Sodium hydroxide grinding equipment working principle

(PDF) Principles of Modern Grinding Technology

2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent decades Removal rates and2021年8月27日 The working principle of electrochemical grinding is When a metal surface is acted upon with an electrolyte under a high current, the metal surface gets oxidized to form an oxide layer (corrosive layer) This layer is Electrochemical Grinding: Definition, Parts or 2023年7月4日 Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the Roller Mill Springer6 天之前 We emphasize that good grinding economy is essential to overall productivity, pointing out how direct and indirect manpower costs dominate A brief review of the working Pocket Guide to Grinding Technique Atlas Copco

.jpg)

Electrochemical Grinding: Parts, Working,

2024年6月6日 In Electrochemical grinding, the metalbonded grinding wheel is filled with a nonconductive abrasive The grinding wheel acts as a cathode and the workpiece acts as an anode The electrolyte, which is usually sodium Working principle of the grinding machine As acknowledged, biomass has been identified as the most promising alternative for replacing fossil fuel due to its sustainability Grinding is known toWorking principle of the grinding machineWorking Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed Types of Grinding Machine: Parts, Working 2018年3月1日 Savona Equipment Ltd is a Canadian Mining and Milling Equipment Supply Company backed by over 100 years of experience Grinding Mills — Types, Working Principle ApplicationsScreening Plants — Types, Working Principle Applications

.jpg)

Cyclone Separator Working Principle (Dust

Introduction Cyclonic separation is a means of separating different liquid phases (different liquid densities), or, separating particles from a gas streamCyclone separators often form part of a precleaning stage prior to a gas or liquid being 2023年11月28日 A singleside grinder is a type of process equipment for grinding one side (the front side) of Si wafers with a diamond grinding wheel tool This equipment, also known as a wafer grinder, is used to further reduce the surface damage layer depth (SDD) and improve the total thickness variation (TTV) and surface roughness of Si wafersManufacturing Equipment for Silicon Wafer SpringerLink6 天之前 Jet mills operate in compressed air, gas or high pressure superheated steam Jet mills have no moving parts, thereby eliminating contamination due to contact with external grinding media It is also an ideal process to grind heatsensitive and waxy material because no attritional heat is generated Jet mill works on fluid energyJet mill working principle jetmillmfg2014年10月25日 4 Principle of the Surface grinding machine • Surface grinding is used to produce a smooth finish on flat surface It is a widely used abrasive machining process in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance from a work piece, making a face of it flat or smoothSurface grinding machine PPT SlideShare

Ball Mill Grinding Machines: Working Principle, Types, Parts

Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders2024年5月29日 Working Principle of Ultrasonic Machining The figure shows the Ultrasonic machining operation The electronic oscillator and amplifier, also known as the generator , converts the available electrical energy of low frequency to highfrequency power of the order of 20 kHz which is supplied to the transducerUltrasonic Machining: Diagram, Working Principle, Applications2024年11月16日 The working principle of the highpressure homogenizer (HPH) is based on the use of a highpressure pump and a valve (nozzle, orifice), which makes the equipment large, heavy, and expensive The processed slurry is forced with high flow velocity through a small orifice, which reduces particle size as particles require a certain small size in Homogenizers Working Principle, Use and ScaleUp2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent decades Removal rates and quality standards have (PDF) Principles of Modern Grinding Technology

Ball mill: Principles, construction, working, uses, merits, and

2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the 2021年11月23日 The principle of the gear grinder is shown in the figure Grinding wheels of different forms are used in this grinder to cut dents of different sizes and shapes There are four main parts of this grinder: (1) Grinding 14 Types of Grinding Machines [Working, 2022年1月12日 The working principle of chemical machining is based on chemical etchant An etchant is a mixture of strong chemical acids which are reactive to metal The Design Features of the FiveAxis Tool Grinder March Chemical Machining: Definition, Working 2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other Guide to Centerless Grinding Machine:

.jpg)

Types of Grinding Machine: Parts, Working Principle Grinding Wheel

Working Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed of abrasive particles is given a relative motion with the workpieceWorking principle of a lathe machine These days lathe machine is the most popular and essential machinery in metalworking LATHE is an abbreviation of “Longitudinal Access Turning Horizontal Equipment” Lathes are intended to spin a workpiece against a tool bit, unlike milling machines According to the complete form, it works on the What is Lathe Machine? Working Principle, Main Parts and 2024年2月3日 Multimill; Working and principle Last Updated on: February 3, The mechanism involves the pulverization process (Pulverization is the grinding and crushing of materials into small particles) knife blades are used to cut the large particles into small size particles, that are generated during the FBD drying process The hummer process is Multimill; Working and principle in Pharmaceutical2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

Grinding Machine PPT PPT SlideShare

2020年4月24日 6 6 • The grinding machine consists of a bed with a fixture to guide and hold the work piece, and a powerdriven grinding wheel spinning at the required speed The speed is determined by the wheel’s diameter and manufacturer’s rating The user can control the grinding head to travel across a fixed work piece, or the work piece can be moved while the grind head 2021年9月28日 The principle of grinding precision machining: Grinding is an abrasive precision machining method that uses a lapping tool and abrasive to grind off a thin layer of metal from the surface of the workpiece based on fine machining The processing quality is guaranteed by mechanical equipment, and the work efficiency is relatively high But it What Is Grinding and Its Working Principle and Type?2022年7月14日 01 Grinding Equipment Working Principle Back Taking a ball mill as an example, during grinding, the grinding medium and minerals in the cylinder rotate with the cylinder When reaching the critical height, they fall off the cylinder and crush the ore The grinding media grinds each other during the rotationEverything You Need to Know about Mineral Grinding Equipment2016年3月26日 The gravity spiral circuit is designed to extract and concentrate “coarse gold’ from the recirculating load in the mill grinding circuit and hence prevent a buildup within that circuit and the eventual escape of some of that Gravity Spiral Concentrator Working Principle

.jpg)

Electrochemical Grinding: Parts, Working,

2024年6月6日 These protruding abrasive particles also remove the unactive layers formed on the work by abrasion to make the surface more receptive It can be seen that the process is similar to conventional grindingIn that, an 302 Principles of comminution Since a unit area of solid has a definite amount of surface energy, the creation of new surface requires work, which is supplied by the release of energy of stress when the particle breaks Size Reduction1: Grinding – Unit Operations in 2016年12月8日 However, the ability to do precision centerless grinding in addition to precise machining is a definite advantage How does precision centerless grinding work? Precision centerless grinding is one of several machining processes that use abrasive cutting to remove material from a part (workpiece) The process involves the part being supported on 8 Principles of Precision Centerless Grinding Metal Cutting CorporationInstruments and equipment: Tissue homogenizer Cooling centrifugation system Vortex Mortar and pestle Freeze and deepfreeze (20℃ and 80℃) Incubator Laminar hood or extraction chamber Chemicals and reagents: RNA lysis solution Saturatedphenol Sodium Acetate Phenol; Chloroform; Isoamyl alcohol Ethanol RNasefree waterRNA Extraction: Principle, Procedure, Protocol and Importance

.jpg)

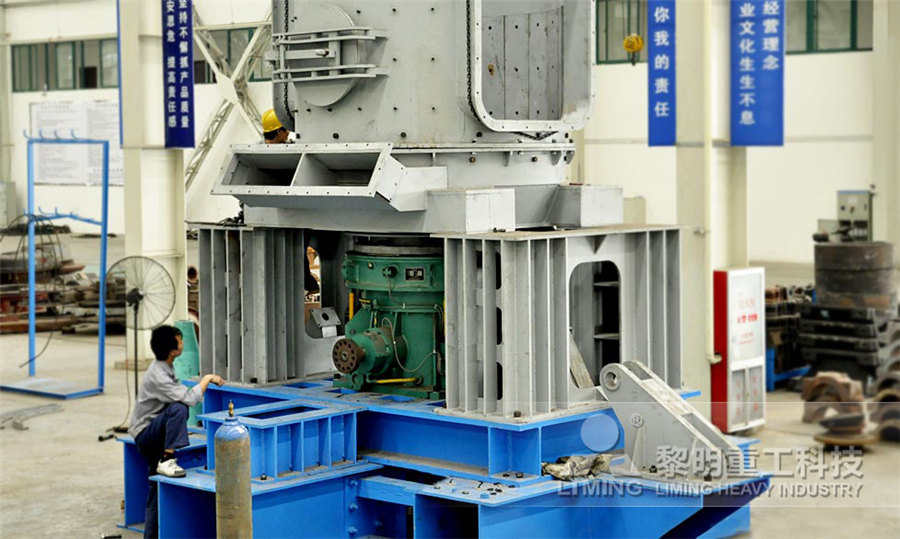

Working principle of the grinding machine ResearchGate

Download scientific diagram Working principle of the grinding machine from publication: Development of newly designed combined grinding equipment As acknowledged, biomass has been identified 2024年2月24日 Grinding is a type of abrasive machining process which uses a grinding wheel or abrasive belt as a cutting tool Grinding is basically a finishing process used for producing close dimensional accuracies and desired smooth surface finishIt is commonly used to remove the material from a workpiece, to produce a smooth finish on the surface of the workpieceWhat is Grinding? Definition, Working Principle, Types, 2017年10月3日 Share with Facebook; Share with Twitter; Share with Google+; Share with LinkedIn; Posted: October 3, 2017 Grinding Mills Types, Working Principle Applications The purpose of this article is to explain the usage of grinding mills in a mineral processing operation and to enable buyers to understand the best suitable grinding mill as per their specific needsGrinding Mill Types, Working Principle Applications Savona Equipment2023年7月4日 The highpressure roller mill, also called the roller presser or the extrusion mill, is a grinding equipment based on the principle of material layer crushing It was successfully designed in 1984, the first high pressure roller mill was applied in the cement industry in 1985, and by 2015 it had been widely used in various metal and non Roller Mill SpringerLink

.jpg)

Roller Mill Springer

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and Working principle: the material is fed by the feeder between two parallel, opposite, and syn2018年3月1日 Savona Equipment Ltd is a Canadian Mining and Milling Equipment Supply Company backed by over 100 years of experience Grinding Mills — Types, Working Principle ApplicationsScreening Plants — Types, Working Principle ApplicationsIntroduction Cyclonic separation is a means of separating different liquid phases (different liquid densities), or, separating particles from a gas streamCyclone separators often form part of a precleaning stage prior to a gas or liquid being Cyclone Separator Working Principle (Dust 2023年11月28日 A singleside grinder is a type of process equipment for grinding one side (the front side) of Si wafers with a diamond grinding wheel tool This equipment, also known as a wafer grinder, is used to further reduce the surface damage layer depth (SDD) and improve the total thickness variation (TTV) and surface roughness of Si wafersManufacturing Equipment for Silicon Wafer SpringerLink

Jet mill working principle jetmillmfg

6 天之前 Jet mills operate in compressed air, gas or high pressure superheated steam Jet mills have no moving parts, thereby eliminating contamination due to contact with external grinding media It is also an ideal process to grind heatsensitive and waxy material because no attritional heat is generated Jet mill works on fluid energy2014年10月25日 4 Principle of the Surface grinding machine • Surface grinding is used to produce a smooth finish on flat surface It is a widely used abrasive machining process in which a spinning wheel covered in rough particles cuts chips of metallic or nonmetallic substance from a work piece, making a face of it flat or smoothSurface grinding machine PPT SlideShareBall Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts 2024年5月29日 Working Principle of Ultrasonic Machining The figure shows the Ultrasonic machining operation The electronic oscillator and amplifier, also known as the generator , converts the available electrical energy of low frequency to highfrequency power of the order of 20 kHz which is supplied to the transducerUltrasonic Machining: Diagram, Working Principle, Applications

Homogenizers Working Principle, Use and ScaleUp

2024年11月16日 The working principle of the highpressure homogenizer (HPH) is based on the use of a highpressure pump and a valve (nozzle, orifice), which makes the equipment large, heavy, and expensive The processed slurry is forced with high flow velocity through a small orifice, which reduces particle size as particles require a certain small size in 2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent decades Removal rates and quality standards have (PDF) Principles of Modern Grinding Technology2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and