Want to run a semifinished small limestone processing plant

.jpg)

How to set up a limestone processing plant?

Setting up a limestone processing plant involves several key steps to ensure efficiency, safety, and compliance with regulations Here’s a guide to help you through the process: Market 2023年8月18日 As a professional solution provider of lime manufacturing plants, we are familiar with related equipment, spare parts, layout design, processing technology, and other configurations A lime manufacturing plant is designed How To Start A Lime Manufacturing Plant?2018年8月18日 The processing of limestone is mainly pulverization, classification and production of lime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide and theHow to start a limestone processing plant, and whatProcess flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Limestone Quarrying and Processing: A LifeCycle Inventory

How to set up a limestone processing plant? LinkedIn

2023年1月6日 Setting up a limestone processing plant requires a comprehensive knowledge of the industry and the regulations that are in place to protect workers and theHow much invest for the limestone crushing plant? How to start a stone aggregate making business? machine selection and processing plant layout design This article to answer these questions as much as possible, from Limestone Crushing Plant Layout and Price JXSC Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by A LifeCycle Inventory of Limestone Dimension Stone Quarrying 2022年2月3日 Procuring the right equipment is one of the most critical steps in getting a new lime plant up and running Here are the top ten types of equipment every lime plant needs to compete 1 Limestone Bin Limestone bins are 10 Types of Equipment Every Industrial Lime Plant Needs

1117 Lime Manufacturing US EPA

In some lime plants, the resulting lime is reacted (slaked) with water to form hydrated lime The basic processes in the production of lime are: (1) quarrying raw limestone; (2) preparing Turnkey washing plant processing 6mm crushed limestone with high fines content and producing aggregates and manufactured sands We help wash previously discarded lowgrade by Limestone Processing Limestone Wash Plant CDE CDELimestone calcination process is selected on basis of limestone If size of limestone is less than 4 inches and capacity of plant is less than 200 tonnes per day, then shaft kiln is selected Whereas for higher capacities and for small Hydrated, Quick, and PCC Lime Processing PlantSummary of a Profit and Loss Statement for a Hypothetical Fish Processing Plant Processing 1,000,000 Pounds with a 60% Yield Terms Sales, costs and profit Common term Standard Per used in fish accounting Per round processed SIMPLE FINANCIAL ANALYSIS FOR A SMALL FISH

.jpg)

How to setup manufacturing of semiconductors in India

2022年1月28日 The semiconductor chip is basically the brain of any electronic device and they are responsible to conduct every small action in our electronic devices and cars "The semiconductor plant in the United States was built in recognition of the Limestone application The compact limestone has a compressive strength of 20~120MPa and a density of 2000~2600 kg/m3 When the clay impurities in the limestone exceed 3% to 4%, the frost resistance and water resistance are remarkably loweredLimestone Crushing Plant Layout and Price JXSC Machine2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in originA LifeCycle Inventory of Limestone Dimension Stone Quarrying 2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in originA LifeCycle Inventory of Limestone Dimension Stone Quarrying

A Visual Guide: Steel Making Process Chart Cabaro Group

2024年3月17日 They are pivotal in defining the quality and characteristics of the finished steel The primary raw materials used in the production of steel include iron ore, coal, and limestone, and each plays a crucial role: Iron Ore: It is the source of iron, which is the fundamental component of steelDraft solution of primary crushing at limestone and stone aggregates processing plant from deposit 'Suvodo' AD – Jelen Do January 2006 Journal of Mining and Metallurgy A Mining 42(1)(PDF) Draft solution of primary crushing at limestone and stone Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains 30 to 45 percent magnesium carbonate, it is referred to as dolomite, or dolomitic limestone Lime can also be1117 Lime Manufacturing US EPA2012年4月5日 NOTE: Graymont personnel provided an outstanding and educational tour of the limestone quarry and processing plant near Exshaw, AB Any factual errors in this post are entirely due my poor memory This last week of spring break we had the privilege of touring a limestone quarry and processing plant, thanks to one of Mr GeoKs’ Continue reading Limestone Quarry and Processing Plant Tour Out About with

Starting a Poultry Processing Plant

Hello, Am Andrew and would need a sample business plan for a small scale poultry processing plant in my rural area I want to start up one as we addressing poultry rearing as a tool to eradicate poverty in the rural areas of Uganda, especially the single headed women households I hope your technical advice would be of great helpThe processing of limestone is mainly crushing, grading and producing quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc Limestone generally adopts dry crushing process For Limestone Crushing Solution Eastman Rock Crusher2020年7月6日 The next cost is for equipment for slaughter and processing, which includes rails, hand tools, cookers, smokers and grinders Maddock estimates this equipment to cost $300,000 to $400,000 for a small plant He So you want to build a slaughter plant? Department From 3 million cubic metres of blue limestone reserves at Old Leighlin, Kellymount and Holdensrath, Kilkenny Limestone annually quarries c 75000m³ for processing into limestone slab and its full suite of finished stone products RD Advanced geological research, coupled with analysis of core samples extracted from future reserves, provides essential information on Kilkenny Limestone® production process Brachot

.jpg)

So You Want To Start A Meat Plant?

The following table describes average operating costs for a very small customexempt plant, small federally inspected plant, and regional federally inspected plant These data are from 2016 and it is likely that in five years these costs have increased by about 20% across all expense categories 2 Potential Barriers Assessing Feasibility2024年3月20日 The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a flow diagram It discusses the key ingredients involved in steel production, their roles, advantages and disadvantages of the workflow Understanding the Steel Making Process: A Flow DiagramExtraction and processing of minerals is a driver of the development of the renewable energy sector According to the World Bank, mining companies will have to ramp up production of lithium, cobalt and graphite by almost 5 times by 2050 to meet the growing needs of the renewable energy sector, including the development of energy storage technologiesMining and processing plant design ESFC Investment GroupLimestone Processing, Pelletized (Pelletised) Limestone Pelletized (Pelletised) Limestone Limestone pellets offer reduced dust, more accurate application, improved handling, and less product lost to dust Limestone Processing ChallengesLimestone Processing Equipment FEECO International Inc

Comminution a Heart of Mineral Processing ResearchGate

2021年7月6日 The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of treating crude material from excavation into mineral Study with Quizlet and memorize flashcards containing terms like NO1 In your plant, MRP is activated Which options do you have to exclude a material from the MRP run? Note: There are 2 correct answers to this question A Use a specific material status B Use a specific MRP controller C Use a specific material group D Use a specific MRP type, NO2 What is the PP on premise Flashcards QuizletExplore our mining equipment to find the ideal wholesale limestone processing plant model and mills for any mining challenge All categories Featured selections Trade Assurance Buyer Central Help Center Get the app Small Limestone Processing plant for Active Lime Production Line $200,00000$1,000,00000 Min Order: 1 setLimestone processing plant2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for Limestone Crushing And SandMaking Plant

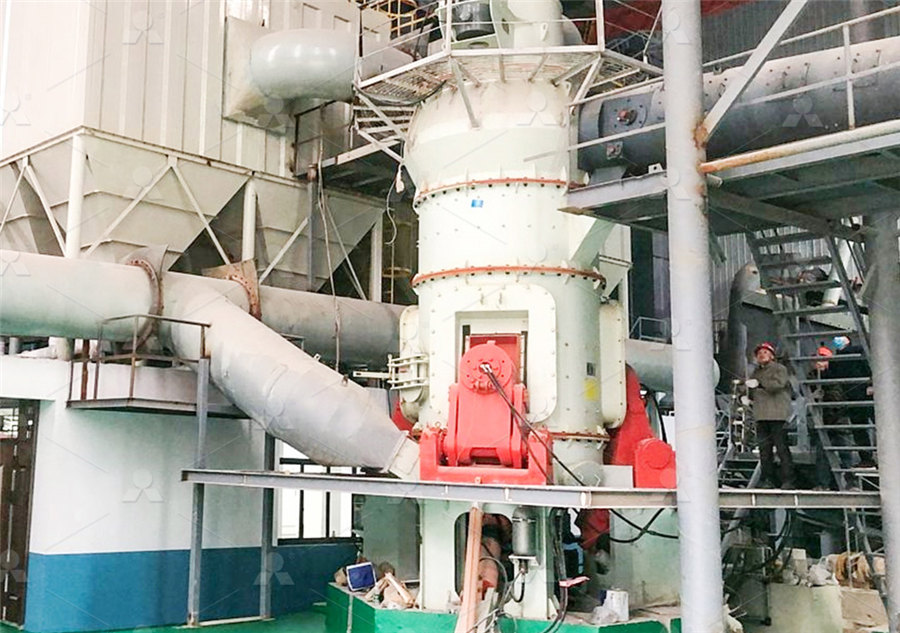

Limestone Processing Plant Design

2024年1月17日 The specific equipment and processes used in a limestone processing plant will vary depending on the desired end product However, the basic steps outlined above are common to all limestone processing plants Design Considerations There are a number of factors to consider when designing a limestone processing plant These include:2024年11月22日 In addition to the land cost, the construction or renovation of the processing plant building can be a significant expense Depending on the size and complexity of the facility, the building costs can range from $50 to $150 per square footThis includes the necessary features such as temperaturecontrolled environments, hygienic flooring, and specialized Essential Startup Costs For A Milk Processing Plant FinModelsLab13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At this point, the ore is called runofmine material because there has been no treatment performed on it There are three primary types of runofmine materials: Runofmine consisting of useful materialsIntroduction to Mineral Processing or Beneficiation2021年7月20日 A plant layout substantially varies according to a clientspecified economics, process requirements, operation philosophy and maintenance method(PDF) PROCESS PLANT LAYOUT, Kolmetz Handbook Of Process

Crushing Plant Design and Layout Considerations 911 Metallurgist

RUN TIME (Operating Time) 6,277 Prod time minus unplanned downtime Total yearly downtime 2,483 Planned and unplanned hours System utilization % 78 Run time/prod time Average hours per shift 624 Hours per day/3 3 shifts, hours 1872 Utilization % x 24 hrs System availability % 72 Runtime hours/total time availableSmall Dairy Processing Plant: A small dairy processing plant is a dairy plant which is not located on a farm, processes dairy products, and less than 700,000 lbs of milk a year Both onfarm dairy processing plants and small dairy processing plants are required to meet many of the same rules and regulations as larger dairy plants Whether it is Starting a Small Dairy Processing Plant: The BasicsSecond stage: Crushed limestone is lifted to the hopper by hoist, then transported by feeder Third stage: Qualified products after the grinding process enter the collector through classifier and pipe The discharged powder is finished product Unqualified powder cannot pass the classifier, and falls back to the main unitLimestone Processing Plant, Limestone Grinding Machine2023年1月6日 Designing the plant: The plant should be designed to optimize the production of finished limestone products, taking into account factors such as the available raw materials, the desired output How to set up a limestone processing plant? LinkedIn

Hydrated, Quick, and PCC Lime Processing Plant

Limestone calcination process is selected on basis of limestone If size of limestone is less than 4 inches and capacity of plant is less than 200 tonnes per day, then shaft kiln is selected Whereas for higher capacities and for small Summary of a Profit and Loss Statement for a Hypothetical Fish Processing Plant Processing 1,000,000 Pounds with a 60% Yield Terms Sales, costs and profit Common term Standard Per used in fish accounting Per round processed SIMPLE FINANCIAL ANALYSIS FOR A SMALL FISH 2022年1月28日 The semiconductor chip is basically the brain of any electronic device and they are responsible to conduct every small action in our electronic devices and cars "The semiconductor plant in the United States was built in recognition of the How to setup manufacturing of semiconductors in IndiaLimestone application The compact limestone has a compressive strength of 20~120MPa and a density of 2000~2600 kg/m3 When the clay impurities in the limestone exceed 3% to 4%, the frost resistance and water resistance are remarkably loweredLimestone Crushing Plant Layout and Price JXSC Machine

A LifeCycle Inventory of Limestone Dimension Stone Quarrying

2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in originA LifeCycle Inventory of Limestone Dimension Stone Quarrying 2024年3月17日 They are pivotal in defining the quality and characteristics of the finished steel The primary raw materials used in the production of steel include iron ore, coal, and limestone, and each plays a crucial role: Iron Ore: It is the source of iron, which is the fundamental component of steelA Visual Guide: Steel Making Process Chart Cabaro GroupDraft solution of primary crushing at limestone and stone aggregates processing plant from deposit 'Suvodo' AD – Jelen Do January 2006 Journal of Mining and Metallurgy A Mining 42(1)(PDF) Draft solution of primary crushing at limestone and stone

1117 Lime Manufacturing US EPA

Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains 30 to 45 percent magnesium carbonate, it is referred to as dolomite, or dolomitic limestone Lime can also be2012年4月5日 NOTE: Graymont personnel provided an outstanding and educational tour of the limestone quarry and processing plant near Exshaw, AB Any factual errors in this post are entirely due my poor memory This last week of spring break we had the privilege of touring a limestone quarry and processing plant, thanks to one of Mr GeoKs’ Continue reading Limestone Quarry and Processing Plant Tour Out About with