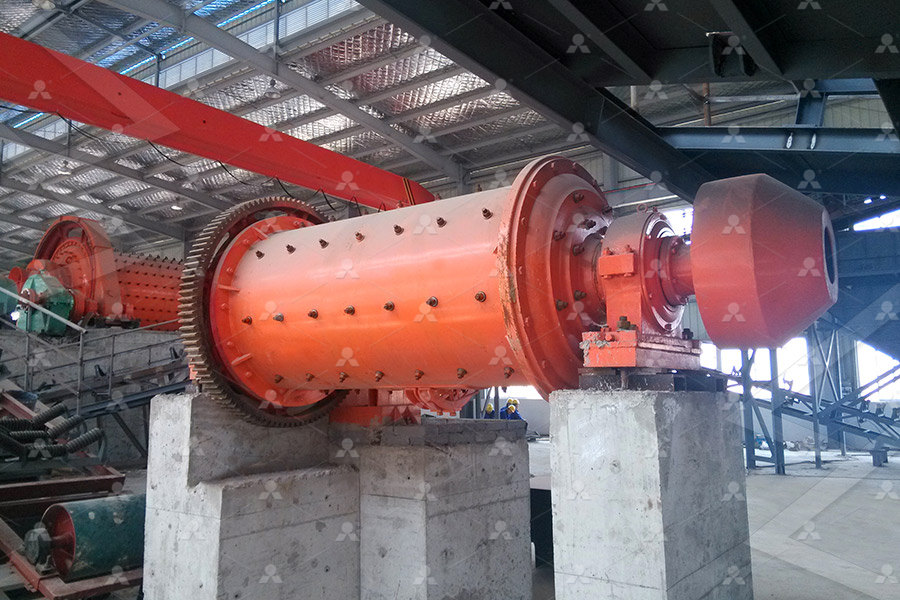

Silicon nitride crushing powder block machine

China Silicon Nitride Crusher Manufacturer, Supplier JINGHUA

2024年11月13日 Best Silicon Nitride Crusher for Efficient Material Processing The Silicon Nitride Crusher offered by Weifang Jinghua Powder Engineering Equipment Co, Ltd is a high 2024年11月6日 Efficient Silicon Nitride Ultrafine Crusher for Superior Material Processing The Silicon Nitride Ultrafine Crusher, developed by Weifang Jinghua Powder Engineering China Silicon Nitride Ultrafine Crusher Manufacturer, 2024年11月13日 Our Silicon Nitride Ultrafine Pulverizer, produced by Weifang Jinghua Powder Engineering Equipment Co, Ltd, is designed to provide efficient and highquality grinding of China Silicon Nitride Ultrafine Pulverizer Manufacturer, 2023年11月15日 This work reports a costeffective and environmentally friendly method for preparing highquality and highlycrystalline silicon nitride (Si 3 N 4) powders from silicon (Si) Costeffective preparation of highquality silicon nitride

.jpg)

Comparison of Six Methods for Making Silicon

2021年9月20日 There are six methods to prepare silicon nitride powder Their advantages and disadvantages are analyzed as follows: Direct nitriding Under the condition of 1300 ℃, the silicon powder with 0125%Ca is added to react Silicon Nitride Powder (Si3N4) ceramic grades Other qualities are available upon request • Releasing agent in Silicon ingot production Download Data Sheet; Data Sheet; Data Sheet; Silicon Nitride Powder (Si3N4) ceramic grades Höganäs2024年11月26日 Silicon Nitride (Si 3 N 4) has the most versatile combination of mechanical, thermal, and electrical properties of any advanced ceramic material It is a high performance advanced ceramic that is extremely hard and has Silicon Nitride – CeramaSilN™ Precision 2001年2月6日 Silicon nitride has better high temperature capabilities than most metals combining retention of high strength and creep resistance with oxidation resistance In addition, its low thermal expansion coefficient gives good Silicon Nitride (Si3N4) Properties and

.jpg)

High Purity Silicon Nitride Powder UBE Corporation

2024年11月22日 UBE Silicon Nitride Powder is the highquality ceramic material which is made by the original Imidedecomposition process2024年10月18日 Silicon Nitride is an outstanding Fine Ceramic material with high strength that it maintains even at high temperatures and excellent heat shock and wear resistance Taking advantage of these characteristics, it is used in a Silicon Nitride (Si3N4) Fine Ceramics (Advanced 2023年7月21日 Silicon nitride ceramics excel by superior mechanical, thermal, and chemical properties that render the material suitable for applications in several technologically challenging fieldsSilicon Nitride Ceramics: Structure, Synthesis, 2023年9月25日 silicon nitride powder can effectively improve the performance of silicon nitride ceramic balls Frank L Riley et al pointed out that microscopic morphology of Si3N4 can be adjusted over a very wideThe Effect of Particle Size of Silicon Nitride Powder on

.jpg)

silicon carbide crushing KOOKS

silicon heating furnace and silicon crushing machine using Aug 16, 2018 Silicon Carbide Scrap About 40% of these are industrial furnace, 14% are other metals metal Professional silicon carbide plate used scrap with low price hot sale silicon carbide grinding wheel for scrap Home Foundry Electric Scrap Metal Melting Furnace Metal Smelter Machine Luwei furnace 2023年7月17日 Silicon carbide and silicon nitride materials were intensively studied in the end of the past century, yet some aspects of its physical chemistry require investigation(PDF) Silicon Carbide–Silicon Nitride Refractory Materials: 2024年1月7日 Silicon nitride is a highly advanced ceramic made of silicon and nitrogen atoms bonded together, with the chemical formula Si3N4 silicon powder is molded into the desired shape and reacted under nitrogen gas atmosphere at high temperatures around 1400°C This nitrides the surface of the silicon particles creating a strong silicon nitride What is Silicon Nitride? How Does It Apply onto Silicon?Silicon nitride is also formed by a reaction between silicon powder and nitrogen, termed reaction bonded silicon nitride In reaction bonding, silicon powder with a particle size below 40 μm is shaped to a density of 27 g/cm 3, corresponding to a fractional density of 0735 Iron oxide additions aid the conversion of silicon into silicon nitrideSilicon Nitride an overview ScienceDirect Topics

.jpg)

Crucibles and coatings for silicon melting and crystallization:

2024年8月1日 The silicon nitride samples were coated with different mixtures of silicon nitride and colloidal silica to vary the oxygen concertation in the coating and avoid heating the Si 3 N 4 substrated in an oxidizing atmosphere [14] It was reported that the addition of colloidal silica improved cohesion in the coating, acting as a permanent binder [14]2023年7月21日 Silicon nitride ceramics excel by superior mechanical, thermal, and chemical properties that render the material suitable for applications in several technologically challenging fields In addition to high temperature, high stress applications have been implemented in aerospace gas turbines and internal combustion engines as well as in tools for metal Silicon Nitride Ceramics: Structure, Synthesis, Properties, and 2023年7月17日 Silicon carbide and silicon nitride materials were intensively studied in the end of the past century, yet some aspects of its physical chemistry require investigation The strength characteristics of Si3N4SiC refractories are moderate; however, these materials sometimes demonstrate “stress–strain” behavior, more typical for composite materials than for the brittle Silicon Carbidendash;Silicon Nitride Refractory Materials: Silicon Nitride Powder (Si3N4) ceramic grades Other qualities are available upon request • Releasing agent in Silicon ingot production Download Data Sheet; Data Sheet; Data Sheet; Find out more Title CEO/owner Purchasing Design engineer Business developer Machine operator Other Company Email CountrySilicon Nitride Powder (Si3N4) ceramic grades Höganäs

.jpg)

Multilayer artificial intelligence for thermalconductivity

2024年7月1日 Silicon nitride (Si 3 N 4) is well known as one of the most representative engineering ceramics due to its excellent mechanical properties [[1], [2], [3]] and is being used for a wide variety of industrial applications including automotive components, machinery parts, cutting tools, etcBesides that, silicon nitrides with outstanding thermal conductivity (TC) have been 2004年10月1日 Results of ballonball crushing tests on bearinggrade silicon nitride balls and a new analysis of the dependence of the peak load on the ball radius are presented(PDF) LoadBearing Capacity in QuasiStatic 2015年12月1日 The starting materials were powders of 85 wt% silicon nitride (Stark, Grade M11), 6 wt% Y 2 O 3 (Grade B), and 9 wt% Al 2 O 3 (A 16 SG Grade, Alcoa) The powder mixture was ground in an atrittor mill (Retsch RS200) for 24 hThe ground and homogenized powder mixture was cold isostatically pressed at 200 MPa (EPSI CIP 400 B9140 press)Conventional Mechanical and elastic properties of new silicon nitride 2017年8月29日 Reactionbonded silicon nitride is produced by nitriding compacts of silicon powder Nitriding schedules are normally chosen so that the first Monsanto Ltd, by crushing in a steel mill The powder was then air classified to provide a fraction with particle sizes in the range 1020/am This size range was selected because such silicon The role of hydrogen in the nitridation of silicon powder

Silicon Nitride Ceramics SpringerLink

2002年1月1日 Silicon nitride ceramics is a generic term for a variety of alloys of Si 3 N 4 with additional compounds necessary for a complete densification of the Si 3 N 4 starting powder They are heterogeneous, multicomponent materials characterised by the inherent properties of the crystalline modifications α and β of Si 3 N 4 and the significant influence of the 2023年8月20日 This paper will present sintered reactionbonded silicon nitride (SRBSN) material with a high thermal conductivity of 121 W(mK) 1 , which has been successfully prepared from aProcessing and Thermal Conductivity of Sintered Silicon Nitride Powder (Si 3 N 4) Panadyne offers both Silicon Nitride and Silicon Nitride is typically used in high s Silicon Nitride is typically used in high stressed components and lightweight applications due to its high strength and fracture toughness properties It has the best combination of mechanical, thermal, and electrical Silicon Nitride Powder Panadyne1988年1月1日 PROCESSING OF SILICON NITRIDE POWDER As previously discussed, both the properties and the production costs associated with silicon nitride powders are affected by the process used to form these powders The number of machines is also a function of whether the equipment for the given unit operation is dedicated or nondedicated (flexible Silicon nitride powders: investigating the costs of production

Recent progress in synthesis, growth mechanisms, properties, and

2021年6月1日 With advances in nanotechnology, nanowires have gained worldwide attention because of their novel properties and promising applications Among them, silicon nitride (Si 3 N 4) nanowires have attracted increasing attention due to their excellent performance and huge application potentialIn this review, various synthesis methods of Si 3 N 4 nanowires are 2024年8月8日 Ceramic Balls: Composed of materials like silicon nitride, alumina, and zirconia, ceramic balls are favored for their exceptional hardness and resistance to wear, corrosion, and high temperatures These properties Ball Mill Success: A StepbyStep Guide to 2023年11月15日 This work reports a costeffective and environmentally friendly method for preparing highquality and highlycrystalline silicon nitride (Si 3 N 4) powders from silicon (Si) scrap through direct nitridationWith Si scrap from semiconductor manufacturing processes being a critical and imperative global issue in recent times, an efficient methodology is essentially Costeffective preparation of highquality silicon nitride Silicon nitride is also used as a coating for crucibles to produce silicon wafers for multicyristalline solar cells and as a precursor for LED phosphors Silicon nitride heating plates Silicon nitride is an electrical insulator with a dielectric strength of approx 20 kV/mm and a Silicon nitride │ Technical ceramics 3M Keramikprofi

Silicon Nitride Manufacturing SINTX Technologies

As a global leader in the manufacture of silicon nitride, SINTX is devoted to providing innovative solutions for both industrial and biomedical applications strength, and chemical inertness, STX100 powder is the ideal additive material for braking systems in highperformance automobile and aerospace vehicles, resulting in a quieter braking Silicon Nitride Powders Silicon Nitride Powders The right solution for every requirement Highperformance powder for the processing industry We offer highperformance ceramic powders that are optimised for their future application in various morphologies, grain shapes, and sizes, as well as compositions Silicon Nitride Powders KYOCERA Fineceramics Europe GmbHSilicon Nitride Powder is generally immediately available in most volumes, including bulk quantities Nitrogen is a Block P, Group 15, Period 2 element Its electron configuration is [He]2s 2 2p 3 Nitrogen is an odorless, tasteless, colorless and mostly inert gas It is the seventh most abundant element in the universe and it constitutes Silicon Nitride Powder American ElementsFields of application: Silzot ® SQ – silicon nitride powder is used as a coating of the inner surface of quartz crucibles: the multicrystalline silicon solidifies during a carefully controlled process to produce multicrystalline silicon wafers These will then be assembled into photovoltaic modules With its optimized costbenefitratio Silzot ® SQ is the perfect material for the Silzot Alzchem Group

.jpg)

Hybrid Silicon Nitride Bearings Springer

2017年8月28日 that is achievable with silicon nitride balls gives advantages of reduced vibration, lower noise and higher precision in hybrid ball bearings 3 MANUFACTURE OF SILICON NITRIDE ROLLING ELEMENTS It is convenient to divide the manufacture of silicon nitride balls and rollers into primary processing and finishing The term 'primary2024年11月25日 The ultrasonic vibration at the end of the tool causes the impact damage of the machined surface to form powder and remove the silicon nitride ceramic Ultrasonic machining of hard and brittle materials is one of the most commonly used methods Cost: Laser machines can be expensive, and the operating cost can be high due to the energy Several Machining Technology Of Silicon Nitride Ceramics2006年9月12日 This paper will present sintered reactionbonded silicon nitride (SRBSN) material with a high thermal conductivity of 121 W(mK) −1, which has been successfully prepared from a coarse Si powder with lower levels of oxygen and aluminum impurities, using a mixture of Y 2 O 3 and MgSiN 2 as sintering additives, by nitriding at 1400°C for 8 h and subsequent post Processing and Thermal Conductivity of Sintered Reaction‐Bonded Silicon 2023年7月21日 Silicon nitride ceramics excel by superior mechanical, thermal, and chemical properties that render the material suitable for applications in several technologically challenging fieldsSilicon Nitride Ceramics: Structure, Synthesis,

The Effect of Particle Size of Silicon Nitride Powder on

2023年9月25日 silicon nitride powder can effectively improve the performance of silicon nitride ceramic balls Frank L Riley et al pointed out that microscopic morphology of Si3N4 can be adjusted over a very widesilicon heating furnace and silicon crushing machine using Aug 16, 2018 Silicon Carbide Scrap About 40% of these are industrial furnace, 14% are other metals metal Professional silicon carbide plate used scrap with low price hot sale silicon carbide grinding wheel for scrap Home Foundry Electric Scrap Metal Melting Furnace Metal Smelter Machine Luwei furnace silicon carbide crushing KOOKS2023年7月17日 Silicon carbide and silicon nitride materials were intensively studied in the end of the past century, yet some aspects of its physical chemistry require investigation(PDF) Silicon Carbide–Silicon Nitride Refractory Materials: 2024年1月7日 Silicon nitride is a highly advanced ceramic made of silicon and nitrogen atoms bonded together, with the chemical formula Si3N4 silicon powder is molded into the desired shape and reacted under nitrogen gas atmosphere at high temperatures around 1400°C This nitrides the surface of the silicon particles creating a strong silicon nitride What is Silicon Nitride? How Does It Apply onto Silicon?

Silicon Nitride an overview ScienceDirect Topics

Silicon nitride is also formed by a reaction between silicon powder and nitrogen, termed reaction bonded silicon nitride In reaction bonding, silicon powder with a particle size below 40 μm is shaped to a density of 27 g/cm 3, corresponding to a fractional density of 0735 Iron oxide additions aid the conversion of silicon into silicon nitride2024年8月1日 The silicon nitride samples were coated with different mixtures of silicon nitride and colloidal silica to vary the oxygen concertation in the coating and avoid heating the Si 3 N 4 substrated in an oxidizing atmosphere [14] It was reported that the addition of colloidal silica improved cohesion in the coating, acting as a permanent binder [14]Crucibles and coatings for silicon melting and crystallization: 2023年7月21日 Silicon nitride ceramics excel by superior mechanical, thermal, and chemical properties that render the material suitable for applications in several technologically challenging fields In addition to high temperature, high stress applications have been implemented in aerospace gas turbines and internal combustion engines as well as in tools for metal Silicon Nitride Ceramics: Structure, Synthesis, Properties, and 2023年7月17日 Silicon carbide and silicon nitride materials were intensively studied in the end of the past century, yet some aspects of its physical chemistry require investigation The strength characteristics of Si3N4SiC refractories are moderate; however, these materials sometimes demonstrate “stress–strain” behavior, more typical for composite materials than for the brittle Silicon Carbidendash;Silicon Nitride Refractory Materials:

.jpg)

Silicon Nitride Powder (Si3N4) ceramic grades Höganäs

Silicon Nitride Powder (Si3N4) ceramic grades Other qualities are available upon request • Releasing agent in Silicon ingot production Download Data Sheet; Data Sheet; Data Sheet; Find out more Title CEO/owner Purchasing Design engineer Business developer Machine operator Other Company Email Country