Calcium carbonate diatomite grinding machine Kunming agent

.jpg)

CationicModified diatomite as a novel carrier Material for

In this study, diatomite was cationically modified using aminebased modifying agents such as 3aminopropyltriethoxysilane (APTES) and diethylene triamine (DETA) to prepare SMD with 2019年4月1日 The aim of this work is to fabricate high apparent porosity ceramics from diatomite and to use calcium carbonate as a modifying agent to change the pore structure of Diatomitebased porous ceramics with high apparent 2018年4月17日 The influence of the calcium carbonate addition to a ceramic composition of diatomite was studied The results showed that calcite addition causes a porosity increasing Preparation of DiatomiteBased Porous Ceramics2022年11月18日 Calcium carbonate has high whiteness and good hiding power The filler (diatom mud) is commonly used for producing papers and interior decoration materials Hu et Effects of mixed carriers on diatomite supported nanoTiO

.jpg)

(PDF) Effects of Grinding Aids Used in Grinding

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with2018年4月18日 In this paper, diatomitebased porous ceramics were prepared using diatomite as main raw material and calcite as poreforming agent The effect of calcite were studied by Preparation of DiatomiteBased Porous Ceramics SpringerLink2021年12月3日 The most commonly used additive in wet grinding of calcium carbonate is a lowpolydispersityindex sodium polyacrylate with an optimized molecular weight A similar Effect of Neutralization of the Grinding Aid in the Production 2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or Effects of Grinding Aids Used in Grinding

.jpg)

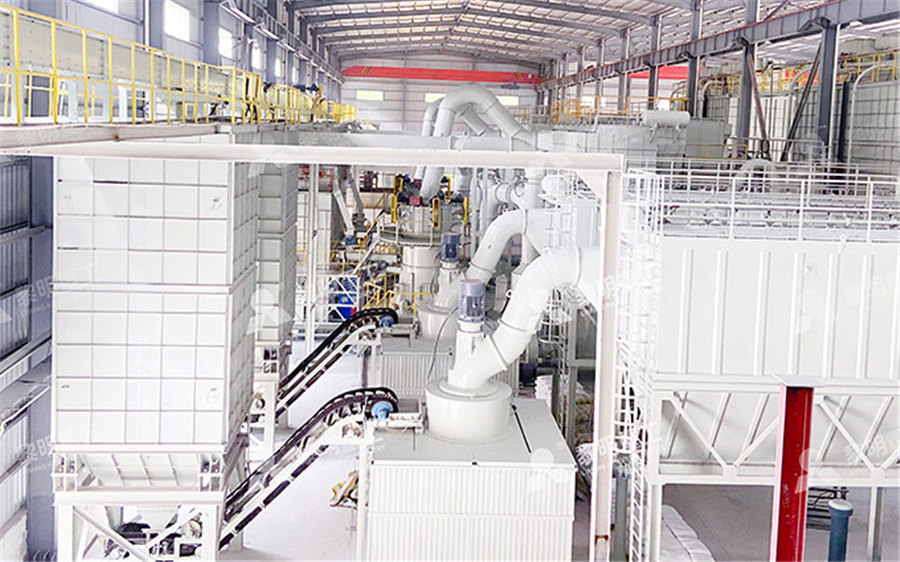

Heavy calcium carbonate grinding, surface modification

2024年7月10日 Ring roller mill is the most widely used fine grinding and ultrafine grinding equipment in the field of heavy calcium carbonate in China in the past decade It is 2019年4月1日 The aim of this work is to fabricate high apparent porosity ceramics from diatomite and to use calcium carbonate as a modifying agent to change the pore structure of Diatomitebased porous ceramics with high apparent 2021年9月9日 Diatomite ultrafine grinding mill is a highly efficient ores powder grinder machine It can grind diatomite into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind nonmetallic Diatomite Ultrafine Grinding Mill SBM Ultrafine 2017年10月31日 Calcium carbonate as cavitation agent in white cavitated BOPP films is well established and known since many years The use of calcium carbonate in BOPET and BOPLA films to create white voided (PDF) Calcium Carbonate CaCO3 as cavitation

.jpg)

Diatomitebased porous ceramics with high apparent

2018年12月1日 Diatomite, one of clay mineral materials, has characteristics as high porosity, large specific surface area, strong absorbability, heat and corrosion resistance [24] [25][26][27], which is thereby 2021年10月15日 As the calcium carbonate further increased to 30 wt%, the more calcium carbonate made the FCs–334/R samples had much different composition to the FCs–(514 and 424)/R samples As seen from Fig 9 (c), when the sintering temperature was 750 °C, the crystalline phase of the FCs–334/R samples was quartz, calcium silicate and calcium Foaming mechanism and performance of closed–pore foamed ceramics 2017年3月1日 Three kinds of novel diatomite/ground calcium carbonate composite humidity control materials were prepared with different calcination temperatures using diatomite and ground calcium carbonate (GCC Preparation and characterization of novel diatomite/ground calcium 2014年11月1日 Free radical polymerization was used to prepare a series of P(AA/AMPS) polymers using acrylic acid (AA) and 2acrylamido2methyl propane sulfonic acid (AMPS) as monomers, ammonium persulfate as the initiator, and isopropanol as the chain transfer agentThe effects of the AA/AMPS and isopropanol/water weight ratios, the initiator dosage, the reaction Synthesis and application of a polyacrylate dispersant on the

.jpg)

Preparation of DiatomiteBased Porous Ceramics

2018年4月17日 diatomite is large, which is beneficial to porous ceramics [9, 10] In this study, experimental results regarding to the use of calcium carbonate as pore generating agent in diatomitebased porous ceramics is reported Experimental Procedure The commercial natural powder of Diatomite (Jilin Changbai Diatomite Co, Ltd,2019年4月1日 The chemical compositions of diatomite and calcium carbonate were shown in Table 1 SiO 2 (8717 wt%) was found to be the main chemical composition of diatomite, and few CaO (157 wt%), Fe 2 O 3 (419 wt%), K 2 O (110 wt%) and TiO 2 (065 wt%) also occurred in diatomite Compared with diatomite, the chemical composition of calcium carbonate was Diatomitebased porous ceramics with high apparent 2024年5月3日 Download scientific diagram Typical XRD patterns of calcium carbonate polymorphs synthesized under different conditions: (a) aragonite, sample D, 50% acoustic amplitude, 45 min; (b) calcite Typical XRD patterns of calcium carbonate polymorphsCalcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds on earth, calcium carbonate has proven valuable in a variety of industries The paper, plastics, paints and coatings industries all rely heavily upon this chalky mineral, due in large part to itsCalcium Carbonate Grinding Union Process

.jpg)

Costeffective foaming agents Imerys

2024年11月16日 Lighter, stronger foamed plastics If you’re producing lightweight materials from polyolefinbased foam composites, or other foamed plastics such as PVC or expanded polystyrene, minerals like calcium carbonate and talc* can improve stiffness at lower densities and increase foaming Ground calcium carbonates like our PolCarb™ and ImerCarb™ grades are 2019年4月1日 DOI: 101016/JCERAMINT201812082 Corpus ID: ; Diatomitebased porous ceramics with high apparent porosity: Pore structure modification using calcium carbonate @article{Jiang2019DiatomitebasedPC, title={Diatomitebased porous ceramics with high apparent porosity: Pore structure modification using calcium carbonate}, Diatomitebased porous ceramics with high apparent 2018年4月18日 The effect of the presence of calcium carbonate in the formulations must be considered and, for this, Table 3 showed the main chemical composition of the formulations used in this work calculated based on the raw materials According to the reaction and the CaO and SiO 2 content in the raw materials, the resultant content of CaSiO 3 and residual silica can be Preparation of DiatomiteBased Porous Ceramics SpringerLink6 Adhesives: Calcium carbonate ultrafine powder vertical grinding machine is used in the adhesive industry to produce fine powder of adhesive materials such as resins and polymers These powders are then used to create highquality Calcium Carbonate Ultrafine Powder Vertical Mill

(PDF) Dispersion, Stabilisation and Casting of Calcium Carbonate

1997年4月1日 The shear forces developed during the preparation of ground calcium carbonate (GCC) suspensions by ball milling were varied by using different solids loading in the starting slurries2024年11月19日 Calcium Carbonate Mineral Fine Grinding Machine German Technology, Find Details and Price about Grinding Milling Grinding Machine from Calcium Carbonate Mineral Fine Grinding Machine German Technology Shanghai HySailing Chemical Tech Co, Ltd pyrophyllite and vermiculite, sepiolite, attapulgite, recto r ite, diatomite, barite, gypsum Calcium Carbonate Mineral Fine Grinding Machine German 2024年9月13日 The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions Production method of calcium carbonate powderHow to Choose a Calcium Carbonate Grinding Mill DASWELL2023年9月28日 A calcium carbonate processing plant is a facility where calcium carbonate is processed and produced for various industrial applications The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specificationsExploring Different Grinding Mills for Calcium Carbonate

.jpg)

Grinding calcium carbonate down to size Making

Ground calcium carbonate grains can be as coarse as 1,300 microns in poultry feed or as fine as 2 microns in paper coatings Milling the limestone to the correct particle size distribution is a test for GCC processing But addressing this challenge successfully makes the difference between high and lowquality calcium carbonate materialsCalcium carbonate, or CaCO3, comprises more than 4% of the earth’s crust and is found throughout the world Its most common natural forms are chalk, limestone, and marble Calcium carbonate appears as white, odourless powder or colourless crystals Calcium carbonate (CaCO3) is the most widely used filler in polymer formulations As a filler, calcium carbonate []Calcium Carbonate SNG Microns Pvt Ltd2019年10月24日 Figure 2 shows the FTIR spectrum of synthesized calcium carbonate nanoparticle by precipitation method The bands at 712, 848 and 872/cm were attributed to the CO 3 2− (calcite) vibration mode of calcium carbonate nanoparticle The symmetric stretching vibrational of CO 3 2− and C–H band was observed at 1406 and 2850/cm, respectively Also, Performance of carbonate calcium nanoparticles as filtration 2014年2月1日 In this paper, the influence of calcium carbonate and slip agent on linear medium density polyethylene (LMDPE) processed by rotational molding was evaluated LMDPE was dry blended with different (PDF) Influence of Calcium Carbonate and Slip

Diatomaceous earth: A review of its characteristics and

2024年3月29日 DE is composed of silicon oxide (>70%), but small amounts of aluminum, iron and calcium oxides may be present Most of the silica present in diatomite is amorphous However, these materials may contain impurities, especially clay minerals and organic matter2022年11月18日 In this study, calcium carbonate, sepiolite, and commonly used diatomite (DE) carriers were mixed to prepare calcium carbonate or sepiolite mixed DE/nanotitanium dioxide (TiO 2)The analyses of X Effects of mixed carriers on diatomite supported nanoTiO2021年8月5日 Calcite, widely distributed, hardness 2730, specific gravity 2628, also called stalactite, stalagmite white marble, and so on The main component of calcite is calcium carbonate, and its main purpose is to make heavy calcium powder and light calcium powderCalcite Industrial Ultrafine Powder Grinder5 天之前 We offer a selective range of calcium carbonate and talcbased* certified food additives and processing aids designed to preserve flavor, simplify processing, and enhance the taste and the appearance of the finished product while our talcs are excellent texturizing agents for gum base and chewing gum minerals such as diatomite and Filtration solutions and minerals for Food Beverage – Imerys

Manufacturing of Al–Mg–Si alloy foam using calcium carbonate as foaming

2009年2月1日 The using calcium carbonate and Al cans offered cheaper fabrication of aluminum foam compare to other methods which are depending on using TiH2 as a foaming agent Calcium carbonate was a highly 2008年9月1日 In paper manufacturing industry, concentrated calcium carbonate (CaCO 3) suspensions with 72–75 wt% are widely used as a white pigment, and impart high brightness, gloss and good printability on coated paper To decrease the viscosity and increase the fluidity of highly concentrated dispersions, the aggregation of solid particles must be prevented, and Preparation and property analysis of polyacrylate dispersant 2024年11月26日 As abrasive and polishing agent in toothpaste; As mineral fertilizer; And as mineral filler or pigment in diverse industrial applications (paper, paint, plaster, plastic, carpet) In addition to kaolin and talc, calcium carbonate is used in the paper industry as a filler and coating pigment in the production of paperCalcium Carbonate NETZSCH Grinding Dispersing2021年9月9日 Diatomite ultrafine grinding mill is a highly efficient ores powder grinder machine It can grind diatomite into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind nonmetallic Diatomite Ultrafine Grinding Mill SBM Ultrafine

(PDF) Calcium Carbonate CaCO3 as cavitation

2017年10月31日 Calcium carbonate as cavitation agent in white cavitated BOPP films is well established and known since many years The use of calcium carbonate in BOPET and BOPLA films to create white voided 2018年12月1日 Diatomite, one of clay mineral materials, has characteristics as high porosity, large specific surface area, strong absorbability, heat and corrosion resistance [24] [25][26][27], which is thereby Diatomitebased porous ceramics with high apparent 2021年10月15日 As the calcium carbonate further increased to 30 wt%, the more calcium carbonate made the FCs–334/R samples had much different composition to the FCs–(514 and 424)/R samples As seen from Fig 9 (c), when the sintering temperature was 750 °C, the crystalline phase of the FCs–334/R samples was quartz, calcium silicate and calcium Foaming mechanism and performance of closed–pore foamed ceramics 2017年3月1日 Three kinds of novel diatomite/ground calcium carbonate composite humidity control materials were prepared with different calcination temperatures using diatomite and ground calcium carbonate (GCC Preparation and characterization of novel diatomite/ground calcium

Synthesis and application of a polyacrylate dispersant on the

2014年11月1日 Free radical polymerization was used to prepare a series of P(AA/AMPS) polymers using acrylic acid (AA) and 2acrylamido2methyl propane sulfonic acid (AMPS) as monomers, ammonium persulfate as the initiator, and isopropanol as the chain transfer agentThe effects of the AA/AMPS and isopropanol/water weight ratios, the initiator dosage, the reaction 2018年4月17日 diatomite is large, which is beneficial to porous ceramics [9, 10] In this study, experimental results regarding to the use of calcium carbonate as pore generating agent in diatomitebased porous ceramics is reported Experimental Procedure The commercial natural powder of Diatomite (Jilin Changbai Diatomite Co, Ltd,Preparation of DiatomiteBased Porous Ceramics2019年4月1日 The chemical compositions of diatomite and calcium carbonate were shown in Table 1 SiO 2 (8717 wt%) was found to be the main chemical composition of diatomite, and few CaO (157 wt%), Fe 2 O 3 (419 wt%), K 2 O (110 wt%) and TiO 2 (065 wt%) also occurred in diatomite Compared with diatomite, the chemical composition of calcium carbonate was Diatomitebased porous ceramics with high apparent 2024年5月3日 Download scientific diagram Typical XRD patterns of calcium carbonate polymorphs synthesized under different conditions: (a) aragonite, sample D, 50% acoustic amplitude, 45 min; (b) calcite Typical XRD patterns of calcium carbonate polymorphs

.jpg)

Calcium Carbonate Grinding Union Process

Calcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds on earth, calcium carbonate has proven valuable in a variety of industries The paper, plastics, paints and coatings industries all rely heavily upon this chalky mineral, due in large part to its