Relocation of movable crushing station

天池能源南露天煤矿原煤破碎站移设方案优化刘振远

2021年6月30日 This article putsforward the design scheme of crushing station moving at the same level and small step distance under the condition of limited pitspace, and quantitatively analyzes the economy and feasibility of the relocation scheme, which provides a scientific 2018年2月20日 This paper defines the optimum location and relocation plan of the SMIPCC in the context of a transportation problem with different ‘year levels’ as the sources and ‘levels’ Optimum location and relocation plan of semimobile inpit 2019年7月4日 This paper investigates the longterm production scheduling and the crusher relocation plan of openpit mines using a semimobile IPCC system and highangle conveyor Optimum location and relocation plan of semimobile inpit 2021年4月13日 This study solves the scheduling problem from the conveyor location’s perspective, aiming to propose a new mathematical framework for optimizing both HAC’s and A Framework for OpenPit Mine Production Scheduling under

.jpg)

Inpit crusher location as a dynamic location problem SciELO

Relocation of the inpit crushing station is required when the haulage distances become uneconomic for trucks So, the other most important parameter affecting the problem is the 2021年5月4日 The main scientific contributions of this research on the body of knowledge are: (i) introducing a new production scheduling optimization strategy under semimobile IPCC OpenPit Mine Production Scheduling and Crusher Location This document discusses using a transportation problem model to determine the optimum location and relocation plan of semimobile inpit crushing and conveying systems in openpit mines Optimum Location and Relocation Plan of SemiMobile InPit the fixed and semi fixed inpit crushing and conveying system, semi mobile inpit crushing needs to be periodically relocated based on the scheduling process of the mine This relocation plan Optimum location and relocation plan of semi mobile inpit

v117n6a11 Inpit crusher location as a dynamic location problem

One major aspect of utilizing this system is determining the location of the inpit crusher and the timing of relocations Facility location models are rarely used in the mining sector, but these The research results show that the relocation time point of No 3 crushing station is before April 2026, and the relocation path is to retreat along the layout direction of the belt transportation 露天煤矿半固定破碎站移设研究#br# #br# TCC SemiMobile Crushing Station (SMCS) is specifically designed for openpit mining operations SMCS provides a modular and intelligent solution that is easy to construct and relocate, saving costs It also increases safety and reliability while ensuring maximum productivityTCC Semimobile Crushing Station, Crusher CEMSARelocation of the inpit crushing station is required when the haulage distances become uneconomic for trucks So, the other most important parameter affecting the problem is the relocation cost of the crusher, which involves the costs Inpit crusher location as a dynamic location problem

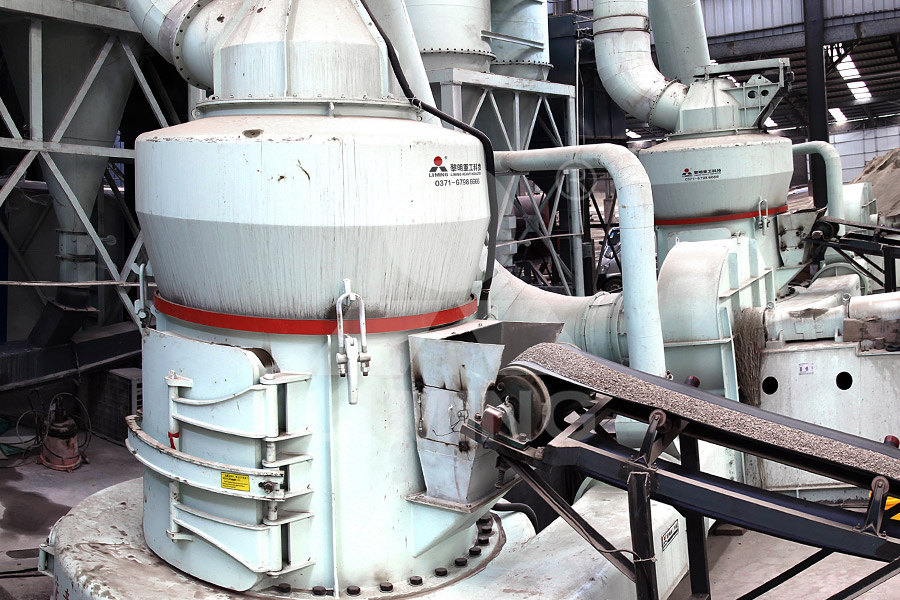

A Catalog of All Mobile Crushing Station Fote

The mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant It can be used for coarse, medium, fine crushing or sand crushing station in openpit mine based on twostage fusion particle swarm algorithm, Engineering Optimization, DOI: 101080/X2020Layout optimization of crushing station in openpit mine based 101080@2018 Free download as PDF File (pdf), Text File (txt) or read online for free This document discusses using a transportation problem model to determine the optimum location and relocation plan of semimobile inpit crushing and conveying systems in openpit mines The transportation problem model can calculate the optimum solution Optimum Location and Relocation Plan of SemiMobile InPit Crushing Crushing Stations Crushing stations are just one of the many elements that make up a processing plant No matter what the capacity or the material your plant is processing, we can help design, fabricate and install a crushing station that will serve the purpose wellCrushing Stations Steel Systems Installation

.jpg)

Inpit crusher location as a dynamic location problem

2017年6月1日 In another article (Paricheh, Osanloo, and Rahmanpour 2017), the same group modelled the location problem of the crushing station as a dynamic facility locationrelocation problem model by Semantic Scholar extracted view of "How to determine the optimum location of inpit movable crushers" by J Sturgul Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,613,451 papers from all fields of scienceHow to determine the optimum location of inpit movable crushers2007年3月1日 InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the futureSelection of the optimum inpit crusher location for an aggregate 2021年2月12日 Inpit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of openpit mining operations and what is likely to happen in the future The use of trucks and shovels for loading and hauling has been used as a dominant system in openpit and opencast mines due to their largescale operations Determination of semimobile inpit crushing and conveying

Review of the inpit crushing and conveying (IPCC) system

3 Fig 2: Crushing arrngement of IPCC system [5] 3 Inpit crushing system Inpit crushing and conveying is an alternative system for transport in open pit mines2011年10月24日 24 34 12001800 Slow relocation movable inpit crushing with ex tendable conve ying optimization of the layout of the fixed crushing station in the inpit crusher and conveyor system (PDF) Review of the inpit crushing and conveying Mobile crushing station is mainly used to process materials in metallurgy, chemical industry, building construction, hydropower project, etc which needs to be moved around frequently It is especially applied in the crushing and screening work of movable materials in highway, railway and hydropower engineering project轮胎式移动破碎站Crushing Screening Technology Powerful Productive Proven These rugged horizontal shaft impactor (HSI) crushers are matched with our highstroke feeders to create portable crushing plants that are tough to beat in terms of productivity and efficiency – and designed to deliver years of tough primary crushing Hard Working Fuel EfficientPortable Crushing Screening Technology

Energy Saving and Consumption Reduction of Cement Mine

2022年1月8日 Movable crushing station, also known as assembled crushing station, is a structure between fixed and mobile crushing stations, which is used when relocation is not frequent (more than 2 ~ 3 years) They can be disassembled into several large pieces, and their size and weight meet the lifting capacity of the crane and the bearing capacity of the trailer2011年2月15日 The crusher station of the Qi Dashan mine is the semimobile crushing station The crusher station has three parts They are a heavy plate type material feeder having a receptacle trough, a crusher having a tower for controlling and a blowdown equipment The hazard rate of the heavy plate type material feeder having a receptacle trough is hign and it Reformation Design of the Feeding System of the SemiMobile Crushing 2024年6月17日 A semimobile crushing station represents a versatile, costeffective solution for mining and quarrying operations that require significant material handling capability combined with flexibilitySemimobile crushing station for sale LinkedInprogramming model for making production scheduling and crushing station decisions, aiming to maximize the net present value (NPV) considering the material handling and crushing station relocation A Framework for OpenPit Mine Production Scheduling

.jpg)

Advantages and Disadvantages of 4 Types of Stone Crusher Machines

2023年2月15日 Because its transitional movement relies on traction, it is not as good as movable crushing station; The equipment is small, suitable for the size reduction of small and mediumsized production, but not largescale mines Semifixed stone crusher machines2015年12月23日 The crushing station of the modular crusher can be dismounted into “light weight” modules and reassembled to the desired located generally in under 30 days Since the resulting modules will still push over 60 tons plus measure over 40′, and the moving of such crusher still takes a month, the frequency of relocation is around 3 to 5 years apartMobile Crushers 911MetallurgistCrawler crushing station is widely used in mining ore crushing, hydropower project, etc which needs to be moved around frequently It is especially applied in the crushing and screening work of movable materials in highway, railway and Crawler Crushing StationHenan Shanky Machinery 2020年10月22日 In this article, optimization of the layout of the fixed crushing station in the inpit crusher and conveyor system of openpit mining is studied First, the entire ore body is discretized into multiple ore blocksLayout optimization of crushing station in openpit mine based

.jpg)

Advantages And Disadvantages Of Four Different

2024年7月23日 The difference between semi mobile crushing plant and mobile crushing plant lies in the time of relocation and the location of equipment layout Semi mobile crushing plant are usually shows on the working side of the an inpit crushing solution with the goal of increasing productivity and profitability Flexibilty and minimum handling We offer a complete range of semimobile solutions in mining and aggregate primary crushing applications Inpit crushing minimizes material handling costs by reducing truck hauling requirementsStationary Semimobile crushing solutions Primary gyratory 2015年4月5日 The relocation of the station further upstream moves it away from the chasm and ensure Halley’s continued safe operation into the future The Clean Air Sector Laboratory As part of the relocation project, the Clean Air Sector Laboratory ( CASLab ) was moved to a new position during the 201818 field seasonHalley Research Station relocation British Antarctic SurveyMobile crushing screening station is a kind of movable crushing equipment,which integrates crushing and screening operation on one machineIt is widely used to process stones, ores and other minerals, such as granite, limestone, quartz, Mobile Crushing Screening Station Crawler Type

Mobile Crusher and Screener Manufacturers Suppliers in China

A tracked mobile crusher is a movable crushing equipment that crushers can easily move to different operating locations without the need for complex infrastructure and equipment relocation work key equipment such as crushing stations and screening machines played a crucial roleCrushing station: adopting advanced Request PDF A heuristic approach for inpit crusher and conveyor system’s time and location problem in large openpit mining Cost efficiency and high reliability of InPit Crushing and A heuristic approach for inpit crusher and conveyor system’s time Once they were fully clad, the modules were moved 10 miles inland to the Halley VI site, proving the relocation strategy Fit out was completed in the final fourth season Following completion of the station, Hugh Broughton Architects collaborated with the client on the development of a Post Occupancy Evaluation strategyHalley VI Antarctic Research Station SpaceArchitect2019年10月2日 Our new SemiMobile Crushing Station with Top Service (TS) Gyratory Crusher is ideal for inpit crushing and conveying (IPCC) operations The SemiMobile Crushing Station consists of movable modules that can be shifted to follow the mine development, reducing truck haulage requirementsSemiMobile Crushing Station FLSmidth

TCC Semimobile Crushing Station, Crusher CEMSA

TCC SemiMobile Crushing Station (SMCS) is specifically designed for openpit mining operations SMCS provides a modular and intelligent solution that is easy to construct and relocate, saving costs It also increases safety and reliability while ensuring maximum productivityRelocation of the inpit crushing station is required when the haulage distances become uneconomic for trucks So, the other most important parameter affecting the problem is the relocation cost of the crusher, which involves the costs Inpit crusher location as a dynamic location problemThe mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant It can be used for coarse, medium, fine crushing or sand A Catalog of All Mobile Crushing Station Fote crushing station in openpit mine based on twostage fusion particle swarm algorithm, Engineering Optimization, DOI: 101080/X2020Layout optimization of crushing station in openpit mine based

Optimum Location and Relocation Plan of SemiMobile InPit Crushing

101080@2018 Free download as PDF File (pdf), Text File (txt) or read online for free This document discusses using a transportation problem model to determine the optimum location and relocation plan of semimobile inpit crushing and conveying systems in openpit mines The transportation problem model can calculate the optimum solution Crushing Stations Crushing stations are just one of the many elements that make up a processing plant No matter what the capacity or the material your plant is processing, we can help design, fabricate and install a crushing station that will serve the purpose wellCrushing Stations Steel Systems Installation2017年6月1日 In another article (Paricheh, Osanloo, and Rahmanpour 2017), the same group modelled the location problem of the crushing station as a dynamic facility locationrelocation problem model by Inpit crusher location as a dynamic location problemSemantic Scholar extracted view of "How to determine the optimum location of inpit movable crushers" by J Sturgul Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,613,451 papers from all fields of scienceHow to determine the optimum location of inpit movable crushers

Selection of the optimum inpit crusher location for an aggregate

2007年3月1日 InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the future2021年2月12日 Inpit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of openpit mining operations and what is likely to happen in the future The use of trucks and shovels for loading and hauling has been used as a dominant system in openpit and opencast mines due to their largescale operations Determination of semimobile inpit crushing and conveying