Can vertical mill grind cement

.jpg)

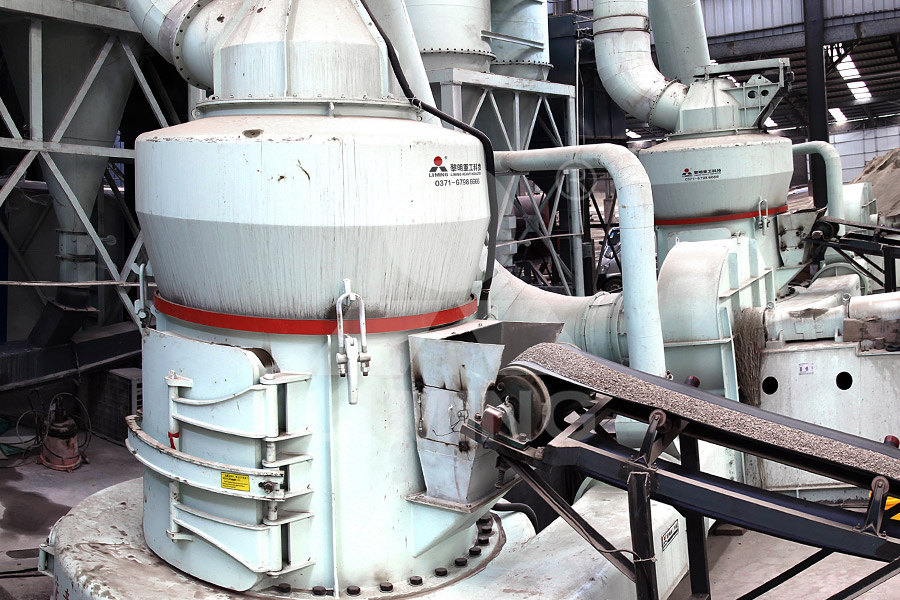

Cement Vertical Roller Mill CEMENTL

Improve grinding efficiency: The vertical cement mill adopts the material bed grinding principle, with low energy consumption and high efficiency Reduce environmental pollution: The vertical 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to(PDF) Performance Evaluation of Vertical Roller 2023年7月25日 In this paper we describe in details an industrial test performed during the production of slag cement in a vertical mill, showing how the use of grinding aids can improve Improvement of cement performances through the use 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Operational parameters affecting the vertical roller mill

Review on vertical roller mill in cement industry its

2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system 6 天之前 CEMENT 4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills SikaGrind® for vertical roller mills2017年10月27日 The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in PROCESS CONTROL FOR CEMENT GRINDING IN 2014年4月1日 Large cement plants can now be designed with the onemill concept for both raw material and cement grinding Investors plan to install small plants and therefore need to keep (PDF) The latest innovative technology for vertical roller mills

.jpg)

Grinding process optimization IEEE Xplore

2017年6月19日 The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the 2024年7月1日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate energy saving ́ Higher fineness faster strength development CEMENT Limestone is much easier to grind than clinker The common intergrinding of limestone and clinker in classical Picture: Loesche GmbH, Germany CEMENT SikaGrind® Learn about the key features and benefits of vertical roller mills in cement plant operations Get expert insights and recommendations for optimizing your cement plant production with vertical roller mills which can be challenging to grind using traditional ball mills Construction Industry In the construction industry, VRMs are used to Vertical Roller Mill in Cement Plant ball mills supplier2024年11月26日 LOESCHE Vertical Roller Mill: The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhow Cement Industry Loesche

.jpg)

Cement Vertical Roller Mill CEMENTL

Highquality cement vertical roller mill manufacturer Tongli ZJTL series cement vertical mill is a very important link in cement production and is the best choice for raw material grinding and clinker grinding As an iterative product of the ball mill, the vertical mill occupies a small area, which is about 50% less than the ball millThis article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features VRMs are used to grind the raw materials used in cement production, such as limestone, clay, and silica After being crushed and processed in crushers,the raw materials are fed into the Application of Vertical Roller Mill in Cement ProductionThe choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainabilityVertical roller mill vs ball mill for cement grinding: 2023年10月19日 It relies on the use of steel balls to crush and grind the clinker Ball mills are often used for grinding cement clinker into a fine powder before it is mixed with other materials to produce cement Vertical Roller Mill (VRM): Vertical roller mills are increasingly popular in modern cement plants They use rollers and a table to grind clinker Understanding the Role of Clinker Grinding in Cement

The vertical raw mill: A key component in cement production

2024年10月13日 The Role of Vertical Raw Mills in Cement Production: 1 Grinding Limestone: The primary function of a vertical raw mill is to grind limestone, the main raw material in cement production, into a fine powder This powder, known as lime, is a key ingredient in the production of clinker 2 Raw Material Preparation: Before being fed into the kiln The specific energy consumption of a ball mill is greater than that of a vertical mill (VRM) that performs the same operations by a factor of between 15 and 2, depending on the degree of optimization of the ball mill Today, cement producers have the option of using a wide variety of different systems for cement grinding A complete list of An Introduction to Clinker Grinding and Cement StorageThe twostage grinding system composed of a ball mill and a pregrinding roller press or vertical mill and the vertical roller mill final grinding system are the most mature and widely used grinding systems at present, and they are also the systems we most recommend to customers Of course, in the actual project, we will design the most Cement Grinding Plant Expert Cement Grinding AGICO Cement 2021年1月1日 The metal wear of the unit product is low The wear is generally only 5 to 15 g/t, and even only 3 to 5 g/t Therefore, the wearing parts have long service life; the metal powder resulted from metal wear is small, so vertical roller mills can also grind the white cement raw material [15], [16] •Review on vertical roller mill in cement industry its

.jpg)

How to Grind Concrete: A StepbyStep Guide to

2023年11月28日 Concrete grinding is a crucial process for achieving a smooth and even surface on concrete floors, countertops, or other concrete installations Whether you’re preparing the concrete for a new finish or removing Pfeiffer's compact mill solution is perfectly suited for annual production rates of up to 550,000 tons of cement, slag, and granulated blastfurnace slag Find out more! The design of the ready2grind system is based on the Pfeiffer vertical Modular grinding plant Mill system Many cement companies and steel companies have introduced slag vertical mills to grind fine powder, which has better realized the comprehensive utilization of slag However, since the wear of the wearresistant parts inside the vertical mill is difficult to control, severe wear can easily cause major shutdown accidents and bring unnecessary How to properly maintain cement and slag vertical mills?2019年10月18日 Vertical cement mill and related vertical mill system The vertical cement mill system has features of high output and less energy consumption, so it is widely applied to the cement grinding The vertical cement mill has some similarities with cement roller press, both of them use the material bed to do the full crush But the contact surface How To Select Cement Mill? Cement Ball Mill, Vertical Cement

.jpg)

SikaGrind® for vertical roller mills

2019年9月12日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development CEMENT Limestone is much easier to grind than clinker The common intergrinding of limestone and clinker in classical 2024年1月31日 The UBE vertical mill produces less vibration and noise than other grinding mills 6 Uniform quality of products The highly efficient grinding mechanism and classifier are equipped to provide the more stable particle size distribution than other roller millsUBE Vertical Mill UBE Machinery Corporation, LtdCement milling is the process of grinding raw materials (typically limestone, clay, and silica) into a fine powder that can be used to create cement The process involves feeding the raw materials into a cement ball mill or vertical roller mill, where they are ground into a fine powder The Purpose of Cement MillingWhat is Cement Milling? ball mills supplierIntroduction HRM and PRM vertical mill grind materials(044mm) to related fineness by grinding rollers This equipment has high grinding efficiency and high drying capacity, and you can easy adjusting your product fineness, and this equipment has low noise, low power consumption and simple process, less wear lost and save investmentVertical mill pfcementmachine

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Compared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding Mill2019年9月12日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development CEMENT Limestone is much easier to grind than clinker The common intergrinding of limestone and clinker in classical SikaGrind® for vertical roller mills2024年5月18日 The cement vertical roller mill is one of the most important cement equipment It is the key grinding machine of materials being crushed It makes dry or wet grinding for all kinds of ores and other grindable materials FeaturesLow Investment Cost This vertical roller mill itself can crush, dry, grind and classify, so the system is Cement Vertical Mill

.jpg)

2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill

2024年10月22日 The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3 2021年1月4日 is a 70t/hr modular ready2grind vertical roller mill from Gebr Pfeiffer, which was commissioned in De cember 2020 These three mills combine to produce around 4320t/day (14Mt/yr) of lowclinker cement GC: How do you distribute these products? GLOBAL CEMENT: PLANT REPORT Global Cement Magazine January 2021 51 Left: Construction of thePlant report: BIGBOSS Cement, Philippines Gebr Pfeiffer25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations MODULAR AND PORTABLE GRINDING STATION PLUG GRIND 2023年8月14日 Since the installation of the first modular grinding plant with a vertical roller mill in 2016, the cement market has gone through a number of ups and downs and was severely affected not least by the global pandemic and its aftermath Since an MVR vertical roller mill is always used in a ready2grind plant, this also means the greatest Are you ready to grind? World Cement

.jpg)

Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill

Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and 2017年10月27日 The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN 2024年11月4日 A 6week modular course is designed to give the course attendee a solid understanding of the grinding system and its auxiliary equipment The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether it is a ball mill, vertical mill, or crushing processGRINDING TECHNOLOGY COURSE The Cement Institute2024年7月1日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate energy saving ́ Higher fineness faster strength development CEMENT Limestone is much easier to grind than clinker The common intergrinding of limestone and clinker in classical Picture: Loesche GmbH, Germany CEMENT SikaGrind®

.jpg)

Vertical Roller Mill in Cement Plant ball mills supplier

Learn about the key features and benefits of vertical roller mills in cement plant operations Get expert insights and recommendations for optimizing your cement plant production with vertical roller mills which can be challenging to grind using traditional ball mills Construction Industry In the construction industry, VRMs are used to 2024年11月26日 LOESCHE Vertical Roller Mill: The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhow Cement Industry LoescheHighquality cement vertical roller mill manufacturer Tongli ZJTL series cement vertical mill is a very important link in cement production and is the best choice for raw material grinding and clinker grinding As an iterative product of the ball mill, the vertical mill occupies a small area, which is about 50% less than the ball millCement Vertical Roller Mill CEMENTLThis article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features VRMs are used to grind the raw materials used in cement production, such as limestone, clay, and silica After being crushed and processed in crushers,the raw materials are fed into the Application of Vertical Roller Mill in Cement Production

Vertical roller mill vs ball mill for cement grinding:

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainability2023年10月19日 It relies on the use of steel balls to crush and grind the clinker Ball mills are often used for grinding cement clinker into a fine powder before it is mixed with other materials to produce cement Vertical Roller Mill (VRM): Vertical roller mills are increasingly popular in modern cement plants They use rollers and a table to grind clinker Understanding the Role of Clinker Grinding in Cement 2024年10月13日 The Role of Vertical Raw Mills in Cement Production: 1 Grinding Limestone: The primary function of a vertical raw mill is to grind limestone, the main raw material in cement production, into a fine powder This powder, known as lime, is a key ingredient in the production of clinker 2 Raw Material Preparation: Before being fed into the kiln The vertical raw mill: A key component in cement production The specific energy consumption of a ball mill is greater than that of a vertical mill (VRM) that performs the same operations by a factor of between 15 and 2, depending on the degree of optimization of the ball mill Today, cement producers have the option of using a wide variety of different systems for cement grinding A complete list of An Introduction to Clinker Grinding and Cement Storage

.jpg)

Cement Grinding Plant Expert Cement Grinding AGICO Cement

The twostage grinding system composed of a ball mill and a pregrinding roller press or vertical mill and the vertical roller mill final grinding system are the most mature and widely used grinding systems at present, and they are also the systems we most recommend to customers Of course, in the actual project, we will design the most