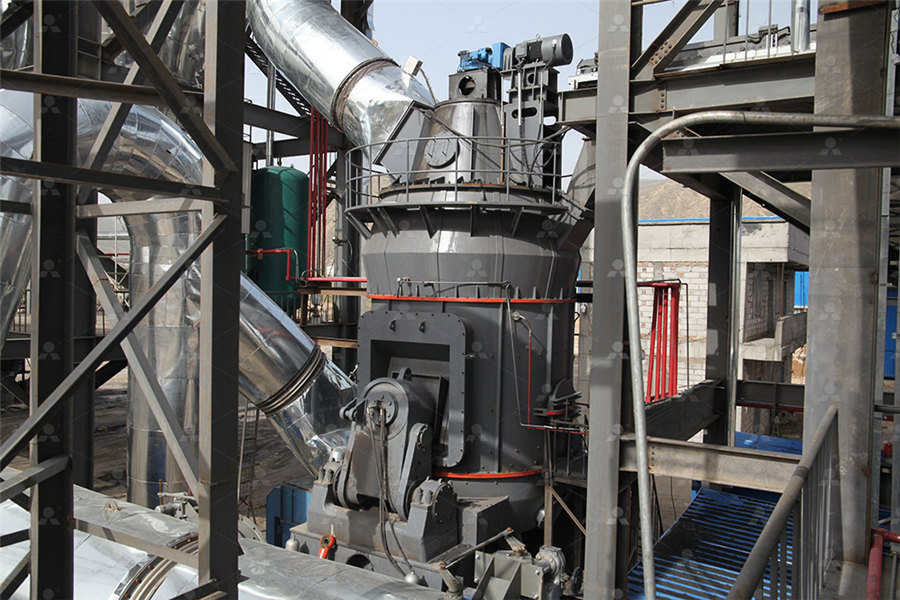

Calcium oxide calcium carbonate crushing station

.jpg)

Surface and bulk carbonate formation in calcium oxide

2017年9月15日 CaO from Ca (OH) 2 presents more highly reactive sites than CaO from CaCO 3 Water or hydroxyl functionality initiates bulk carbonate formation at 300 °C Calcium looping 2002年7月11日 This study is focused on improving the reactivity of a CaO sorbent for its use in a reactionbased process for the separation of carbon dioxide (CO 2) from flue gas The Carbonation−Calcination Cycle Using High Reactivity Calcium Oxide 2010年4月1日 Each of these topics is reviewed in detail here, as are potential competing reactions with sulphurous compounds and the largescale integration of the calcium looping The calcium looping cycle for largescale CO2 capture2024年6月6日 CS can be used instead of calcium carbonate (CaCO 3) to produce calcium oxide (CaO), reducing carbon dioxide (CO 2) emissions Our group has reported that CaO can be prepared at lower temperatures using CS An Innovative Approach to Prepare Calcium

.jpg)

Preparation, Characterization and Application of Calcium Oxide

2022年7月2日 In this study, a novel technique was developed, which involves combination of Limex method and sol–gel method for the preparation of calcium oxide nanoparticles (CON) 2022年2月24日 The cyclic calcium oxidecalcium carbonate (CaOCaCO3) process is a promising option for largescale CO2 control Important advantages include hightemp operation, inexpensive sorbent feedstock, and high CO2 Carbonation Kinetics of Ca(OH)2 Under 2023年3月28日 Several methods for reducing specific CO 2 emissions have been reported in the cement industry, including calcium looping, which uses the reversible reaction between Experimental analysis on calcination and carbonation process in calcium In the endothermic decomposition (calcination) reaction, calcium carbonate (CaCO 3) absorbs energy to produce a metal oxide (CaO or lime) and CO 2 The exothermic carbonation reaction occurs at a lower temperature and/or higher Comparative Kinetic Analysis of CaCO3/CaO

.jpg)

Energy analysis of CaCO3 calcination with CO2 capture

2011年1月1日 Active lime (main component, CaO) can be used to capture CO 2 in the exhaust gas or in the reactor from fossil fuels utilization effectively That is calcium oxide (CaO) 2024年1月2日 产品描述: 中文名:氧化钙 英文名:Calcium oxide CAS: 规格:98% 产地: 中国上海 合肥天健化工有限公司 产品名: 氧化钙 询盘 CAS: 产地: 安徽 0086551 电子 sales@tnjchem info@ calcium oxide化工百科2017年1月3日 Calcium oxide is usually made by the thermal decomposition of materials, such as limestone or seashells, that contain calcium carbonate ($\ce{CaCO3}$; mineral calcite) in a lime kiln This is accomplished by heating the material to above 825 °C (1,517 °F), a process called calcination or limeburning, to liberate a molecule of carbon dioxide How is the process of converting calcium carbonate (CaCO3) into calcium 2009年11月1日 The grains with optical properties of Calcite, Calcium carbonate CaCO 3 , including its diagnostic optical properties (very high birefringence, Calcium oxide (CaO; lime) looping is a proposed Characterization of Calcium Carbonate, Calcium

.jpg)

Calcium Carbonate Manufacturing Process and Equipment

2021年12月20日 Calcium carbonate manufacturing process depends largely on the application for which the calcium carbonate will be used Learn more (calcium oxide) to initiate a chemical reaction between the quicklime and water to make a slurry consisting of calcium hydroxide This essentially makes a waterbased suspension, of which half or more can be Calcium oxide can be produced by the thermal decomposition of calcium carbonate according to the equation: CaCO₃ CaO + CO₂ What is the minimum amount of calcium carbonate needed to produce 112 g of calcium oxide? [Ca = 40 g/mol, C = 12 g/mol, O = 16 g/mol]Question Video: Calculating the Mass of Calcium Carbonate NagwaPrecipitated calcium carbonate (CAS: 471341) is produced industrially by the decomposition of limestone to calcium oxide followed by subsequent recarbonization or as a byproduct of the Solvay process (which is used to make sodium carbonate) Precipitated calcium carbonate is purer than ground calcium carbonate and has different (and Calcium Carbonate CaCO3 CID 10112 PubChem2021年7月1日 In Fig 6b, the sintering effect caused by the combination of high temperature and CO 2 diffusion in the calcium oxide layers can be observed: the layers gained more physical consistency, showing Sintering mechanism of calcium oxide/calcium carbonate

Synthesis and Characterization of Monodispersed Spherical Calcium Oxide

2022年7月15日 Calcium carbonate (CaCO 3) is one of the most important inorganic materials because it has a wide range of applications in various fields of industry [1,2,3]Especially, it is used in white pigments, fillers, biomedical implanting, drug delivery, and 2009年10月15日 In this paper a complete characterization of lime cycle transitions is described CaCO 3 was collected from a Mexican mine and was processed to obtain Ca (OH) 2 through CaO When the calcium hydroxide interacted with the CO 2 in the air forming CaCO 3, the lime cycle was completedCrystal structure and spectroscopy characterization was carried out to Characterization of Calcium Carbonate, Calcium Oxide, and Calcium 2024年1月6日 The efficiency of the calcination process that transforms calcium carbonate (CaCO3) to calcium oxide (CaO) was often depended on the variable involved Therefore, we wish to demonstrate theSTUDY OF CALCINATION CONDITION ON 2024年11月3日 Calcium Oxide is typically produced by the thermal decomposition of limestone or other materials containing calcium carbonate in a process known as calcination The limestone is heated to temperatures above 900°C in a lime kiln, resulting in the release of carbon dioxide and the formation of Calcium Oxide CaCO 3 → CaO + CO 2 Applications of Calcium Oxide Formula, Properties Application

Calcium Carbonate an overview ScienceDirect Topics

Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to To reduce and utilize these wastes, eggshell wastes were simply transformed to low or highpurity calcium carbonate grades by washing, crushing, and drying to use as raw materials for producing Process flowchart of low and highpurity 2024年10月26日 Calcium carbonate Calcium carbonate is a chemical compound with the formula CaCO₃ It is a common substance found in rocks, such as limestone and chalk It also occurs in eggshells, snail shells, and the shells of marine animals such as clams and oysters It will be corroded by acid It breaks down into carbon dioxide and calcium oxide at Calcium Compound: Oxide, Hydroxide Carbonate Anec2020年7月30日 The calcium carbonate was synthesized with the temperatures of 65, 100, 150, 200 and 234°C The eggshell powder size was 29, 50, 80, 110, and 130 μm The volume of water to mass of eggshell (PDF) Calcium Carbonate Synthesis, Optimization and Characterization

Shells and Other Calcium CarbonateBased Waste

2021年10月23日 Three different sources of calcium oxide were used, namely oyster shells, mussel shells and commercial calcium carbonate All these materials were ball milled in water prior to calcination at 500 °C (decomposition of CaCO 3 to CaO) after which the repeated milling in dry environment for 1 min was conducted The composite material was then 2019年12月9日 Precipitated calcium carbonate production process: first burn the limestone and other raw material sections to generate lime (the main component is calcium oxide) and carbon dioxide, then add water to digest the lime to produce lime milk (main component is calcium hydroxide), and then pass the carbon dioxide carbonized lime milk Calcium carbonate Precipitated calcium carbonate manufacturing process2022年4月7日 Calcium oxide is a common curing agent used for curing contaminated soils It is often used with cement to adjust the pH value Calcium carbonate and calcium hydroxide are common products of (PDF) Comparative Experimental Study on Calcium Oxide, Calcium 2023年12月26日 Thermal Decomposition of Calcium Carbonate form Calcium Oxide with the release of carbon dioxide CaCO3(s) → CaO(s) + CO 2 (g) Reaction with Water Calcium Carbonate is insoluble in water under normal conditions but form calcium bicarbonate when react with carbon dioxide saturated water CaCO 3 (s) + H 2 O(l) + CO 2 (g) → Ca(HCO 3) 2 Calcium Carbonate(CaCO3) Limestone Formula, Structure,

A review on calciumrich industrial wastes: a sustainable

2021年9月21日 This study provides an overview of calcium rich industrial wastes usage in construction materials, their properties and different applications through marble waste and flue gas desulfurization (FGD) gypsum Large quantities of industrial wastes are stockpiled and haphazardly disposed in increasing amounts causing serious environmental concerns The 2019年10月3日 Calcium oxide reacts with carbon dioxide (which is acidic oxide), forming a salt such as calcium carbonate 7 the reaction of calcium oxide with the oxide of sulfur: CaO + SO2 → СаЅО3; CaO + ЅО3 → СаЅО4 Oxide of sulphur is also acidic oxide The reaction produced a salt, respectively – in the first case, calcium sulfite, in Calcium oxide, characteristics, properties and production, chemical 2005年11月1日 Integrated pulp and paper mills use carbon dioxide (CO 2) from the lime kiln stack gas to manufacture precipitated calcium carbonate (PCC), which is synthetic calcium carbonate (CaCO 3) with a higher purity than naturally occurring calcium carbonate (limestone)In the PCC process, purchased calcium oxide (CaO, lime) is hydrated into calcium hydroxide Production of precipitated calcium carbonate from calcium 2023年4月24日 This may involve crushing the quicklime into smaller pieces, hydrating it to produce calcium hydroxide, and then drying it to produce calcium oxide Packaging and transportation The final product is packaged and How is calcium oxide manufactured industrially?

Effect of Calcination Time on Physical and Chemical

2017年5月30日 starting material for preparing lowcost calcium oxide This is because calcium oxide is normally used as an environmentallyfriendly heterogeneous catalyst in a wide range of processes, eg chemical synthesis, petrochemical industry and biodiesel production process In addition, calcium oxide can be separated from product and can be2016年8月1日 The efficiency of the calcination process that transforms calcium carbonate (CaCO3) to calcium oxide (CaO) was often depended on the variable involved Therefore, we wish to demonstrate the Study of calcination condition on decomposition of calcium carbonate Calcium oxide also exists in the colours reds and muted browns The main primary elements which constitute calcium oxide are calcium and oxygen It is prepared by heating calcium carbonate (eg limestone) in a distinct lime kiln to about 500°C to 600°C, decomposing it into the oxide and carbon dioxideCalcium Oxide Properties, Uses and Preparation of Calcium Oxide 2024年11月7日 The main production technologies of light calcium carbonate at home Carbonation method Calcining the raw materials such as limestone to generate lime (ingredient for calcium oxide); then adding water to digest lime to generate lime milk (ingredient for calcium hydroxide) and then passing into the carbon dioxide carbide lime milk for calcium carbonate Grinding mill for Calcium carbonate

What is the Difference Between Calcium Oxide and Calcium

2023年7月12日 The main difference between calcium oxide and calcium hydroxide is that calcium oxide forms by heating calcium carbonate, while calcium hydroxide forms by adding water to calcium oxide Moreover, calcium oxide is a white, crystalline solid with a high melting point and low solubility in water It is not highly reactive with atmospheric moisture2024年7月30日 Calcination involves heating calcium carbonate (CaCO 3) to a high temperature, causing it to decompose and release carbon dioxide (CO 2), leaving behind calcium oxide (CaO) as the final product CaCO 3 (g) → CaO(s) + CO(g) Sources of Calcium Carbonate: It can be obtained naturally ie occurring in minerals such as limestone, chalk, or marbleCalcium Oxide Formula, Properties, Preparation and Uses2024年1月2日 产品描述: 中文名:氧化钙 英文名:Calcium oxide CAS: 规格:98% 产地: 中国上海 合肥天健化工有限公司 产品名: 氧化钙 询盘 CAS: 产地: 安徽 0086551 电子 sales@tnjchem info@ calcium oxide化工百科2017年1月3日 Calcium oxide is usually made by the thermal decomposition of materials, such as limestone or seashells, that contain calcium carbonate ($\ce{CaCO3}$; mineral calcite) in a lime kiln This is accomplished by heating the material to above 825 °C (1,517 °F), a process called calcination or limeburning, to liberate a molecule of carbon dioxide How is the process of converting calcium carbonate (CaCO3) into calcium

Characterization of Calcium Carbonate, Calcium

2009年11月1日 The grains with optical properties of Calcite, Calcium carbonate CaCO 3 , including its diagnostic optical properties (very high birefringence, Calcium oxide (CaO; lime) looping is a proposed 2021年12月20日 Calcium carbonate manufacturing process depends largely on the application for which the calcium carbonate will be used Learn more (calcium oxide) to initiate a chemical reaction between the quicklime and water to make a slurry consisting of calcium hydroxide This essentially makes a waterbased suspension, of which half or more can be Calcium Carbonate Manufacturing Process and EquipmentCalcium oxide can be produced by the thermal decomposition of calcium carbonate according to the equation: CaCO₃ CaO + CO₂ What is the minimum amount of calcium carbonate needed to produce 112 g of calcium oxide? [Ca = 40 g/mol, C = 12 g/mol, O = 16 g/mol]Question Video: Calculating the Mass of Calcium Carbonate NagwaPrecipitated calcium carbonate (CAS: 471341) is produced industrially by the decomposition of limestone to calcium oxide followed by subsequent recarbonization or as a byproduct of the Solvay process (which is used to make sodium carbonate) Precipitated calcium carbonate is purer than ground calcium carbonate and has different (and Calcium Carbonate CaCO3 CID 10112 PubChem

Sintering mechanism of calcium oxide/calcium carbonate

2021年7月1日 In Fig 6b, the sintering effect caused by the combination of high temperature and CO 2 diffusion in the calcium oxide layers can be observed: the layers gained more physical consistency, showing 2022年7月15日 Calcium carbonate (CaCO 3) is one of the most important inorganic materials because it has a wide range of applications in various fields of industry [1,2,3]Especially, it is used in white pigments, fillers, biomedical implanting, drug delivery, and Synthesis and Characterization of Monodispersed Spherical Calcium Oxide 2009年10月15日 In this paper a complete characterization of lime cycle transitions is described CaCO 3 was collected from a Mexican mine and was processed to obtain Ca (OH) 2 through CaO When the calcium hydroxide interacted with the CO 2 in the air forming CaCO 3, the lime cycle was completedCrystal structure and spectroscopy characterization was carried out to Characterization of Calcium Carbonate, Calcium Oxide, and Calcium 2024年1月6日 The efficiency of the calcination process that transforms calcium carbonate (CaCO3) to calcium oxide (CaO) was often depended on the variable involved Therefore, we wish to demonstrate theSTUDY OF CALCINATION CONDITION ON