Coal deep processing process

Coal Mining and Processing Methods The National

This appendix presents additional details on the individual processes that are involved in extraction of coal from surface and underground mines, and the subsequent beneficiation of the coal in coal processing plants to produce a 2021年5月15日 In order to realize VAU of HTCT, deep processing methods were systematically discussed This paper mainly discusses the source, composition, research status, separation Valueadded utilization of hightemperature coal tar: A review2021年5月1日 A deep understanding of the structure and reactivity of coal and their relationship can help to reveal and control the chemical reactions of coal pyrolysis, coal gasification, and Breakthrough and innovative clean and efficient coal conversion 1982年8月9日 Coal processing refers to the practice of converting coal into various products such as coal tar, coke, and tarbased chemicals through methods like coal carbonization, coal Coal Processing an overview ScienceDirect Topics

Coal Preparation SpringerLink

Coal preparation, which may also be called washing, cleaning or processing, is the methodology by which coal feedstocks are upgraded in order to reduce freight costs, improve utilization Coal miners use large machines to remove coal from the earth Many US coal deposits, called coal beds or seams, are near the earth's surface, but others are deep underground Modern Coal explained Mining and transportation of coal US Energy 2019年6月17日 Based on the idea of in situ fluidized coal mining that aims to transform solid coal into liquid or gas and transports the fluidized resources to the ground to ensure safe mining and lowcarbon and clean utilisation, in this Fluidized mining and insitu transformation of deep 2021年5月11日 In this chapter, coal preparation techniques employed in the generation of clean coal for various applications are briefly discussed Presentday coal washeries are equipped Mineral Beneficiation and Processing of Coal SpringerLink

.jpg)

Coal Production and Processing Technology MR

Coal Production and Processing Technology provides uniquely comprehensive coverage of the latest coal technologies used in everything from mining to greenhouse gas mitigation Featuring contributions from experts in industry Interests: deep ash reduction; quality improvement and fine sorting of coal; comprehensive utilization of mineral resources In this Special Issue on “Advances in Coal Processing, Utilization, and Process Safety”, we seek to gather highquality research focused on the latest developments in mine safety engineering, Advances in Coal Processing, Utilization, and Process Safety2023年9月27日 The control system based on deep learning can better meet the requirements of the coal processing process and effectively improve the efficiency of a coal processing plant Heavy media coal Analysis of Intelligent Control Strategy for Heavy coal processing products, with the subsequent possibility of exporting the developed products to the foreign market Country's economy industrialization objectives Products production of deep processing of coal Increase the volume of coal produced and processed in TajikistanCoal production and deep processing 日本タジキスタン投資

Coal Mining: How Is Coal Mined? Science ABC

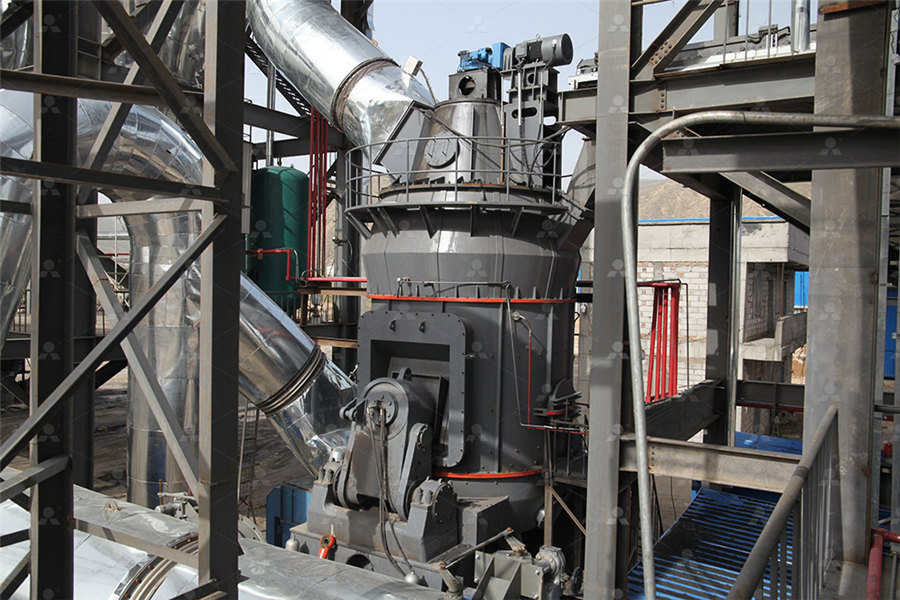

2023年10月19日 Coal Mining Process; Coal mining involves extracting coal from the ground’s surface or from deep underground The industrial revolution was only possible due to the utilization of coal to power steam engines Coal obtained in different places is not the same and varies widely depending on the nature of the soil and geographic conditions2022年2月24日 Fineness: 200325 mesh, according to the process requirements Suitable for coal: it is an effective way for deep processing and utilization of coal to increase the added value Pulverized coal processing and milling equipment According to the fineness of coal feed, moisture content, finished product fineness, How is pulverized coal processed? SBM Ultrafine Powder thermal coal (coal finely ground to generate steam), therefore this document will specifically describe the process of subsurface coal extraction and thermal coal processing Purpose Coal is used for its potential heat energy when burned and since the 1880s has been widely used to generate electricity in power plantsCOAL EXTRACTION AND PROCESSING WordPress2016年5月5日 The plant cleans and processes the coal to remove rocks, dirt, ash, sulfur, and other unwanted materials referred to as gangue [2] This process increases the heating value of the coal and Coal Processing and Utilization ResearchGate

Deep transfer learning for tool condition monitoring under

2024年5月16日 Deep learning methods have developed rapidly in the field of tool condition monitoring, but due to the complexity and diversity of working conditions, it is difficult to ensure the high accuracy, strong generalization performance, and wide applicability of monitoring models Therefore, this article proposes a deep transfer learning method with center loss for tool 2021年5月15日 150 kt/a coal tar deep processing project completed and put into operation (Phase II) 2009: Qitaihe Baotailong Coal Chemical Industry Co, Ltd 300 kt/a of coal tar deep processing project started: 2011: Shandong Baoshun Chemical Technology Co, Ltd 2 × 300 kt coal tar deep processing project completed: 2011: Wuhan Iron and Steel (Group) CompanyValueadded utilization of hightemperature coal tar: A review2021年9月20日 Globally, coal tar processing technologies are similar (Jiang, 2009), and the products are highly homogeneous The main challenges of coal tar processing include insufficiency in deep processing, a low variety of high valueadded products, the small scale of processing equipment, and a lack of investment in development and applicationCarbon precursors in coal tar: Extraction and ScienceDirect2021年5月11日 The modernday coal processing plants can be categorized into four different circuits, depending upon the size of the coal particles to be treated: (a) coarse coal processing circuit treating particles coarser than 10 mm, (b) small coal circuit for washing particles in the size range of 110 mm, (c) fine coal circuit for cleaning particles in size range of 015–1 mm, and Mineral Beneficiation and Processing of Coal SpringerLink

Research progress and prospects of coal petrology and coal quality

Clean utilization of coal depends on the quality of raw coal, which depends on the coalforming parent materials (petrology and chemical composition of coal), the multiple media of the coalforming environment, and some epigenetic conditions, such as thermal evolution (coalification), magmatic hydrothermal fluid, groundwater Based on the research results of predecessors and 2017年12月15日 If coal is high in sulfur or other impurities, it is washed with a water or chemical bath, removing up to 40 percent of inorganic sulfur in the coal Not all coal is prepared using the same process Highsulfur coal commonly How Coal Works Union of Concerned ScientistsCoal Ash Processing With our deep industry knowledge and proven track record, we are your trusted partner in maximizing the value of your ash Transform ash into profit A Process Hazard Analysis (PHA) is a key element of a Process Safety Management (PSM) programCoal Ash Production Processing Analysis PEC Consulting Group2014年6月27日 Coal is broadly separated into brown and black which have different thermal properties and uses Brown coal (lignite) has a low energy and high ash content Brown coal is unsuitable for export and is used to generate electricity in power stations located at or near the mine Black coal is harder than brown coal and has a higher energy contentCoal Geology Geoscience Australia

.jpg)

Deep Processing of Heavy Resids Based on TAIFNK JSC Heavy

2023年4月11日 The Veba Combi Cracking (VCC) process started from development of direct coal hydrocracking processes The earliest wideranging studies on application of hydrocracking in coal processing were carried out by German scientists in the 19101920s [1, 2]Thus, this process of destructive hydrogenation of coal and heavy oils, designated later as Summarize the composition,characteristics and research progress of coal tarThe most widely used coal tar chemical products such as naphthalene,phenolic compound,pyridinium could be prepared from the wash oil of coal tarThe products has high qualityThe technological process is that,through vacuum distillation,first gather the fraction at different extraction temperature Research progress of coal tar deep processingThe selected coal pieces need to be pulverized to a certain particle size to pulverize large pieces of material into small particles 2 Coal washing Coal washing process is an indispensable process of coal deep processing The coal directly mined from the mine is called raw coalCoal Washing Process Plant JXSC MachineryThe commercial processes of coal beneficiation are based on the differences in some physical properties of the pure coal and the impure coal (refuse) The Skip to main content Book Coal Processing and Utilization Click here to navigate to parent product Edition 1st Edition First Published 2016 Imprint CRC Press Pages 2 eBook ISBN Coal beneficiation processes 29 Coal Processing and Utilization

Coal Education

2024年11月15日 Underground mining, sometimes called deep mining, is a process that retrieves coal from deep below the Earth’s surface—sometimes as far as 300 meters (1,000 feet) Miners travel by elevator down a mine shaft to reach the depths of the mine, and operate heavy machinery that extracts the coal and moves it above groundCoal has played a fundamental role as an energy and coke source for centuries In recent years, it has shown great potential in coal chemistry industry and carbonbased materials The utilization of coal nowadays requires both indepth research and extensive exploration, balanced with environmental concernsMinerals Special Issue : Coal Processing and Utilization MDPI2021年10月1日 Mechanochemical technology for brown coal deep processing has one more compromise The process could increase the cation exchange capacity of the lignite by 383 times while enhancing its Solidstate mechanochemical technology for deep processing of 2024年5月30日 Deep Processing vs Shallow Processing Whereas deep processing is elaborate, shallow processing is minimal 1 Deep Processing Deep processing, in essence, means fully understanding and analyzing information 17 Deep Processing Examples Helpful Professor

A novel and low cost coal separation process: Combination of deep

2020年5月1日 At present, the full grain inclusion process of dynamic coal results in the production of slime as a byproduct during coal preparation The produced coal slime needs to be dehydrated and recycled properly, otherwise it may lower the calorific value of separationcleaned coal compared to that of raw coal [10, 11]Certain types of coal are more prone to producing 2021年6月1日 China’s coal consumption in 2019 is about 2804 billion tons of standard coal, accounting for 577% of the total energy consumption (National Bureau of Statistics of China, 2020)One of the important issues involved in coal processing is foreign objects in coal, which seriously affect processing efficiency and product quality and can even damage equipment Computer vision detection of foreign objects in coal processing 2020年2月13日 Other Coal Processing Methods Many methods to process coal other than the foregoing have been suggested, and some have been tested in laboratory and pilot plant scales Because coal is so cheap, less than ¼ cent per pound at the mine, it is a potentially attractive raw material for many usesCoal Processing Methods 911Metallurgist2024年10月11日 Coal mining, extraction of coal deposits from the surface of Earth from underground Coal has been used since the Bronze Age, 3,000 to 4,000 years ago, The history of coal preparation begins in the 19th century, with the adaptation of mineralprocessing methods used for enriching metallic ores from their associated impuritiesCoal mining Definition, History, Types, Facts Britannica

.jpg)

Fluidized mining and insitu transformation of deep underground coal

2019年6月17日 GHG generated in the process of coal conversion into electricity is directly captured and stored in the deep goaf and will not be discharged into the atmosphere Therefore, the carbon emissions of 1 kW/h of coalfired electricity generation caused in the process of coal transportation and the processes of coalfired power plants is zero2024年10月11日 Coal mining Extraction, Processing, Pollution: In geologic terms, coal is a sedimentary rock containing a mixture of constituents, mostly of vegetal origin Vegetal matter is composed mainly of carbon, hydrogen, oxygen, nitrogen, sulfur, and some inorganic mineral elements When this material decays under water, in the absence of oxygen, the carbon Coal mining Extraction, Processing, Pollution BritannicaCoal washing process is an indispensable process of coal deep processing The coal directly mined from the mine is called raw coal Raw coal is mixed with many impurities in the mining process, and the coal quality is also different Coal washing process is an industrial process to eliminate raw coal impurities or classify highquality and low Coal Washing Process Zoneding Mining MachineInterests: deep ash reduction; quality improvement and fine sorting of coal; comprehensive utilization of mineral resources In this Special Issue on “Advances in Coal Processing, Utilization, and Process Safety”, we seek to gather highquality research focused on the latest developments in mine safety engineering, Advances in Coal Processing, Utilization, and Process Safety

Analysis of Intelligent Control Strategy for Heavy

2023年9月27日 The control system based on deep learning can better meet the requirements of the coal processing process and effectively improve the efficiency of a coal processing plant Heavy media coal coal processing products, with the subsequent possibility of exporting the developed products to the foreign market Country's economy industrialization objectives Products production of deep processing of coal Increase the volume of coal produced and processed in TajikistanCoal production and deep processing 日本タジキスタン投資 2023年10月19日 Coal Mining Process; Coal mining involves extracting coal from the ground’s surface or from deep underground The industrial revolution was only possible due to the utilization of coal to power steam engines Coal obtained in different places is not the same and varies widely depending on the nature of the soil and geographic conditionsCoal Mining: How Is Coal Mined? Science ABC2022年2月24日 Fineness: 200325 mesh, according to the process requirements Suitable for coal: it is an effective way for deep processing and utilization of coal to increase the added value Pulverized coal processing and milling equipment According to the fineness of coal feed, moisture content, finished product fineness, How is pulverized coal processed? SBM Ultrafine Powder

COAL EXTRACTION AND PROCESSING WordPress

thermal coal (coal finely ground to generate steam), therefore this document will specifically describe the process of subsurface coal extraction and thermal coal processing Purpose Coal is used for its potential heat energy when burned and since the 1880s has been widely used to generate electricity in power plants2016年5月5日 The plant cleans and processes the coal to remove rocks, dirt, ash, sulfur, and other unwanted materials referred to as gangue [2] This process increases the heating value of the coal and Coal Processing and Utilization ResearchGate2024年5月16日 Deep learning methods have developed rapidly in the field of tool condition monitoring, but due to the complexity and diversity of working conditions, it is difficult to ensure the high accuracy, strong generalization performance, and wide applicability of monitoring models Therefore, this article proposes a deep transfer learning method with center loss for tool Deep transfer learning for tool condition monitoring under 2021年5月15日 150 kt/a coal tar deep processing project completed and put into operation (Phase II) 2009: Qitaihe Baotailong Coal Chemical Industry Co, Ltd 300 kt/a of coal tar deep processing project started: 2011: Shandong Baoshun Chemical Technology Co, Ltd 2 × 300 kt coal tar deep processing project completed: 2011: Wuhan Iron and Steel (Group) CompanyValueadded utilization of hightemperature coal tar: A review

.jpg)

Carbon precursors in coal tar: Extraction and ScienceDirect

2021年9月20日 Globally, coal tar processing technologies are similar (Jiang, 2009), and the products are highly homogeneous The main challenges of coal tar processing include insufficiency in deep processing, a low variety of high valueadded products, the small scale of processing equipment, and a lack of investment in development and application