Ceramic toilet grinding equipment and process flow

A PROCESS DESIGN ON THE COMMERCIAL PRODUCTION

The research project outlines the design procedure for the production of 1200 metric tonnes of ceramic sanitary wares per annum from clay2024年2月1日 Currently, there are three main types of production equipment: highpressure grouting production line, vertical casting mold production line, and pavement mold production Detailed production process for ceramic toilets and ceramic 2021年6月15日 Ceramic industry manufacturing requires a great amount of energy and water Its sustainability and environmental impact demand an effort to develop more efficient Introduction to Ceramic SanitaryWare Manufacturing2023年7月5日 In this context, this study addresses the implementation of a Life Cycle Assessment (LCA) on the production of ceramic sanitaryware, based on a cradletograve Life Cycle Assessment (LCA) of ceramic sanitaryware: focus

Introduction to Ceramic SanitaryWare Manufacturing

2023年12月3日 In this regard, the sanitaryware production sector presents a defined special map of consumption through the manufacturing process characterized by the levels of 2015年9月10日 Figure 1171 presents a general process flow diagram for ceramic products manufacturing The basic steps include raw material procurement, beneficiation, mixing, AP42, CH 117: Ceramic Products Manufacturing US EPA2024年1月9日 In this article, we’ll explore the precise manufacturing process of ceramic toilets Starting with selecting the ideal mix of materials, to shaping, glazing, and the final inspection, each step is carried out with precision and Unveiling The Craft: How Ceramic Toilets Are 2017年11月1日 The use of right glaze compositions, which enable ceramic sanitary ware (such as sink, toilet bowl, toilet bowl, etc) to have better hygienic, aesthetic and technical properties, is of great(PDF) A INDUSTRIAL APPROACH TO CERAMICS:

.jpg)

Fine Grinding of Ceramics with Attritors Union Process

2021年5月26日 For the ceramic industry, grinding media commonly used include alumina, zirconium steatite ceramic, silicon nitride, silicon carbide, glass beads, tungsten carbide With The process of grinding ceramic tile edges requires precision and skill, ensuring that the edges are clean and smooth But how does one go about grinding these edges effectively? In this discussion, we will explore the necessary steps and Mustread Guide to Grinding Ceramic Tile Edges 14 Figure 21: General flow of major process and equipment 15 Figure 22: General process flow diagram showing different processing paths 16 23 EQUIPMENT FOR CERAMIC MANUFACTURING 231 RAW MATERIALS PREPARATION EQUIPMENT Hammer mills achieve size reduction by impact forces – pieces of raw material fed into the mill are shattered A PROCESS DESIGN ON THE COMMERCIAL PRODUCTION OF SANITARY CERAMIC 2018年12月27日 A Premetalliation Guide to Lapping, Polishing, and Grinding Ceramic Substrates 4 accumet Lapping 101 The lapping process begins with precision equipment and a welltrained and skilled technician Material can be lapped down to as thin as 003’’ with a tolerance as low as ± 0001’’ Materials as large as 16’’ square or diameterA Premetallization Guide to Lapping and Polishing

Grinding Mechanisms for Ceramics ScienceDirect

1996年1月1日 Keynote Papers Grinding Mechanisms for Ceramics S Malkin (1) T W Hwang, Department of Mechanical b Industrial Engineering, Engineering Lab Building, University of Massachusetts, Amherst, MA, USA Abstract The widespread utilization of high strength ceramic materials has been limited by the high cost of machining these materials by grinding2023年7月5日 The reduction of environmental impact is today the main challenge of the ceramic industry that is always more focusing on materials in line with the principles of economic and environmental sustainability In this context, this study addresses the implementation of a Life Cycle Assessment (LCA) on the production of ceramic sanitaryware, based on a cradleto Life Cycle Assessment (LCA) of ceramic sanitaryware: focus 2023年10月14日 To investigate the machining mechanism of silicon carbide (SiC) ceramic materials, this study utilized sintered diamond tools to perform drilling and grinding simulations on the material and developed a drilling model for SiC ceramic materials By analyzing parameters such as surface morphology, stress, and cutting force, the material removal mechanism of SiC Simulation experimental investigations into material removal 2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) (PDF) Grinding in Ball Mills: Modeling and Process Control

A StepbyStep Guide on How to Grind Ceramic Tile

The table below provides ceramic tile grinding tips for step 4 of the grinding process: Step 5 Once the grinder has cut all the way through the ceramic tile, make sure to turn it off and unplug it for safety Here are some important points to consider when grinding down ceramic floor tile:2020年8月13日 Once the ceramic basin or toilet is formed initially, the faucet hole, overflow hole (if needed), and drainer hole will be made Then the basin will be dried in the natural air or under the industrial fan When it’s dried to 60% to 70%, it could proceed to the ceramic basin or toilet body repair stateStep By Step Process of Manufacturing Ceramic Basin And ToiletFerroCeramic's Unit Cell Production Approach Here at FerroCeramic, we pride ourselves on our production quality and efficiency Every step of our ceramic grinding services and production process is carefully coordinated and exercised for efficiency and quality FerroCeramic production facilities are strategically arranged to capitalize on the inherent manufacturing Ceramic Grinding Services Ferro21 GENERAL CERAMIC FORMING PRINCIPLES 397 211 PowderForming Processes / 397 212 Industrial Forming Equipment / 404 213 Process Flow Charts / 405 214 Dimensional Control / 411 Summary / 413 Suggested Reading / 413 Problems / 414 Examples / 415 22 PRESSING 418 221 Process Variables in Dry Pressing / 419 222 Powder Flow and Die PRINCIPLES OF CERAMICS PROCESSING dandelon

.jpg)

Ceramic Machining 101: A Comprehensive Guide

2023年9月17日 By implementing these troubleshooting techniques and preventive measures, you can optimize your ceramic machining processes and achieve highquality results Ceramic Machining Applications in Various 2024年8月17日 Fig 2 Schematic diagram of molding sand structure Casting process characteristics Casting remains a fundamental method for producing component blanks, particularly for parts made from brittle metals or alloys Casting Production: Process Flow, Equipment, 2020年8月4日 The effects of grinding parameters on the surface roughness of zirconia ceramics were investigated in this paper under such two working conditions as dry grinding and wet grindingUnder the Study on surface roughness of zirconia ceramics in high 2018年8月7日 The process of grinding, lapping as well as the stages of technical ceramics processing have been reported Up to 80% of the material to be removed at the first stage, where a rough tool was (PDF) Research and Application of Engineering Ceramic Material

.jpg)

How Are Ceramics Made? (Step By Step Process)

2 天之前 Manufacturers use different kinds of clay to make various ceramics The process is almost the same for all ceramics First, the clay is made flexible with water and some other chemicals Then they are given the desired shape The next step is to bake the clay at a high temperature The final phase of making ceramics involves glazing and 2021年5月5日 The FerroCeramic Grinding Inc staff are trained to operate multiple units FerroCeramic Grinding Inc is ISO 9001:2015 + AS9100D LEARN MORE FerroCeramic Grinding Inc machines over 15 different materials 55 Years of Excellence in Ceramic Machining LEARN MORE FerroCeramic Grinding Inc Our Quality is Built Into Our Process Manufacturing efficiencies Home Ferro2024年9月24日 Ceramic grinding media overview Two manufacturing processes may be distinguished in the production of ceramic media commonly used in fine grinding for noncontaminating applications: • Sintered ceramic beads obtained by a cold forming of ceramic powder and by firing in hightemperature kilns • ‘Fused’ ceramic formed by electric fusion Fine grinding—Developments in ceramic media These wheels will effectively dissipate heat and prevent it from building up during the grinding process Coolant Flow: Look for grinding wheels with open structures and a higher degree of porosity This allows for better coolant flow, which helps in reducing heat buildup and maintaining the temperature within acceptable limitsCeramic Grinding Wheels 101: Types, Functions, and Best

A DEM Methodology for Simulating the Grinding

2023年10月28日 1804 Shengqiang Jiang et al / Procedia Engineering 102 ( 2015 ) 1803 – 1810 grinding process is the object of extensive research of past 20 years of ceramics [1] Questions such as how the 2002年1月8日 In ceramics grinding, the process of material removal by brittle fracture predominates 10 However, from observations in microindentation tests, ductile machining of brittle materials has been (PDF) On the Precision Grinding of Advanced 2023年12月21日 where C is the density of the grinding grain and r is the widthtothickness ratio of the chip In Malkin’s model, the maximum UCT was based on the uniform location distribution and grain size Under these assumptions, the calculated UCT was estimated to be 02~1 μm [], 06 μm [] or 03~098 μm [], and less than the critical depth of plowingcutting transition (1~2 A multiscale model revealed in the grinding process and its 2020年2月10日 Advanced ceramics have unique physical and mechanical properties While its high hardness and low fracture toughness makes the surface quality difficult to guarantee, which seriously affect the performance and reliability of ceramic parts As the main factor affecting the surface quality of advanced ceramics, grinding force needs effective prediction to facilitate the Modeling and experimental investigation on grinding force

.jpg)

Ceramic Grinding DCM Tech

6 天之前 Precision Ceramics Grinding » INCREASE EFFICIENCY with precision grinding » Remove LARGE OR SMALL AMOUNTS of material fast » Grind to TIGHT TOLERANCES and surface finish specs » Expert help to OPTIMIZE YOUR GRINDING PROCESSES LEARN MORE DCM Rotary Surface Grinders » 1848" ELECTROMAGNETIC/VACUUM CHUCKS » 1050HP 2024年6月10日 Andy Duncan, Business Development Director at Precision Ceramics, has spent over 30 years in Engineering Ceramics within Technical Management and Business Development roles Andy’s ceramics application experience is broad, spanning the design and selection of ceramic materials to metal joining, and piezoceramicsCeramic Manufacturing Process: Quantity, Design and Cost2023年5月3日 In largescale aspheric precision grinding of the space optical mirror based on RBSiC ceramic, precision grinding is the necessary process for obtain machined surface finish To further obtain the minimum tolerances and morphological and planar changes of the workpiece, the resinbond of the grain size 600# precision grinding diamond grinding wheel Study on the Cold Atmospheric Plasma Process via Oxygen (O2) Fluid Flow 2021年11月22日 Ceramic Tile Manufacturing Processs Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document describes the manufacturing process for ceramic tiles There are 6 main steps: (1) raw material treatment and preparation, (2) forming or molding tiles, (3) drying, (4) glazing and Ceramic Tile Manufacturing Processs PDF Tile Mill (Grinding)

Optimization of grinding process for hard and brittle

2024年3月1日 The main influencing factors for grinding damage include abrasive grit size, grinding depth, workpiece feed speed, and wheel speed According to the research of Sabia et al [13], the grinding subsurface damage depth (SSD) of glass ceramics is proportional to 5 times the average abrasive grit sizeMa et al [14] found that the SSD of fused silica is 4–6 times the 2019年8月14日 process involved in the very beginning of the ceramic tile manufacturing process Nowadays, the most widely used ceramic tile shaping method is uniaxial pressing of spraydried powder in hydraulic presses The base case involves a wet route procedure where the initial freeflowing powder isCase Study 2: Ceramic Powder Processing aspire年11月1日 Grinding force model is an important tool for the selection and optimization of ultrasonicassisted grinding of advanced ceramics Meanwhile, there is still a lot of room for performance improvement and application expansion In particular, it is generally recognized that the grinding wheel wear state directly affects the accuracy of grinding force model To address Grinding force modeling in ultrasonicassisted face grinding The process of grinding ceramic tile edges requires precision and skill, ensuring that the edges are clean and smooth But how does one go about grinding these edges effectively? In this discussion, we will explore the necessary steps and Mustread Guide to Grinding Ceramic Tile Edges

.jpg)

A PROCESS DESIGN ON THE COMMERCIAL PRODUCTION OF SANITARY CERAMIC

14 Figure 21: General flow of major process and equipment 15 Figure 22: General process flow diagram showing different processing paths 16 23 EQUIPMENT FOR CERAMIC MANUFACTURING 231 RAW MATERIALS PREPARATION EQUIPMENT Hammer mills achieve size reduction by impact forces – pieces of raw material fed into the mill are shattered 2018年12月27日 A Premetalliation Guide to Lapping, Polishing, and Grinding Ceramic Substrates 4 accumet Lapping 101 The lapping process begins with precision equipment and a welltrained and skilled technician Material can be lapped down to as thin as 003’’ with a tolerance as low as ± 0001’’ Materials as large as 16’’ square or diameterA Premetallization Guide to Lapping and Polishing 1996年1月1日 Keynote Papers Grinding Mechanisms for Ceramics S Malkin (1) T W Hwang, Department of Mechanical b Industrial Engineering, Engineering Lab Building, University of Massachusetts, Amherst, MA, USA Abstract The widespread utilization of high strength ceramic materials has been limited by the high cost of machining these materials by grindingGrinding Mechanisms for Ceramics ScienceDirect2023年7月5日 The reduction of environmental impact is today the main challenge of the ceramic industry that is always more focusing on materials in line with the principles of economic and environmental sustainability In this context, this study addresses the implementation of a Life Cycle Assessment (LCA) on the production of ceramic sanitaryware, based on a cradleto Life Cycle Assessment (LCA) of ceramic sanitaryware: focus

.jpg)

Simulation experimental investigations into material removal

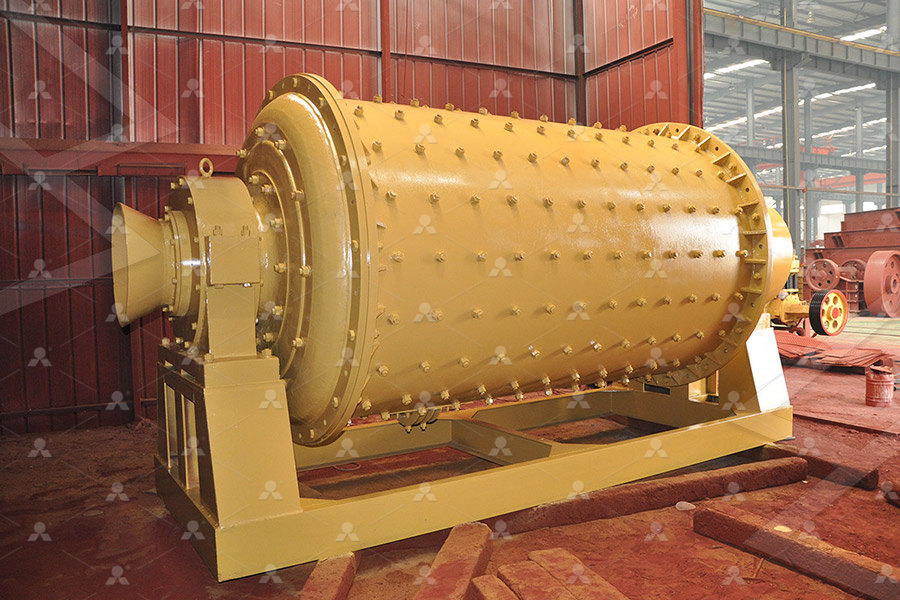

2023年10月14日 To investigate the machining mechanism of silicon carbide (SiC) ceramic materials, this study utilized sintered diamond tools to perform drilling and grinding simulations on the material and developed a drilling model for SiC ceramic materials By analyzing parameters such as surface morphology, stress, and cutting force, the material removal mechanism of SiC 2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) (PDF) Grinding in Ball Mills: Modeling and Process ControlThe table below provides ceramic tile grinding tips for step 4 of the grinding process: Step 5 Once the grinder has cut all the way through the ceramic tile, make sure to turn it off and unplug it for safety Here are some important points to consider when grinding down ceramic floor tile:A StepbyStep Guide on How to Grind Ceramic Tile2020年8月13日 Once the ceramic basin or toilet is formed initially, the faucet hole, overflow hole (if needed), and drainer hole will be made Then the basin will be dried in the natural air or under the industrial fan When it’s dried to 60% to 70%, it could proceed to the ceramic basin or toilet body repair stateStep By Step Process of Manufacturing Ceramic Basin And Toilet

Ceramic Grinding Services Ferro

FerroCeramic's Unit Cell Production Approach Here at FerroCeramic, we pride ourselves on our production quality and efficiency Every step of our ceramic grinding services and production process is carefully coordinated and exercised for efficiency and quality FerroCeramic production facilities are strategically arranged to capitalize on the inherent manufacturing