Slag vertical mill maintenance

How to properly maintain cement and slag

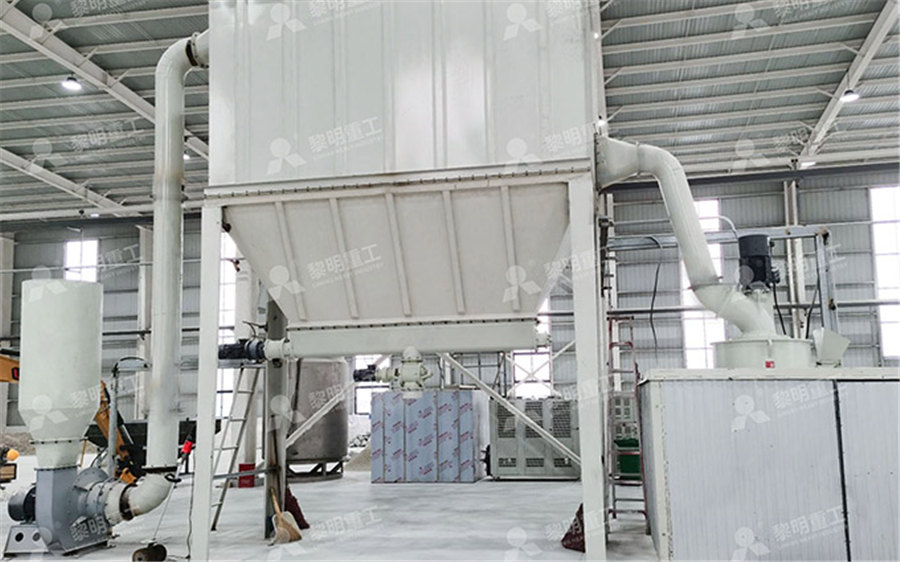

Maintenance maintenance is the focus of enterprise equipment maintenance For slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve 2013年3月13日 R MILL TRM series slag vertical roller mill(hereinafter named as “Slag VRM”)is specialized in slag grinding and developed on basis of TRM series raw grinding vertical roller TRM SERIES SLAG VERTICAL ROLLER MILL TRM Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and Vertical roller mills FLSmidth Cement2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the PROCESS OPTIMISATION FOR LOESCHE GRINDING

.jpg)

Slag Vertical Roller Mill msbmchina

2023年1月10日 As the core equipment in the production process of slag grinding, the LM slag vertical roller mill of SBM integrates fine crushing, grinding, drying, powder selection and The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani Mohanta, Citation 2015) The Full article: Reliability assessment of the vertical roller mill 2007年11月1日 In the cement industry MPS vertical roller mills with installed powers of over 5000kW are currently in operation or on order These mills are used to grind cement raw MPS vertical roller mills for slag and slag cements2023年12月6日 Vertical roller mills have been used successfully for the combined drying and grinding of cement raw material, coal, cement clinker, blastfurnace slag and composite Grinding Process Optimization Featuring Case Studies

2 µm 5 µm Loesche

2017年8月11日 Loesche mills showed poor running behaviour of the mill owing to unsatisfactory formation of the grinding bed The application of this knowledge led to a patented solution in 6 天之前 Vertical Roller Mills (VRM) have a clearly higher energy eficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments led to the increased SikaGrind® for vertical roller mills2024年10月22日 The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag 2006 Slag Grinding With MPS Vertical Roller 2020年8月13日 UBE Machinery Corporation Ltd (UBE) has been supplying Vertical Mills for the last 60 years UBE Mills are energy efficient and easy to operate maintain The Mills are available in wide range of capacity for all the applications UBE has been pioneers in cement and slag grinding where “2Way System”is applied toVERTICAL ROLLER MILLS AMCL

Slag grinding with the Polysius Roller Mill in China

2007年2月1日 The picture in Figure 6 shows typical iron contents found in a slag grinding plant with vertical roller mill The incoming granulated blast furnace slag has an iron content of 028%, corresponding to an iron quantity of 210kg/h Special installation equipment, which facilitates rapid replacement through the large maintenance doors in the 2023年1月19日 PRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in construction,coal,power plant,steel plant,construction,cement,ceramic and easy maintenance, power saving, fast investment LM series vertical millMaintenance maintenance is the focus of enterprise equipment maintenance For slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve advance prediction and control, and eliminate hidden dangers in advance, which can prevent major accidents and How to properly maintain cement and slag vertical mills?Compared with other equipment, the slag vertical roller mill has obvious advantages in energy consumption, which can save more than 40% of power consumption, and has low noise, low maintenance cost, good shape and stable quality of finished mineral powder Therefore, it has become an ideal slag grinding mill equipment choice for slag powderNews Application Of Slag Grinding Mill Introduction To

Vertical Roller Mills Cement Processing Equipment CITIC HIC

2024年10月15日 2 vertical roller mills for slag (LGMS5727), annual output 1,400,000 ton Vietnam Hoa Phat Group Operation and maintenance training, onsite installation guide, commissioning and trial running (mechanical, hydraulic and electrical systems), high quality original spare parts supply ;2024年11月13日 This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h the grinding roller can be raised by reverse pressurization to achieve noload start and noload maintenance Separator The separator completes the sorting process by a vortex plane, making the powder selection efficiency Slag Mill Vertical Slag Mill Provider SINOMALYA vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding Production costs (including wages, electricity, coal burning, maintenance management fees, sales expenses, etc) ≈50 yuan/ton: Profit Slag Grinding Plant GGBS Plant Slag Mill, Slag Cement 2024年8月26日 PFRM30立式磨PFRM30 vertical mill使用手册User manual 江苏鹏飞集团股份有限公司Jiangsu Pengfe Company Information Move the roller out of the mill by the hydraulic unit, replace the roller sleeve lining and large PFRM30 vertical mill user manualvertical

Vertical roller mill routine maintenance note

2014年2月25日 Vertical roller mill routine maintenance note Download as a PDF or view online for free Technology production and application method of tripod machine vertical roller mill processing water slag is the diagenetic agent Advantages of HCM Machinery HLM Vertical Mill Steel Slag Grinding The steel industry is a pillar industry related to a country’s national economy and people’s livelihood, and is also one of the industries that emits the largest amount of solid waste There is a large space for replacing the roller sleeve lining and mill maintenance Advantages of HCM Machinery HLM Vertical Mill Steel Slag 2013年3月13日 TRM series Cement Vertical Roller Mill is the specialized equipment for cement grinding based on TRM series Raw Vertical Roller Mill The initial TRMK4541 Cement Vertical Roller Mill was operated inTRM SERIES CEMENT VERTICAL ROLLER MILL TRM Simple and reliable operation: Limit device for preventing the direct contact between grinding roller and grinding table, to avoid the severe vibration of the mill caused by the collision between roller and tables; With hydraulic roller turningout device, the grinding roller can be turned out of the machine completely to ensure enough maintenance space,which replace and repair easy LM Vertical Roller Mill, slag vertical mill, coal vertical mill

News Carbide Slag Grinding Plant HLM Vertical Mill

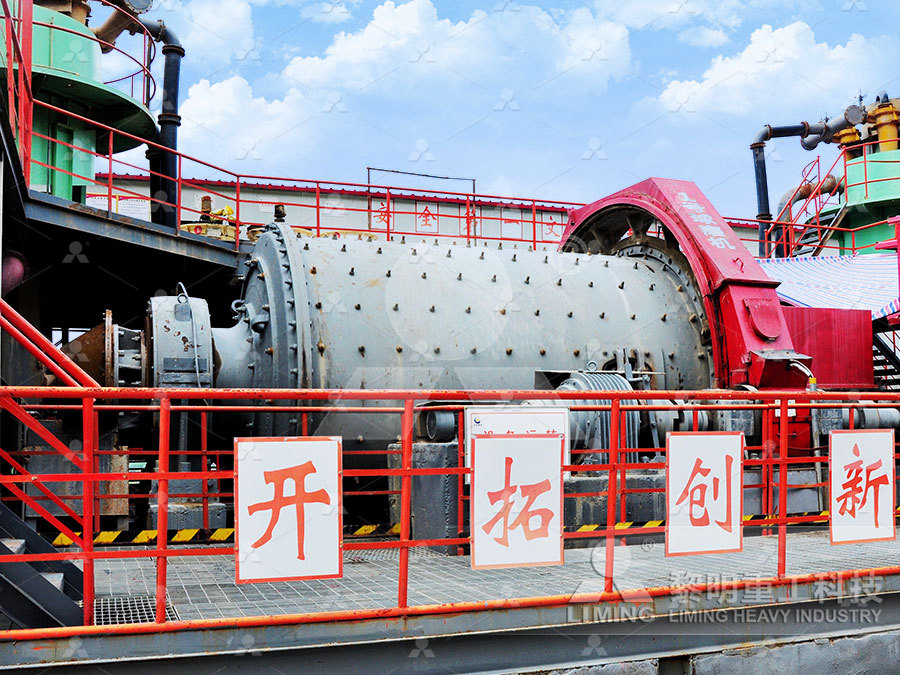

How to choose carbide slag production line? HLM vertical mill is a preferred slag grinding mill for carbide slag powder making Carbide slag has uniform composition and high calcium content which is a highquality cement raw material It is the most thorough method to replace limestone to produce cement2019年4月5日 7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRY2022年5月18日 7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRYFor grinding of slag or slag cement in a vertical roller mill, grinding aid is generally not required Likewise, in terms of ease of maintenance, the ball mill has an advantage over a vertical roller mill Aside from the consumption of electrical energy, in which respect the vertical roller mill is superior compared to a ball mill, other Cement grinding Vertical roller mills VS ball mills

Vertical Raw Mill CHAENG

2024年11月20日 Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, sewage treatment Vertical Raw Mill Remarkable energysaving and environmental protection, convenient maintenance The system is in the state of negative pressure, no dust runs out and environment is clean, meeting the national 2021年3月10日 First vertical mill for cement grinding Gebr Pfeiffer Granulated blastfurnace slag Raw material 15 MPS vertical mill Optimized free fl ow areas SLS high effi ciency classifi er for sharp classifi cation Maintenance door Closed mill housing LiftandSwing System Maintenance drive Torque support Liftable grinding rollers External pull PASSION FOR GRINDING irpcdnmultiscreensite2023年6月25日 Large vertical mill is widely used in the modern cement industry and the maintenance of their supporting components is related to the normal production of vertical mills The large reducer supporting the vertical mill Large Vertical Mill Reducer MaintenanceThe optimized grinding roll design can quickly and finely grind the slag into a fine powder, effectively improving the grinding efficiency, reducing grinding time, and increasing production efficiency Compared to traditional tube mills, the slag vertical mill can save 4560% of electrical energy, while material grinding can save 3540%Slag Grinding Vertical Milling Machine Vertical Mill

.jpg)

Slag vertical mill NEWS SMMVIK Machinery millvik

2024年10月13日 A slag vertical mill is a type of grinding equipment used in the production of slag powder It is a vertical roller mill designed to grind granulated blast furnace slag, a byproduct of the steelmaking process, into a fine powder Vertical mills are designed to operate continuously, with minimal downtime required for maintenance and Our vertical roller mills are able to pulverise steel slag into powder Cement Pulverisation Steel Slag Vertical Roller Mill Technology 01403 223 101 enquiriesUK@loescheCement Pulverisation Steel Slag Vertical Roller Mill Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOK™ Raw and Cement Mill FLSmidth Cement6 天之前 slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills

.jpg)

2 µm 5 µm Loesche

2017年8月11日 slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical2023年12月6日 For cement, composite cement and blast furnace slag grinding many modular vertical roller mills are in operation, starting with first industrial experience in 2008Grinding Process Optimization Featuring Case Studies 2024年10月22日 The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag 2006 Slag Grinding With MPS Vertical Roller 2020年8月13日 UBE Machinery Corporation Ltd (UBE) has been supplying Vertical Mills for the last 60 years UBE Mills are energy efficient and easy to operate maintain The Mills are available in wide range of capacity for all the applications UBE has been pioneers in cement and slag grinding where “2Way System”is applied toVERTICAL ROLLER MILLS AMCL

.jpg)

Slag grinding with the Polysius Roller Mill in China

2007年2月1日 The picture in Figure 6 shows typical iron contents found in a slag grinding plant with vertical roller mill The incoming granulated blast furnace slag has an iron content of 028%, corresponding to an iron quantity of 210kg/h Special installation equipment, which facilitates rapid replacement through the large maintenance doors in the 2023年1月19日 PRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in construction,coal,power plant,steel plant,construction,cement,ceramic and easy maintenance, power saving, fast investment LM series vertical millMaintenance maintenance is the focus of enterprise equipment maintenance For slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve advance prediction and control, and eliminate hidden dangers in advance, which can prevent major accidents and How to properly maintain cement and slag vertical mills?Compared with other equipment, the slag vertical roller mill has obvious advantages in energy consumption, which can save more than 40% of power consumption, and has low noise, low maintenance cost, good shape and stable quality of finished mineral powder Therefore, it has become an ideal slag grinding mill equipment choice for slag powderNews Application Of Slag Grinding Mill Introduction To

.jpg)

Vertical Roller Mills Cement Processing Equipment CITIC HIC

2024年10月15日 2 vertical roller mills for slag (LGMS5727), annual output 1,400,000 ton Vietnam Hoa Phat Group Operation and maintenance training, onsite installation guide, commissioning and trial running (mechanical, hydraulic and electrical systems), high quality original spare parts supply ;2024年11月13日 This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h the grinding roller can be raised by reverse pressurization to achieve noload start and noload maintenance Separator The separator completes the sorting process by a vortex plane, making the powder selection efficiency Slag Mill Vertical Slag Mill Provider SINOMALYA vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding Production costs (including wages, electricity, coal burning, maintenance management fees, sales expenses, etc) ≈50 yuan/ton: Profit Slag Grinding Plant GGBS Plant Slag Mill, Slag Cement