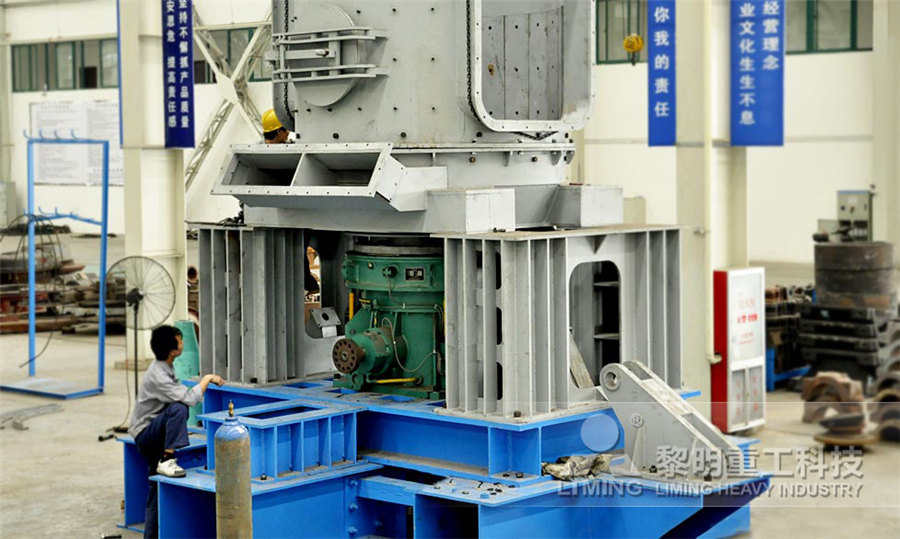

Industrial grinding mill manufacturer dust control project diagram

.jpg)

Dust Control Handbook for Industrial Minerals Mining and

Dust Control Handbook for Industrial Minerals Mining and Processing Andrew B Cecala, Andrew D O’Brien, Joseph Schall, Jay F Colinet, William R Fox, Robert J CRUSHING, MILLING, The handbook describes both dustgenerating processes and the control strategies necessary to enable mine operators to reduce worker dust exposure Implementation of the engineering Dust control handbook for industrial minerals mining and processing2024年1月18日 Understanding the specific contributions of drilling and blasting, loading and hauling, and crushing and grinding to dust generation is critical to Dust Control in Mines: Methods, Sources, SolutionsBühler offers a wide variety of flexible dust aspiration systems Extracting dust from mills and grain facilities helps you keep your plant clean and comply with environmental protection law It can reduce dust explosions and the wear on Industrial Dust Extraction Systems Bühler Group

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

changes to the grinding process Features • Process control of vertical mills • Control of grinding feed and of classifier speed to achieve the required throughput • Improvement in mill stability • 2024年2月8日 Avoiding fire and explosion incidents in a milling operation involves considering the risks, the dust’s characteristics and the milling equipment and examining the process through a DHA, which is required to meet industry Reducing the risk of dust explosions in mills and size The modular control system structure results in reduced projectspecific engineering as it is based on proven hardware and software modules The distributed I/O architecture allows for most of Grinding mill solutions Mill Control System2020年7月22日 Dust collection systems are key to maintaining appropriate conditions for employees and equipment in industrial workspaces Dust collectors are designed and constructed to filter airborne dust and debris that can cause Industrial Dust Collection System Design Considerations

Dust collection basics for powder and bulk solid

2023年10月18日 For powder and bulk applications, dustproducing processes include material receiving and unloading, conveying and material transfer, mixing and blending, grinding/milling/crushing, screening/sieving, weighing and 2024年1月30日 Discover the key factors for Choosing the Right Industrial Dust Control System Learn how to identify your application needs, understand dust characteristics, size the collector right, and make a valuedriven decisionHow to Choosing the Right Industrial Dust Control Welcome Introduction Drotsky has been manufacturing hammer mills and feed mixers since 1962 Over a period of more than 50 years we have built a solid reputation based on professionalism, sound business principles and unsurpassed experience and expertiseDrotsky Hammermills and Maize Mixers Since 1962The hammer mill is used primarily in industrial settings It can provide a reduction ratio of as much as 20:1 Technologies Depending on the material to be treated and the desired particle size, the mill's hammers will be of different weights Hammer mill, Hammer grinding mill All industrial

.jpg)

Grinding mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Final grain size: 200 µm Rotational speed: 50 rpm 3,000 rpm Machine width: 270 mm A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL2070 makes the sample grinding process into a simple pre Highspeed mill, Highspeed grinding mill All industrial manufacturersWilliams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed modulation varies the centrifugal force of the grinding rollsIndustrial Roller Mills Williams Crusher2021年9月23日 Small footprint, simple operation, stable operation, long service life, high efficiency and energy saving, environmental protection, and no dust pollution The industrial ultrafine grinding mill has a material layer control valve, which can control the amount of the feeder, limit the height of the material layer, extend the life of the belt Barite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder

.jpg)

stone dust manufacturer plan diagrams – Grinding Mill China

2010 Fugitive Dust Plan Revised – Lafarge Ravena Facts The Fugitive Dust Control Plan 1 Site Location Diagram Control of fugitive emissions during drilling at the quarry is achieved by manufacturer installed dust » More detailed! wiring diagram for stone crusher in india Comprehensive Industry Document Stone Crushers Schematic diagram of wet dust 2024年11月20日 Planetary Ball Mill: This diagram showcases a unique configuration where multiple grinding jars are mounted on a rotating platform, providing high energy input for ultrafine grinding Horizontal Ball Mill: The traditional design where the cylinder is horizontal, often found in industrial applicationsA Comprehensive Guide to Ball Mill DiagramsDust is a hazard that gets overlooked because too few people know what kinds of risks are involved Once the dust in your workplace has been clearly identified as toxic or combustible, your employees will make greater efforts to minimize its accumulation Selecting a Dust Control System There are lots of dust control system options out thereDust Control in Manufacturing 5 best Practices HSSE WORLD2023年12月23日 The raw mill fan should be regularly inspected and maintained The raw mill fan should be operated in accordance with the instructions Function: Provides the necessary air flow for the raw milling process Application: Used in the preheater and raw mill system to transport raw materials and assist in the grinding processPowering Progress: Unveiling the Technology Behind Industrial

.jpg)

Dry milling mill, Dry milling grinding mill All industrial manufacturers

Final grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory Rotational speed: 3,000 rpm 6,500 rpm Motor power: 1,000 W Machine length: 320 mm Continuously operating universal grinder with a speed range of 3000 6500 rpm • Powerful drive • Easy to clean working surface made of stainless Micronization mill, Micronization grinding mill All As a grinding mill manufacturers, CIC can produce a variety of large industrial grinding mill machine including Overflow Ball Mill, Wet Grid Ball Mill, Dryer Ball Mill, Rod Mill, SAG Mill We have more than 60 years of big grinding mill Industrial Ball Grinding Mill Machine The Tube Mill 100 control Pharma Solution package, Hammer Mill DFZC Bühler is a leading manufacturer of food processing and animal feed processing equipment grinding is in closed system, low dust and noise, clean and environmentally friendly production processImpact mill, Impact grinding mill All industrial manufacturers

Raymond Grinding Mill JXSC Machine

【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to %PDF17 %µµµµ 1 0 obj >/Metadata 3631 0 R/ViewerPreferences 3632 0 R>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI Design and Sizing of Baghouse Dust Collectors2020年1月12日 Overall, this creative project showcases an innovative approach to fugitive dust control, potentially leading to improved environmental and public health outcomes in diverse industrial settings Design analysis of Dust collection system ResearchGateground again Fig 1 shows the grinding circuit layout of the industrial cement plant under study The elements identified in the cement grinding circuit are: G20 is the ball mill; G24 is the dust collector of the ball mill; G31 is the bucket elevator; G35 is the centrifugal separator; and G39 is the dust collector of the separatorPredictive Control of a Closed Grinding Circuit System in Cement

.jpg)

Industrial Dust Collectors Donaldson

For decades, Donaldson Torit® has offered manufacturers the most advanced and reliable dust collectors, industrial dust collection systems and filters available The pairing of these industryleading dust collectors and filters helps increase manufacturing efficiencies and provides a cleaner environment for employees2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill managementOutput: 6 t/h 350 t/h Motor power: 75 kW 3,300 kW Machine length: 2,400 mm 7,200 mm WTM intelligent vertical mill is dedicated to the highefficiency dissociation of minerals, providing users with energysaving, consumption Stone mill, Stone grinding mill All industrial Distance between centers: 1 mm 50 mm Grinding wheel diameter : 305, 405, 455, 510 mm Machine weight: 1,500, 2,400, 3,200, 3,700, 4,000 kg The RC series centerless grinding machines can be used for infeed grinding and Grinding machine All industrial manufacturers

Classifier mill All industrial manufacturers

The particular grinding principle of this jet mill guarantees a The PPS Air Classifier Mill incorporates an internal airclassifying wheel with an independent drive giving precise control over no iron pollution, reduce the damage rate, Rieco is a trusted manufacturer of Air Classifying Mill ACM, specializing in highquality air classifier mill solutions Our ACM mills are designed for precise and efficient grinding, offering excellent particle size reduction capabilities Contact us for topnotch air classifier mill equipment and reliable powder processing solutionsAir Classifying Mill ACM Air Classifier Mill Manufacturer RiecoThe industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 micronsGrinding mill Palamatic Process2024年5月10日 Dust is a hazard that gets overlooked because too few people know what kinds of risks are involved Once the dust in your workplace has been clearly identified as toxic or combustible, your employees will make greater efforts to minimize its accumulation Selecting a Dust Control System There are lots of dust control system options out there5 Best Practices for Dust Control in Manufacturing Safeopedia

.jpg)

Pugmill Mixers FEECO International Inc

CONTINUOUS PUGMILL MIXERS When it comes to industrial mixing applications, FEECO manufactures the industry’s most reputable pugmill mixers, also referred to as paddle mixersThese continuous mixers feature heavyduty construction, along with their Utype trough design, which makes them an excellent choice for agglomerating, mixing, or conditioning in Grinding in a complete closed system, no dust, low noise, continuous for fine grinding of industrial minerals Features Centrifugal ball mill / Roller mill Plant layout and operation similar to conventional roller mills optimal mash structure The C25 grinding mill was developed to mash apples and pears with optimal output Centrifugal mill, Centrifugal grinding mill All industrial manufacturersHammer Mills In machinery manufacturing and milling industries there is a saying that if you have a hammer mill, you have a business Drotsky says: “If you have a Drotsky hammer mill, you are guaranteed a successful business” Milling is the process of breaking up or crushing material into smaller pieces to make it more palatable for human and animal consumptionHammer Mills for Sale South Africa DrotskyRotational speed: 980 rpm Output: 420 kg/h 500 kg/h Motor power: 132 kW Scrap Tyre Rubber Crushing Mill In Waste Tire Recycling Line is mainly used to grinding waste rubber, tir , tube, flap and break the raw rubber materials Finally the steel wire Plastic mill, Plastic pulverizer All industrial manufacturers

Drotsky Hammermills and Maize Mixers Since 1962

Welcome Introduction Drotsky has been manufacturing hammer mills and feed mixers since 1962 Over a period of more than 50 years we have built a solid reputation based on professionalism, sound business principles and unsurpassed experience and expertiseThe hammer mill is used primarily in industrial settings It can provide a reduction ratio of as much as 20:1 Technologies Depending on the material to be treated and the desired particle size, the mill's hammers will be of different weights Hammer mill, Hammer grinding mill All industrial The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine Grinding mill Palamatic ProcessFinal grain size: 200 µm Rotational speed: 50 rpm 3,000 rpm Machine width: 270 mm A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL2070 makes the sample grinding process into a simple pre Highspeed mill, Highspeed grinding mill All industrial manufacturers

.jpg)

Industrial Roller Mills Williams Crusher

Williams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed modulation varies the centrifugal force of the grinding rolls2021年9月23日 Small footprint, simple operation, stable operation, long service life, high efficiency and energy saving, environmental protection, and no dust pollution The industrial ultrafine grinding mill has a material layer control valve, which can control the amount of the feeder, limit the height of the material layer, extend the life of the belt Barite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder 2010 Fugitive Dust Plan Revised – Lafarge Ravena Facts The Fugitive Dust Control Plan 1 Site Location Diagram Control of fugitive emissions during drilling at the quarry is achieved by manufacturer installed dust » More detailed! wiring diagram for stone crusher in india Comprehensive Industry Document Stone Crushers Schematic diagram of wet dust stone dust manufacturer plan diagrams – Grinding Mill China2024年11月20日 Planetary Ball Mill: This diagram showcases a unique configuration where multiple grinding jars are mounted on a rotating platform, providing high energy input for ultrafine grinding Horizontal Ball Mill: The traditional design where the cylinder is horizontal, often found in industrial applicationsA Comprehensive Guide to Ball Mill Diagrams

.jpg)

Dust Control in Manufacturing 5 best Practices HSSE WORLD

Dust is a hazard that gets overlooked because too few people know what kinds of risks are involved Once the dust in your workplace has been clearly identified as toxic or combustible, your employees will make greater efforts to minimize its accumulation Selecting a Dust Control System There are lots of dust control system options out there2023年12月23日 The raw mill fan should be regularly inspected and maintained The raw mill fan should be operated in accordance with the instructions Function: Provides the necessary air flow for the raw milling process Application: Used in the preheater and raw mill system to transport raw materials and assist in the grinding processPowering Progress: Unveiling the Technology Behind Industrial