Nonmechanical crushing

Energy Efficiency Measurement of Mechanical

2024年6月28日 In this paper, we introduce a noncontact measurement technique for mechanical crushing efficiency based on deep learning algorithms This technique utilizes closerange imaging equipment to capture images of 2024年6月28日 introduce a noncontact measurement technique for mechanical crushing efficiency based on deep learning algorithms This technique utilizes closerange imaging Energy Efficiency Measurement of Mechanical Crushing Based on Non 2023年5月15日 The crushing energy is analysed based on the first law of thermodynamics The shear strength of irregular granular materials shows significantly nonlinear behavior due to Mechanical behavior and particle crushing of irregular The manufacture and use of the powders of nonferrous metals has been taking place for many years in what was previously Soviet Russia, and a huge amount of knowledge and experience Handbook of NonFerrous Metal Powders ScienceDirect

.jpg)

Stone Crushers: A Technical Review on Significant Part of

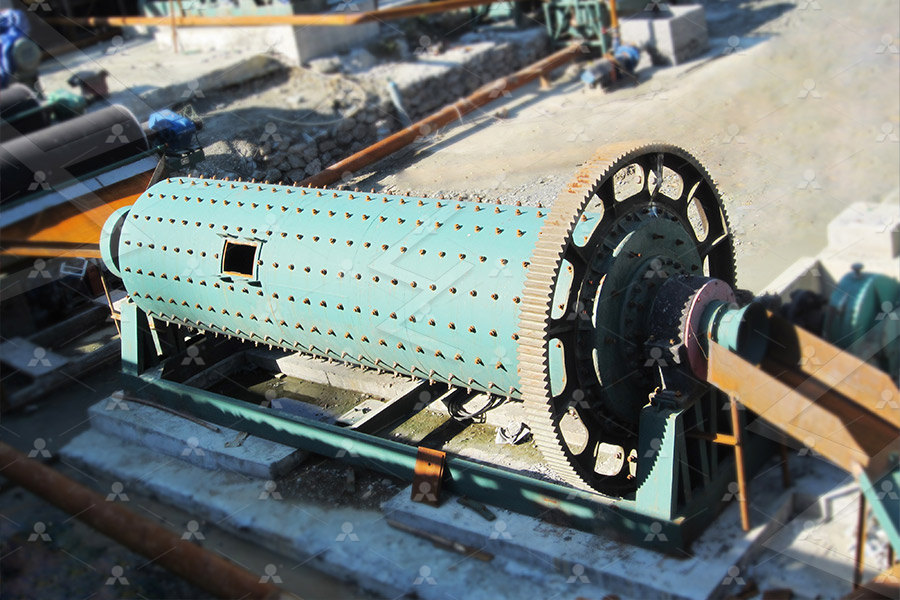

2022年5月14日 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones It normally highlights a huge crushing rate and high return 2021年11月1日 Compound impact drilling technology is a new method to achieve efficient crushing of hard rock by exerting axial and torsional impacts on the drilling bit In this study, to Numerical simulation study on rockbreaking process and mechanism 2017年3月30日 To enable particle crushing, noncrushable elementary particles are boned together to represents the granular aggregates which can be crushed when the external force Discrete numerical modeling of granular materials considering 2001年12月1日 In the mineral industry crushing is the first mechanical stage in the process of comminution The purpose of crushing is to reduce the particle size of rock materials or to Numerical investigation of particle breakage as applied to mechanical

Symmetry Free FullText Energy Efficiency Measurement of Mechanical

2024年6月28日 Lu X, Duan M, Su H, Li B, Liu Y Energy Efficiency Measurement of Mechanical Crushing Based on NonContact Identification Method Symmetry 2024; 16(7):810 首先总结了温度、含水率、围压等对冻土复杂力学特性的影响,进而调研分析了冻土机械切削破碎的典型切削力学模型,发现冻土切削机械破碎模式不仅与冻土力学特性密切相关,也与切削参 冻土机械切削破碎机理的研究进展2023年5月15日 Therefore, the micromechanics caused by particle crushing have received more attention from several researchers due to the nonreproducibility of the particle crushing tests 16,17,18 In DEM, two Mechanical behavior and particle crushing of irregular 2019年9月10日 In this study, a novel process of mechanical crushing combined with a pyrolysisenhanced flotation was developed to recover LiCoO 2 and graphite from spent lithiumion batteries, which lays the foundation for the subsequent metallurgical process Pyrolysis technology was used to solve the problem of low flotation efficiency of electrode materialsApplication of mechanical crushing combined with pyrolysis

.jpg)

Crushing Principles of Mechanical Crushing 911

2024年9月24日 Principles of Mechanical Crushing Objective Explain the interaction between rock material and crusher Take home messages Agenda • Crusher Application • Cone Crusher Operating Principle • Crusher Capacity • Crusher Operation • Optimization and Crusher Performance Map • Conclusions2024年7月26日 Manager Crushing Chamber and Materials Development Product Development Center Crushing (RD) Master of Science in Mechanics, specialized in mechatronics PhD 2007, Chalmers University Partly funded by Sandvik Modeling, simulation and optimization of crushing plants TechnicalEconomic Optimization Sandvik employee since 2004Crushing Principles of Mechanical Crushing 911 2022年5月14日 Many factors influence the effectiveness of the crushing in the chamber and the amount of size reduction achieved The factors can be Feed Material Variables (FMV), Mechanical Design Variables (MDV), Machine Operating variables (MOV), and Machine limits like maximum feed size, capacity, Power, Force and interaction with other equipmentStone Crushers: A Technical Review on Significant Part of2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage

Mechanical Preparation Techniques SpringerLink

2010年1月1日 11 Principle Crushing is used to very quickly produce a fine powder from a bulk material or fine particle using mechanical crushing This technique is essentially used to investigate ceramics, minerals, and mixed–composite materials2009年1月1日 The basic methods for the production of Mg powders include mechanical crushing, the atomization of molten metal, evaporationcondensation, and electrolysis [30] The powder size that is suitable Handbook of NonFerrous Metal Powders Request PDFHandbook of NonFerrous Metal Powders: Technologies and Applications, Second Edition, provides information on the manufacture and use of powders of nonferrous metals that has taken place for many years in the area previously known as Soviet RussiaIt presents the huge amount of knowledge and experience that has built up over the last fifty yearsHandbook of NonFerrous Metal Powders 2nd Edition2024年7月26日 Manager Crushing Chamber and Materials Development •Construction Crusher and Screens, RD Quality Master of Science in Mechanics, specialized in mechatronics PhD 2007, Chalmers University •Partly funded by Sandvik •Modeling, simulation and optimization of crushing plants •TechnicalEconomic Optimization Sandvik employee since 2004 Road Principles of Mechanical Crushing 911 Metallurgist

.jpg)

Effect of mechanical energy input during mechanical crushing

2024年3月1日 Research in the field of inorganic nonmetallic materials has shown that this kind of mechanochemical effect has a significant impact on the chemical properties of materials [29] Therefore, underground mining is generally simplified as a mechanical crushing and pulverization process of coal [30] The mechanochemistry theory holds that 2024年7月26日 •The entire chamber is utilized for crushing •The rocks falls/slides through the chamber until they are crushed directly between the concave and mantle •The rocks are crushed in one strike which yields big forces •Most of the crushing in the lower part of the chamber Feeding: Choke feeding yields more inter particular crushingPrinciples of Mechanical Crushing 911 Metallurgist2024年6月28日 AMA Style Lu X, Duan M, Su H, Li B, Liu Y Energy Efficiency Measurement of Mechanical Crushing Based on NonContact Identification MethodSymmetry Free FullText Energy Efficiency Measurement of Mechanical 2020年9月28日 2 Mechanical Crushing and Grinding OlegD Neikov Introduction 65 Mechanismofthe Ductile Metal Deformation 66 Regularitiesof Milling 68 Impact Process byColliding Balls 68 Grindability 70 Temperature Rise During Milling 72 Crushing and Grinding Equipment 74 Crushers 74 GrindingTechniques 75 MediumAgitating Mills 81 Jet Mills 85 Handbook of NonFerrous GBV

.jpg)

Crushing Principles of Mechanical Crushing 911

2024年7月26日 • Crushing Chamber Design and Selection • Conclusions NCC, Borås, Sweden Crusher Selection Feed size 5” 15” 20” 40” 60” [Reduction Ratio] • Mechanical Liberation of Valuable Minerals Product Feed Power Operating Principle Heat Noise Lube Oil Hydraulic Oil Operating Principle 2021年1月9日 It's worth noting that when the nonuniformity coefficient(C u) wass close,the compression and a crushing amount of calcareous sand gradually increased with the increase of average particle size(d 50) However,when d 50 was close,its compression and crushing STUDY ON COMPRESSION AND CRUSHING 2024年6月28日 Figure 11 shows the loadbearing mechanical model of dry crushing gangue filled with Qin, L Yu, G Q Evaluation research of the fracturing capacity of nonexplosive expansion material Study on compaction characteristics and mechanical model 2024年3月1日 That is, mechanical forces can also induce certain chemical reactions that can alter the chemical properties of the material itself Research in the field of inorganic nonmetallic materials has shown that this kind of mechanochemical effect has a significant impact on the chemical properties of materials [29] Therefore, this study considers Effect of mechanical energy input during mechanical crushing

.jpg)

Energy Efficiency Measurement of Mechanical Crushing Based on Non

The efficiency of mechanical crushing is a key metric for evaluating machinery performance However, traditional contactbased methods for measuring this efficiency are unable to provide realtime data monitoring and can potentially disrupt the production process In this paper, we introduce a noncontact measurement technique for mechanical crushing efficiency based on 2023年8月20日 The photovoltaic (PV) market started in 2000, and the first batch of crystalline silicon (cSi) PV panels with a lifespan of 20–30 years are about to be retired Recycling Si in waste cSi PV panels is critical for resource reuse and environmental preservation Electrostatic separation is a nonpolluting and lowcost technology for recovering Si from mechanical Recycling Si in waste crystalline silicon photovoltaic panels Select Chapter 2 Mechanical Crushing and Grinding Book chapter Full text access Chapter 2 Mechanical Crushing and Grinding Oleg D Neikov Pages 4762 View chapter The manufacture and use of the powders of nonferrous metals has been taking place for many years in what was previously Soviet Russia, and a huge amount of knowledge Handbook of NonFerrous Metal Powders ScienceDirect3 天之前 Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that direction Crushing Wheel Create Wiki Fandom

.jpg)

Energy Efficiency Measurement of Mechanical Crushing

2024年7月1日 Mechanical crushing energy pertains to the energy expended by a crushing unit in the process of breaking down rock, which is a crucial parameter in optimizing the effi2022年8月1日 Therefore, DEM is suitable for investigating the influence of coarse aggregate crushing on concrete mechanical properties The fragment replacement method (FRM) [38], [39] and bonded particle model (BPM) [40], [41], [42] are two strategies used in DEM to simulate particle breakage Breakable particles are replaced by a succession of sub Numerical simulation of influence of coarse aggregate crushing 2024年10月3日 The exfoliation of layered crystals can produce diverse twodimensional (2D) materials and heterostructures However, the micromechanical cleavage of nonstratified materials into 2D flakes Mechanical exfoliation of nonlayered metal oxides into 机械碾压法是采用碾压、振动压实机械,如压路机、振动压路机、推土机、羊足碾等机械,来回反复碾压、震动使地基土密实、强度提高、压缩性降低,从而使地基得到处理的一种密实方法。此法常用于基坑面积大及开挖土方量大的工程,特别适用于处理大面积素填土地基,如大面积垫层、大 机械碾压法百度百科

International Journal of Mechanical Sciences

3 天之前 From the microscopic morphology of organisms displayed in Fig 1 C and D, the topographic structure of antler and vascular tissue exhibits radial gradient distributions of composing cells It takes on a progressive gradation of the morphology density from center to edge, and exhibited advantageous mechanical properties akin to the biological tissue, eg, Introduction: Chapter 1 Classification of methods for production of nonferrous metal powders Chapter 2 Manufacture methods of metal and alloy powders; Chapter 3 Treatment of powders and equipment for their realization; Chapter 4 Powders of nonferrous metals and alloys; Chapter 5 Safety engineering techniques and environment protectionHandbook of NonFerrous Metal Powders Works To prevent crushing hazards in a machine shop, it’s essential to implement comprehensive safety measures, including safe work practices, and training programs for workers Regular inspections, maintenance, and hazard assessments should be conducted to identify and address potential hazards before they lead to accidents or injuriesMachine Shop Safety – Crushing Hazards2023年5月15日 Therefore, the micromechanics caused by particle crushing have received more attention from several researchers due to the nonreproducibility of the particle crushing tests 16,17,18 In DEM, two Mechanical behavior and particle crushing of irregular

Application of mechanical crushing combined with pyrolysis

2019年9月10日 In this study, a novel process of mechanical crushing combined with a pyrolysisenhanced flotation was developed to recover LiCoO 2 and graphite from spent lithiumion batteries, which lays the foundation for the subsequent metallurgical process Pyrolysis technology was used to solve the problem of low flotation efficiency of electrode materials2024年9月24日 Principles of Mechanical Crushing Objective Explain the interaction between rock material and crusher Take home messages Agenda • Crusher Application • Cone Crusher Operating Principle • Crusher Capacity • Crusher Operation • Optimization and Crusher Performance Map • ConclusionsCrushing Principles of Mechanical Crushing 911 2024年7月26日 Manager Crushing Chamber and Materials Development Product Development Center Crushing (RD) Master of Science in Mechanics, specialized in mechatronics PhD 2007, Chalmers University Partly funded by Sandvik Modeling, simulation and optimization of crushing plants TechnicalEconomic Optimization Sandvik employee since 2004Crushing Principles of Mechanical Crushing 911 2022年5月14日 Many factors influence the effectiveness of the crushing in the chamber and the amount of size reduction achieved The factors can be Feed Material Variables (FMV), Mechanical Design Variables (MDV), Machine Operating variables (MOV), and Machine limits like maximum feed size, capacity, Power, Force and interaction with other equipmentStone Crushers: A Technical Review on Significant Part of

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processes2010年1月1日 11 Principle Crushing is used to very quickly produce a fine powder from a bulk material or fine particle using mechanical crushing This technique is essentially used to investigate ceramics, minerals, and mixed–composite materialsMechanical Preparation Techniques SpringerLink2009年1月1日 The basic methods for the production of Mg powders include mechanical crushing, the atomization of molten metal, evaporationcondensation, and electrolysis [30] The powder size that is suitable Handbook of NonFerrous Metal Powders Request PDFHandbook of NonFerrous Metal Powders: Technologies and Applications, Second Edition, provides information on the manufacture and use of powders of nonferrous metals that has taken place for many years in the area previously known as Soviet RussiaIt presents the huge amount of knowledge and experience that has built up over the last fifty yearsHandbook of NonFerrous Metal Powders 2nd Edition