Grinding machine completes every hour

.jpg)

What Preventative Maintenance of Grinding Machines Can

2020年11月3日 UNITED GRINDING recommends preventive maintenance of the machines every 2,080 operating hours; this corresponds to one 8hour shift per day, 5 days a week over A grinding machine consists of several key components, each playing a critical role in the grinding process 1 in³ every 3040 seconds: Grinding custom shapes for turbine blades, gear hobs, Guide to Precision Grinding: Processes, Techniques and Applications2020年6月26日 UNITED GRINDING recommends preventive maintenance on its machines for every 2,080 hours of usage, which is the equivalent of the machine operating one 8hour shift The Value of Preventive Maintenance for Grinding Machines2010年8月1日 As the volume of parts per print drops, machine uptime is reduced, and multiple setups can mean that the machine is actually removing material fewer hours per day “You Grinding: A Dynamic Machining Process Canadian Metalworking

.jpg)

Grinding Machine Efficiency and Productivity GCHTool

2023年1月27日 Grinding machines are essential tools in manufacturing and industrial settings, as they are used to shape and finish materials to precise dimensions It is important to Using a systems approach can improve your grinding efficiency/profitability by monitoring four major categories and tracking measurable parameters Learn how to optimize your process to How to Improve Your Grinding Efficiency and Profitability2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, (PDF) A comprehensive review on the grinding process: The world of grinding machine technology is hurtling towards automation Lured by benefits including improved productivity, access to better machine data and the promise of lower How grinding machine automation is the key to innovation

A study on intelligent grinding systems with industrial perspective

2021年6月11日 Although tremendous strides have been made, a substantial amount of work is still required in achieving a fullfledged realtime intelligent grinding system The 2024年8月22日 Centerless Grinding – How it Works, When It’s Used, and Everything In Between Definition of centerless grinding Centerless grinding is a machining process where cylindrical parts are ground to precise dimensions Centerless Grinding: A Complete Guide Ripley High process reliability due to complete grinding in a single setup; Optimum grinding quality due to automatic compensation of disturbance variables; High dimensional stability due to inprocess measuring system; Flexible use for Grinding machines: JUCRANKThe utility company charges you for the total kilowatthour of energy you have consumed Kilowatthour is the product of the power consumption of the load and the number of hours of usage Power consumption of Mixer grinders A typical Power consumption and energy usage of Mixer

WEMA Glauchau : universal cylindrical grinding machines for all

– With this in mind we build customi s ed universal grinding machines, internal (cylindrical) grinding machines, external (circular) grinding machines and roll er bearing grinding machines as well as complete machining centres for all abr asive cutting tasks – quality ›M ade in Germany‹2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial grinding millsAs of 2019, Shibang Industry and its affiliated companies have 5 advanced mining machine production bases and a production base in Xiuwu, Jiaozuo, Henan, which is under construction, with a total production area of 1,200,000 square meters, and will be able to better meet the needs of global customers in the future Stone Crushers, Mill and GrindingKlingelnberg is regarded as the leading specialist for highprecision cylindrical gear grinding machines, a position it maintains through significant investments in research and development Extreme reliability and high efficiency are hallmarks of the Höfler cylindrical gear grinding machines in the HELIX/PROMAT, RAPID, VIPER 500 and SPEED VIPER rangesKlingelnberg Group: Cylindrical Gear Grinding Machines

What Is CNC Grinding? The Future Of Machine Processing

2024年2月29日 What is CNC Grinding Understanding the Basics of CNC Grinding Computer Numerical Control grinding (CNC grinding) falls in the category of machining processes that rely on computerized controls to remove materials from the workpieces By using specialized grinding machines and tools, CNC grinders offer unparalleled accuracy and notably increased June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2017年2月2日 Asurion Complete Protect: We provide professional operation explanations to every customer Swing type Grain Grinder Visit the Store CGOLDENWALL Commercial Stainless steel Spice and Herb Grinder Industrial Electric Peppe Grain Mill Soybean Grain Food Grinding Machine 33110 Pounds per hour (Voltage: 110V)CGOLDENWALL Commercial Stainless steel Spice and Herb 1234 West 78 th Street Cleveland, Ohio 441021914 PHONE 8883393006 Fax 2166315264 info@universalgrindingTypes of Grinding Machines for Every Applications

.jpg)

The Complete Guide to CNC Machines: Everything

2023年7月30日 Grinding machine: Grinding tools are For the complete set of continuous casting and rolling equipment, large gantry milling machine and large CNC lathe are required (8) For ball screws lubricated with grease, clean 2024年11月7日 You can find our complete grinding machine range here To the product overview; External cylindrical grinding machines European safety standard ISO 16089 recommends replacing the polycarbonate windows of your STUDER cylindrical grinding machine every two years Read more here; Digitalization CORC Cylindrical grinding machines Fritz Studer AG2024年6月14日 It guarantees that every grinding operation is done to the highest standards per the industry standards These standards include those in the Oil Gas, Aerospace, and Manufacturing industries High Manufacturing Productivity The efficiency of manufacturing has improved Precision grinding makes it easier to maintain qualityPrecision Grinding: A Complete Guide for You ChansMachining2024年11月14日 250600kg/h Corn grits making machine/grain corn crusher/maize grinding mill: N209,000 – N310,000; How to choose maize grinding machine before purchase Choosing a maize grinding or milling machine is a very difficult task Maize Grinding Machine Prices in Nigeria Nigerian Tech

.jpg)

Animal Feed Grinding Machine pelletrichi

Applications Of Animal Feed Grinding Machine The crushing of feed ingredients is a very important part of animal feed mill processing When producing powdered compound feed, the power consumption of the crushing section accounts for more than 60% of the entire animal feed mill and animal feed production line The animal feed grinding machine has the advantages of 2023年12月12日 For example, if a CNC machine has an estimated life of 10,000 hours and costs $100,000, the machine cost per hour would be $10 When combined with the hourly rates for labor, overhead, and the specific material costs How to Calculate CNC Machining Costs per Hour2020年8月20日 A standard overhaul of a machine involves the complete dismantling and inspection of every mechanical, electrical, pneumatic and hydraulic component In the rebuild departments of the UNITED GRINDING Group, the components are reconditioned or renewed as necessary in accordance with the OEM standardsOverhaul, Retrofit or Replace Machines? UNITED GRINDINGWe deal with a complete line of sugar grinding machines and their accessories for multiple industrial applications Some of the grinding capacities that you can opt for are 10 kg/hour, 40kg/hour, and as much as 100kg/hour You should, therefore, clean the machine well after every process of grinding sugarSugar Grinding Machine Yinda

Grinding Machine Operator Jobs, Employment Indeed

6,018 Grinding Machine Operator jobs available on Indeed Apply to Machine Operator, is either on crew 1 or 2 [Crew 1] SunTues, every other Sat, or [Crew 2] WedFri, and human machine interfaces (HMI) Complete paperwork and log production information accurately (labor reports, recipe weight, waste sheets, Master Sanitation Learn all about Grinding Machine Operators: personality traits, daily activities, education and there should be roughly 7,500 open positions for Grinding Machine Operators every year Median annual salary $36,880 Typical salary Educational degrees among Grinding Machine Operators 226% did not complete high school or secondary Career profile for Grinding Machine Operator TraitLab2021年1月16日 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine Surface Grinder Types of Grinders How They Work grains of the grinding wheel and the flank of workpiece (Ref 3) At the onset of grinding burn, the grinding forces and the rate of wheel wear increases abruptly, thereby deteriorating the surface finish of the gear flank (Ref 4) It generates a rehardened zone near to the surface and a softened, tempered zone beneath it (Refs 4, 12)Optimization of Generation Gear Grinding Process Gear

.jpg)

How many types of cassava grinding machine? cassava starch machine

There are different types of cassava grinding machines on the market, including cassava grater, grind cassava with high efficiency in a short time, which reduce human labor It can process 115 tons of cassava per hour Tips: Henan Jinrui’s cassava grinding machine sells thousands of units every yearPrevious Next About Us Qiandao Machinery Dongguan Qiandao Machinery Manufacturing Co, Ltd is a professional enterprise specializing in the research and development, production, and sales of CNC tool grinding machines, CNC profile grinding machines, and other tool grinding and processing equipment Focus on the production and sales of CNC tool grinders, CNC step CNC grinding machine manufacturers Qiandao Machinery Complete grinding of a variety of workpieces in a single clamping setup results in numerous advantages, both in terms of cycle time and handling effort An array of configuration options prepares every machine from the standard model to the highly customized Cylindrical grinding machines for high precision and efficiencyA formal spare parts plan for your centerless grinding machines can save money and reduce downtime Follow this easytoachieve solution to create a plan that meets your needs • 3 2 1 A Spare Parts Plan that Saves Time and Money Identify the centerless grinding machines that are causing problems in your facilityCenterless Grinding for Pros GCH Tool

Automatic Rice Husk Grinding Machine at Rs Rice

Automatic Rice Husk Grinding Machine Automatic Rice Husk Grinder machine Complete With Hammer Mill Grinder Machine, Pipe Line Tank Stand blower airlock filter etc Machine body make in ms and ss as per client requirements Machine capacity range 100 kg per hour to upto 1000 kg per hour Get Latest Price Arihant Engineering CorporationGrinding machines remove the material by means of grinding wheels, abrasive heads or abrasive cloths For this purpose, KNUTH offers you solutions for various areas of application, from CNC grinding machines for series production to conventional cylindrical grinding machines for occasional useGrinding Machines Grinders KNUTH Machine ToolsFor fouredge chamfering at work piece length of 20 mm approx 1,200 pieces per hour S:\Vertrieb\Produktkatalog\Katalog\Katalog Englisch\Grinding Machinesiin Arbeitdoc 9 Every chamfer is individual adjustable over slides and dials, Direct attachment to a line grinding machine The complete unit can be slide or pivoted when not in useGRINDING MACHINES Babitsch2024年8月22日 Centerless Grinding – How it Works, When It’s Used, and Everything In Between Definition of centerless grinding Centerless grinding is a machining process where cylindrical parts are ground to precise dimensions Centerless Grinding: A Complete Guide Ripley

.jpg)

Grinding machines: JUCRANK

High process reliability due to complete grinding in a single setup; Optimum grinding quality due to automatic compensation of disturbance variables; High dimensional stability due to inprocess measuring system; Flexible use for The utility company charges you for the total kilowatthour of energy you have consumed Kilowatthour is the product of the power consumption of the load and the number of hours of usage Power consumption of Mixer grinders A typical Power consumption and energy usage of Mixer – With this in mind we build customi s ed universal grinding machines, internal (cylindrical) grinding machines, external (circular) grinding machines and roll er bearing grinding machines as well as complete machining centres for all abr asive cutting tasks – quality ›M ade in Germany‹WEMA Glauchau : universal cylindrical grinding machines for all 2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial grinding mills

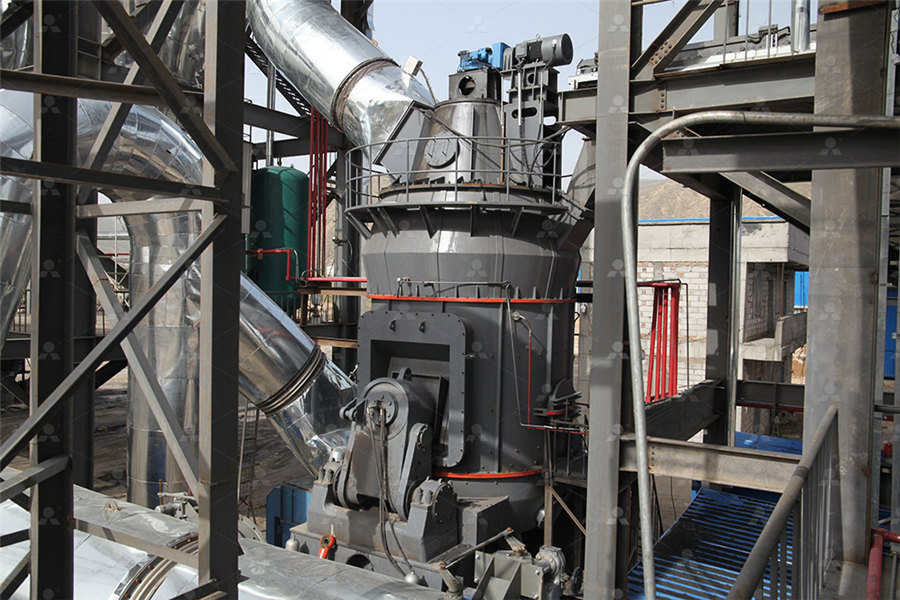

Stone Crushers, Mill and Grinding

As of 2019, Shibang Industry and its affiliated companies have 5 advanced mining machine production bases and a production base in Xiuwu, Jiaozuo, Henan, which is under construction, with a total production area of 1,200,000 square meters, and will be able to better meet the needs of global customers in the future Klingelnberg is regarded as the leading specialist for highprecision cylindrical gear grinding machines, a position it maintains through significant investments in research and development Extreme reliability and high efficiency are hallmarks of the Höfler cylindrical gear grinding machines in the HELIX/PROMAT, RAPID, VIPER 500 and SPEED VIPER rangesKlingelnberg Group: Cylindrical Gear Grinding Machines2024年2月29日 What is CNC Grinding Understanding the Basics of CNC Grinding Computer Numerical Control grinding (CNC grinding) falls in the category of machining processes that rely on computerized controls to remove materials from the workpieces By using specialized grinding machines and tools, CNC grinders offer unparalleled accuracy and notably increased What Is CNC Grinding? The Future Of Machine ProcessingJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

CGOLDENWALL Commercial Stainless steel Spice and Herb

2017年2月2日 Asurion Complete Protect: We provide professional operation explanations to every customer Swing type Grain Grinder Visit the Store CGOLDENWALL Commercial Stainless steel Spice and Herb Grinder Industrial Electric Peppe Grain Mill Soybean Grain Food Grinding Machine 33110 Pounds per hour (Voltage: 110V)