Zhaosu ore mill Zhaosu ore mill Zhaosu ore mill

Insight into the genesis of the Zhaosu Carboniferous Mn

2022年3月26日 The genesis (primary versus secondary) of Mn carbonaterich sediments, which consist of subeconomic rocks and ore deposits, remains hotly debated Here, we investigated we argue that ancient Mn carbonaterich sediments, especially economic ore deposits, might result from original Mn oxide reduction during diagenesis and thus are a reliable proxy for oxic Insight into the genesis of the Zhaosu Carboniferous Mn 2022年10月1日 Here, we investigated the petrographic, geochemical, and C–Mo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide constraints on its originInsight into the genesis of the Zhaosu 2022年3月26日 Here, we investigated the petrographic, geochemical, and C–Mo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide Insight into the genesis of the Zhaosu Carboniferous Mn

中国科学院机构知识库网格系统: Insight into the genesis of

The genesis (primary versus secondary) of Mn carbonaterich sediments, which consist of subeconomic rocks and ore deposits, remains hotly debated Here, we investigated the 2022年10月1日 Insight into the genesis of the Zhaosu Carboniferous Mn carbonate deposit (NW China): constraints from petrography, geochemistry, and C–Mo isotopes 来自 Semantic Insight into the genesis of the Zhaosu Carboniferous Mn 2024年7月1日 Most of the nonore accessory minerals identified in the Malkansu and Zhaosu Mn ore samples resulted from the combined diagenesis of the Fe and Mn microbial systems, Microbial contribution to the formation of the Carboniferous Here, we investigated the petrographic, geochemical, and CMo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide constraints on its Insight into the genesis of the Zhaosu Carboniferous Mn

Conceptual depositional model of the Zhaosu

OM, organic matter from publication: Insight into the genesis of the Zhaosu Carboniferous Mn carbonate deposit (NW China): constraints from petrography, geochemistry, and C–Mo isotopes The 2013年3月3日 通过对地处西风区的新疆伊犁盆地昭苏黄土剖面的全岩样品和分粒级样品的Ⅹ射线衍射测试,分析了其碳酸盐矿物组成,利用麦夸特算法计算了碳酸盐矿物的含量。 综合碳酸盐矿物的含量、粒径分布及风化特征等因素,对其古环 西风区昭苏黄土剖面中碳酸盐矿物组成及其古环境意 2022年8月25日 The genesis (primary versus secondary) of Mn carbonaterich sediments, which consist of subeconomic rocks and ore deposits, remains hotly debated Here, we investigated the petrographic, geochemical, and C–Mo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide constraints on its originInsight into the genesis of the Zhaosu Carboniferous Mn Ore: Historic county : Sussex: Country : England, United Kingdom: NGR: TQ 839 118: Latitude/longitude : 50, 0: Location Gallery References Anthony Bryan, Mills Research Group Database; Related publications in the library Standing windmills of East Sussex Missing information? Click here to tell us about this mill Black Mill, Ore – The Mills Archive

.jpg)

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

2024年9月20日 Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of Mine to Mill developments is followed by brief descriptions of the very wide range of Mine to Mill applications which have been implemented over the last 15 years2022年3月26日 The genesis (primary versus secondary) of Mn carbonaterich sediments, which consist of subeconomic rocks and ore deposits, remains hotly debated Here, we investigated the petrographic, geochemical, and C–Mo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide constraints on its origin The Mn ores occur Insight into the genesis of the Zhaosu Carboniferous Mn 2017年12月21日 (a) Acidic iron ore pellet without mill scale (b) Acidic iron ore pellet with 15% mill scale Figure 6 Effect of mill scale on apparent porosity in acidic pellet(PDF) Mill scale as a potential additive to improve the quality 2023年10月10日 The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drumUnderstanding the SAG Mill in Copper Ore Mining Process

.jpg)

Unlocking the Secrets of Gold Ore Mill: A Comprehensive

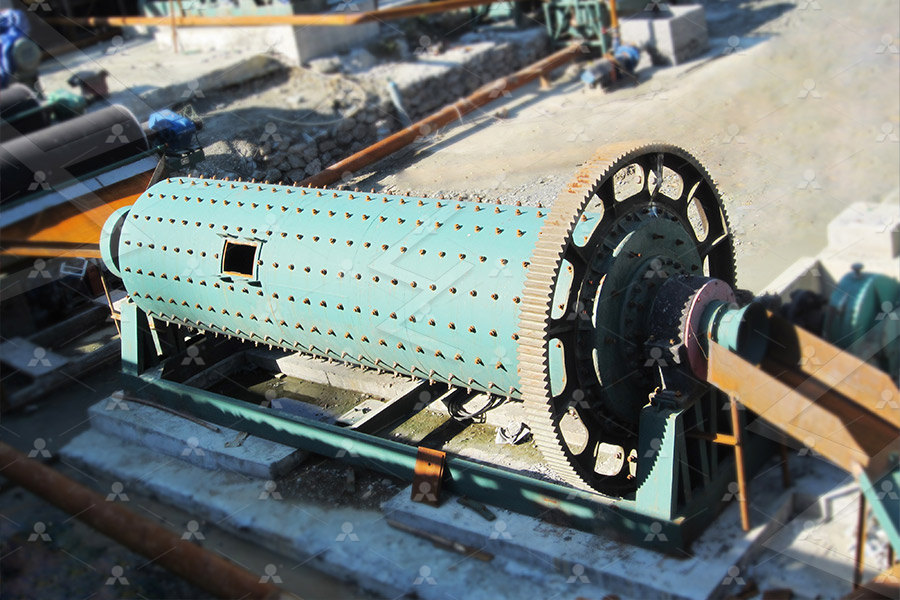

The choice of grinding circuit configuration is critical for optimizing gold recovery Common configurations include singlestage AG/SAG mills followed by ball mills or twostage AG/SAG mills followed by a ball mill circuit The selection depends on factors such as hardness of the ore, desired grind size, and energy requirements 3The ore ball mill designed by our company, which is represented by gold ore ball mill and iron ore ball mill, is manufactured with highquality materials and advanced technology They have the characteristics of high efficiency, energysaving, green environmental protection, simple operation, stable operation, and low failure rate, and have a Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill2022年8月29日 drive system to be overloaded when the mill filled with copper ore is started For this reason, the mill is stopped only in the case of a failure or planned maintenance work The aim is to minimize the potential number of startups, as the mill at a standstill must be later started under full load In the case of a prolonged downtime, the Energy Efficiency Analysis of Copper Ore Ball Mill Drive 2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O3Recycling of steel plant mill scale via iron ore ResearchGate

.jpg)

The performance improvement of a fullscale autogenous mill by setting

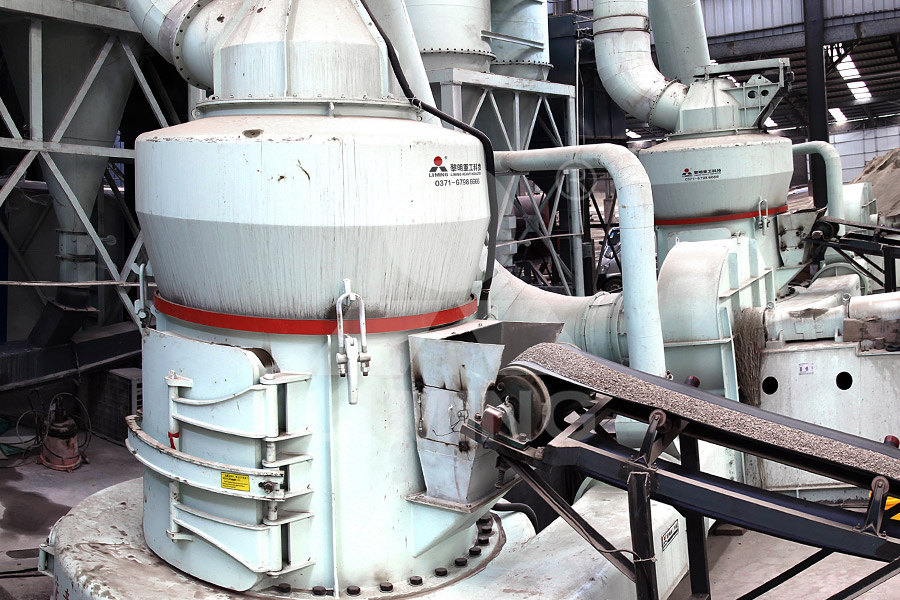

2020年10月20日 One of the feed ore properties which can affect the grinding charge of an AG mill is particle size distribution Bergstedt and Fagremo (1977) studied the effect of feed size distribution on the performance of an AG during a series of pilot plant tests They reported that the ideal feed ore to an AG mill should have 10–15 wt% materials coarser than 100 mm Bouajila 2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Friction and wear of liner and grinding ball in iron ore ball mill 2015年3月15日 The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring system Between the working surfaces of track and Research of iron ore grinding in a verticalrollermillZhaosu County Tourism: Tripadvisor has 18 reviews of Zhaosu County Hotels, Attractions, and Restaurants making it your best Zhaosu County resourceZhaosu County, China: All You Must Know Before You Go

.jpg)

Adaptive control of ore mill charge e3sconferences

of mill charge Let us consider the transfer function of the object under study to be the firstorder relaxation circuit звеном (Fig 1) The input value Х(t) conditioning mill capacity is a controlled variable which is correlated with the mill charge Р(t) Input product sorting results in part of the product being returned for regrindingThe most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill The selection of is according to customers’ requirements and the nature of the minerals Ore grinding can be divided into grinding with media and without It can also be divided into dry grinding and wet grinding SBM can offer ball mill SBM Iron ore grinding plant for ores milling process unisbm2024年11月27日 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;Ball Mill Mining Grinding Mill JXSC Machinery2022年3月19日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesGrinding iron ore concentrate by using HPGR and ball mills

Ili horses gallop in Zhaosu County, NW China’s Xinjiang

2024年9月6日 Zhaosu actively develops new horse breeds, including speed types, trotting types, and warmbloods, as part of a comprehensive initiative to breed highquality horses and promote the development of the equestrian competition sector Concurrently, the county is establishing the regional public brand And "heavenly horses" have become synonymous 2024年11月26日 Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process Mills for minerals and ores Loesche2018年1月19日 The Ban Houayxai is a structurally controlled epithermal goldsilver deposit hosted within an early Permian volcanosedimentary sequence of the Trong Son Fold belt in the south western extremity of the Phu Bia Contract Area (Manaka et al 2014)The deposit is located on a steep narrow northsouth oriented ridge that protrudes into the Nam Ngum 2 Reservoir, a Predicting Mill Ore Feed Variability Using Integrated 2018年10月1日 The impact of ore variability on process performance was observed at the OK Tedi mine in Papua New Guinea, where the variations in feed ore hardness (Bond work index 5–16 kWh/t) and in feed size distributions caused the SAG mill throughput to fluctuate between 700 and 3000 t/h (Sloan et al, 2001)Quantifying variability of ore breakage by impact – Implications

Ore Sawmill The Miner's Haven Wikia Fandom

5 天之前 The Ore Sawmill is a Reborntier utility upgrader added in the Reincarnation Update It was first revealed in a screenshot on Foxy's Twitter The Ore Sawmill has a unique hybrid function that duplicates ore, but also halves both their value and size Ores may be duplicated again with the Ore Replicator The description is a parody of a nowinfamous infomercial for Flex Tape, a 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911Metallurgist2024年1月4日 The chromite ore, mill scale, and petroleum coke were dried in an oven at around 473K for 24h Then the materials were ground by a ball mill into various particle sizes (chromite ore: D 80¼147mm Direct Alloying Steel with Chromium by Briquettes Made 2012年4月1日 Measurements are not readily available for grinding mills owing to the nature of the milling operation State and parameter estimation for a grinding mill which forms part of a runofmine ore Dual particle filters for state and parameter estimation with

.jpg)

Predicting Mill Ore Feed Variability Using Integrated

2018年1月18日 The process plant consists of a 26 ft 65 MW SAGBall mill circuit feeding a conventional carbon in leach (CIL) circuit Three ore types have been defined at Ban Houayxai based on the weathering profile—oxide, transitional and primary Average throughputs were assigned to these ore types, based on test work within the feasibility study and Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifying Ground material will be classified, coarse powder will fall back to the main mill for ground againIron ore grinding mill Grinding plants for Iron Ore2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to optimize solids concentration in Optimization of Solids Concentration in Iron Ore Ball Milling 2022年8月25日 The genesis (primary versus secondary) of Mn carbonaterich sediments, which consist of subeconomic rocks and ore deposits, remains hotly debated Here, we investigated the petrographic, geochemical, and C–Mo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide constraints on its originInsight into the genesis of the Zhaosu Carboniferous Mn

.jpg)

Black Mill, Ore – The Mills Archive

Ore: Historic county : Sussex: Country : England, United Kingdom: NGR: TQ 839 118: Latitude/longitude : 50, 0: Location Gallery References Anthony Bryan, Mills Research Group Database; Related publications in the library Standing windmills of East Sussex Missing information? Click here to tell us about this mill 2024年9月20日 Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of Mine to Mill developments is followed by brief descriptions of the very wide range of Mine to Mill applications which have been implemented over the last 15 yearsUNDErsTaNDINg MINE TO MILL 911 Metallurgist2022年3月26日 The genesis (primary versus secondary) of Mn carbonaterich sediments, which consist of subeconomic rocks and ore deposits, remains hotly debated Here, we investigated the petrographic, geochemical, and C–Mo isotopic characteristics of the Zhaosu Mn carbonate deposit in northwestern China, in order to provide constraints on its origin The Mn ores occur Insight into the genesis of the Zhaosu Carboniferous Mn 2017年12月21日 (a) Acidic iron ore pellet without mill scale (b) Acidic iron ore pellet with 15% mill scale Figure 6 Effect of mill scale on apparent porosity in acidic pellet(PDF) Mill scale as a potential additive to improve the quality

Understanding the SAG Mill in Copper Ore Mining Process

2023年10月10日 The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drumThe choice of grinding circuit configuration is critical for optimizing gold recovery Common configurations include singlestage AG/SAG mills followed by ball mills or twostage AG/SAG mills followed by a ball mill circuit The selection depends on factors such as hardness of the ore, desired grind size, and energy requirements 3Unlocking the Secrets of Gold Ore Mill: A Comprehensive The ore ball mill designed by our company, which is represented by gold ore ball mill and iron ore ball mill, is manufactured with highquality materials and advanced technology They have the characteristics of high efficiency, energysaving, green environmental protection, simple operation, stable operation, and low failure rate, and have a Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill2022年8月29日 drive system to be overloaded when the mill filled with copper ore is started For this reason, the mill is stopped only in the case of a failure or planned maintenance work The aim is to minimize the potential number of startups, as the mill at a standstill must be later started under full load In the case of a prolonged downtime, the Energy Efficiency Analysis of Copper Ore Ball Mill Drive

.jpg)

Recycling of steel plant mill scale via iron ore ResearchGate

2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O3