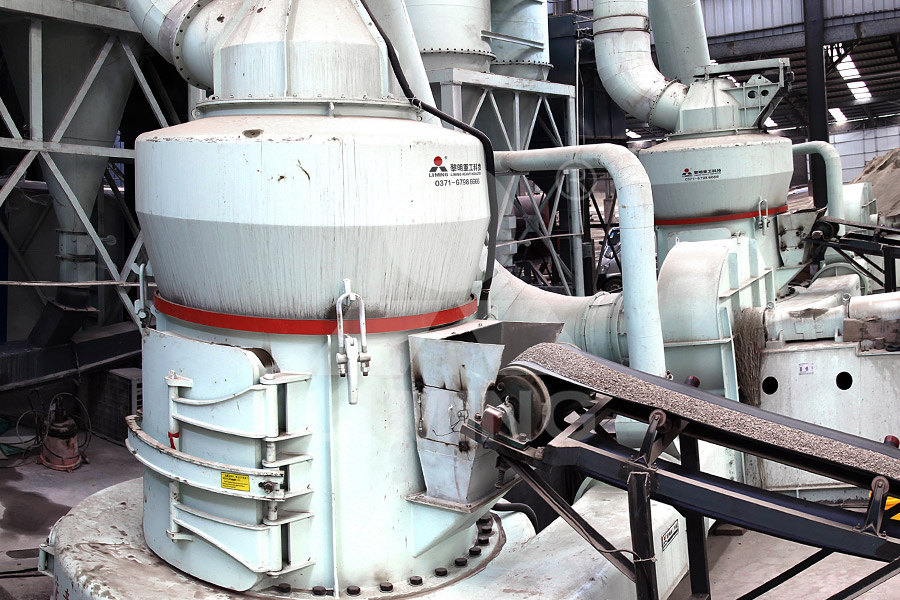

Air ore mill

.jpg)

河南中原黄金冶炼厂有限责任公司 中原冶炼厂官方网站

2024年11月6日 公司采用我国自主研发的具有世界先进水平的“富氧底吹造锍捕金”集成旋浮吹炼技术,具有原料适应能力强、金属回收率高、能耗低、自动化装备水平高等突出特点。 公司引 河南省黄金资源综合利用重点实验室 黄金资源综合利用重点实验室,两家依托单位 首页Vortex air mill for ultrafine grinding of materials 1 Increases the extraction of micron and encapsulated gold in the gravity extraction circuit from concentrates and tails without leachingVortex Air Mill flexicone2020年7月13日 Micronizer®: Jet mills dry particles to submicron size; some models USDAaccepted Powderizer®: Airswept impact mill with integral classifier; grinds to lowmicron MICRONIZER JET MILL Sturtevant Inc

.jpg)

Chapter 8 Air Jet Milling ScienceDirect

2007年1月1日 Air jet milling, or more correctly fluid energy milling, uses high velocity jets of gas to impart energy to particles for size reduction Air jet mills have mainly been developed for 1 天前 The air classifier mill combines a mechanical impact mill with an integrated dynamic air classifier It is an air swept mechanical impact mill designed to grind materials down to 10 microns The air classifier mill uses air Air Classifier Mill jetmillmfgAir jet mill (also known as micronizer) is designed for grinding hygroscopic, heat sensitive and explosive materials to achieve consistent steep particle size distribution Air Jet Mill allows greater control over the grinding parameters Air Jet Mill Air Jet Milling Machine Rieco2021年7月11日 The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 Air Classifying Mill

Laboratory Jet Mill jetmillmfg

2024年11月25日 Laboratory jet mills are recommended for process and product research and development work This jet mill process system is a combination of spiral jet mill and integrated dynamic air classifier High fineness can be 2021年7月11日 ticle concentrates on air classifier mills, which produce fine particles with a nominal top size of 45 microns or finer, depending on the material An air classifier mill applies How to operate an air classifier mill to meet your fine Dodds et al [6] proposed an overall model of the grinding and classification in an air jet mill with an integrated classifier The mill is divided into a perfectly mixed grinding zone, a transport zone with prevailing plug flow and a classification (PDF) Grinding in an air classifier mill2018年10月1日 Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Author links open overlay panel A Azevedo, HA Oliveira, J Rubio Show more (DAF), water saturated with air under pressure (>3 bar) passes through a nozzle (flow constriction) whereby the bubblesare formed and reach the flotation Treatment and water reuse of leadzinc sulphide ore mill wastewaters

.jpg)

Vortex Air Mill Ore Grinding Gold Refining Metal

2023年9月26日 The air mill air discharge is strong so its flowing through the unit The problem we are having is when we add the feed material through the intake port, air is blowing back up the intake port and the feed is pushed back upwards Its like a tornado around the intake port in that the out edge of air is blowing up and there is suction in the centerFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchases The Universal mill is equipped with air insufflation at bearing level to eliminate all risk of crosscontamination in the case of multiproduct use The Ore mill, Ore grinding mill All industrial manufacturers2023年6月7日 In the grinding mill, the ore blocks sized >100 mm function as grinding medium The ore particles smaller than 80 mm but bigger than 20 mm have poor grindability and they cannot be easily ground by big lump ore, so such material is usually called “hardtogrind ore” or “hard rock” decrease the resistance loss of the air flowing Autogenous Mill SpringerLinkRadiatori elettrici norvegesi Mill Gli unici che consumano il 30% di energia elettrica in meno rispetto ai radiatori svedesi sul mercato grazie all’integrazione del WiFi e della Tecnologia PID che fa diminuire automaticamente la potenza del radiatore Scegli il modello più adatto a te: dai classici radiatori elettrici ai termoconvettori con WiFi e PID integrati con cui puoi gestire i Radiatori Elettrici Norvegesi Mill Heat

A comparison of portable XRF and ICPOES analysis for lead on air

2006年4月1日 Good correlation between ICPOES and XRF was also proved by examination the content of Pb in solid samples (air filter samples from a lead ore concentrator mill and a leadacid battery recycler 2007年1月1日 Air jet milling, or more correctly fluid energy milling, uses high velocity jets of gas to impart energy to particles for size reduction Albus [1] gives a brief history of air jet mills The first versions, developed in the late 19th century, used a jet of compressed air to project solids against a targetChapter 8 Air Jet Milling ScienceDirectThe choice of grinding circuit configuration is critical for optimizing gold recovery Common configurations include singlestage AG/SAG mills followed by ball mills or twostage AG/SAG mills followed by a ball mill circuit The selection depends on factors such as hardness of the ore, desired grind size, and energy requirements 3Unlocking the Secrets of Gold Ore Mill: A Comprehensive 2018年10月1日 Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Author links open overlay panel A Azevedo, HA Oliveira, J Rubio Show more (DAF), water saturated with air under pressure (>3 bar) passes through a nozzle (flow constriction) whereby the bubblesare formed and reach the flotation Treatment and water reuse of leadzinc sulphide ore mill wastewaters

Comminution and classification technologies of iron ore

2022年1月1日 Air classification is used in many industries including mining industries where the dry processing is required Nowadays the classifiers are highly efficient when compared with the old type of air classifiers While there are not HIG mills operating in iron ore applications, globally this technology is used in copper and gold circuits to 2017年7月20日 With some ores, it is possible to send minerun ore directly to the semiautogenous mill so that the primary crusher can be eliminated An autogenous or semiautogenous circuit, as the name implies, uses the ore Autogenous Grinding Semi Autogenous 2018年10月1日 Request PDF Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Simulated wastewaters (concentrate and tailings thickener overflows), from Treatment and water reuse of leadzinc sulphide ore mill2011年7月1日 Highefficiency separators have also found applications in integrated grinding circuits such as vertical roller mill (Roy and Terembula 2003), air classifier mill (Ito et al 1993(Ito et al Grinding in an air classifier mill Part I: Characterisation of

Roller Mill SpringerLink

2023年7月4日 The Raymond grinding mill, Raymond mill for short, is a roller mill in which the central spindle drives the multiple grinding rollers installed on the plumblossom rack to swing outwardly under the action of centrifugal force and press the grinding ring on the inner wall of the casing to grind the material6 天之前 Jet mills operate in compressed air, gas or high pressure superheated steam Jet mills have no moving parts, thereby eliminating contamination due to contact with external grinding media Mica, Talc, Tentalum ore etc Paints: Carbon black, Fluorescent pigment, Titanium dioxide etc Pharmaceuticals: Amino Acid, Antibiotics, Aspirin Jet mill working principle jetmillmfg2021年7月11日 MIKRO ACM® AIR CLASSIFYING MILL The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Mikro ACM® Air Classifying Mill is available in a range of sizes and can be supplied for laboratory use or large Air Classifying Mill2017年5月25日 In an airswept mill, the body of which does not differ significantly in general design from a trunnion overflow mill, a powerful stream of air is passed 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Air Air Swept Mill 911Metallurgist

.jpg)

YGM Industrial Raymond Mill

YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 72024年9月25日 Air Quality gives information using weather conditions, pollutants, and research from The Weather Channel and weather Today's Air QualityMill City, OR 51 ModerateAir Quality Forecast for Mill City, OR The Weather Channel2024年8月26日 In addition, PPS Air Classifier Mills benefit from flexibility of design, allowing systems to be customized to fit into all types of physical layouts Cleaning and maintenance of the PPS Air Classifier Mill system is enhanced by: ClamShell design mill body for easy access to the grinding chamber; Pressure capable quickrelease pipe connectionsDairy Process Air Classifier Mill ratetechnologygroupThe airswept ball mill has a similar structure to the ordinary mill, but the input size and the output size are less, and most of the power of the material is supported by wind The airswept coal mill is a critical component in coalfired Air Swept Coal Mill Cement Plant Equipment

}@~3SRDG`IA1KP_ICWAA.jpg)

AIR SWEPT BALL MILL

The air swept ball mill is an ideal grinding machine that merges pulverizing and drying into a single It has the characteristics of high efficiency, energy saving, and environmental protection It is often used as the main equipment in the Ultrafine Air Classifying Mill are used for size reduction of various products to microfine particle sizes The system incorporates integral classifier where the fine particles of desired size are segregated and the over size particles back to the Air Classifying Mill Shalimar EngineeringOre Mill Bar Grille 17 Lake Tarleton Road, Warren, New Hampshire 03279, United States (603) 7646069Ore Mill Bar Grille2023年10月25日 Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities The iron ore supply chain begins with the mining of iron ore, which is then transported to processing plants for beneficiation and further refinement The refined iron ore is then transported to steel mills for Iron Ore Supply Chain: From Mining to Steel Production

PREDICTING THE PRODUCT PARTICLE SIZE

2024年4月1日 VTM mill processing copper ore 70 Figure 37 Size analysis for a repeat experiment performed in a vertical mill shown as a function of grinding time for a single 595 +420μm feed size 71 Figure 38 Vertical mill geometry (left) and RockyDEM simulation of 2023年10月10日 The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drumUnderstanding the SAG Mill in Copper Ore Mining ProcessUltrafine Air Classifying Mills are used for size reduction of various products to microfine particle sizes The system incorporates integral classifier where the fine particles of desired size are segregated and the over size particles back to the grinding chamber and regrinded until the desired particle size is obtainedAir Classifying Mill Shalimar EngineeringPersonal and area samples for airborne lead were taken at a lead mine concentrator mill, and at a leadacid battery recycler Lead is mined as its sulfidic ore, galena, which is often associated with zinc and silver The ore typically is concentrated, and partially separated, on site by crushing and A comparison of portable XRF and ICPOES analysis for lead on air

Treatment and water reuse of leadzinc sulphide ore mill wastewaters

2018年10月1日 Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Author links open overlay panel A Azevedo, HA Oliveira, J Rubio Show more (DAF), water saturated with air under pressure (>3 bar) passes through a nozzle (flow constriction) whereby the bubblesare formed and reach the flotation 2023年9月26日 The air mill air discharge is strong so its flowing through the unit The problem we are having is when we add the feed material through the intake port, air is blowing back up the intake port and the feed is pushed back upwards Its like a tornado around the intake port in that the out edge of air is blowing up and there is suction in the centerVortex Air Mill Ore Grinding Gold Refining Metal Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchases The Universal mill is equipped with air insufflation at bearing level to eliminate all risk of crosscontamination in the case of multiproduct use The Ore mill, Ore grinding mill All industrial manufacturers2023年6月7日 In the grinding mill, the ore blocks sized >100 mm function as grinding medium The ore particles smaller than 80 mm but bigger than 20 mm have poor grindability and they cannot be easily ground by big lump ore, so such material is usually called “hardtogrind ore” or “hard rock” decrease the resistance loss of the air flowing Autogenous Mill SpringerLink

.jpg)

Radiatori Elettrici Norvegesi Mill Heat

Radiatori elettrici norvegesi Mill Gli unici che consumano il 30% di energia elettrica in meno rispetto ai radiatori svedesi sul mercato grazie all’integrazione del WiFi e della Tecnologia PID che fa diminuire automaticamente la potenza del radiatore Scegli il modello più adatto a te: dai classici radiatori elettrici ai termoconvettori con WiFi e PID integrati con cui puoi gestire i 2006年4月1日 Good correlation between ICPOES and XRF was also proved by examination the content of Pb in solid samples (air filter samples from a lead ore concentrator mill and a leadacid battery recycler A comparison of portable XRF and ICPOES analysis for lead on air 2007年1月1日 Air jet milling, or more correctly fluid energy milling, uses high velocity jets of gas to impart energy to particles for size reduction Albus [1] gives a brief history of air jet mills The first versions, developed in the late 19th century, used a jet of compressed air to project solids against a targetChapter 8 Air Jet Milling ScienceDirectThe choice of grinding circuit configuration is critical for optimizing gold recovery Common configurations include singlestage AG/SAG mills followed by ball mills or twostage AG/SAG mills followed by a ball mill circuit The selection depends on factors such as hardness of the ore, desired grind size, and energy requirements 3Unlocking the Secrets of Gold Ore Mill: A Comprehensive

Treatment and water reuse of leadzinc sulphide ore mill wastewaters

2018年10月1日 Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Author links open overlay panel A Azevedo, HA Oliveira, J Rubio Show more (DAF), water saturated with air under pressure (>3 bar) passes through a nozzle (flow constriction) whereby the bubblesare formed and reach the flotation 2022年1月1日 Air classification is used in many industries including mining industries where the dry processing is required Nowadays the classifiers are highly efficient when compared with the old type of air classifiers While there are not HIG mills operating in iron ore applications, globally this technology is used in copper and gold circuits to Comminution and classification technologies of iron ore