Cyclone powder collector

Cyclone design Step by step guide Powderprocess

2023年10月28日 Cyclone dust collectors are fairly simple from a mechanical point of view and therefore generally provide a cost effective solution However, assessing the performance of a The page discusses powder buildup in pneumatic conveying systems, its Pneumatic TransportOur cyclone dust collectors are designed specifically for powder processes involving a wide variety of problematic materials and particle sizes The need for cyclone dust collectors is particularly necessary in processes with high Cyclones Powder ProcessSolutions2024年11月22日 The Donaldson Torit® Cyclone dust collector is designed specifically for high dust load, high temperature, and product recovery applications It has a mechanical separator that uses centrifugal force to Cyclone Dust Collectors Donaldson Industrial

Cyclone design and specification considerations

2019年2月6日 When specifying cyclones, one of the first steps is understanding the type of gas and particulate material to be separated Particle size, shape, density, melt temperature and moisture content rank among the key 2023年7月30日 Model of Leith Licht for design of cyclones How to design a cyclone step by step ? What is the cut off diameter of a cyclone ? What is the efficiency of a cyclone ? What is the performance of a cyclone ? How to Design of a cyclone (Leith Licht) : calculation 5 天之前 Air/solids cyclone technology provides an effective and very efficient solution for the separation and collection of powders in dust extraction applicationsPowder Recovery Cyclones nasirint2022年1月1日 We have designed this dust collection machine for collecting the dust of polyurethane material which is removed during the grinding operation The inlet of the dust Design and fabrication of cyclone dust collector for industrial

.jpg)

(PDF) Design and fabrication of cyclone

2015年8月15日 1D3D and 2D2D are the most efficient cyclone collectors for fine dust (particle diameters less than 100 μm) Mihalski e t al (1993) reported “cycling lint” near the trash exit for the 1D3D and2023年1月26日 High eficiency, filterless cyclone technology for the capture of excess dust from powder processes Specifically designed for sanitary applications in the pharmaceutical, food Powder Recovery Cyclones Hanningfield2021年12月7日 Powder losses also occur in milling, micronization and tablet pressing applications To recover these sensitive products, cyclone collectors are increasingly Hurricane Numerically Optimized Cyclones for Powder 2021年12月7日 The Problem With Efficient Powder Recovery A New Approach to Cyclone Design Efficient recovery of Active Pharmaceutical Ingredients (APIs), chemical substances and food powders after drying applications, such as spray and fluid bed drying, is frequently a problem Powder losses also occur in milling, micronization and tablet pressing applicationsHurricane Numerically Optimized Cyclones for Powder

Cyclone design and specification considerations

2019年2月6日 When the maintenance team altered the system configuration, they neglected to consider the potential effect on the cyclone When the process was fired up, the cyclone expanded downward into the dipleg, overcoming a Buy Dewalt Dust Separator for Wet/Dry Shop Vacuums, Cyclone Dust Collector Up To 995% Efficiency, Highperformance Cycle Powder Collector Filter, Dust Collector Model: DXVCS001: Power Tools Replacement Parts Amazon Dewalt Dust Separator for Wet/Dry Shop Cyclone Powder Coating Dust Collector This cyclone dust collector is one of the necessary part in high volume powder coating jobs, especially for automatic powder coating lines The powder coating booth with cyclone will maximize powder collection efficiency thats significantly reduces downtime during color change operationCyclone Powder Coating Dust CollectorFirstly, the standard efficiency cyclone collector offers up to 8,000 CFM (cubic feet per minute) of airflow Secondly, the highefficiency cyclone collector can be sized up to 70,000 CFM for projects that require more airflow Many industries and applications use cyclonic dust collectors Above all, cyclones effectively remove large or heavy Custom Industrial Cyclone Dust Collectors from Imperial

Powder Recovery Cyclones nasirint

5 天之前 How Does it Work? The cyclone separates the solids from the clean air, typically capturing at least 95% of excess powder in a collection pot The air is then passed through a "police" HEPA filter which increases system efficiency to 9999% before the clean air flows to the normal dust extraction unitIf you use a shop vac or dust collector very often a cyclone separator is more than worth the investment Cyclone separators typically separate 99% of the dust particles >10 microns from the air stream and deposit them into a collection bin before reaching the filter This means you won't have to clean your shop vac or dust collector filter How cyclone dust collectors work SHOP HACKS2015年8月15日 Cyclone collectors can be designed for many app lications, and they are typically categorized powder recover y c yc lone filter in pharmaceutical sterile processes cyclone separator (PDF) Design and fabrication of cyclone separatorSC Series PullThrough (with BagType After Filter) Dust Collectors The AGET DUSTKOP SC series provides an industrial quality, 2stage dust collector, consisting of a high efficiency pullthrough cyclone that removes chips and wood dust from the air, and a bagtype afterfilter that captures the remaining fine dust and returns cleaned air to the work areaCyclone Separators Dust Collection Systems AGET

.jpg)

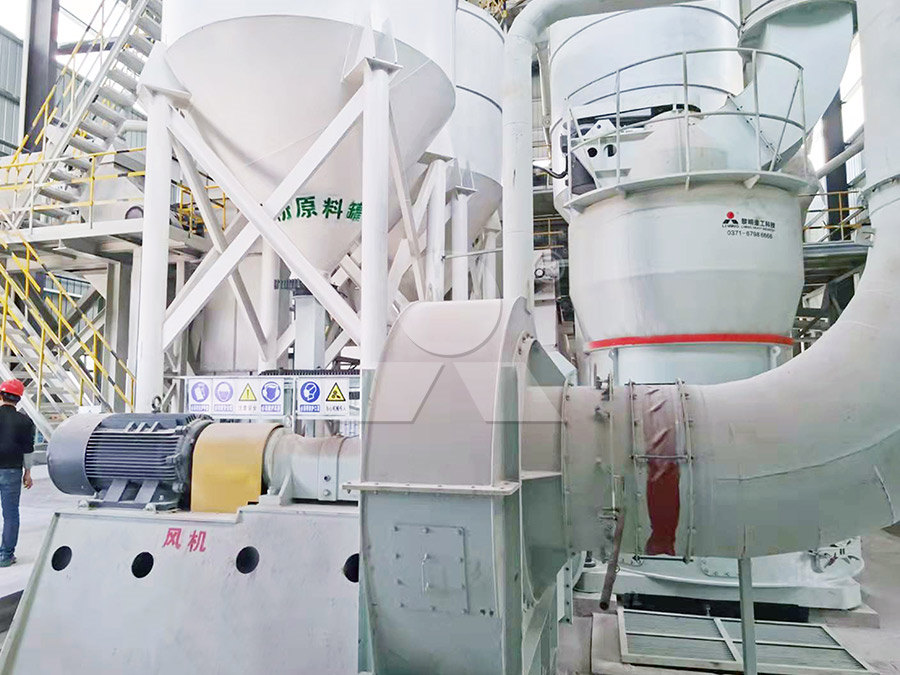

Cheap Highquality Industrial Cyclone Powder Dust Collector

2024年10月10日 The Cyclone Powder Dust Collector is simple in structure, easy to manufacture, install, maintain and manage (1) Stable operating parameters The operating parameters of the cyclone dust collector mainly include: the inlet air velocity of the dust collector, the temperature of the processed gas and the inlet mass concentration of the dustcontaining 2023年1月26日 Powder Recovery Cyclones High efficiency, filterless cyclone technology for the capture of excess dust from powder processes Specifically designed for sanitary applications in the pharmaceutical, food and related industries When a tablet or capsule is formed, small amounts of excess powder spill onto the Powder Recovery Cyclones Hanningfield2024年11月9日 Dust collector for Powder Coating Booth Details Introduction 1The first stage recovery system is Cyclone, with 9 pcs of mini cyclones, it use centrifugal force to seperator the powder which were mixed in the airAnd the MultiCyclone Powder Coating Recovery System 2020年3月15日 The cyclone dust collector is a Lappletype cyclone and the dimensions are shown in Fig 3 The power system includes a highpressure fan (HG9000S) and a matching frequency converter three charging schemes are tested with different charging voltages Molecular sieve and talcum powder particles are used in these experiments, and the Enhancing the collection efficiency of a gas cyclone with

Standalone Steel Cyclone Separators Oneida Air Systems

This heavygauge steel cyclone can be used in custom material handling solutions to preseparate bulk debris and fine dust from the incoming air; prolonging filter life and maintaining high suction Features full seamwelded construction with powder coat finish for long lasting durability Rated for use with 23HP dust collection fan blower motors2011年8月8日 Although a cyclone dust collector may not be suitable for every application, a wide range of benefits can be realized from their use From product reclamation to air pollution control, cyclone dust collectors remain a valuable tool for many industrial processes Bart Eggert is product manager, Aerodyne (Chagrin Falls, OH)Five Questions to Ask When Considering a Cyclone Dust CollectorCyclone Filter Powder Dust Collector Vacuum Dust Extractor Woodworking Separator Cyclone Enhance your dust collection efficiency with the Cyclone Filter Powder Dust Collector Vacuum Dust Extractor Woodworking Separator Cyclone This innovative separator utilizes centrifugal force to effectively filter and separate dust from the airflow, making it an essential tool for Turbocharged Cyclone Dust Collector The Shopsite2022年1月1日 The initial cyclone is designed as a PM 10 collector Since pollen particles are categorized as PM 10 [28], it is proposed that this PM10 collector be developed into an electric cyclone to improve its efficiency in collecting pollen indoor environments such as greenhouses or areas where people suffer from pollen allergies Our main focus is to Introduction and simulation of a small electro cyclone for collecting

Cyclone Dust Collectors nedermanmikropul

Cyclone dust collectors can be used as preseparators to reduce the dust load reaching a final, more efficient filter They can act as protective devices to remove large hot particles from the gas or air stream to prevent damage to the filter media/material Inertial separators are the simplest type of dust collectorDynavac: Your OneStop Shop for Industrial Dust Control Solutions Protecting Your Environment and Workers’ Health Airborne dust poses a significant health risk in industrial and commercial settings Dynavac addresses this challenge with a comprehensive line of industrial dust collection systems designed to capture and eliminate dust particles from the airDust Collectors Dynavac Dust Collection System, Industrial 2018年10月4日 What is a Cyclone Dust Collector? Cyclone dust collectors are a special kind of equipment that are designed to use in industrial applications for separating large dust particles from useful particles These are mechanical separators, which use centrifugal force and inertia effect for separation of particlesKey Benefits and Application of Cyclone Dust Collector JM 2018年2月8日 Dust collector cyclone technology can address these challenges by localizing dust capture, preventing filter blockage and even allowing pharmaceutical manufacturers to recover lost powder UniDust: Pharma Dust Powder Capture: Pharma Dust Collector

Design and fabrication of cyclone dust collector for industrial

2022年1月1日 The type of dust collector we are using is a “Single stage Cyclone Dust Collector” There are two types of cyclone type dust collector Some of them are single stage and others are two stage or multi stage cyclone dust collector Powder Technol, 131 (2003), pp 111119 Crossref Google Scholar [5] Li Enliang, W Yingmin A new Amazon: vacuum cyclone dust collector Highperformance Cycle Powder Collector Filter, Dust Collector Model: DXVCS001 39 out of 5 stars 39 50+ bought in past month $3999 $ 39 99 20% off coupon applied Save 20% with coupon FREE delivery Fri, Dec 13 Amazon: Vacuum Cyclone Dust Collector2024年11月25日 The Hanningfield UniDust cyclone is specifically designed for the recovery of waste powder from pharmaceutical OSD processes such as compression and encapsulation, typically capturing between 90 – 999% of waste powder We have successfully installed our cyclone to Fette, Manesty, Korsch, Zanasi, Bosch, Kilian and numerous other process Cyclones HanningfieldHONLONE Cyclone dust collecto, Strong Cyclone Dust Collector Filter Turbocharged Cyclone, Powder Dust Collector Filter Flange Base Dust Separation, Upright Filters (White) [Energy Class A++] Brand: HONLONE 45 out of 5 stars 10HONLONE Cyclone dust collecto, Strong Cyclone Dust Collector

.jpg)

Dewalt Separator with 10 Gal Stainless Steel Tank, 995

Dewalt Dust Separator with 10 Gal Stainless Steel Tank, 995% Efficiency Cyclone Dust Collector, HighPerformance Cycle Powder Collector Filter, Dust Cyclone Collector, DXVCS003 Product information Collapse all Expand all Dimensions Additional details Power Item details ) Feedback Would you like to tell 1 What is the pin milling machine ? pin milling machine is a complete powder grinding system, consists of pin grinder, cyclone unit, and pulse jet dust collecting systemBy using the high speed relative motion between the rotating milling components and fixed tooth diss, which result in the raw materials to be ground by tooth impact, friction and materials' impact between each other, Pin Milling Machine® Cyclone and Powder Dust CollectorOneida Air Systems' dust collectors are the industry leaders in airflow performance, filtration, and build quality 3hp 230V VSystem 3000 HEPAGFM Cyclone Dust Collector As low as $3,49900 Add to Cart Add to Wish List Add to Compare SKU: XXVM003 Est Lead Time (Business Days): 5Cyclone Dust Collectors Made in USA Oneida Air SystemsOil/Gas Fired Steam Boiler WASTE WATER Product Overview The cyclone is a centrifugal separator In operation, dustladen air enters the tangential inlet, swirls through several revolutions in the body and cone, deposits its dust load and leaves the collector through the axial cylindrical outlet Under the influence of centrifugalCyclone Dust Collector Rollce Engineering

.jpg)

(PDF) Design and fabrication of cyclone dust collector for

2021年3月1日 Design and fabrication of cyclone dust collector for industrial Application March 2021; Materials Today Proceedings 49(4) The powder sample was characterized by the Fourier Transform infra 2021年12月7日 The Problem With Efficient Powder Recovery A New Approach to Cyclone Design Efficient recovery of Active Pharmaceutical Ingredients (APIs), chemical substances and food powders after drying applications, such as spray and fluid bed drying, is frequently a problem Powder losses also occur in milling, micronization and tablet pressing applicationsHurricane Numerically Optimized Cyclones for Powder 2019年2月6日 When the maintenance team altered the system configuration, they neglected to consider the potential effect on the cyclone When the process was fired up, the cyclone expanded downward into the dipleg, overcoming a Cyclone design and specification considerationsBuy Dewalt Dust Separator for Wet/Dry Shop Vacuums, Cyclone Dust Collector Up To 995% Efficiency, Highperformance Cycle Powder Collector Filter, Dust Collector Model: DXVCS001: Power Tools Replacement Parts Amazon Dewalt Dust Separator for Wet/Dry Shop

.jpg)

Cyclone Powder Coating Dust Collector

Cyclone Powder Coating Dust Collector This cyclone dust collector is one of the necessary part in high volume powder coating jobs, especially for automatic powder coating lines The powder coating booth with cyclone will maximize powder collection efficiency thats significantly reduces downtime during color change operationFirstly, the standard efficiency cyclone collector offers up to 8,000 CFM (cubic feet per minute) of airflow Secondly, the highefficiency cyclone collector can be sized up to 70,000 CFM for projects that require more airflow Many industries and applications use cyclonic dust collectors Above all, cyclones effectively remove large or heavy Custom Industrial Cyclone Dust Collectors from Imperial 5 天之前 How Does it Work? The cyclone separates the solids from the clean air, typically capturing at least 95% of excess powder in a collection pot The air is then passed through a "police" HEPA filter which increases system efficiency to 9999% before the clean air flows to the normal dust extraction unitPowder Recovery Cyclones nasirintIf you use a shop vac or dust collector very often a cyclone separator is more than worth the investment Cyclone separators typically separate 99% of the dust particles >10 microns from the air stream and deposit them into a collection bin before reaching the filter This means you won't have to clean your shop vac or dust collector filter How cyclone dust collectors work SHOP HACKS

.jpg)

(PDF) Design and fabrication of cyclone separator

2015年8月15日 Cyclone collectors can be designed for many app lications, and they are typically categorized powder recover y c yc lone filter in pharmaceutical sterile processes cyclone separator SC Series PullThrough (with BagType After Filter) Dust Collectors The AGET DUSTKOP SC series provides an industrial quality, 2stage dust collector, consisting of a high efficiency pullthrough cyclone that removes chips and wood dust from the air, and a bagtype afterfilter that captures the remaining fine dust and returns cleaned air to the work areaCyclone Separators Dust Collection Systems AGET 2024年10月10日 The Cyclone Powder Dust Collector is simple in structure, easy to manufacture, install, maintain and manage (1) Stable operating parameters The operating parameters of the cyclone dust collector mainly include: the inlet air velocity of the dust collector, the temperature of the processed gas and the inlet mass concentration of the dustcontaining Cheap Highquality Industrial Cyclone Powder Dust Collector