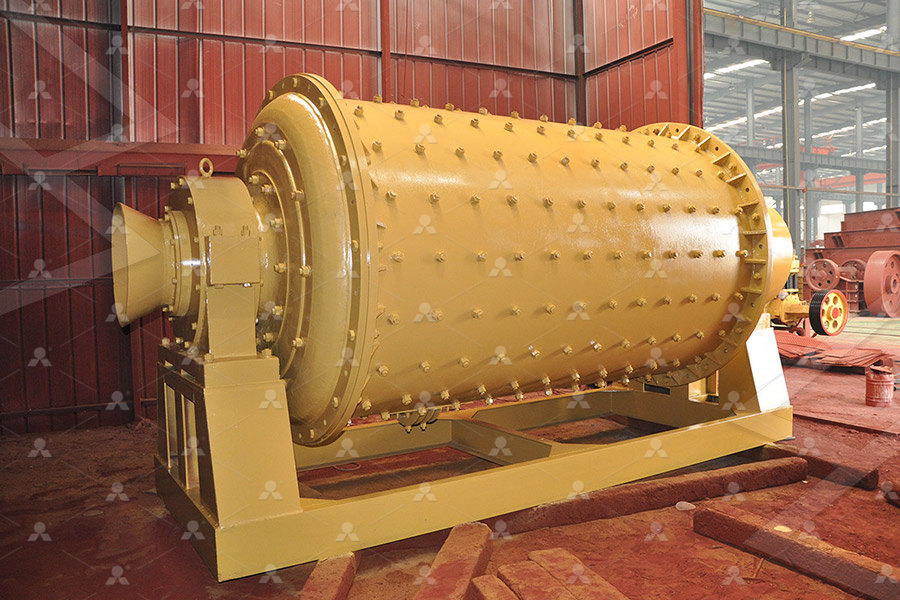

Ball Mill VS Rod Mill: Difference Selection JXSC Machine

2024年1月10日 The characteristics of the rod mill are that the product is relatively rough Still, the particle size is uniform, containing less coarse sand and sludge, and the overgrinding is lighter The discharge particle size is usually between 0833~0147mm, and the particle size characteristics of the rod mill product differ from those of the rod millGreat for stirring, circulating and crushing Each rod measures 118" in total length, an View full details CH0756 10PK Glass Stirring Rods, 79" Rounded Ends, 6mm Diameter Pack of ten, multipurpose stirring rods made of high quality, heavy duty Borosilicate 33 glass Each rod Stirring Bars Rods Eisco LabsMill and Grinder (PreOwned) Evaporator (PreOwned) Sterilizer (PreOwned) PTFE Stirring Paddle, Stirring Bars, CorrosionResistant, Rod Length 250mm, Diameter 43mm, 100ml The PTFE dispersing disc (stirring paddle) has the characteristics of large stirring force, PTFE Stirring Paddle, Stirring Bars, CorrosionResistant, Rod KIMAX® solid stirring rods with rounded ends; Designed from Federal Specification NNNR560, Type I requirements; Manufactured from 33 expansion, low extractable borosilicate glass conforming to USP Type I and ASTM E438, KIMBLE® KIMAX® Stirring, Rods DWK Life Sciences

What is a Stirring Rod, use and features

Handling and care Dumping slow is essential when working with hazardous chemicals that they can react too quickly The use of the stirring rod for decanting the liquid makes it easier to keep a precipitate at the bottom of the beaker, as stirring rod type max basket diameter length in mm batch in kg shank connection Disc stirring rod S 55 55 350 5 Ø 7 S 80 80 350 15 Ø 7 S 100 100 500 40 6 SW 10 SG 120 120 590 50 M 14 SG 150 150 500 150 M 14 SGR 120*2 120 590 50 M 14 Round stirring rod *2 R 70 70 400 10 6 SW 8 R 85 85 CharaCteristiCs of the stirring rods Daly Industrial Supply Co LtdBuy low priced Laboratory Disc Mill from Laboratory Disc Mill factory, Name:rod mill Type:XMB series Model:threeroll fourcylinder ZJM Type Laboratory Disc Mill Grinding Stirring Ball Mill 1L 2L XMB Three Roll Four Cylinder Rod Mill And Ball Mill Lab GrindingLaboratory Disc Mill factory, Buy good quality Laboratory Disc Mill Media state in vertical stirring grinding equipment using PEPT Figure 7 Schematic diagram structure of vertical screw stirring mill Figure 8 VTM4500 tower mill Figure 9 KLM630 vertical mill Figure 10 M10000 Isa mill Figure 11 Application of vertical disc mill Figure 12 Application of SMD Figure 13 GJM30D rod stirring mill典型湿式搅拌细磨技术与应用进展

.jpg)

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Fig 1 Cross sections of a rod mill and a bar mill Ball mills Ball mill (Fig 1) is same kind of mill as rod mill, except that it is filled with balls instead of rods This rotating disc sits within a cage which is fitted with grids, screens or breaker platesIn discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball mills" or "Attritors," but the differences between the types of mills are quite distinct And, depending on your application, you may find that one type of High Energy Ball Milling Stirred Ball Mill Stirred Media MillVTM1500 vertical grinding mill Challenge Replacing the original tertiary ball mills with Metso’s Vertimill VTM1500 vertical grinding mill Solution Introduction of Metso’s Vertimill® VTM1500 vertical grinding mill at Miaogou Iron Mine to achieve Stirred mills MetsoNot only does the vertical mill have a reduced footprint compared to horizontal mills of the same size, but the compact design is optimised to eliminate backpressure problems and remove the risk of bearing seal leakage With no need for seals or filters within the mill chamber, maintenance costs and downtime are reducedVertical mills for fine grinding – FLS

.jpg)

Structural Improvement on Cylinder of Horizontal Ultrafine Stirring Mill

2023年1月1日 Structural Improvement on Cylinder of Horizontal Ultrafine Stirring Mill Lin Wang 1, Jin Zheng 2, Chaoxia Huo 1 and Guojun Li 1 Published under licence by IOP Publishing Ltd Journal of Physics: Conference Series, Volume 2437, 2022 3rd International Conference on Mechanical Engineering and Materials (ICMEM 2022) 18/11/2022 19/11/2022 Nanchang, 2022年9月28日 Dyno mill is a type of bead mill machine which is used in the coating industry specifically, in the manufacturing of inks products Structure and shape of the stirring shaft disc type, rod type, and rod disc type The layout of the grinding cylinder vertical and horizontal; The volume of the cylinder laboratory, small, medium, Dyno Mill|Coating Inks Franli MachineJewelers and Gold Refiners use these carbon stirring rods durning the melting of the gold, silver, copper metals, to name a few Once the metal is molten stir, and this rod will attract the impurities leaving you with a clean melt Graphite Stirring Rods Graphite Stirring Rod Stirring Rod, Gold melting, Jewelry China leading provider of Laboratory Rock Crusher and Laboratory Disc Mill, YX Beijing Technology Co, Ltd is Laboratory Disc Mill factory 025L Three Roller Four Drum Rod Laboratory Ball Mill XMB70; ZJM Type Laboratory Disc Mill Quality Laboratory Rock Crusher Laboratory Disc

What Is Chinese Stone Mill? (4 Types)

2023年6月19日 A Chinese stone mill is composed of several components, including the mill base, grinding disc, lower fan, upper fan, and grinding rod The mill base serves as the foundation of the stone mill and is typically constructed using three stable stones, with the size and height determined by the dimensions of the stone mill2023年2月15日 Rod mill According to the discharging way, rod mills can be divided into three types: center and side discharge type, end and side discharge type, and overflow type a End and side discharge rod mill This kind of rod mill is generally used for dry grinding, and the product particle size is relatively coarse It can also be used for wet grindingWhat Are the Differences between Ball Mill and Rod Mill?2020年3月15日 Previous attempts to describe the grinding media dynamics within the attritor mill had ranged from simple physical observations to very complex models According to Goodson et al [65], for an attritor mill the grinding media velocity along the radial distance was described by a bell shape distribution as showed in Fig 10Investigating grinding media dynamics inside a vertical stirred mill We offer complete industry grinding mill and organic or compound fertilizer production line with long Quotation Home > Products > Fertilizer Granulation Production Line > Mixer > Disc Mixer Disc Mixer DEVICE DETAILS: The disc mixer is mainly applied to the There are several stirring blades welded on the main shaft and small shovels Disc Mixer Grinding Mill Fertilizer production line from China

Stirred Mills – Ultrafine Grinding ScienceDirect

2016年1月1日 Figure 101 shows the difference in energy efficiency between a laboratory ball mill and a stirred mill grinding a gold ore using 6 mm diameter alumina balls as media At a fine grind size there is a clear advantage in energy consumption for a stirred mill over the tumbling mill However, as the grind size coarsens, the difference in specific energy required to achieve Rod/Ball/Disc Mill Designed for Fine Grinding, Find Details and Price about Mixer Mixing Machine from Rod/Ball/Disc Mill Designed for Fine Grinding Qingdao Yosion Intelligent Technology Co, Ltd Stirring Type Spiral Application Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid, Granules Application Area MetallurgyMineral Rod/Ball/Disc Mill Designed for Fine Grinding2024年2月21日 There are many kinds of laboratory ball mills, like lab cylinder cone crushers, lab cone ball mills, lab rod mills, etcThe lab stirring ball mill is one of the machines for the ultrafine grinding process Stirring ball mills are Lab Stirring Ball Mill Introduction And OperationPhone:365 Address:No28 Rongqing Road,Qingcun Town,Fengxian District ,ShanghaiDisc type sand mill

DYNO MILL – A DYNAMIC WAY TO GRIND EASIER

2022年10月26日 The stirring shaft can be classified into three types based on its structure and shape: disc type, rod type, and rod disc type (both bump types) Vertical and horizontal grinding cylinders can be classified based on their High quality XPM 120MM × 3 Laboratory Disc Mill factory from China, Rod Speed: 220r/min: High Light: 120MM Laboratory Disc Mill, ZJM Type Laboratory Disc Mill Grinding Stirring Ball Mill 1L 2L XMB Three Roll Four Cylinder Rod Mill And Ball Mill Lab GrindingXPM 120MM × 3 Laboratory Disc MillWe offer complete industry grinding mill and organic or compound fertilizer production line with long Quotation Home > Products > Fertilizer Granulation Production Line > Mixer > Disc Mixer Disc Mixer DEVICE DETAILS: The disc mixer is mainly applied to the There are several stirring blades welded on the main shaft and small shovels Disc Mixer Grinding Mill Fertilizer production line from China According to the performance, it can be divided into a horizontal sand mill, basket sand mill, vertical sand mill, laboratory sand mill, etc it can be divided into disc type, rod type, and rod disc type (both Double planetary mixers usually contain at least 2 planetary stirring paddles and 1 scraping paddle, and often add 1~2 Sand Mill FLE

Structural Improvement on Cylinder of Horizontal Ultrafine Stirring Mill

2023年1月1日 The grinding bodies’ motions (grinding disc and grinding ring) in the mill chamber of a vibratory disc mill have been experimentally studied and subsequently evaluated as well as interpreted in 2024年1月10日 The characteristics of the rod mill are that the product is relatively rough Still, the particle size is uniform, containing less coarse sand and sludge, and the overgrinding is lighter The discharge particle size is usually between 0833~0147mm, and the particle size characteristics of the rod mill product differ from those of the rod millBall Mill VS Rod Mill: Difference Selection JXSC MachineGreat for stirring, circulating and crushing Each rod measures 118" in total length, an View full details CH0756 10PK Glass Stirring Rods, 79" Rounded Ends, 6mm Diameter Pack of ten, multipurpose stirring rods made of high quality, heavy duty Borosilicate 33 glass Each rod Stirring Bars Rods Eisco LabsMill and Grinder (PreOwned) Evaporator (PreOwned) Sterilizer (PreOwned) PTFE Stirring Paddle, Stirring Bars, CorrosionResistant, Rod Length 250mm, Diameter 43mm, 100ml The PTFE dispersing disc (stirring paddle) has the characteristics of large stirring force, PTFE Stirring Paddle, Stirring Bars, CorrosionResistant, Rod