Which factory produces calcite fine powder 260kw anthracite lignite grinding mill

.jpg)

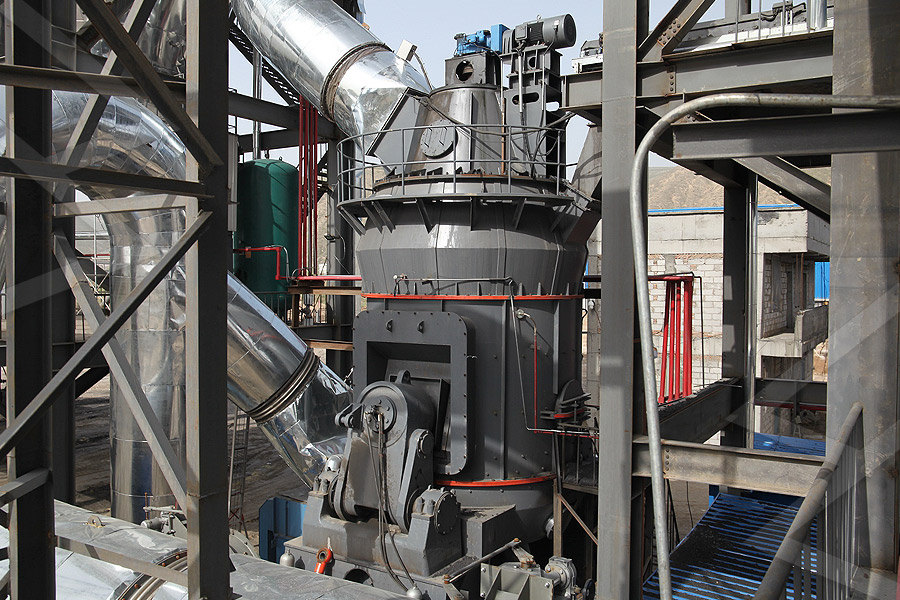

The specialist ultrafine grinding mill for calcite processing

2024年10月13日 One of the key advantages of the ultrafine grinding mill is its ability to produce calcite powder with a variable particle size, ranging from 325 mesh to 2500 mesh, depending 2013年4月11日 In this study, the effects of various operating parameters, such as grinding time (min), stirrer speed (rpm), feed quantity (% of ball weight), and ball filling ratio (%) on fine Dry Fine Grinding of Calcite Powder by Stirred Mill2024年10月13日 The calcite grinding mill employs a unique grinding technology that combines compression, impact, and shear forces to achieve a finer and more uniform particle size This Innovative production process of calcite grinding mill2023年8月1日 The usage of grinding aids prevents particle pelleting and leads to reduced energy consumption The work aims to research the impacts of three pure grinding aids from Effective role of grinding aids in the dry grinding performance of calcite

The effects on the grinding parameters of chemical,

2022年1月1日 In these sectors, there is a need for fine and very fine grinding of calcite minerals (Deniz Polat, 2020) Dry grinding is one of the most important issues for the chemical, China Calcite Powder Mill wholesale Select 2024 high quality Calcite Powder Mill products in best price from certified Chinese Powder Can manufacturers, Powder Material suppliers, China Calcite Powder Mill, Calcite Powder Mill Wholesale, 2022年3月1日 Influences of different grinding aids on dry fine grinding of calcite using a laboratorytype ball mill were investigated Tested grinding aids had affected the flowability Analysis of grinding aid performance effects on dry fine milling of calcite2024年10月13日 The ultrafine grinding mill is engineered to meet the stringent requirements of producing powders with a high degree of fineness, typically in the range of 325 mesh to 2500 The ultrafine grinding mill for processing heavy calcium

Calcite Ultra Fine Powder Grinding Mill China Grinding

2023年12月24日 Calcite Ultra Fine Powder Grinding Mill, Find Details and Price about Grinding Machine Dolomite Powder Making Machine from Calcite Ultra Fine Powder Grinding Mill Lignite Powder Grinding Mill For Lignite Powder Production Line , Find Complete Details about Lignite Powder Grinding Mill For Lignite Powder Production Line,Lignite Powder Grinding Lignite Powder Grinding Mill For Lignite Powder Production HGM125 ultra fine grinding mill, ultra fine powder grinder is a kind of representative machine, and it is the new type industrial ultra fine grinding equipment specializing in producing fine and superfine powder of non Ultra Fine Mill,Ultra Fine Grinder,Ultra Grinding Super Fine Limestone Grinding Mill/Powder Mill/Pulverizer Machine Energy Saving Mining Machinery Calcite Limestone Grinding Ball Mill US$ 150011000 / Piece 1 Piece we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Limestone Grinding Mill factory list to enhance your sourcing Limestone Grinding Mill MadeinChina

.jpg)

HLMX 2500 Mesh Superfine Powder Grinding Mill

We have several decades of experience in manufacturing super fine grinding mill HLMX series super fine mill is independently developed by our engineers which is used for large scale production of nonmetallic powders This 2500 mesh superfine powder grinding mill using static and dynamic separators which is able to produce adjustable fineness Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, good performance Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable Such as marble, calcite, dolomite, calcium carbonate, barite, pumice, etc It can also Limestone Ultrafine Grinding Mill2012年1月1日 In this study, the effects of various operating parameters, such as grinding time (minute), stirrer speed (rpm), feed quantity (% of ball weight), ball filling ratio (%) on fine grinding of Dry Fine Grinding of Calcite Powder by Stirred Mill2021年8月5日 Recommendations for calcite industrial ultrafine powder grinder: Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses Common calcite powder has 3000 mesh, 2500 mesh, 2000 mesh, 1000 mesh, 1500 mesh, 1250 mesh, 800 mesh, and so on They are applicable to different fieldsCalcite Industrial Ultrafine Powder Grinder SBM Mill

Ultra Fine Grinding Mill Ultra Fine Powder Grinder AGICO

What Is Ultra Fine Grinding Mill The ultrafine powder grinding system is a new product independently developed by our company, mainly used to grind and classify various nonmetallic ores in cement plants, such as the grinding of limestone powder, deep processing of pulverized coal, etcThis system is composed of an elevator, airlock device, superfine vertical mill (ultra 2022年3月1日 The efficiency of most grinding processes which are performed wet or dry is very low Dry grinding, in particular, is a difficult process in terms of material transportation since the particles are prone to form agglomerates and coating on the media and mill liners due to the static forces that occur during the grinding operation [1]Chemicals that are known as “grinding aids Analysis of grinding aid performance effects on dry fine milling of calcite2021年11月27日 The powder grinding mill is the equipment used to grind and process materials such as ore It can crush the materials into smaller particles, and then supply them to the production of other equipment or the use of various industries The fine powder after material grinding is brought into the analyzer with the circulating air of the blower What is Powder Grinding Mill? JXSC Machine2021年9月30日 Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 meshes It is a highly efficient industrial micro powder grinding mill Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 meshes For those with a purer texture, the calcite content can reach more than 99% It often contains Chalk Micro Powder Mill SBM Ultrafine Powder Technology

.jpg)

Calcite Powder Manufacturing Process Vertical Roller Grinding Mill

2024年7月10日 Grinding l Ball Mill/Vertical Roller Mill: The crushed calcite is then ground into fine powder using grinding mills Ball mills or vertical roller mills are typically used in this process l Grading and Screening: The ground material is passed through sieves and classifiers to obtain uniform particle size This step ensures the powder is of 2021年3月12日 So far, the biggest mill for lignite coal grinding will be delivered to Cemindo’s Bayah plant in Indonesia This MPS 4500 BK has been ordered for grinding lignite with a maximum moisture of 37% and it is able to produce a MPS mills for coal grinding AYS Engineering2024年11月23日 The powder grinding machine is a grinding mill that can efficiently grind rocks, minerals, or coal The resulting powders are essential for industries like coal, cement, construction, steel, electricity, and energy Our Powder Grinding Mills Engineered by FTM Fote 2023年9月9日 This study aims to investigate the variations in the morphology of lignite samples under different grinding conditions such as grinding time and powder/grinding media ratio (U)The Effects of BallMill Grinding Parameters on Lignite

.jpg)

How to Choose a Calcium Carbonate Grinding Mill DASWELL

2024年9月13日 Methods Equipment Finished product(D97/ μ m) Features Dry grinding process Raymond roller mill 25150 1Applicable materials: medium and low hardness; 2Product features: medium and lowend products, suitable for the production of coarse powder;2009年7月1日 a b s t r a c t An experimental investigation was carried out on the ultrafine grinding of inorganic powders using a stirred ball mill The power consumed in the grinding process was measured Effect of grinding aids on the kinetics of fine grinding energy Should We Choose Raymond Mill or Vertical Roller Mill For Aluminum Powder Processing? Aluminum powder is widely used and in great demand Since the 19th century, it has been produced by a single ball millVertical Roller Grinding Mill Machine CLIRIK Machinery produces SHANGHAI CLIRIK MACHINERY CO, LTD have established a whole production chain, the products cover micro powder grinding mill, ultrafine vertical roller mill and so on Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East ultramillindustrial grinding mill, ultrafine grinding mill,

Selecting the Best Grain/Flour Mill, Ultimate Buyers Guide EZPrepping

5 Reasons Why You Need a Home Grain Mill (Flour Grinder) Freshly ground flour has a much better flavor and produces better breads and pastries after baking than storebought flour; Buying specialty flours can be very expensive so having your own grain mill and a variety of grains to grind will save you a good amount of money, especially over time2023年8月1日 The inefficiency of grinding, especially in dry grinding, is generally explained by the slowing effect caused by fine particles This may originate from the particle regrowth or rebuilding from smaller particles as a result of either agglomeration, including van der Waal's forces, or direct briquetting, or ball coating in order to provide soft surfaces [1, 7, 16, 17]Effective role of grinding aids in the dry grinding performance of calcite2017年9月1日 The first stirred mill was installed in the platinum industry in 2002, and by the year 2010, forty stirred mills had been installed at various platinum operations in South Africa, and these led to a step change in flotation recoveries (Rule, 2011, Rule, 2010)Over the last decade, approximately 200 Automated Scanning Electron Microscopy (AutoSEMEDS) systems have Fine grinding: How mill type affects particle shape characteristics Phase one: raw material crushing Calcite blocks will be crushed to 15mm50mm by crusher Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground Calcite Grinding Mill Calcite Powder Processing Solution

.jpg)

Grinding aids for dry fine grinding processes ScienceDirect

2020年9月20日 The history of grinding aids in dry fine grinding processes starts in the late 1930s with the application of the first commercial grinding aids in the cement industry [1] Since that time, the importance of grinding aids in industrial dry fine grinding processes has strongly increased; so did the number of scientific papers dealing with this topic2018年2月28日 Peat, Lignite, Bituminous Anthracite Coal This division is based on carbon, ash and moisture content Peat First stage of transformation Contains less than 40 to 55 per cent carbon == more impurities Contains sufficient volatile matter and lot of moisture [more smoke and more pollution]Types of Coal: Peat, Lignite, Bituminous Coal Anthracite Coal This unit was designed specifically for fine grinding of calcium carbonate These units combine a grinding mill with a large holding tank equipped with both a highspeed disperser and a lowspeed sweep blade The entire contents of the holding tank pass through the milling chamber at least once every 75 minutes or about 8 times per hour Solids Choose the Right Grinding Mill Chemical Processing2013年4月11日 In this study, the effects of various operating parameters, such as grinding time (min), stirrer speed (rpm), feed quantity (% of ball weight), and ball filling ratio (%) on fine grinding of calcite powder (CaCO 3) (d 50 = 3404 µm) were studied using a laboratory vertical stirred mill under dry conditionsDry Fine Grinding of Calcite Powder by Stirred Mill

Energysaving and Efficient Vertical Roller Mill Fote Machinery

6 天之前 A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for 2024年10月13日 1 Customized for Calcite A specialized grinding mill production line for calcite is designed to handle the unique characteristics of the mineral Calcite has a Mohs hardness of 3, which means it requires a grinding mill that can process soft to mediumhard materials without excessive wear 2 HighQuality Final ProductThe grinding mill production line for calcite processing2024年5月16日 Jaw CrusherPrimary Crusher Process: Feeding: Large chunks of calcite, as extracted from the mines, are fed into the jaw crusher Action: The jaw crusher consists of two jaws, one fixed and the other movingThe moving jaw exerts a compressive force on the calcite, breaking it into smaller pieces Output: The output from the jaw crusher is in the range of 6 to How To Make Calcite Powder?Calcite Powder 2023年11月5日 This document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within the mill 2 Diagrams of beater wheel mills with different configurations, such as with or without a separating classifier or with a precrusher 3 Beater Wheel Mill PDF Lignite Mill (Grinding)

Ultra Fine Mill,Ultra Fine Grinder,Ultra Grinding

HGM125 ultra fine grinding mill, ultra fine powder grinder is a kind of representative machine, and it is the new type industrial ultra fine grinding equipment specializing in producing fine and superfine powder of non Super Fine Limestone Grinding Mill/Powder Mill/Pulverizer Machine Energy Saving Mining Machinery Calcite Limestone Grinding Ball Mill US$ 150011000 / Piece 1 Piece we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Limestone Grinding Mill factory list to enhance your sourcing Limestone Grinding Mill MadeinChinaWe have several decades of experience in manufacturing super fine grinding mill HLMX series super fine mill is independently developed by our engineers which is used for large scale production of nonmetallic powders This 2500 mesh superfine powder grinding mill using static and dynamic separators which is able to produce adjustable fineness HLMX 2500 Mesh Superfine Powder Grinding MillLimestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, good performance Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable Such as marble, calcite, dolomite, calcium carbonate, barite, pumice, etc It can also Limestone Ultrafine Grinding Mill

Dry Fine Grinding of Calcite Powder by Stirred Mill

2012年1月1日 In this study, the effects of various operating parameters, such as grinding time (minute), stirrer speed (rpm), feed quantity (% of ball weight), ball filling ratio (%) on fine grinding of 2021年8月5日 Recommendations for calcite industrial ultrafine powder grinder: Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses Common calcite powder has 3000 mesh, 2500 mesh, 2000 mesh, 1000 mesh, 1500 mesh, 1250 mesh, 800 mesh, and so on They are applicable to different fieldsCalcite Industrial Ultrafine Powder Grinder SBM MillWhat Is Ultra Fine Grinding Mill The ultrafine powder grinding system is a new product independently developed by our company, mainly used to grind and classify various nonmetallic ores in cement plants, such as the grinding of limestone powder, deep processing of pulverized coal, etcThis system is composed of an elevator, airlock device, superfine vertical mill (ultra Ultra Fine Grinding Mill Ultra Fine Powder Grinder AGICO2022年3月1日 The efficiency of most grinding processes which are performed wet or dry is very low Dry grinding, in particular, is a difficult process in terms of material transportation since the particles are prone to form agglomerates and coating on the media and mill liners due to the static forces that occur during the grinding operation [1]Chemicals that are known as “grinding aids Analysis of grinding aid performance effects on dry fine milling of calcite

.jpg)

What is Powder Grinding Mill? JXSC Machine

2021年11月27日 The powder grinding mill is the equipment used to grind and process materials such as ore It can crush the materials into smaller particles, and then supply them to the production of other equipment or the use of various industries The fine powder after material grinding is brought into the analyzer with the circulating air of the blower 2021年9月30日 Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 meshes It is a highly efficient industrial micro powder grinding mill Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 meshes For those with a purer texture, the calcite content can reach more than 99% It often contains Chalk Micro Powder Mill SBM Ultrafine Powder Technology