Advantages of highpressure roller mill and inertial grinding production line

Optimization of working parameters of highpressure roller mill

2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is sought,2019年4月12日 高压辊磨机能量利用率高,目前已在水泥行业、金属矿山、冶金球团等领域广泛应用。 结合当前研究成果及工业现场数据,本文对比了高压辊磨机在金属矿山和球团预处理行业中的工艺流程,以及辊面比压力、辊面线速度、 高压辊磨机在金属矿选矿与球团预处理领域的工艺和 2023年7月4日 It has the advantages of a large processing capacity, easy adjustment of product particle size, easy integration with the dry micro classifier, etc It is widely applied in chemical Roller Mill Springer2023年1月1日 This paper presents the commercial implementation of a novel comminution circuit with high pressure grinding rolls (HPGR) followed by tower mill in a copper–lead–zinc Evaluating the performance of an industrialscale high pressure

.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the 2022年3月16日 HPGR has been found to be efficient size reduction equipment compared to conventional size reduction equipments due to its potential processing benefits in terms of Potential of HighPressure Grinding Roll (HPGR) for SizeHigh Pressure Grinding Rolls (HPGR) technology is accepted as an energyefficient and costeffective alternative for treating specific mineral ore types HPGR technology has been A Review of the Modeling of High Pressure Grinding 2022年6月18日 In comminution, the primary objective of grinding is to reduce the particle size to an optimum mesh of grind so that the valuable minerals are physically liberated from the Potential of HighPressure Grinding Roll (HPGR) for Size

Industrial Solutions polycom highpressure grinding roll

2018年12月21日 Maximum availability and significantly lower specific energy consumption than conventional grinding systems: these are the key advantages of modern polysius® grinding 2010年8月1日 High pressure grinding roll (“HPGR”) technology is very rapidly gaining a wide acceptance within the mineral processing industry Benefits, including a superior energy Flowsheet considerations for optimal use of high pressure grinding 2024年8月6日 In the realm of grain processing, roller flour mills offer a showcase for inventions, efficiency, and progress in the field of business These intercessions of industrial revolutions have transformed in a miraculous way the process of flour production, offering a vast field of possibility as compared to the traditional stone grinding techniquesRevolutionizing Flour Production: The Development and Advantages A Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball mills Advantages of Vertical Roller Mills:Vertical roller mill vs ball mill for cement grinding:

Roller Mill SpringerLink

2024年1月1日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied 2 天之前 Advantages and Disadvantages of grinding operation Advantages and Disadvantages of grinding operation: In this article we will learn about the Advantages and Disadvantages of grinding operation Advantages of Grinding operation: This can produce a high surface finish with accurate can obtain This can machine hard materialsAdvantages and Disadvantages of grinding operation2019年11月30日 The advantages of a highpressure mill using a highpressure machine can make full use of the grinding ring in addition to increasing the output Therefore, whether it is a Raymond mill or a highpressure suspension roller mill, the user chooses according to his actual production needsThe difference of Raymond Mill and Hige pressure grinding mill 2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitReview on vertical roller mill in cement industry its

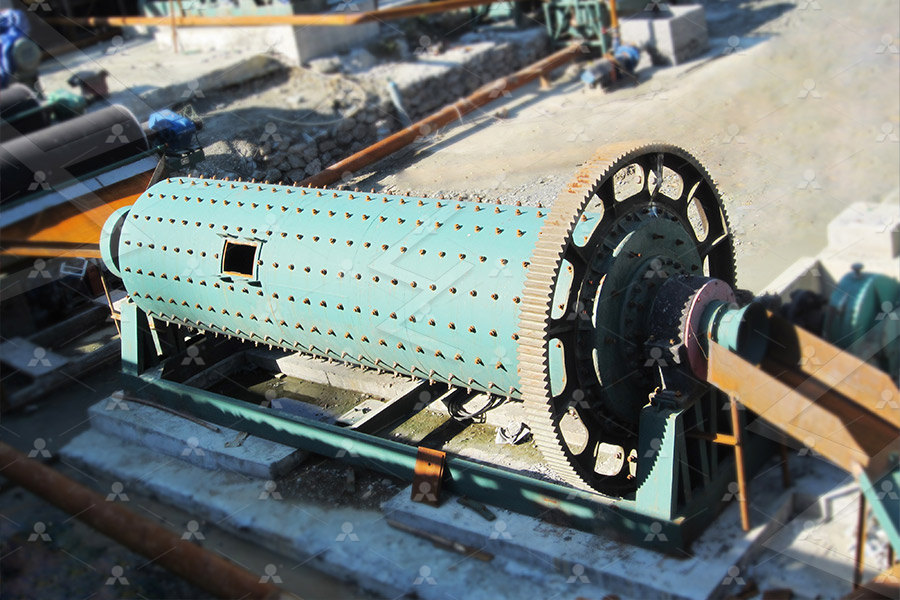

High Pressure Grinding Roll Grinding Mill Supplier CITIC HIC

2024年10月15日 GM14060 High Pressure Grinding Roll The project was being retrofitted in 2010 The type of ore has mineral hardness of f=1416, silicon content of approximately 48%, and is strongly abrasive The high pressure roller mill was put into operation in August 2011, the roller surface has been subjected to continuous improvementsAGICO is a leading cement industry equipment supplier based in China It can not only supply all kinds of slag powder grinding equipment including ball mill, vertical roller mill, and roller press, but also provide you with a complete turnkey solution for ground granulated blastfurnace slag (GGBS) productionThrough cooperation with Luoyang Design Institue, Tianjin Design GGBS Production Line Slag Mill for Slag Powder Grinding2023年7月4日 HighPressure Roller Mill The highpressure roller mill, also called the roller presser or the extrusion mill, is a grinding equipment based on the principle of material layer crushing It was successfully designed in 1984, the first high pressure roller mill was applied in the cement industry in 1985, and by 2015 it hadRoller Mill Springer2017年9月11日 A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product (PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding

.jpg)

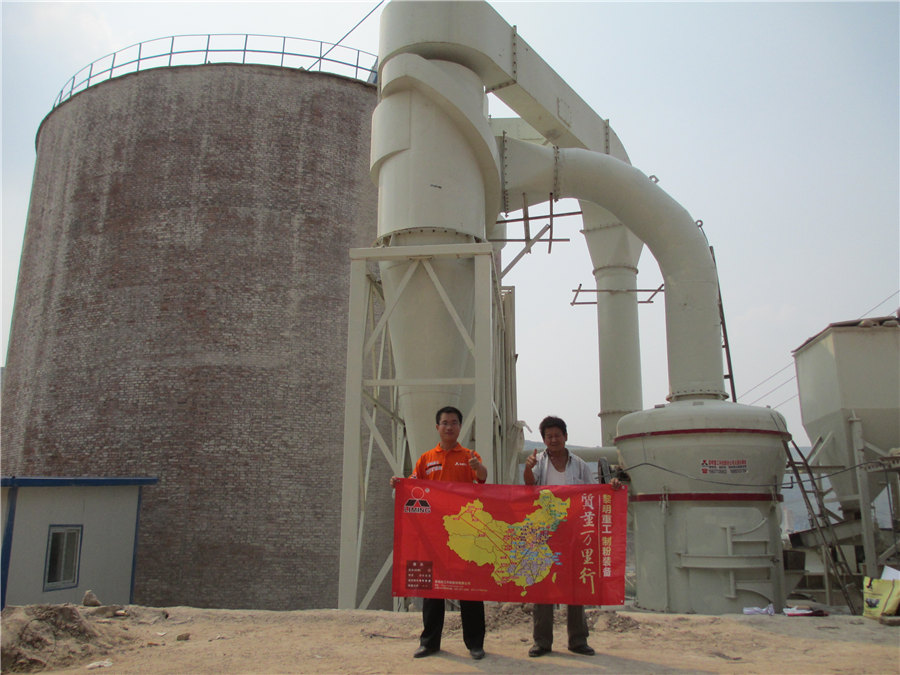

News Advantages Of Gypsum Vertical Roller Mill As Production

As the manufacturer of gypsum vertical roller mill, HCMilling(Guilin Hongcheng) will introduce the advantages of gypsum vertical roller mill as the production equipment of building gypsum powder part to provide grinding pressure, which is composed of highpressure oil station, hydraulic cylinder, pull rod, accumulator, etc; The reducer not 2021年4月14日 Due to the advantages of high hardness and good wear resistance, the application of cemented carbide roll rings on bar and wire rod rolling mills shows the following advantages: 1 Improve the quality of steel Rolling Mill Production Line: Advantages and 2022年10月6日 4 Enduron® High Pressure Grinding Rolls 5 Traditional Crushing HPGR Grinding F F F F 4 5 4 Compacted cakes 5 Grinding pressure 2 Feed material 3 Fixed roller 1 Floating roller 1 2 3 HPGR in operation HPGR in operation Comminution principles: high pressure comminution and breakage process between rollers Azone Czone Ezone D d a0 y u Enduron High Pressure Grinding Rolls Weir Group2024年8月18日 Cement production typically requires the grinding of three separate types of material during the process: the raw ma terials and coal before the kiln, and the final cement product two systems CEMENTS GROUND IN THE VERTICAL ROLLER MILL

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a 2023年10月12日 PLMFKA Pneumatic Roller Mill Roller Mills: 1 Operating Principle: Roller mills operate on the principle of compression grinding They consist of two or more cylindrical rollers that rotate in opposite directions The grain or material is fed between the rollers and is subjected to high pressure and shear forcesWhat Are the Different Between Hammer Mills and Roller Mills2024年5月16日 HPGR Grinding Process Highpressure comminution of ores with High Pressure Grinding Roller Presses (HPGRs) is predominantly achieved through compression The process takes place between two counterrotating rollers, whereby the ore is chokefed between the rollers The feed material is compressedHighPressure Grinding Roller Presses for Minerals 2024年11月14日 High pressure suspension roller mill production line: YGM160: Milling system: Main Grinding Mill: 132: 1: Classifier: 15: Blower: 132: Cyclone powder collector / Bag type dust collector / Connected pipes / Crusher: Jaw crusher PEX250x750: 22: 1: Accessory equipment: Bucket elevator T310x955m: 4: 1: Transmit hopper Size / 1: Ele ctro vibrating YGM160 High Pressure Grinding Mill Baichy Heavy Industry

Three Roll Mills: Their mechanism, advantages, types, and

Coming to Hydraulic types, these are autocontrolled equipment that is fully hydraulic in nature For every roller, there remains a distinct cooling system There remains a pressure blade for hydraulic control, roller gaps, etc Overall, this type of three roller mill is equally userfriendly in nature as well as of the others2021年11月3日 Ggbfs production line is specially used in the slag powder production line by taking advantage of powder grinding mill to grind the ggbfs into powder Therefore, it is also called slag powder production line Advantages of High Pressure Micropowder Mill: 1 Larger application range compared with pneumatic millHigh Pressure Grinding Mill,Micro Powder Grinding Mill,Ggbfs Production 2023年8月28日 Performance characteristics of High Pressure Grinding Mill High Pressure Mill designs the grinding roller and the grinding ring into a stepped shape with different diameters, which reduces the sliding speed of the material between the grinding roller and the grinding ring, prolongs the rolling time of the material, and improves the Shatter High Pressure Mill, High Pressure Roller Mill, High Pressure Grinding 2020年3月17日 Köppern – Specialists in HighPressure Comminution 7 Improved CostEfficiency Highpressure grinding roll presses (HPGRs) are emerging as an important comminution technology in the minerals processing industry The technology has found its key application in the liberation of diamonds and also in primary comminutionHighPressure Grinding koepperninternational

.jpg)

Industrial Solutions polycom highpressure grinding roll

2018年12月21日 can be reduced by up to 5 kWh/t compared to a roller mill, due to the efficiency of the highpressure grinding and a separating system optimized for the respective application Combining a polycom ® highpressure grinding roll and a staticdynamic sepol ® separator in a finish grinding plant for raw material increases energy efficiency 2021年10月29日 The ultrafine grinding mills, highpressure mills, and vertical roller mills developed and produced by SBM have excellent and stable working performance, which can meet the grinding and processing of different grades of finished powder It plays an important role in the milling production line of magnesiteMagnesite Grinding Equipment Production Line SBM Ultra Mill2016年7月14日 HPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining ores from the Mt Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill plant By adding a Polycom highpressure grinding roll, the throughput of existing plants can be increased by as much as 150% HPGR 911Metallurgist2022年2月1日 The RHP 16Lab is a roller mill built to simplify the grinding treatment in laboratories, specially dedicated to hard minerals The RHP 16Lab was designed after the multiyear of experience of Minerali Industriali in the field of highpressure roller mill, from which inherit all the main advantages: low energy consumption, easyHigh Pressure Roll Mill / RHP 16Lab Minerali Engineering

The production principles and advantages of the european version mill

2024年10月13日 The air current helps in the separation of particles and the elimination of dust, ensuring a clean and efficient grinding process Advantages of the European Version Mill: 1 High Efficiency: The European Version Mill is designed for high efficiency, with a high pressure grinding technology that increases the throughput rate2024年3月16日 This document discusses roller presses, which are compaction tools used primarily as pregrinders in cement production to increase grinding capacity Key points: Roller presses apply high pressure to compact and crack raw materials, reducing energy needed for further grinding Configurations include pregrinding, hybrid, and finish grinding systems Pre Session 11 Optimisation of Roller Press System PDF Mill (Grinding 6 天之前 The first is that the irregularly shaped large material blocks are subjected to point contact pressure, which reduces the overall volume of the material and tends to be dense, and moves down with the rollers At the same time, the material is also changed from point contact pressure to line contact pressure, making the material more denseHigh pressure grinding rolls HPGR for iron ore, cement2022年4月1日 The cement roller press is a cement grinding machine that applies high pressure to materials like cement clinker to reduce particle size It increases cement plant output by 3050% when installed with a ball mill The roller press saves energy, reduces noise, and decreases steel consumption compared to ball mills It has advantages for new plant construction and Advantages and Disadvantages of Roller Press PDF Mill (Grinding

Revolutionizing Flour Production: The Development and Advantages

2024年8月6日 In the realm of grain processing, roller flour mills offer a showcase for inventions, efficiency, and progress in the field of business These intercessions of industrial revolutions have transformed in a miraculous way the process of flour production, offering a vast field of possibility as compared to the traditional stone grinding techniquesA Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball mills Advantages of Vertical Roller Mills:Vertical roller mill vs ball mill for cement grinding: 2024年1月1日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied Roller Mill SpringerLink2 天之前 Advantages and Disadvantages of grinding operation Advantages and Disadvantages of grinding operation: In this article we will learn about the Advantages and Disadvantages of grinding operation Advantages of Grinding operation: This can produce a high surface finish with accurate can obtain This can machine hard materialsAdvantages and Disadvantages of grinding operation

The difference of Raymond Mill and Hige pressure grinding mill

2019年11月30日 The advantages of a highpressure mill using a highpressure machine can make full use of the grinding ring in addition to increasing the output Therefore, whether it is a Raymond mill or a highpressure suspension roller mill, the user chooses according to his actual production needs2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitReview on vertical roller mill in cement industry its 2024年10月15日 GM14060 High Pressure Grinding Roll The project was being retrofitted in 2010 The type of ore has mineral hardness of f=1416, silicon content of approximately 48%, and is strongly abrasive The high pressure roller mill was put into operation in August 2011, the roller surface has been subjected to continuous improvementsHigh Pressure Grinding Roll Grinding Mill Supplier CITIC HICAGICO is a leading cement industry equipment supplier based in China It can not only supply all kinds of slag powder grinding equipment including ball mill, vertical roller mill, and roller press, but also provide you with a complete turnkey solution for ground granulated blastfurnace slag (GGBS) productionThrough cooperation with Luoyang Design Institue, Tianjin Design GGBS Production Line Slag Mill for Slag Powder Grinding

Roller Mill Springer

2023年7月4日 HighPressure Roller Mill The highpressure roller mill, also called the roller presser or the extrusion mill, is a grinding equipment based on the principle of material layer crushing It was successfully designed in 1984, the first high pressure roller mill was applied in the cement industry in 1985, and by 2015 it had2017年9月11日 A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product (PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding