HOME→How much exciting force does a highfine vertical mill need How much exciting force does a highfine vertical mill need How much exciting force does a highfine vertical mill need

How much exciting force does a highfine vertical mill need How much exciting force does a highfine vertical mill need How much exciting force does a highfine vertical mill need

.jpg)

Optimisation of the performance of a new vertical roller mill

2024年1月15日 The performance of a vertical roller mill is analysed with CFD Adverse air circulation is detected through CFD simulations Design modifications were evaluated and implemented The detected issues were resolved, improving the performance The erosion There are many different types of vertical mills, but for fine grinding we recommend wither Tower Mills – slowspeed vertical mills used for fine and ultrafine grinding with low energy Vertical mills for fine grinding – FLS FLSmidth2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely Vertical roller mill for raw Application p rocess materials2023年12月4日 When higher rolling resistance is applied due to particle shape complexity at less mill speed, more vertical force is exerted on the roller, and the roller speed is insensitive Numerical Investigation of Vertical Roller Mill Operation

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Effect of operational parameters on product size and product rate was investigated Working pressure is normalized with classifier rotor speed Vertical roller mills 2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the Review on vertical roller mill in cement industry its 2016年9月1日 Firstly, an improved coal mill dynamic model considering the joint influence of drying force, ventilation force, and grinding force is established, and a synchronous Operational parameters affecting the vertical roller mill 2015年8月31日 Abstract: With the market demand for efficient, highly flexible, and highcapacity plants for cement production, it was time to develop an innovative drive concept to cope with Introducing the Vertical Roller Mill with Driven Rollers: An

.jpg)

Analysis and Optimization of Grinding

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method 2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power Roller Mill SpringerLink2 天之前 If you improve your vertical jump by only 2 inches your effective hangtime increases by 30% to 051 seconds giving you much more time in the air for stuff like windmills The speed of the dunk becomes much faster as you Dunk Calculator How High Do I Need to Jump G0797 10" x 50" 3 HP Vertical Mill with Power Feed and DRO An industrialgrade machine with amazing features at a low price point The G0797 10" x 50" Vertical Mill with power feed and DRO is a fullfeatured mill built for those that have 10" x 50" 3 HP VariableSpeed Vertical Mill with

.jpg)

JTM1050EVS2/230 Electr Var Spd Vertical Mill

JTM1050EVS2/230 Electronic Variable Speed Vertical Milling Machine 230V 3Ph The store will not work correctly when cookies are disabled Skip to Content The electrical box has been relocated to the back of the mill and 2009年3月5日 I'm scratchbuilding a CNC mill, and need to know how many foot pounds it takes to push the cutting head through CRS and tool steel, aluminum and brass I understand that the cutters need to be at their sharpest, and that the tool path should take off small chips (small depth of cut), and that the XYZ motors should not be rushing alongHow much force does it take to mill steel? CNCzone2024年8月16日 A vertical milling machine is an essential tool in the manufacturing industry, used to shape metal and other solid materials The cutter is mounted on the spindle head and rotates at high speeds, generating the cutting force Meanwhile, the worktable, holding the workpiece, moves in a controlled manner beneath the cutter, exposing fresh What is a Vertical Milling Machine? How Does it Work? BoYi2017年10月27日 the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter 2 PROCESS CONTROL OF VRM The conventional control system of VRMPROCESS CONTROL FOR CEMENT GRINDING IN

.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitStart your 48hour free trial to access everything you need to rise to the top of the class Enjoy expert answers and study guides adfree and take your learning to the next levelHow Much Land Does a Man Need? Summary eNotes2024年7月26日 – Roll into cuts with a face mill as described below under Toolpath Considerations – If you don’t need a square shoulder, a 45 degree lead angle facemill will often leave a better finish than a 90 degree Chips are also about 30 percent thinner versus a 90 degree facemill so faster feedrates are possibleMilling Surface Finish: Complete Guide [Tips Secrets]The clamping force must be high enough to counteract the cutting forces but not so high as to deform the workpiece Cutting forces can vary depending on factors such as the machined material, the tool geometry, cutting parameters, and the depth of cut, making it vital to design your clamping setup to accommodate the highest anticipated cutting Clamping Force Calculations: Guide Calculator Carr Lane

.jpg)

Vertical roller mill for raw Application p rocess materials

2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely Fine product Chimney Vertical Raw Mill EP Raw Mill EP fan 69 4 Item Pregrinding equipment for raw material grinding process Application process Raw material process2023年9月9日 How Much Maintenance Is Required for Vertical Axis Wind Turbines? To maintain a vertical axis wind turbine, regular inspections and servicing are necessary You’ll need to check the components for wear and The Ultimate Guide To Vertical Axis Wind 2024年7月12日 It is the point at which the centrifugal force applied to the grinding media equals the force of gravity, causing the grinding media to cling to the mill’s inner walls As a general rule, the optimal speed for efficient grinding What Is a Ball Mill and How Does It Work?2024年7月26日 Wind turbines convert the kinetic energy from the wind into electricityHere is a stepbystep description of wind turbine energy generation: Wind flows through turbine blades, causing a lift force which leads to the rotation of the blades The central rotor shafts, which are connected to the blades, transmit the rotational forces to the generator The generator uses Wind Turbine Calculator

How to Calculate Force: 6 Steps (with Pictures) wikiHow

2024年8月31日 Newton's second law of motion describes how force is related to mass and acceleration, and this relationship is used to calculate force and was previously in the Math Department at Saint Louis University She has taught math at the elementary, middle, high school, and college levels As an example, if the mass of the object is given to 23 小时之前 CNC Vertical Mill with 30" x 16" x 20" travels Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needsVF2 40Taper Mill Vertical Mills – Haas CNC Machines2024年1月1日 About Chainsaw Milling Chainsaw milling is a method of sawing that uses a chainsaw and a milling attachmentIt’s a viable alternative to large, expensive machinery Different Types of Chainsaw Mills There are primarily two chainsaw mill types: Alaskan Mill – portable and attaches to the saw’s bar Vertical Mill – handles vertical cuts, slicing stumps and Chainsaw Mill Guide: Your Path to Expert Milling2020年11月2日 Mill Configuration REVERSING ROUGHING MILL WIDTH REDUCTION: Slab width is reduced up to two inches with the vertical edging rolls (squeeze) THICKNESS REDUCTION: Roughing mill reduces slab thickness in five (5) to seven (7) reversing passes down to 1125” (transfer bar) DESCALING: High pressure descale water on entry side of mill removesPrinciples of Hot Rolling AIST

How Much Storage Space Does My PC Need? HowTo Geek

2022年5月31日 To determine how much disk space you need on your desktop or laptop, you need to identify what you'll be using your computer for If you're mainly storing files, photos, and videos, you probably won't need more than 500GB of hard disk space at any given time In fact, this is likely overkill unless you're hoarding highresolution photos and 2024年10月2日 There are many components that go into establishing a website You must factor in website costs for domains, hosting and design When building a website, there are three ways to go about it: a How Much Does A Website Cost? (2024 Guide) – Forbes CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill Ultra fine vertical roller millUltra Fine Millultra 5 天之前 Savonius VerticalAxis Wind Turbine The Savonius verticalaxis wind turbine uses cups, called scoops, instead of blades to capture wind power Figure 5 shows an example of a Savonius verticalaxis wind turbine When the wind VerticalAxis Wind Turbine (VAWT): Working,

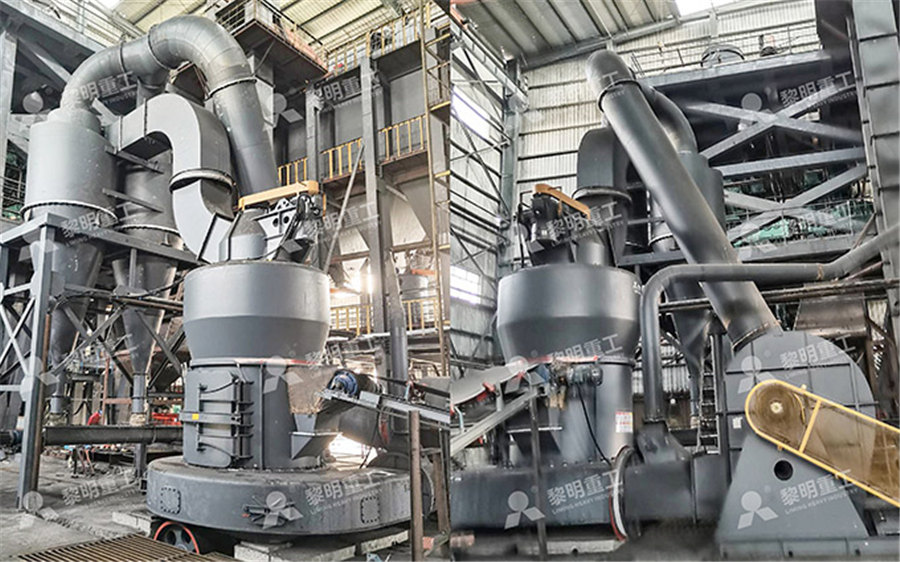

Energysaving and Efficient Vertical Roller Mill

6 天之前 What is a vertical roller mill? A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical 2011年3月21日 HighSpeed 3D Printing With FFF: All You Need to Know As the demand for faster production cycles continues to grow, the ability to produce highquality parts quickly and efficiently has become increasingly important Highspeed 3D printing has emerged as a key solution to reduce lead times and increase productivity across industriesA New Milling 101: Milling Forces and Formulas2021年2月8日 Multipoint saddle, knee, table and ram locks for high rigidity Contact LeBlond for Pricing On a Versatile Knee Mill If you’re like John from Chattanooga and need a versatile knee mill that offers the quality of the LeBlond name, excellent service and OES parts support, please reach out: Please leave a comment, and we’ll be happy to helpWhat Is a Vertical Knee Mill Why Do You Need One?2024年10月13日 Working Principle of a Ball Mill The working principle of a ball mill is based on the rotation of the drum, which causes the grinding media to fall onto the material to be ground The force of impact breaks the material into smaller particles, while the friction between the balls and the material causes further grinding and refinementUnderstanding the mechanism: How does a ball mill work?

How Profitable Is Vertical Farming? (2024 Breakdown)

Vertical farming, a method of growing crops in vertically stacked layers, has gained popularity in recent years, especially in urban areas As of 2024, its profitability hinges on several factors, including technological advancements, energy costs, and market demand for locally grown produce While initial setup costs can be high, the efficiency of space use and potential for Workings of a vertical roller mill and gain an understanding of how this equipment is used in various industries Overview of the components, processes, and benefits of a vertical roller mill The material is ground between the rollers and the table, and the grinding force generated by the rollers is transferred to the material The How does a Vertical Roller Mill Work? ball mills supplierVertical roller mills (VRM) have become increasingly popular in recent years, as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localized rises in cement demand The demand for cement has grown rapidly in recent years, creating a need for a more efficient way to grind clinker and other raw materials used in How does vertical roller mill work? ball mills supplier2018年5月20日 A 60° turn in an airplane doubles the gforce; how much gforce is experienced in a 15°, 30° and 45° turn? Is it 05, 1 and 15g respectively? load factor is already relative to the lift needed to loft the airplane, so constant gravity need not be assumed And yes, a 45 degree banked turn on the moon would be different, since you wouldn How much gforce is experienced in a 45° turn?

.jpg)

Dunk Calculator How High Do I Need to Jump

2 天之前 If you improve your vertical jump by only 2 inches your effective hangtime increases by 30% to 051 seconds giving you much more time in the air for stuff like windmills The speed of the dunk becomes much faster as you G0797 10" x 50" 3 HP Vertical Mill with Power Feed and DRO An industrialgrade machine with amazing features at a low price point The G0797 10" x 50" Vertical Mill with power feed and DRO is a fullfeatured mill built for those that have 10" x 50" 3 HP VariableSpeed Vertical Mill with JTM1050EVS2/230 Electronic Variable Speed Vertical Milling Machine 230V 3Ph The store will not work correctly when cookies are disabled Skip to Content The electrical box has been relocated to the back of the mill and JTM1050EVS2/230 Electr Var Spd Vertical Mill 2009年3月5日 I'm scratchbuilding a CNC mill, and need to know how many foot pounds it takes to push the cutting head through CRS and tool steel, aluminum and brass I understand that the cutters need to be at their sharpest, and that the tool path should take off small chips (small depth of cut), and that the XYZ motors should not be rushing alongHow much force does it take to mill steel? CNCzone

.jpg)

What is a Vertical Milling Machine? How Does it Work? BoYi

2024年8月16日 A vertical milling machine is an essential tool in the manufacturing industry, used to shape metal and other solid materials The cutter is mounted on the spindle head and rotates at high speeds, generating the cutting force Meanwhile, the worktable, holding the workpiece, moves in a controlled manner beneath the cutter, exposing fresh 2017年10月27日 the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter 2 PROCESS CONTROL OF VRM The conventional control system of VRMPROCESS CONTROL FOR CEMENT GRINDING IN 2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitReview on vertical roller mill in cement industry its Start your 48hour free trial to access everything you need to rise to the top of the class Enjoy expert answers and study guides adfree and take your learning to the next levelHow Much Land Does a Man Need? Summary eNotes

Milling Surface Finish: Complete Guide [Tips Secrets]

2024年7月26日 – Roll into cuts with a face mill as described below under Toolpath Considerations – If you don’t need a square shoulder, a 45 degree lead angle facemill will often leave a better finish than a 90 degree Chips are also about 30 percent thinner versus a 90 degree facemill so faster feedrates are possibleThe clamping force must be high enough to counteract the cutting forces but not so high as to deform the workpiece Cutting forces can vary depending on factors such as the machined material, the tool geometry, cutting parameters, and the depth of cut, making it vital to design your clamping setup to accommodate the highest anticipated cutting Clamping Force Calculations: Guide Calculator Carr Lane