Cement crushing

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 According to most of the literature, concrete crushing occurs in the compression zone along with FRP rupture or shear failure in FRPstrengthened structures [56,122] The 2024年1月6日 Concrete crushers are purposebuilt machines designed to break down concrete into smaller, manageable pieces They act as a pivotal solution in recycling concrete debris from demolition sites or construction projects, Concrete Crushers: Turning Waste Concrete into In the cement industry, the application of the hard rock impact crusher is for size reduction of iron ore and quartzite as corrective ingredients for the proper cement raw mix composition; also Complete Lecture about Crushers in Cement IndustryAGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of Cement Crusher Crushers for Cement Plant AGICO

Concrete crushing based on the highvoltage pulse discharge

2021年9月1日 Highvoltage pulse discharge (HVPD) technology has a broad prospect in concrete crushing The model of concrete beam sections is established by ANSYS/LSDYNA 2019年1月1日 Crushing is the first necessary step in the release of usable materials from concrete waste, including gravel, crushed aggregates and sand In addition, aggregates can Concrete aggregates properties crushed by jaw and impact 2023年8月31日 Samples of five laboratorymade concretes have been crushed using the most common mechanical crushing methods (impact crusher and jaw crusher), and the particle size distribution, morphology, hardened cement Effect of Crushing Method on the Properties of Franklin Miller's Cement Crushers are designed to handle various types of cement clinkers and lumps, reducing them to a manageable size for further processing and handling Our robust Cement Crusher and Cement Lump Breaker Solutions Franklin

.jpg)

Mobile Concrete Crushers: 90385 TPH RUBBLE

Crushing process creates a gradeable and compactable material Job requirements change So does your crusher Produce more finished products with one machineThe onboard screen and return conveyor offer more versatility Jaw Crusher Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crusher is a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric Cement Crusher Crushers for Cement Plant AGICO 2020年8月25日 How much do you know about cement production process? A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement grinding process, cement packing Cement Production Process Cement Manufacturing Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement productionCrushing FLSmidth Cement

.jpg)

How Cement is Made Cement Manufacturing Process

Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inches2024年11月23日 Cements may be used alone (ie, “neat,” as grouting materials), but the normal use is in mortar and concrete in which the cement is mixed with inert material known as aggregateMortar is cement mixed with sand or crushed stone that must be less than approximately 5 mm (02 inch) in size Concrete is a mixture of cement, sand or other fine Cement Definition, Composition, Manufacture, History, Facts Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement productionStrikeBar™ Crusher FLSmidth Cement2019年10月30日 How to design cement crushing plant? Customers who need cement crusher should know more about this area, comprehensive analysis of the specific situation and the ability to select the crusher and cement crushing plant As a manufacturer of cement plants, AGICO Cement provides a onestop turnkey project cover design, manufacture, and How To Choose Cement Crusher? Jaw Crusher, Cone Crusher

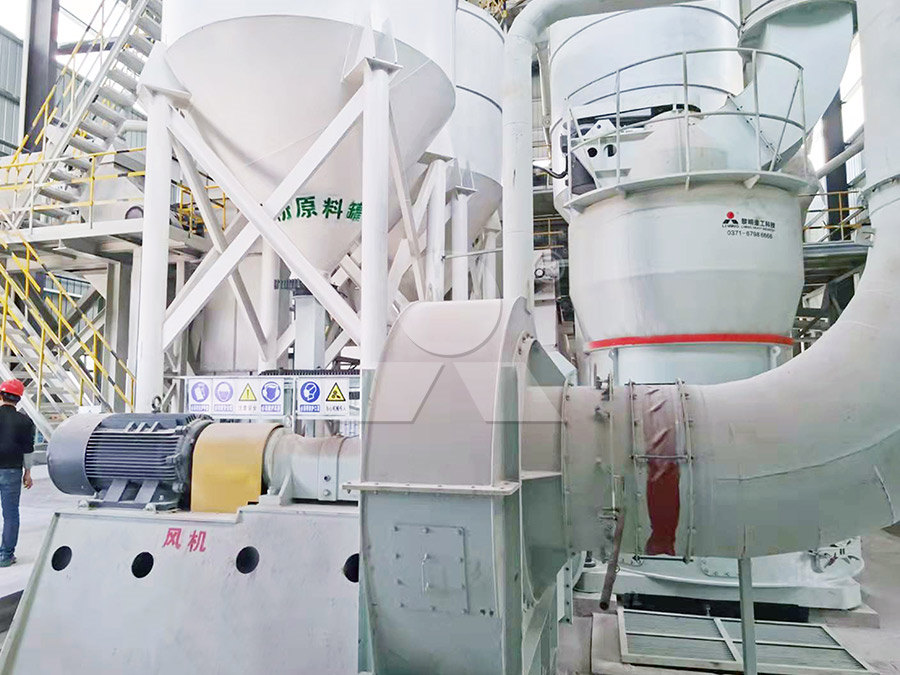

Preparation Of Cement Raw Material Cement Mill, Cement

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing : the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, 2022年1月22日 Cone crusher is advanced crushing equipment in the mining field Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation In the process of cement clinker What Are The Cement Clinker Crushing Equipment?Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industries The Jaw Crusher Jaw Crusher Mannufacturers AGICO cement manufacturing process by tizita moges , selamu abule dereje endalamaw if you need this guide and all other useful excel sheets which will make you master the production , process , maintenance activity in your Cement Manufacturing Process INFINITY FOR

Mobile Crusher Rental: Concrete, Asphalt, Rock RUBBLE MASTER

We’re crushing screening experts and work closely with contractors and aggregate producers worldwide Call 8002300418 What is your service area for rentals? Rentals are accomodated by our dealers We work with premium crushing, screening, 2024年6月29日 Cement concrete is an artificial stone made of cement, water, sand, stone and additives according to a certain proportion, which is widely used in China's infrastructure construction industry []Mixing is a process to make the overall dispersion of concrete mixture more uniform, and it is a key procedure in concrete production []After mixing ordinary Simulation of the Influence of Rotational Speed on the Crushing A cement crusher machine is a specialized equipment used in the crushing and grinding of raw materials These include limestone, clay, shale, and other materials The crusher grinds these materials into smaller pieces to be used in the cement manufacturing processTypes of Cement Crushers Choosing the Right Machine2023年2月28日 To recycle concrete, a crushing process is required There are mainly 5 types of concrete crushers like portable crusher, mobile crusher, small concrete crusher, excavator concrete crusher and bucket crusher, so you have to choose the right crushing machine according to your own situation Portable concrete crusher5 Types of Concrete Crushers for Recycling Concrete Blocks

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Can primary crushing be used for nonaggregates applications? Yes, primary crushing can be used for nonaggregates applications, such as in the mining industry for processing ores and minerals Primary crushers are also used in some industrial applications, such as in the production of cement and other building materials Secondary Crushing2024年9月5日 1 Mining and Crushing The process of making cement begins with mining, where raw materials are extracted from quarries Huge machines called excavators dig the limestone out of the earth The extracted limestone is then taken through a crushing plant, which reduces the size to smaller pieces of about 5 inches in sizeA Comprehensive Guide to the Cement Manufacturing Process2023年10月11日 Crushing material at your cement production plants is a challenging and complex process that can be costly, impacting your bottom line and potentially eroding profits Without costeffective crushing equipment and technology, your operation may suffer from expenditures that spiral out of controlWorld Cement: Clever ways to cut aggregate crushing costsMix the cement and fine aggregate on a watertight noneabsorbent platform until the mixture is thoroughly blended and is The average of three specimens gives the crushing strength of concrete The strength requirements of concrete Compressive Strength of Concrete Cube Test [PDF],

How to Make Money Crushing Concrete (and Other

2022年12月13日 A concrete crushing business typically handles concrete and asphalt, but other materials such as brick, stone and even metals may be crushed If you have the right equipment and are able to handle these other 2019年9月27日 Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, Cement Euipment Overview Cement Making Discover Micro Concrete Crushers Conveyors Portable Rock, Concrete Asphalt Crushing, Recycling Equipment with Cone Jaw Crushers Setup Service Videos (919) 3234830 Senya SCC2818DOT Concrete/Cement Micro Conveyor/Stacker; Senya SCC3218DOT Concrete/Cement Micro Conveyor/Stacker; Senya S3024 Radial Yard Conveyor/Stacker;Micro Concrete Crushers Conveyors Senya CrushersStarted in 1996 by Nick and Lesli Perfili, Roseville Crushed is the premier local concrete crushing and recycling facility in Southeastern Michigan Contact us today! Skip to content Hours: MonFri: 7AM 5PM Sat: 7:30AM 11:30AM; APPLY TODAY! REQUEST AN ESTIMATE Home; About; Products; Services; Locations Roseville; Carleton; Careers Concrete Crushing and Recycling Roseville Crushed

Crushed concrete: The pros, cons and FAQs Machinery Partner

Crushed concrete is a building material that is used for lots of different construction and hardscape projects It's made by crushing down old, concrete structures like roads, sidewalks, curbs, buildings and driveways into smaller pieces It’s also known in the industry as ‘RCA’ Recycled Concrete AggregateHanSon Custom Crushing is a proven leader in the crushing industry in Minnesota and throughout the Midwest We have been a trusted owneroperated mobile crushing company specializing in recycling asphalt and concrete since 2007 Other services offered include quarry and pit crushing, screening of rock, Hanson Custom Crushing2024年1月6日 Types of Concrete Crushers Jaw Crushers: These robust crushers utilize powerful jaws to exert pressure, effectively breaking down concrete into smaller chunksThey excel in both primary and secondary crushing, making them versatile for various applications Jaw crushers are commonly used in the initial stages of concrete processing due to their efficiency Concrete Crushers: Turning Waste Concrete into Valuable 2024年9月10日 Steps of Cement Manufacturing The steps involved in cement manufacturing are as follows: Quarrying: Raw materials such as limestone and clay are extracted from quarries or mines; Crushing and Grinding: The extracted raw materials are crushed and ground into a fine powder; Blending: The crushed and ground raw materials are blended in specific proportions Cement Manufacturing Process: Know Extraction, Processing

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 They are commonly used as tertiary crushers, widely applied in cement, mining, building materials, and abrasive industries for fine crushing and sand making Designed for medium to low hardness and brittle materials, they are effective for crushing sticky or moist materials (up to 30% moisture) like coal, limestone, and clayCrushing process creates a gradeable and compactable material Job requirements change So does your crusher Produce more finished products with one machineThe onboard screen and return conveyor offer more versatility Mobile Concrete Crushers: 90385 TPH RUBBLE Jaw Crusher Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crusher is a type of earlier crushing equipment, which is still widely used in smelting, building materials, electric Cement Crusher Crushers for Cement Plant AGICO 2020年8月25日 How much do you know about cement production process? A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement grinding process, cement packing Cement Production Process Cement Manufacturing

.jpg)

Crushing FLSmidth Cement

Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement productionStage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process2024年11月23日 Cements may be used alone (ie, “neat,” as grouting materials), but the normal use is in mortar and concrete in which the cement is mixed with inert material known as aggregateMortar is cement mixed with sand or crushed stone that must be less than approximately 5 mm (02 inch) in size Concrete is a mixture of cement, sand or other fine Cement Definition, Composition, Manufacture, History, Facts Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement productionStrikeBar™ Crusher FLSmidth Cement

.jpg)

How To Choose Cement Crusher? Jaw Crusher, Cone Crusher

2019年10月30日 How to design cement crushing plant? Customers who need cement crusher should know more about this area, comprehensive analysis of the specific situation and the ability to select the crusher and cement crushing plant As a manufacturer of cement plants, AGICO Cement provides a onestop turnkey project cover design, manufacture, and The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing : the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, Preparation Of Cement Raw Material Cement Mill, Cement