Name the ore milling plant

Mineral Processing Plants Multotec

From individualised equipment to complete plants – greenfield or retrofit – our engineers and metallurgists will work with you to achieve your mineral processing goals Whatever your requirements, we will help you get more from your ore with our wide range of leading For over 50 years, Multotec has focussed on supplying process technology Mineral Processing Equip2024年11月26日 The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile Mills for minerals and ores LoescheMineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from Mineral Processing an overview ScienceDirect Topics

.jpg)

Essential Guide to Mineral Processing

2024年11月26日 Mineral processing is a form of extractive metallurgy that separates valuable minerals from the ore into a concentrated, marketable product Mineral processing is also known as mineral dressing Mineral Process plants and separation systems are critical in mining for extracting and recovering valuable minerals from raw ore These systems include technologies like flotation, Mining Processing Plants Separation Systems Mining 2020年12月3日 Liberation of valuable minerals from associated gangue minerals is an important and fundamental step in separating an ore mineral from gangue during physical or A process mineralogy approach to study the efficiency of milling 269 行 2016年1月1日 Operational and development issues regarding various gold plants and processes detailed in Gold Ore Processing, Second Edition, are summarized Ore types and Summary of Gold Plants and Processes ScienceDirect

Development of ore sorting and its impact on mineral processing

2014年10月15日 The goal of ore sorting is to reduce the total amount of material sent to the high energy milling circuit, while not significantly impacting total metal recovery In general, ore 2017年8月24日 Thus, ores must go through a number of different operations to obtain the final products: comminution or size reduction, size separation, concentration or beneficiation, and Mineral Processing SpringerLink2023年7月20日 Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the Ore Grinding SpringerLinkWhen the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles The large particles are diverted back into the crusher and the fine particles will undergo a spiral The six main steps of iron ore processing

.jpg)

DRILLTOMILL PLANT OPTIMIZATION AT ALTYNALMAS

25% to 30%); improved wall control; reduced ore loss/dilution; and increased crusher throughput (162%); increased mill throughput (116%) This paper explains the methodology followed and presents the results Keywords Drilltomill plant optimization, mill throughput, drill and blast, fragmentation, ore characterization, dig rate,2024年11月26日 The smaller ore will go on to the ball grinding mills where they will be further ground down The larger ore will be routed to a pebble crusher to reduce the size to 13 cm (½ in) and will return to the SAG mill stage The ball Essential Guide to Mineral ProcessingPDF On Sep 1, 2001, J Karageorgos and others published SAG milling at the Fimiston plant (KCGM) Find, read and cite all the research you need on ResearchGate 1989 to process ore from the (PDF) SAG milling at the Fimiston plant (KCGM) ResearchGateHowever, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this study that the MCF should be seen as a method that identify the real problems underground and when Monitoring ore loss and dilution for minetomill integration

.jpg)

Gold Fields South Deep Gold Mine How we process

1 天前 Step 1: Milling When ore enters the plant from underground it first needs to be milled to reduce its size so that the gold is liberated from the host rock South Deep’s milling circuit consists of a singlestage semiautogenous grinding mill (SAG) and a pebble crusher for primary milling, followed by secondary milling using two overflow ball 2017年2月16日 The mill is situated thus far from the mines in order to obtain a plentiful supply of water without recourse to pumping or an elaborate scheme for the conservation of water Each truck contains approximately 2½ tons of ore; these are disconnected from the locomotive at the top of a gravity tramway, and lowered 500 feet to the millTin Ore Processing 911Metallurgist2023年8月28日 Ore milling machines are sophisticated pieces of equipment designed to crush, grind, and process raw ores into finer particles, ultimately extracting valuable minerals and metals Coal Mill Pulverizer in Thermal Power Plants; Contact Info Phone: +86 +86 : info@bellianmachinery Address: West Fourth Ring Unveiling the Efficiency and Significance of Ore Milling 2024年7月9日 Pilot Testing and Plant Design Comparison of Dry VRM Milling plus Magnetic Separation with AG and Ball Milling plus Magnetic Separation for Grange Resources' Southdown Ore D David1, C Stanton2, D Olwagen3, Dr C Gerold4, C Schmitz5, S Baaken6, M Everitt7 FAusIMM CP(Met), Senior Consultant, WooMilling CEEC (Coalition for Eco Efficient Comminution)

Copper Ore Processing Plants, Flow And Equipment

5 天之前 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite If copper ore wants to be fully utilized, it must be processed by flotation Flotation separation is an important copper ore beneficiation process in 2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove Mining and Beneficiation of Phosphate Ore6 天之前 The ball mill is a tumbling mill that uses steel balls as grinding media Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or largescale ore beneficiation plant Dry Ball Mill Mining Grinding Mill JXSC Machinery2016年1月1日 Milling: Hard abrasive ore Crushing threestage, including highpressure grinding rolls (HPGR) producing P 80 6 mm ballmill feed Higher capital expenditure (capex) but lower operating expenditure (opex)7: Tropicana: Western Australia: Milling: Moderately hard ore: Summary of Gold Plants and Processes ScienceDirect

COSTS AND COST ESTIMATION Chapter NUBE MINERA

2019年6月26日 probable ore, but excluding possible ore with no assurance of its existence), and DYT is the number of days per year of operation at full capacity Dyris approximately 250 for a mine operating on a 5 day week and 350 for a mine or mill operating continuously 7 days per week with only minor shutdowns or holidays per year2016年3月18日 Provides a plant to mill ore produced during the development period of prospective large producers This gives an income during development Eliminates the “monuments” of abandoned mills by providing for common sense investments through testing before building Portable Mills or Truck Mills can be used as efficient test units or as pilot Mobile Ore Processing Beneficiation Plant 911Metallurgist2013年1月3日 The most well known carboninpulp plant remains the prototype Homestake plant in Lead, South Dakota Operating since 1973, this facility treats 2130 tonnes of ore per day averaging 27 g gold per tonne Homestake has also operated small silver carboninpulp plants at Creede and Cripple Creek, Colorado since 1979Gold CIL CIP Gold Leaching Process Explained CCD2016年3月21日 The control of a milling operation is a problem in imponderables: from the moment that the ore drops into the mill scoop the process becomes continuous, and 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Common Basic Formulas for Mineral Processing

.jpg)

TIN ORE PROCESSING PLANT Pineer Mining Machinery

2023年7月6日 Alluvial tin ore is separated by the gravity separation method For alluvial tin ore with a high degree of monomer dissociation, the final concentrate is obtained by the 6S shaker tables at one timeThe concentrate grade is above 60% For alluvial tin ore with a low monomer dissociation degree, use a jig machine for primary selection, then concentrate enters 6s 5 天之前 Dasen provides gold ore CIP CIL processing plant and also equipment manufacturing solution with benefits of ultra low power consumption, easy to use and high output rate Cone Crusher, Ball mill, Spiral classifier, Leaching tank, Desorption Electrolysis Related Leaching Method 1 2 Heap leaching Get Details Now Your name Your Gold CIP/CIL Processing Plant Solution Dasen Mining2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration In most underground mines, the ore is blasted and hoisted to the surface for milling The access to ore body can be through shafts and Copper Plant Tailings of Singhbhum in India [46, 49], to name a few 223 Though Pachuca reactors were used in earlier days in some plants like in Moab Mill, Cotter Corporation, Beaverlodge mill at Exploration, Mining, Milling and Processing of Uranium

.jpg)

All About Particles: Modelling Ore Behaviour in Mineral

20 Coarse milling down to 03–05 mm Autogenous Mill 102 (100)* 10−2 Shear Compression up to 100 Coarser particles act as grinding media, allowing high reduction ratios and high throughput Ball Mill 102 (100)* 10−2 Shear Compression 60 Final milling step to reach the target particle size for flotation Stirred Media Mill – 10−1 10 2014年1月1日 Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider sustainable developmentFactors affecting the performance of crushing 6 天之前 Nuggets taken from streams and free gold retrieved by panning, sluicing and dredging could go directly to the smelter Before the gold found in the ore taken from hard rock mines became gold ingots or gold coins, it went several complicated rounds of chemical and mechanical processing Men and machines at mills worked together to pulverize and break down the ore, Gold Milling and Concentration Breckenridge History23 小时之前 EMJ explores the sustainability of a timehonored beneficiation technique By Carly Leonida, European Editor As we look to the future, the mining industry faces a myriad of challenges While demand for metals like copper, cobalt, lithium and iron ore is projected to reach record highs by 2050, ore grades are decreasing, orebodies are becoming more complex, and Flotation: The Past, Present and Future of Mineral Processing?

Designing gold extraction processes: Performance study of a

2017年8月1日 Modelling all facets of a processing plant with a vast number of straightforward rules and deterministic equations is highly challenging, as the available data is often incomplete and fuzzy (Rintala et al, 2012, Rintala et al, 2015)Instead, the target of this study is to develop a software system that is able to give starting points for gold ore process design by helping the The mining process at Macraes is circular and follows a cycle of exploration, mining, processing and rehabilitation and closure With a 30year history of development spanning fluctuating gold prices, there are multiple examples of where an area has been explored, mined, processed and rehabilitated, only to be explored mined, processed and rehabilitated again 10 to 20 years laterThe Mining Process OceanaGold2023年5月11日 It can form ore bodies of iron, nickel, bauxite, and manganese Launder In mining, a launder refers to a chute or trough used to transport pulp, water, or powdered ore in a mill Lava The common term for molten rock expelled by volcanoes Leachable Minerals that can be extracted using chemical solvents are referred to as reachable2024 Mining Terms Explained An Underground Miner2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment The scarcity of undeveloped high grade deposits has brought about the more liberal employment of milling and concentrating plants at the mines, or of custom milk to serve definite mining Mineral Processing and Ore Dressing 911Metallurgist

Ore Dressing Methods 911Metallurgist

2017年4月10日 Plants for treating ore of uniform grade are the simplest to design and operate, other things being equal Sudden additions of considerable highgrade ore to an average medium or lowgrade mill feed tend to throw the process out When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles The large particles are diverted back into the crusher and the fine particles will undergo a spiral The six main steps of iron ore processing25% to 30%); improved wall control; reduced ore loss/dilution; and increased crusher throughput (162%); increased mill throughput (116%) This paper explains the methodology followed and presents the results Keywords Drilltomill plant optimization, mill throughput, drill and blast, fragmentation, ore characterization, dig rate,DRILLTOMILL PLANT OPTIMIZATION AT ALTYNALMAS 2024年11月26日 The smaller ore will go on to the ball grinding mills where they will be further ground down The larger ore will be routed to a pebble crusher to reduce the size to 13 cm (½ in) and will return to the SAG mill stage The ball Essential Guide to Mineral Processing

(PDF) SAG milling at the Fimiston plant (KCGM) ResearchGate

PDF On Sep 1, 2001, J Karageorgos and others published SAG milling at the Fimiston plant (KCGM) Find, read and cite all the research you need on ResearchGate 1989 to process ore from the However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this study that the MCF should be seen as a method that identify the real problems underground and when Monitoring ore loss and dilution for minetomill integration 1 天前 Step 1: Milling When ore enters the plant from underground it first needs to be milled to reduce its size so that the gold is liberated from the host rock South Deep’s milling circuit consists of a singlestage semiautogenous grinding mill (SAG) and a pebble crusher for primary milling, followed by secondary milling using two overflow ball Gold Fields South Deep Gold Mine How we process2017年2月16日 The mill is situated thus far from the mines in order to obtain a plentiful supply of water without recourse to pumping or an elaborate scheme for the conservation of water Each truck contains approximately 2½ tons of ore; these are disconnected from the locomotive at the top of a gravity tramway, and lowered 500 feet to the millTin Ore Processing 911Metallurgist

.jpg)

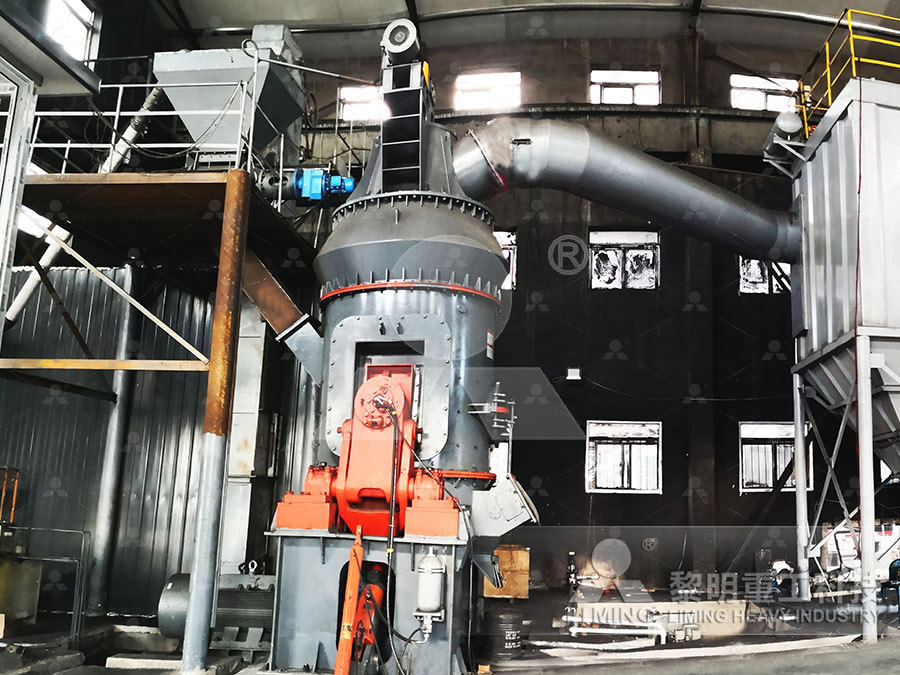

Unveiling the Efficiency and Significance of Ore Milling

2023年8月28日 Ore milling machines are sophisticated pieces of equipment designed to crush, grind, and process raw ores into finer particles, ultimately extracting valuable minerals and metals Coal Mill Pulverizer in Thermal Power Plants; Contact Info Phone: +86 +86 : info@bellianmachinery Address: West Fourth Ring 2024年7月9日 Pilot Testing and Plant Design Comparison of Dry VRM Milling plus Magnetic Separation with AG and Ball Milling plus Magnetic Separation for Grange Resources' Southdown Ore D David1, C Stanton2, D Olwagen3, Dr C Gerold4, C Schmitz5, S Baaken6, M Everitt7 FAusIMM CP(Met), Senior Consultant, WooMilling CEEC (Coalition for Eco Efficient Comminution)5 天之前 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite If copper ore wants to be fully utilized, it must be processed by flotation Flotation separation is an important copper ore beneficiation process in Copper Ore Processing Plants, Flow And Equipment